Application of High Frequency Welding Technology in Fuse Welding and Its Application Method

A high-frequency welding and high-frequency welding machine technology, applied in high-frequency current welding equipment, fuse manufacturing, welding equipment and other directions, can solve the problems of heat dissipation waste, low welding efficiency, complex operation process, etc., to achieve less energy waste , Fast welding speed, good safety effect

Active Publication Date: 2011-11-30

DONGGUAN BETTER ELECTRONICS TECH +1

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The existing fuse welding process mainly has the following deficiencies: 1. The ambient temperature is high during welding, which may easily cause burns to welders; 2. Bad gases such as smoke will be produced during the welding process, polluting the environment; 3. Gases during the welding process Expansion is prone to unqualified phenomena such as tin leakage and crooked caps; 4. It is also easy to produce defective products such as copper cap scratches, false welding, and cap drop; 5. The welding efficiency is not high, time-consuming and power-consuming, etc.

[0003] Chinese Patent Application No. 02134292.X discloses a fuse tube and its manufacturing method, which mainly realizes the fixed welding of the fuse by melting glass, but its operation process is very Complicated, and the temperature requirements for melting glass are relatively high, a large amount of heat is lost in the air and wasted, which does not meet the requirements of energy saving

And only for certain special products.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0038] Embodiment two

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

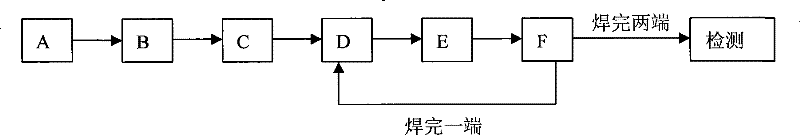

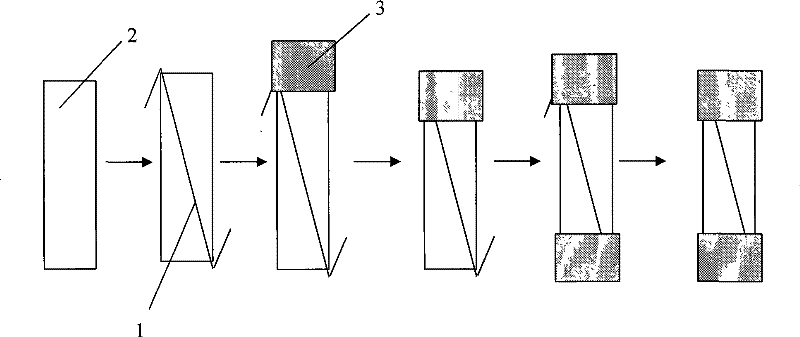

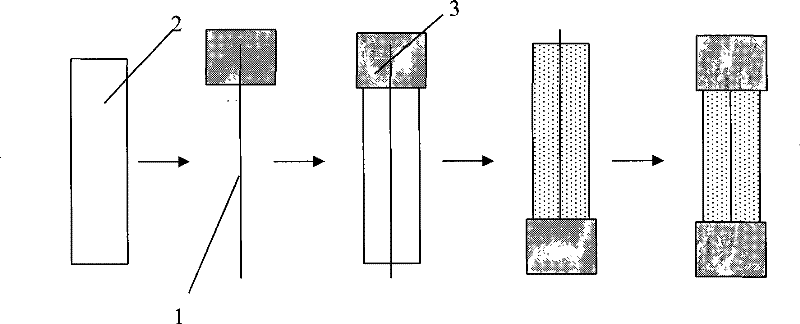

The invention relates to the technical field of fuse welding, in particular to the application of high-frequency welding technology in fuse welding and its application method. The invention is used to weld the fuse, the pipe body, and the tinned copper cap into one, that is, the fuse, the pipe body, and the tinned copper cap are welded together by using the principle of high-frequency welding, and the high-frequency welding machine generates high-frequency Current, set an openable closed welding cavity, the high frequency current generates an alternating magnetic field in the closed welding cavity, control the frequency and time of the high frequency current, and melt the tin on the copper cap in the closed welding cavity welding.

Description

Technical field: [0001] The invention relates to the technical field of fuse welding, in particular to the application of high-frequency welding technology in fuse welding and its application method. Background technique: [0002] The existing fuse welding technology usually adopts the following welding methods, such as heating block welding, hot air welding, current welding, flame welding, etc., which mainly melts tin by heating and then cools to achieve the welding effect. The existing fuse welding process mainly has the following deficiencies: 1. The surrounding environment temperature is high during welding, which may easily cause burns to welders; 2. Bad gases such as smoke will be produced during the welding process, polluting the environment; Swelling is prone to unqualified phenomena such as tin leakage and crooked caps; 4. It is also easy to produce defective products such as copper cap scratches, false soldering, and cap dropouts; 5. The welding efficiency is not h...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01H69/02B23K13/00B23K13/06

Inventor 韩露高连忠

Owner DONGGUAN BETTER ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com