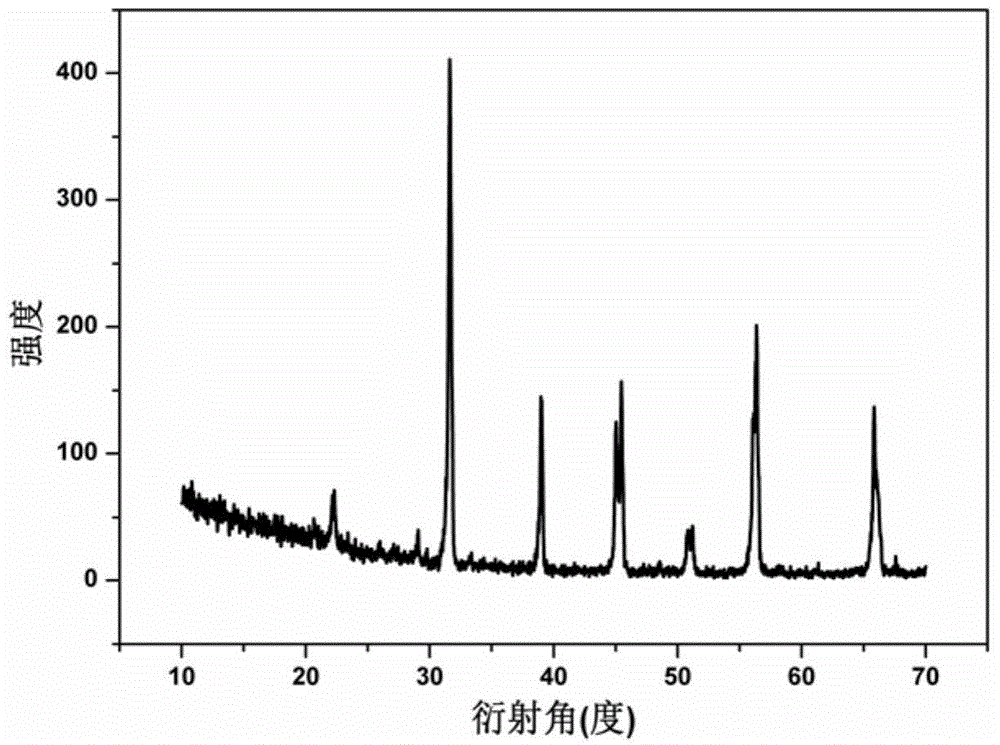

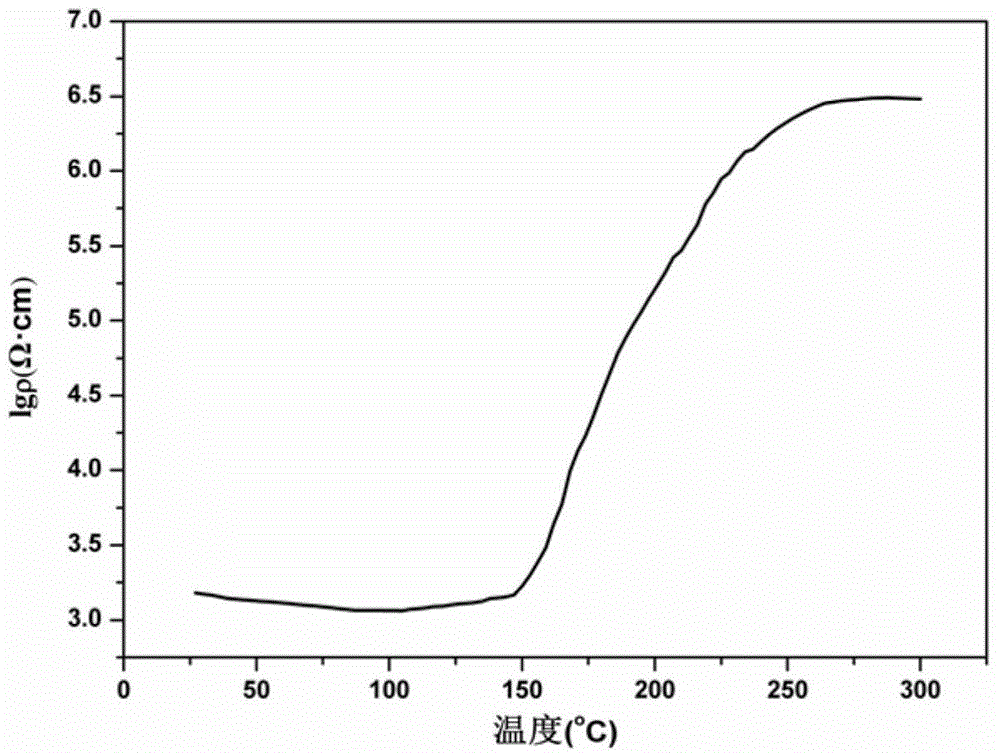

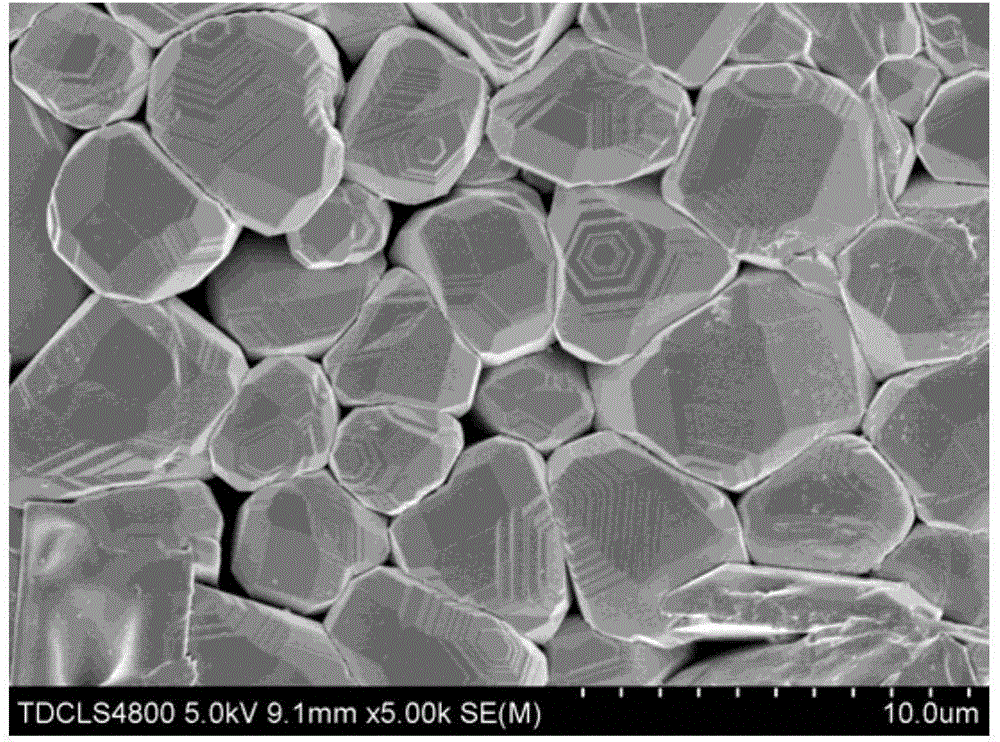

High-Curie-temperature lead-free barium-titanate-base PTCR (positive temperature coefficient of resistance) ceramic material, and preparation and application thereof

A lead-free barium titanate-based, ceramic material technology, applied in the field of electronic ceramics, can solve the problems of complex process operation, difficult semiconducting, and difficult to apply to large-scale industrial production, etc., to increase Curie temperature, reduce The effect of room temperature resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: prepare the thermistor of high Curie temperature lead-free barium titanate-based PTCR ceramic material:

[0023] (1-x-y)BaTiO 3 -xBaBiO 3 -y(Bi 0.5 Na 0.5 )TiO 3 , take x=0.001, y=0; present embodiment according to above-mentioned molar ratio batching. The specific steps are:

[0024] Step 1. BaTiO 3 The synthesis method is: the BaCO 3 with TiO 2 The ingredients are mixed according to the molar ratio of 1:1, according to the ingredients: the mass ratio of ball stone: distilled water is 1:3:4, mixed and placed in a nylon tank for wet ball milling for 6 hours, and then the abrasive is dried at a temperature of 120 ° C, dried The material is placed in a crucible, and the temperature is raised to 1050°C at a heating rate of 5°C / min, and the temperature is kept for 2h to synthesize BaTiO. 3 .

[0025] Step 2. BaBiO 3 The synthesis method is: Bi 2 o 3 with BaCO 3 According to the molar ratio of 1:2, the ingredients are mixed according to the mass r...

Embodiment 2

[0030] Embodiment 2: prepare the thermistor of high Curie temperature lead-free barium titanate-based PTCR ceramic material:

