Treatment system for blast-furnace slag

A blast furnace slag and treatment system technology, applied in the field of blast furnace ironmaking, can solve the problems of slag water spilling environment, pipeline water pump wear, and more water in the slag, and achieves good reference value, long equipment service life and high operation rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

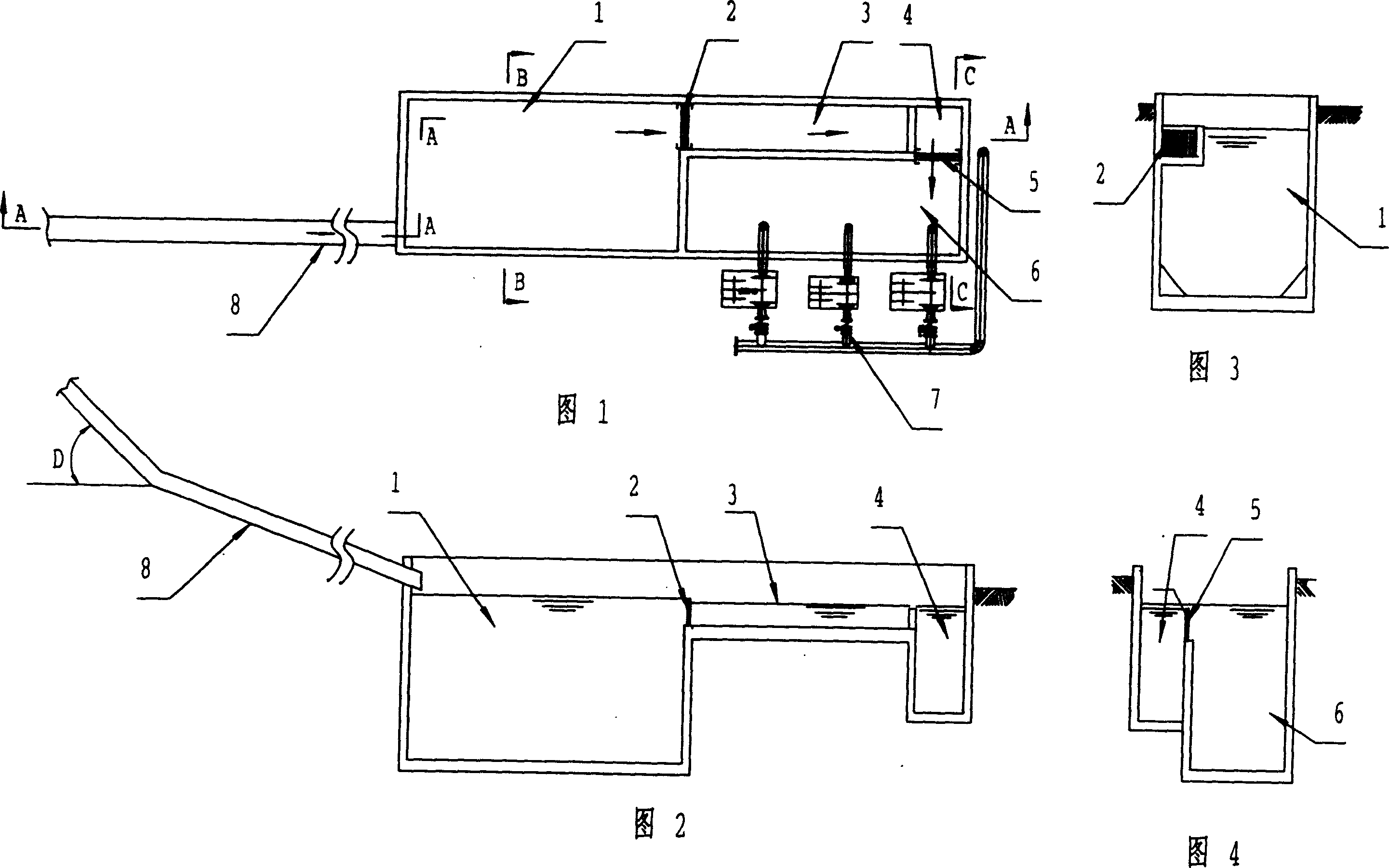

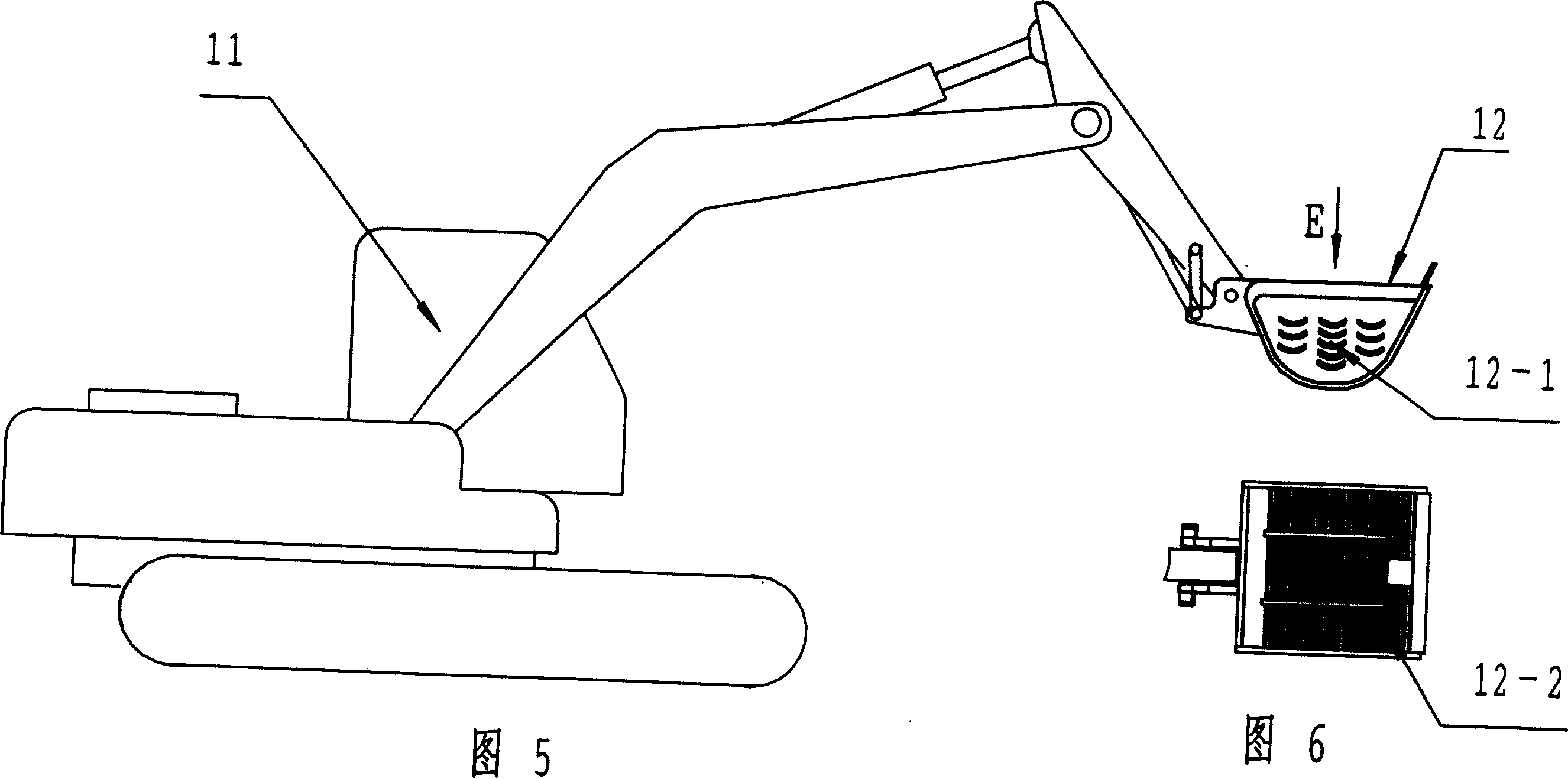

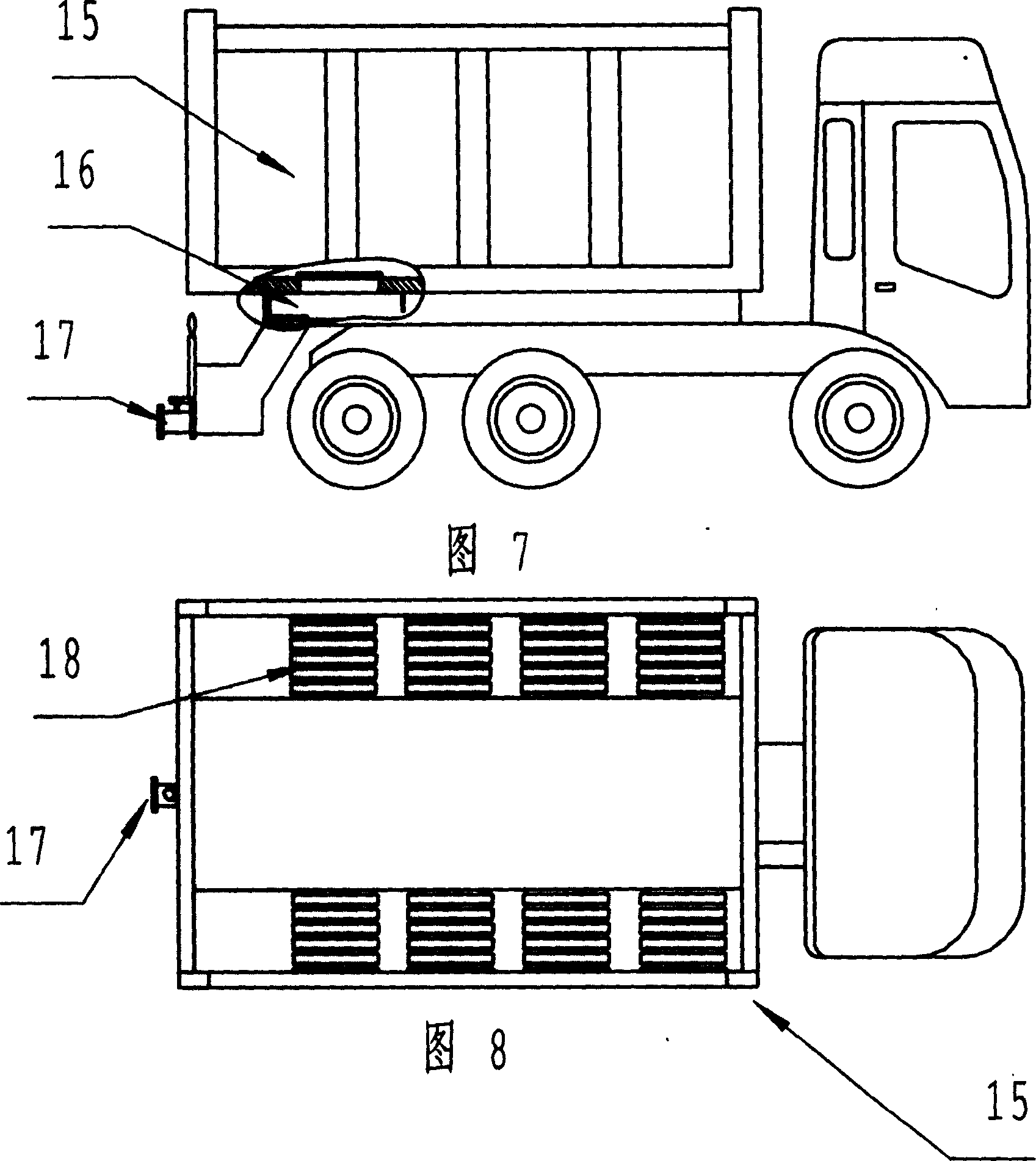

[0019] The blast furnace slag treatment system of the present invention has made many improvements in the blast furnace slag water quenching and conveying device, the sediment pool and the slag flushing water circulation device, the slag water separation and the water slag transporting device and the like. The improvements will be described in further detail below in conjunction with the accompanying drawings.

[0020] The blast furnace slag water quenching and conveying device includes a slag ditch and a slag flushing ditch. The blast furnace slag flows to the slag flushing point at the end of the slag ditch, and the slag is impacted by water with a certain pressure and flow rate, and water quenched and broken into the slag flushing Groove 8. Referring to Fig. 1, Fig. 2, the slope D of the front section 10-20 meters of the slag-washing ditch 8 of the present invention is advisable with 15 ° ~ 45 °, and should increase the front-section slope of the slag-washing ditch as far a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com