BaTiO3-based PTC thermal sensitive ceramic material and preparation method thereof

A heat-sensitive ceramic and bi2o3 technology, which is applied in the field of PTC heat-sensitive ceramic materials and their preparation, can solve the problems of increased room temperature resistivity of ceramic samples, limited increase of Curie temperature, and reduced efficiency of Curie temperature increase. , to achieve good PTC effect, low room temperature resistivity, good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

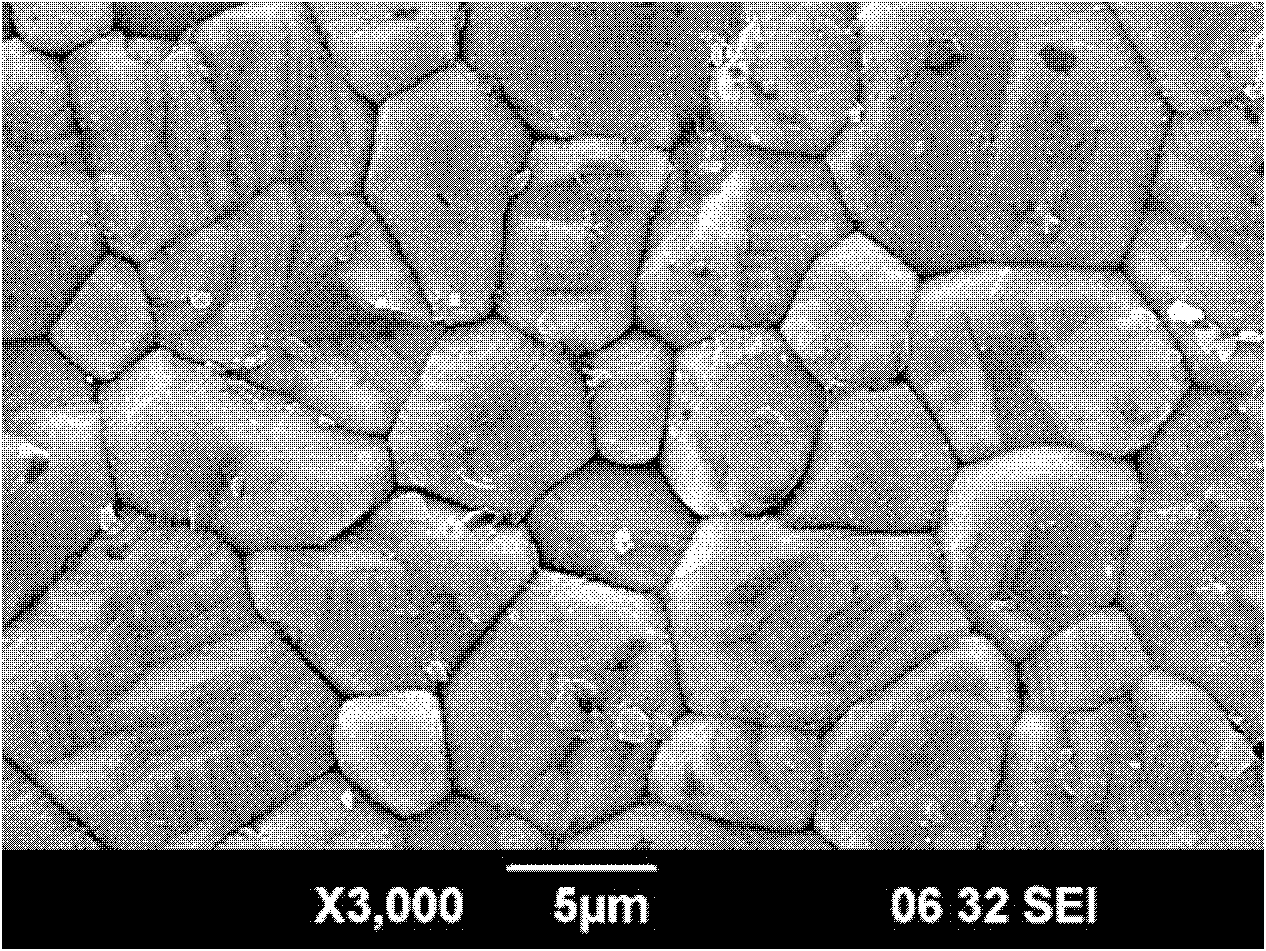

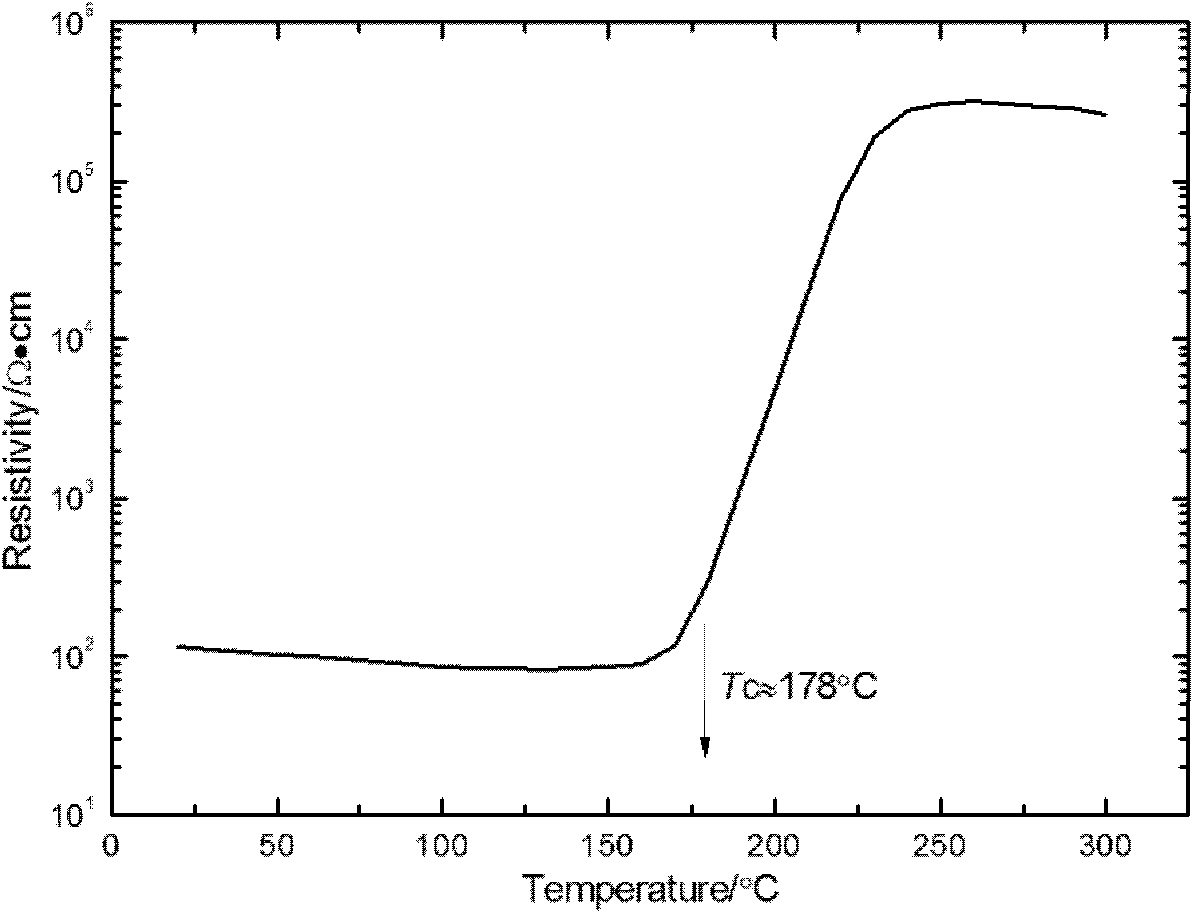

Image

Examples

Embodiment 1

[0023] Step 1: Weigh BaCO according to the molar ratio of 0.96:0.002:0.002 3 、 Bi 2 o 3 , and K 2 CO 3 , mixed to form mixture A, then, weigh TiO 2 , the TiO 2 Mix with mixture A according to the molar ratio of 1:1 to form mixture B;

[0024] Step 2: Weigh the mixture B obtained in Step 1 according to the mass ratio of 1:1:2.5, as well as zirconium balls and deionized water, place it in a ball mill jar for ball milling for 10 hours, move it into an oven, and dry it at 100°C. Then, transfer it to a high-temperature electric furnace and keep it warm at 1100°C for 2 hours to form a pre-mixture, which is set aside;

[0025] Step 3: Take the main material mixture B as 1 mol, and weigh Nb accounting for 0.3 mol% of the main material according to the molar percentage 2 o 5 , accounting for 0.2mol% of the main material Y 2 o 3 , 0.02mol% Mn(NO 3 ) 2 , and 0.2mol% of Sb in the main material 2 o 3 , then, the above Nb 2 o 5 , Y 2 o 3 , Mn(NO 3 ) 2 , and Sb 2 o 3 Ad...

Embodiment 2

[0033] Step 1: Weigh BaCO according to the molar ratio of 0.98:0.001:0.001 3 、 Bi 2 o 3 , and K 2 CO 3 , mixed to form mixture A, then, weigh TiO 2 , the TiO 2 Mix with mixture A according to the molar ratio of 1:1 to form mixture B;

