Non-oxide max phase toughened silicon nitride ceramic composite material and preparation method thereof

A technology for silicon nitride ceramics and composite materials, which is applied in the field of non-oxide MAX phase strengthening and toughening silicon nitride ceramic composite materials, can solve problems such as poor machinability, and achieves promotion of strengthening and toughening, sintering efficiency, and workability. The effect of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

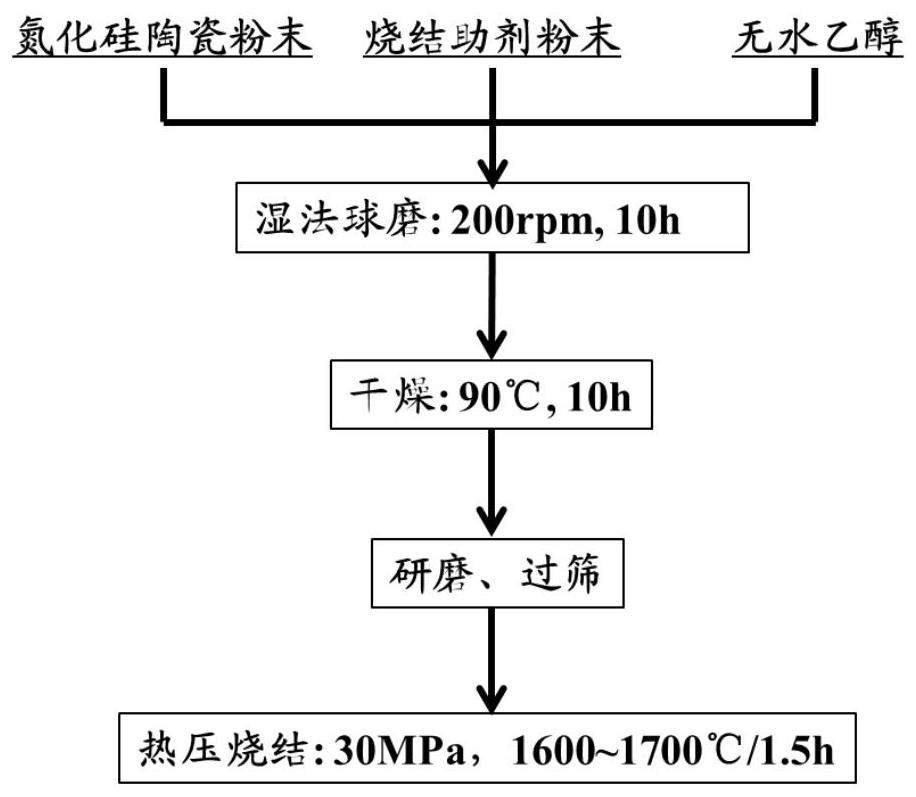

[0033] via as attached figure 2 The process shown for the preparation of silicon nitride ceramic composites specifically includes:

[0034] Accurately weigh two groups of ceramic powders containing silicon nitride (α-Si 3 N 4 powder) and sintering aid Ti 3 SiC 2 Raw material combination of powder, each group of raw material combination contains α-Si 3 N 4 Powder and Ti 3 SiC 2 The mass ratio of the powder is 1.44:100, 4.41:100, 7.51:100, 15.86:100, 25.18:100, 35.68:100 (the corresponding volume ratio is 99:1, 97:3, 95:5, 90:10, 85 :15, 80:20) multiple combinations;

[0035] (2) Using the method of planetary wet ball milling, the weighed α-Si 3 N 4 with Ti 3 SiC 2 The powder, an appropriate amount of ball milling medium and absolute ethanol were placed in a stainless steel ball mill tank lined with polytetrafluoroethylene for wet mixing, and were ball milled at a speed of 200 rpm for 10 hours through a planetary ball mill and zirconia ball mill beads, and each Rev...

