Rubber internal mixing device

A rubber banburying and banburying technology, applied in the field of rubber banburying, can solve the problems of physical injury and hot hands of rubber workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

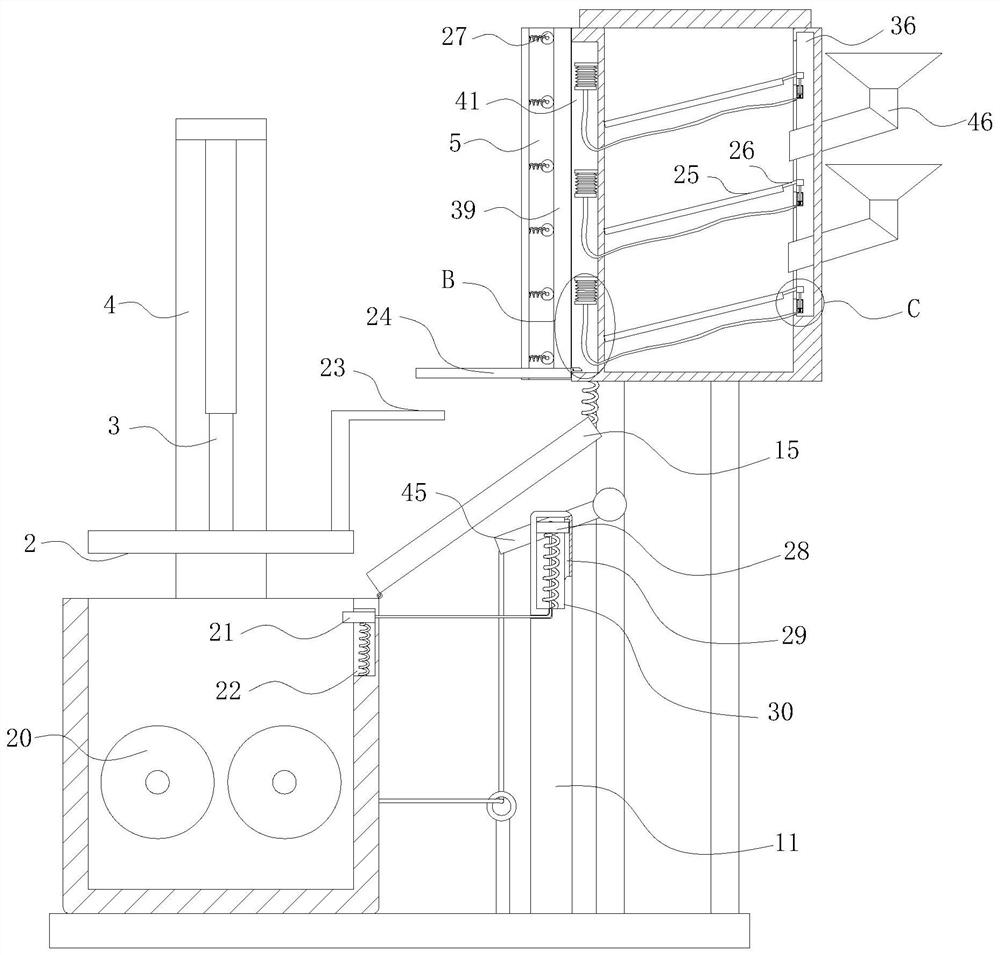

[0029] As an embodiment of the present invention, the air blowing device includes an upper fixed plate 37, a spring compression tube 38, a lower movable plate 40 and a rubber hose 43; The side is provided with a storage groove 41; the inside of the storage groove 41 is fixed with several sets of upper fixing plates 37; the bottom of the upper fixing plate 37 is fixedly connected with the top of the spring compression tube 38, and the bottom of the spring compression tube 38 It is fixedly connected with the lower movable plate 40; when the spring compression tube 38 is in a naturally stretched state, the lower movable plate 40 is located near the top of the discharge port 44; the bottom of the spring compression tube 38 is in contact with the rubber hose 43 One end communicates; the other end of the rubber hose 43 penetrates the inside of the charging box 8, the inside of the installation chamber 36 and communicates with the bottom of the hollow cylinder 34; the side of the slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com