[0034] Step 2: Weigh the mixture B, zirconium balls and deionized water obtained in step 1 according to the mass ratio of 1:1:2.5, place it in a ball mill jar and mill it for 10 hours, then move it into an oven, dry it at 100°C, and then , transferred to a high-temperature electric furnace and kept at 1200°C for 2 hours to form a pre-mixture, and set aside;

[0035] Step 3: Take the main material mixture B as 1 mol, and weigh Nb accounting for 0.15 mol% of the main material according to the molar percentage 2 o 5 , 0.1mol% Y 2 o 3 , 0.025mol% Mn(NO 3 ) 2 , and 0.1mol% Sb 2 o 3 , then, the above Nb 2 o 5 , Y 2 o 3 , Mn(NO 3 ) 2 , and Sb 2 o 3 Add to the premix obtained in step 2, and form the complete batch after mixing;

...

Embodiment 3

[0043] Step 1: Weigh BaCO according to the molar ratio of 0.99:0.005:0.005 3 、 Bi 2 o 3 , and the K 2 CO 3 , mixed to form mixture A, then, weigh TiO 2 , the TiO 2 Mix with mixture A according to the molar ratio of 1:1 to form mixture B;

[0044] Step 2: Weigh the mixture B, zirconium balls and deionized water obtained in step 1 according to the mass ratio of 1:1:2.5, place it in a ball mill jar and mill it for 10 hours, then move it into an oven, dry it at 100°C, and then , transferred to a high-temperature electric furnace and kept at 1230°C for 2 hours to form a pre-composite material for later use;

[0045] Step 3: Take the main material mixture B as 1 mol, and weigh Nb accounting for 0.1 mol% of the main material according to the molar percentage 2 o 5 , 0.05mol% of Y 2 o 3 , 0.02mol% Mn(NO 3 ) 2 , and 0.15 mol% Sb 2 o 3 , then, the above Nb 2 o 5 , Y 2 o 3 , Mn(NO 3 ) 2 , and Sb 2 o 3 Add to the premix obtained in step 2, and form the complete batch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com