Nanostructure multifunctional ferromagnetic composite film material and preparation method

A composite film and nanostructure technology, applied in the application of magnetic film to substrate, metal material coating process, magnetic layer, etc., can solve the problems of single function, difficult control, complicated preparation process, etc. Realize the effect of multi-functionalization and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

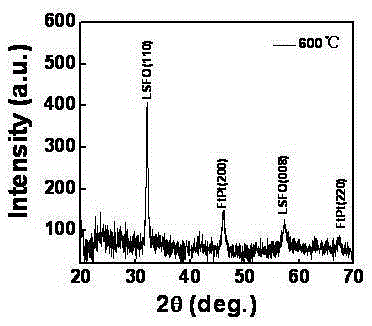

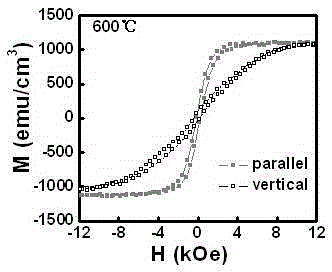

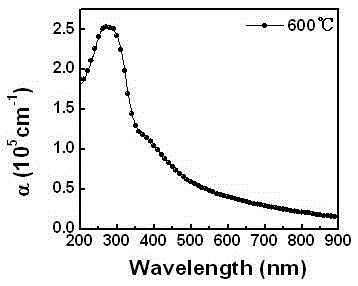

[0040] Embodiment 1 prepares 0-3 type FePt (0.1) :LaSrFeO 4(0.9) Nanoparticle Multifunctional Ferromagnetic Composite Thin Film

[0041] ① Target preparation and substrate cleaning: use high-purity La 0.5 Sr 0.5 FeO 3 (purity >99.95%, Hefei Yuanjing Technology Materials Co., Ltd.) ceramic laser target and high-purity Pt (purity >99.999%) metal magnetron target, respectively installed in the laser target position and the magnetron pulse laser co-sputtering device Magnetically controlled target.

[0042] ②Clean the 0.5mm thick quartz substrate in acetone and absolute ethanol with ultrasonic waves for 10 minutes, then dry it with high-purity nitrogen to ensure that the sample is completely clean, and then quickly put it into the sample stage of the magnetron and pulse co-sputtering device superior.

[0043] ③Grow nanoparticle multifunctional ferromagnetic composite film: the vacuum degree of the back and bottom of the vacuum chamber is 5×10 -5 Pa, the target spacing of las...

Embodiment 2

[0046] Example 2 FePt (0.3) :LaSrFeO4 (0.7) Preparation of Nanoparticle Multifunctional Ferromagnetic Composite Thin Films

[0047] ① Target preparation and substrate cleaning: use high-purity La 0.5 Sr 0.5 Fe 2 o 3 The ceramic laser target and the high-purity Pt metal magnetron target are respectively installed in the laser target position and the magnetron target position of the magnetron pulse laser co-sputtering device.

[0048] ②Clean the 0.5mm-thick double-thrown quartz substrate in acetone and absolute ethanol with ultrasonic waves for 10 minutes, then dry it with high-purity nitrogen to ensure that the sample is completely clean, and quickly put it into the magnetron and pulse co-sputtering device on the sample stage.

[0049] ③Grow nanoparticle multifunctional ferromagnetic composite film: the vacuum degree of the back and bottom of the vacuum chamber is 5×10 -5 Pa, the target spacing of laser pulse sputtering is 5cm, the target spacing of magnetron sputtering ...

Embodiment 31-3

[0053] Example 31-3 type FePt (0.1) :LaSrFeO 4(0.9) Preparation of Nanowire Multifunctional Ferromagnetic Composite Thin Films

[0054] Target preparation and substrate cleaning: use high-purity La 0.5 Sr 0.5 FeO 3 The ceramic laser target and the high-purity Pt metal magnetron target are respectively installed in the laser target position and the magnetron target position of the magnetron pulse laser co-sputtering device. Clean the 0.5mm thick single crystal STO (001) substrate in acetone and absolute ethanol with ultrasonic wave for 10 minutes, then dry it with high-purity nitrogen to ensure that the sample is completely clean, and quickly put it into the magnetron and pulse co-sputtering on the sample stage in the device.

[0055] Growth of nanowire multifunctional ferromagnetic composite film: the vacuum degree of the back and bottom of the vacuum chamber is 5×10 -5 Pa, the target distance of laser pulse sputtering is 5cm, and the target distance of magnetron sputter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com