Preparation method of carbon nanotube-graphene oxide mixed reinforced composite material

A technology for reinforcing composite materials and carbon nanotubes, applied in chemical instruments and methods, materials for heat exchange, etc., can solve the problems of structural regulation, difficult to fully infiltrate the resin matrix, poor self-sustainability of graphene reinforcements, etc. The effect of simple equipment and convenient process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the carbon nanotube-graphene oxide hybrid reinforced composite material of this embodiment is carried out according to the following steps:

[0031] (1) Ultrasonic disperse 0.5g graphene oxide in 2000ml water for 40 minutes to obtain a 0.25mg / ml graphene oxide dispersion;

[0032] (2) The graphene oxide dispersion obtained in step (1) is heated up to 40 o C, add 0.5g of 2-ethyl-4-methylimidazole, then ultrasonically disperse for 1 hour, add 0.5g of multi-walled carbon nanotubes, add 1ml of ammonia water after ultrasonically dispersing for 2 hours, and heat up to 90 o C, hydrothermal reaction for 7 hours;

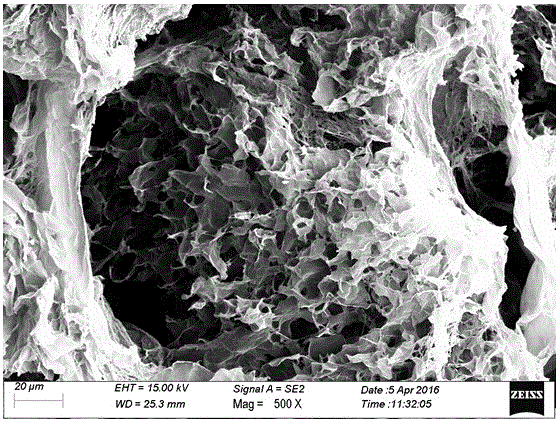

[0033] (3) The reaction product obtained in step (2) was freeze-dried with liquid nitrogen for 14 hours, and then dried at 105°C for 2 hours to obtain a three-dimensional multi-walled carbon nanotube-graphene oxide hybrid reinforcement. The scanning electron microscope picture is as follows figure 1 shown, from figure 1 It can be seen that...

Embodiment 2

[0036] The preparation method of the carbon nanotube-graphene oxide hybrid reinforced composite material of this embodiment is carried out according to the following steps:

[0037] (1) Ultrasonic disperse 1 g of graphene oxide in 2000 ml of water for 60 minutes to obtain a 0.5 mg / ml graphene oxide dispersion;

[0038] (2) The graphene oxide dispersion obtained in step (1) is heated up to 45 o C, add 1g of 2-ethyl-4-methylimidazole, then ultrasonically disperse for 1 hour, add 1g of carboxy-modified multi-walled carbon nanotubes, add 2ml of ammonia water after ultrasonically dispersing for 2 hours, and heat up to 90 o C, hydrothermal reaction for 10 hours;

[0039](3) The reaction product obtained in step (2) was subjected to liquid nitrogen freeze-drying treatment for 14 hours, and then dried at 105°C for 2 hours to obtain a three-dimensional carboxyl-modified multi-walled carbon nanotube-graphene oxide hybrid reinforcement;

[0040] (4) Forming by vacuum-assisted resin tra...

Embodiment 3

[0042] The preparation method of the carbon nanotube-graphene oxide hybrid reinforced composite material of this embodiment is carried out according to the following steps:

[0043] (1) Ultrasonic disperse 2g of graphene oxide in 2000ml of water for 50 minutes to obtain a 1mg / ml graphene oxide dispersion;

[0044] (2) The graphene oxide dispersion obtained in step (1) is heated up to 42 o C, add 1g of 2-ethyl-4-methylimidazole, then ultrasonically disperse for 1 hour, add 1g of hydroxyl-modified multi-walled carbon nanotubes, add 1ml of ammonia water after ultrasonically dispersing for 2 hours, and heat up to 85 o C, hydrothermal reaction for 8 hours;

[0045] (3) The reaction product obtained in step (2) was subjected to liquid nitrogen freeze-drying treatment for 13 hours, and then dried at 105°C for 2 hours to obtain a three-dimensional hydroxyl-modified multi-walled carbon nanotube-graphene oxide hybrid reinforcement;

[0046] (4) Forming by resin film infiltration proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com