Doped BKT-BT series lead-free PTCR ceramic material and preparation method thereof

A technology of BKT-BT and ceramic materials, which is applied in the direction of instruments, measuring heat, measuring devices, etc., can solve problems such as loss of application value, poor comprehensive performance, and unseen problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

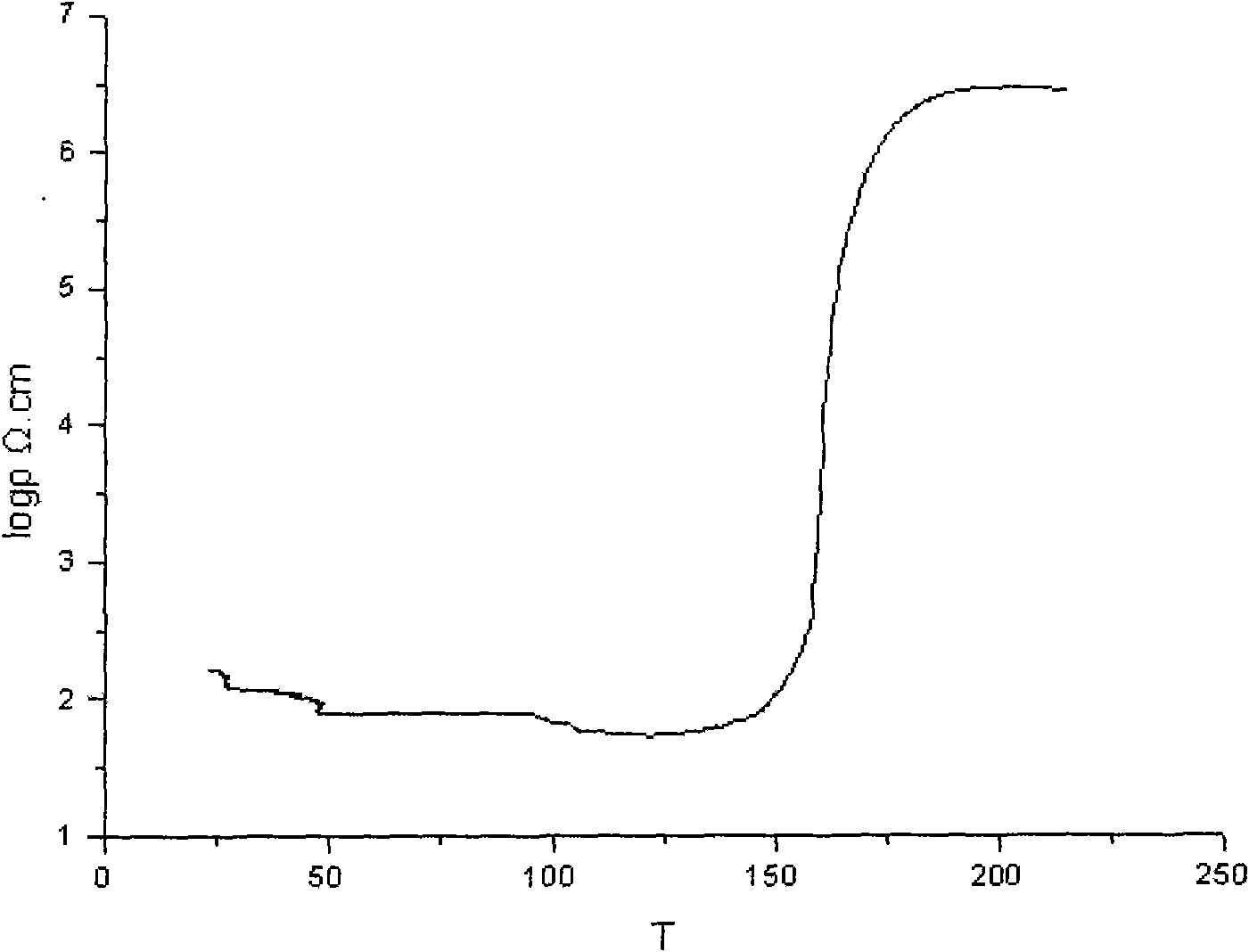

Embodiment 1

[0022] take x 1 =0.03,x 2 =0.5%, A is La, y=0.2%, M is Ta, z=0. Then the molecular formula of the ceramic material is (Bi 0.5 K 0.5 ) 0.03 (Ba 0.965 La 0.005 ) Ti 0.998 Ta 0.002 o 3 , which uses CP or AR grade chemical reagent Bi with extremely low PbO impurity content 2 o 3 、K 2 CO 3 、BaCO 3 , La 2 o 3 、TiO 2 and Ta 2 o 5 As the raw material, after fully drying, weigh according to the stoichiometry of the above formula.

[0023] Use absolute ethanol as the medium, and mix by ball milling for 3 hours. Dry, sieve, put the powder in a corundum crucible, and synthesize at 900°C / 1 hour and 950°C / 2 hours. Then pulverize and sieve, ball mill for 4 hours, dry, add binder, dry press molding, after 800°C / 2 hours of plastic ejection, heat at 1260-1310°C for 2-4 hours and burn. Grinding, ultrasonic cleaning, and ohmic electrodes, that is, doped lead-free PTCR ceramic components. Its main properties are: Tc: 175°C, resistance jump: 2.5×10 3 , α is 32% / °C, ρ RT 6.3×...

Embodiment 2

[0026] take x 1 =0.20,x 2 =0.3%, A is Y and Bi, wherein the mass percentage of Y and Bi is 1:1, y=0.1%, M is Sb, Z=0.5, D is MnO 2 . Raw material is except identical with embodiment 1, adds AR grade CeO in addition 2 , Y 2 o 3 , CP grade Sb 2 o 3 and MnO 2 . The process is the same as in Example 1, the synthesis temperature is 800°C / 1 hour, and 850°C / 2 hours; the firing conditions are 1200-1250°C, heat preservation for 1-3 hours. The properties of the obtained ceramics are: Tc is 182°C, resistance jump: 8.5×10 3 , α: 16% / °C, ρ RT : 1.2×10 2 Ω·Cm.

Embodiment 3

[0028] take x 1 =0.35,x 2 =0.6%, A is La, Ce mass ratio is 1:1, y=0.1%, M is Sb, Z=0.5%, D is MnO 2 . Raw material is except identical with embodiment 1, adds AR grade CeO in addition 2 , Y 2 o 3 , CP grade Sb 2 o 3 and MnO 2 . The process is the same as in Example 1, but the synthesis temperature is changed to 800°C / 1 hour and 850°C / 2 hours; the firing conditions are changed to 1200-1250°C and kept for 1-3 hours in a nitrogen flow with low oxygen concentration. to make. The properties of the obtained ceramics are: Tc is 205°C, resistance jump: 4.0×10 2 , α: 12% / °C, ρ RT : 8.0×10 2 Ω·Cm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com