Conducting composite material with resistance positive-temperature effect and overcurrent-protecting element

A conductive composite material and positive temperature effect technology, applied in the direction of resistors with positive temperature coefficients, current response resistors, etc., can solve the problems of unsatisfactory conductivity and low resistivity, and achieve excellent resistance reproducibility, Low resistivity and excellent weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

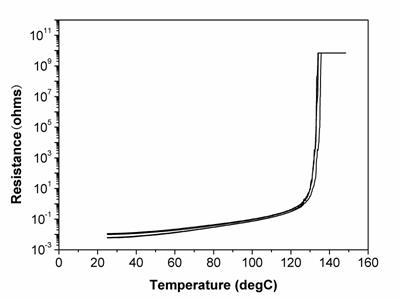

[0037] image 3 It is the resistance-temperature curve diagram of the overcurrent protection element of the present embodiment 1. The overcurrent protection element has a very low resistance value at 25°C. As the temperature increases, the resistance rises slowly. When the temperature increases to about 130°C, the resistance of the overcurrent protection element changes suddenly, increasing by about 10 orders of magnitude. When the overcurrent protection element changes from a conductor to an insulator, the circuit is in an open circuit state to achieve the purpose of protecting the circuit element.

[0038] Example 2

[0039] The composition of the conductive composite material for preparing the overcurrent protection element is the same as in Example 1, but the steps for preparing the conductive composite material with positive temperature effect of resistance and the overcurrent protection element are changed to: grind the polymer and mix it with the conductive filler in t...

Embodiment 2

[0041] The steps of preparing a conductive composite material with a positive temperature effect on resistance and an overcurrent protection element are the same as in Example 1, but the volume fraction of the polymer is changed from 40% to 46%, and the volume fraction of the conductive filler 2 is changed from 60% to 54%. The formulation of the conductive composite material of this embodiment and the electrical characteristics of the overcurrent protection element are shown in Table 1.

Embodiment 3

[0043] The steps of preparing a conductive composite material with a positive temperature effect on resistance and an overcurrent protection element are the same as in Example 1, but the volume fraction of the polymer 2 is changed from 40% to 52%, and the volume fraction of the conductive filler 2 is changed from 60% to was 48%. The formulation of the conductive composite material of this embodiment and the electrical characteristics of the overcurrent protection element are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com