High use temperature lead-free PTCR (positive temperature coefficient resistance) ceramic and preparation method thereof

A ceramic and formula technology, applied in the field of high service temperature lead-free PTCR ceramics and its preparation, to achieve the effects of improving microstructure, promoting semiconducting, and reducing normal temperature resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

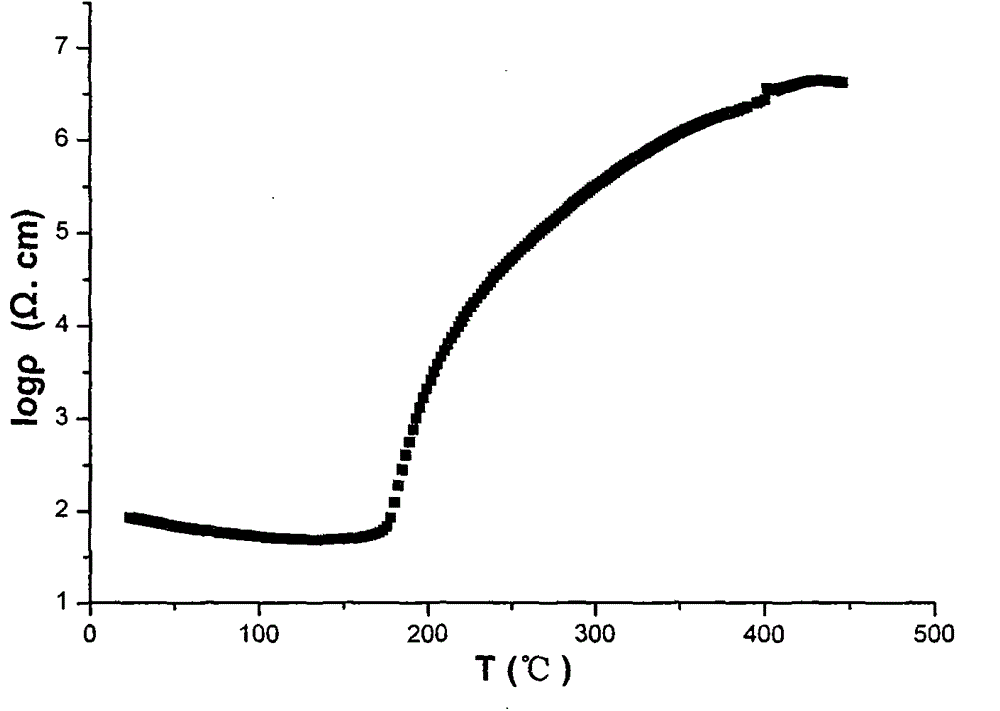

Image

Examples

Embodiment 1

[0026] In an embodiment of the present invention, a method for preparing a lead-free PTCR ceramic with a high service temperature, the specific steps are as follows:

[0027] Take x1=0.15, A is Y, x2=0.002, B is Mn, y=0.001, M is SiO 2 , z=1, then the molecular formula is (Na 0.5 Bi 0.5 ) 0.15 (Ba 0.848 Y 0.002 ) Ti 0.999 mn 0.001 o 3 +1mol%SiO 2 composition of ceramics. Using high-purity TiO 2 、BaCO 3 、Na 2 CO 3 、 Bi 2 o 3 , Y 2 o 3 , MnO 2 , SiO 2 As a raw material, it is weighed according to the stoichiometry of the main components of the above chemical formula.

[0028] Alcohol is used as the ball milling medium, and agate balls are used for ball milling and mixing, and then pressed into blocks after drying. Heat preservation at 900°C for 2 hours in the air for pre-synthesis, after crushing, add modifier and then ball mill, dry, add binder, molding, plastic discharge, heat preservation at 1220°C for 4 hours, sintering in nitrogen atmosphere, processing,...

Embodiment 2-18

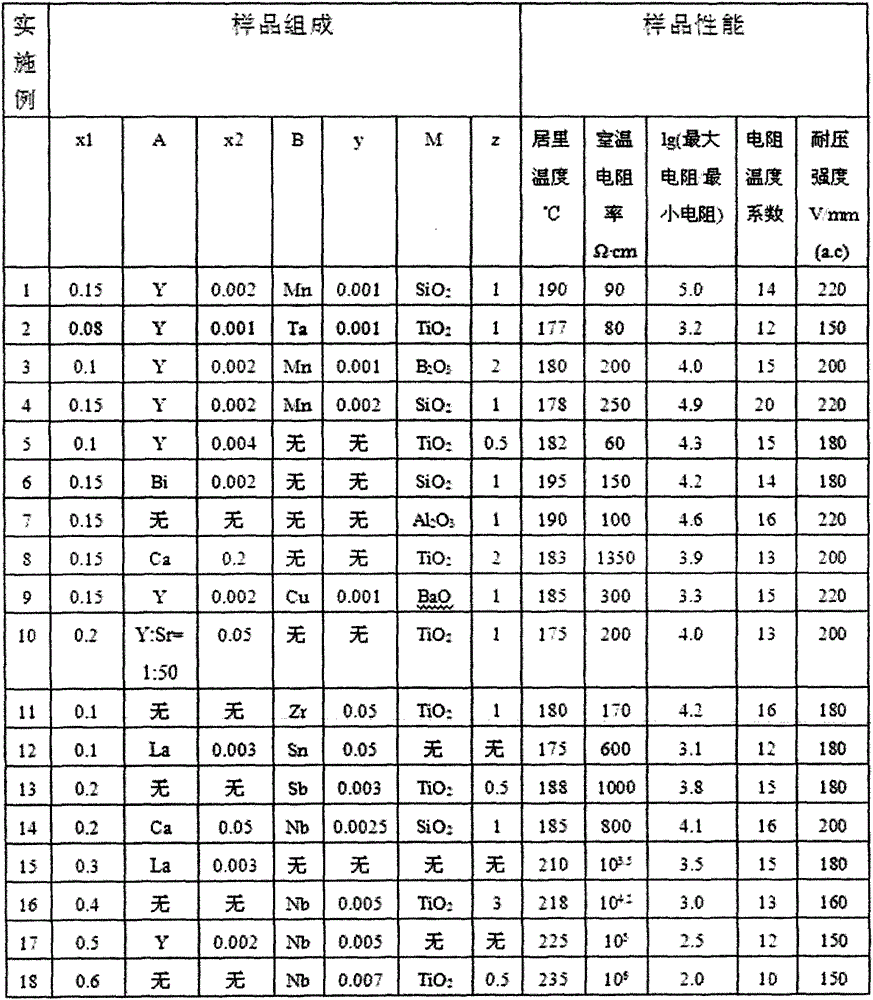

[0030] The Curie temperature of materials and their electrical properties can be adjusted by changing different substitution components and additives. TiO 2 , CaCO 3 , SrCO 3 、BaCO 3 、Na 2 CO 3 、 Bi 2 o 3 , Y 2 o 3 , La 2 o 3 , Nb 2 o 5 、 Ta 2 o 5 , Sb 2 o 5 , MnO 2 , CuO, ZrO 2 , SnO 2 、Al 2 o 3 , SiO 2 , B 2 o 3 etc. are raw materials, according to the chemical composition listed in Table 1, according to the chemical formula (Na 0.5 Bi 0.5 ) x1 (Ba 1-x1 - x2 A x2 ) Ti 1-y B y o 3 Stoichiometric weighing of +zmol%M. Other process conditions are the same as in Example 1. For different x1 values, the sintering temperature is between 1180-1230° C., and its properties are listed in Table 1.

[0031] Composition and performance table of table 1 embodiment 1-16

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com