PTC (Positive Temperature Coefficient) protection element capable of maintaining ultralarge current

A technology for protecting components and currents, applied in the field of PTC protection components, can solve the problems of not meeting the safety development requirements of power battery packs and energy storage battery packs, and being difficult to replace, and achieves low room temperature resistivity, stable performance, and high withstand voltage level. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

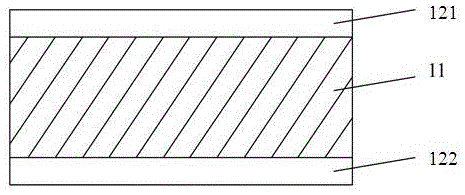

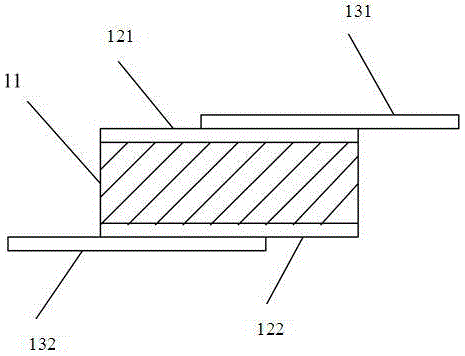

[0039] Such as figure 1 Schematic diagram of the structure of the PTC chip and figure 2As shown in the figure of the PTC element that can maintain a large current, a PTC protection element that can maintain a large current includes a first external conductive metal pin, a second external conductive metal pin, and a conductive metal pin located on the first and second external conductive The resistance between the metal pins is a positive temperature effect chip (PTC), and the resistance of the PTC protection element is lower than 2.0mΩ, wherein,

[0040] (a) At least one chip with a positive temperature effect of resistance, the chip is composed of a composite material layer 11 with a positive temperature effect of resistance, and the first and second electrode foils closely bonded to the upper and lower surfaces of the composite material layer 11 with a positive temperature effect of resistance. , the lower metal electrode foils 121, 122 form a resistance positive temperatu...

Embodiment 2

[0047] Others are the same as in Example 1, on the basis of Example 1, the 65% copper alloy material used in the electrode foil and pins is replaced with an 85% copper alloy material, the resistivity is 4.7μΩ.cm, and the thermal conductivity is 159W / ( m.K).

Embodiment 3

[0049] Others are the same as in Example 1, on the basis of Example 1, the 65% copper alloy material used in the electrode foil and pins is replaced with a 95% copper alloy material, the resistivity is 3.1 μΩ.cm, and the thermal conductivity is 243W / ( m.K).

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com