[0031] (1-x-y)BaTiO 3 -xBaBiO 3 -y(Bi 0.5 Na 0.5 )TiO 3 , take x=0.002, y=0; present embodiment according to above-mentioned molar ratio batching. The specific steps are:

[0032] Step 1. BaTiO 3 The synthesis of is the same as in Example 1;

[0033] Step 2. BaBiO 3 The synthesis of is the same as in Example 1;

[0034] Step 3, according to 0.998BaTiO 3 -0.002BaBiO 3 -0.00036MnO 2 -0.01Si 3 N 4 Formulated with MnO 2 、Si 3 N 4 and the BaTiO synthesized in steps 1 and 2 3 Powder and BaBiO 3 The powder is compounded to form a mixture. According to the mixture: ball stone: distilled water, the mass ratio is 1:3:4, mixed and placed in a nylon tank for wet ball milling for 6 hours, and then the abrasive is dried at a temperature of 120°C to obtain a dry abrasive. ;

[0035] Step 4, with embodiment 1;

[0036] Step 5. Coat both sides of t...

Embodiment 3

[0038] Embodiment 3: Preparation of lead-free barium titanate-based PTCR ceramic material thermistor with high Curie temperature:

[0039] (1-x-y)BaTiO 3 -xBaBiO 3 -y(Bi 0.5 Na 0.5 )TiO 3 , take x=0.002, y=0.002; present embodiment according to above-mentioned molar ratio batching. The specific steps are:

[0040] Step 1. BaTiO 3 The synthesis of is the same as in Example 1;

[0041] Step 2. BaBiO 3 The synthesis of is the same as in Example 1;

[0042] Step three, (Bi 0.5 Na 0.5 ) Synthesis: Bi 2 o 3 with TiO 2 According to the molar ratio of 1:4, the ingredients are mixed according to the mass ratio of ball stone: anhydrous ethanol is 1:3:4 and placed in a nylon tank for wet ball milling for 6 hours, and then the abrasive is dried at a temperature of 90°C. The drying material was placed in a crucible, and the temperature was raised to 800°C at a heating rate of 5°C / min, and the temperature was kept for 2h to synthesize (Bi 0.5 Na 0.5 )TiO 3 .

[0043] Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com