Doped BKT-BT series lead-free PTCR ceramic material and preparation method thereof

A technology of BKT-BT and ceramic materials, which is applied in the direction of instruments, measuring heat, measuring devices, etc., can solve the problems of poor comprehensive performance, unseen, lost application value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

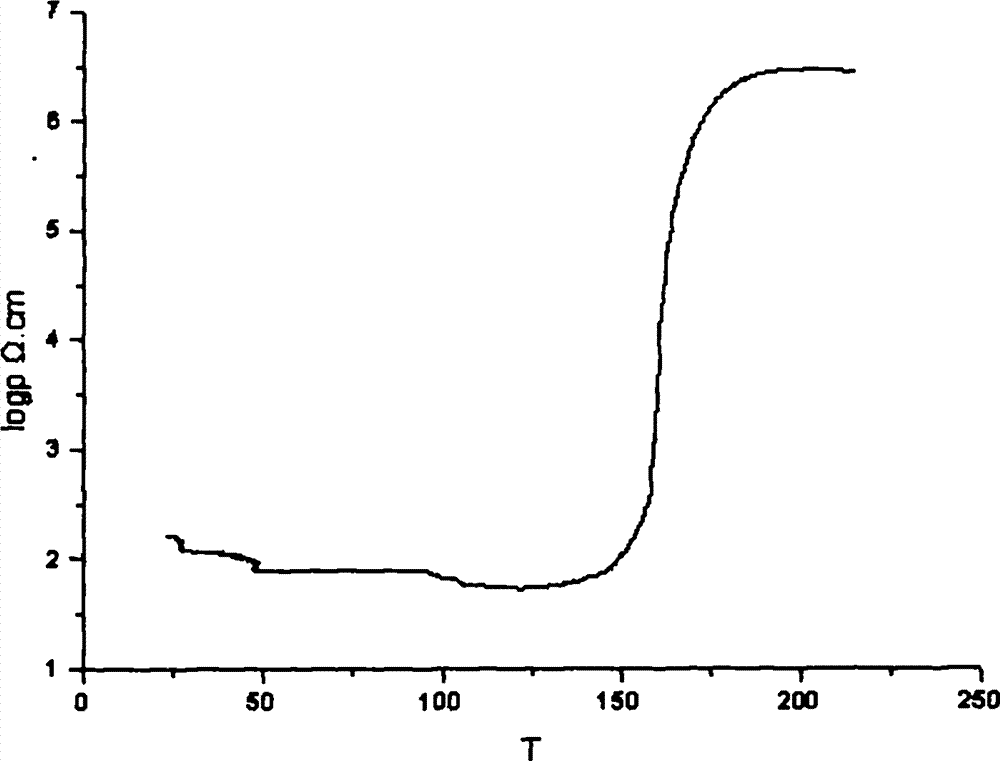

Embodiment 1

[0022] take x 1 =0.03,x 2 =0.5%, A is La, y=0.2%, M is Ta, z=0. Then the molecular formula of the ceramic material is (Bi 0.5 K 0.5 ) 0.03 (Ba 0.965 La 0.005 ) Ti 0.998 Ta 0.002 o 3 , which uses CP or AR grade chemical reagent Bi with extremely low PbO impurity content 2 o 3 、K 2 CO 3 、BaCO 3 , La 2 o 3 、TiO 2 and Ta 2 o 5 As the raw material, after fully drying, weigh according to the stoichiometry of the above formula.

[0023] Use absolute ethanol as the medium, and mix by ball milling for 3 hours. Dry, sieve, put the powder in a corundum crucible, and synthesize at 900°C / 1 hour and 950°C / 2 hours. Then pulverize and sieve, ball mill for 4 hours, dry, add binder, dry press molding, after 800°C / 2 hours of plastic ejection, heat at 1260-1310°C for 2-4 hours and burn. Grinding, ultrasonic cleaning, and ohmic electrodes, that is, doped lead-free PTCR ceramic components. Its main properties are: Tc: 175°C, resistance jump: 2.5×10 3 , α is 32% / °C, ρ RT 6.3×...

Embodiment 2

[0026] take x 1 =0.20,x 2 =0.3%, A is Y and Bi, wherein the mass percentage of Y and Bi is 1:1, y=0.1%, M is Sb, Z=0.5, D is MnO 2 . Raw material is except identical with embodiment 1, adds AR grade CeO in addition 2 , Y 2 o 3 , CP grade Sb 2 o 3 and MnO 2 . The process is the same as in Example 1, the synthesis temperature is 800°C / 1 hour, and 850°C / 2 hours; the firing conditions are 1200-1250°C, heat preservation for 1-3 hours. The properties of the obtained ceramics are: Tc is 182°C, resistance jump: 8.5×10 3 , α: 16% / °C, ρ RT : 1.2×10 2 Ω·Cm.

Embodiment 3

[0028] take x 1 =0.35,x 2 =0.6%, A is La, Ce mass ratio is 1:1, y=0.1%, M is Sb, Z=0.5%, D is MnO 2 . Raw material is except identical with embodiment 1, adds AR grade CeO in addition 2 , Y 2 o 3 , CP grade Sb 2 o 3 and MnO 2 . The process is the same as in Example 1, but the synthesis temperature is changed to 800°C / 1 hour and 850°C / 2 hours; the firing conditions are changed to 1200-1250°C and kept for 1-3 hours in a nitrogen flow with low oxygen concentration. become. The properties of the obtained ceramics are: Tc is 205°C, resistance jump: 4.0×10 2 , α: 12% / °C, ρ RT : 8.0×10 2 Ω·Cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com