Embodiment 2

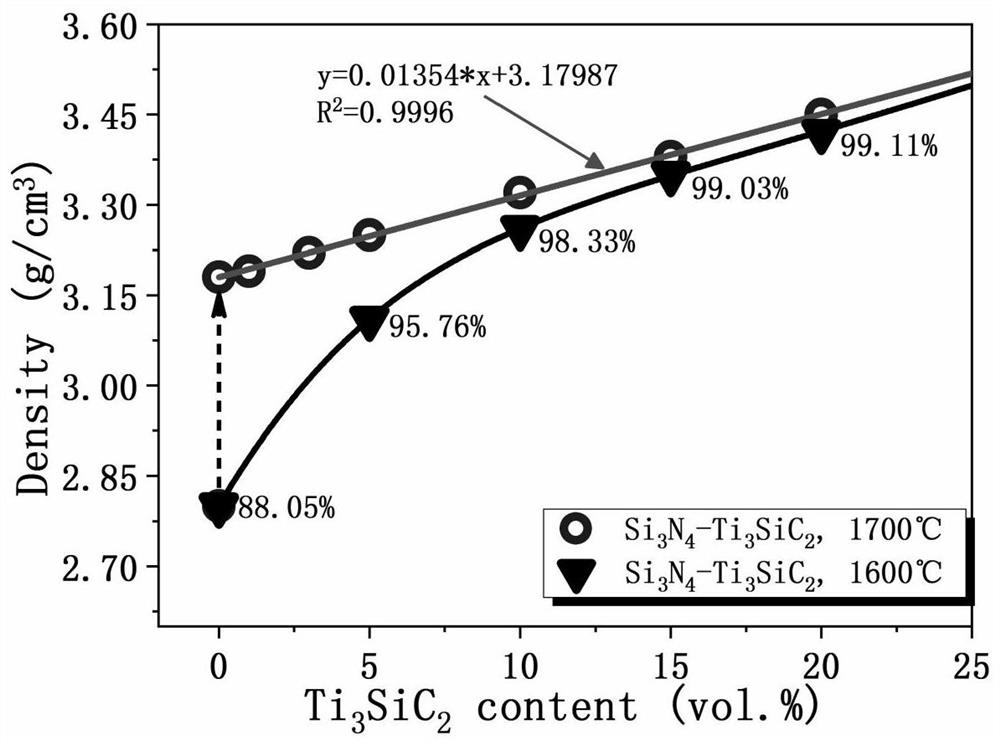

[0040] The silicon nitride ceramic composite material obtained in Example 1 is characterized as follows:

[0041] Based on the measurement principle of Archimedes drainage method, according to ASTMD297-93, D792-00, D618, D891, GB / T1033, JISK6530, ISO2781 test standards, using HTY-120E high-precision solid density tester to measure the apparent density and opening of the sample Ratio, obtain the density of multiple silicon nitride ceramic composite materials obtained, and compare it with the ratio of theoretical density, the results are shown in the attached image 3 As shown, where the theoretical density is calculated as follows:

[0042]

[0043] In the formula, ρ T ——Theoretical density of silicon nitride ceramic composite material (g / cm 3 );

[0044] ρ 1 ——Silicon nitride density (g / cm 3 );

[0045] ρ 2 ——Ti 3 SiC 2 Density (g / cm 3 );

[0046] m 1 - mass of silicon nitride raw material (g);

[0047] m 2 ——Ti 3 SiC 2 Raw material mass (g).

[0048] pass ...

Embodiment 3

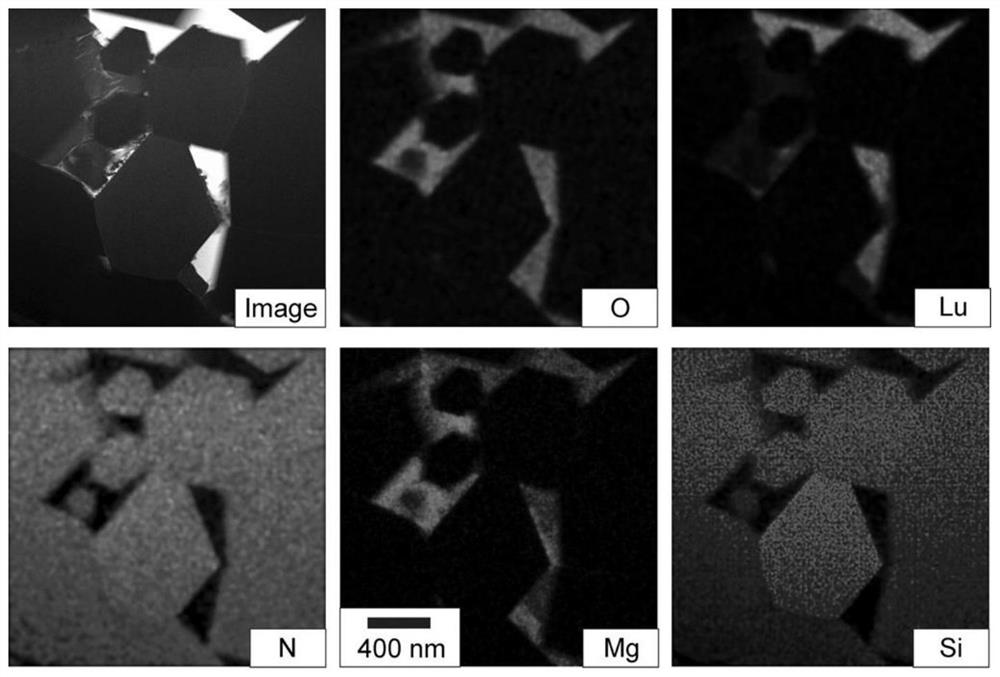

[0055] Carry out X-ray diffraction spectrum and microstructure characterization to the silicon nitride ceramic composite material gained in embodiment 1, as attached Figure 7-8 As shown, it can be seen that the present invention uses the non-oxide sintering aid Ti 3 SiC 2 The prepared silicon nitride ceramic composite is mainly composed of high temperature stable β-Si 3 N 4 Phase, C 0.3 N 0.7 Ti phase and SiC phase composition, and C 0 . 3 N 0.7 The diffraction characteristic peaks at 36.46° and 42.35° of the Ti phase and the peak heights of the SiC phase diffraction peaks show an obvious strengthening trend with the increase of the content of sintering aids, and the C 0.3 N 0.7 The Ti phase and SiC phase are evenly distributed around the hexagonal rod-shaped silicon nitride grains.

[0056] attached Figure 8 The cross-sectional micromorphology of silicon nitride ceramics prepared by hot pressing at 1700 °C under different contents of sintering aids. It can be seen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com