Conductive composite material and PTC (Positive Temperature Coefficient) thermal sensitive element prepared from same

A technology of conductive composite materials and thermal elements, which is applied to conductive materials dispersed in non-conductive inorganic materials, resistors with positive temperature coefficients, layered products, etc. Poor dispersion and other problems, to achieve the effects of good electrical conductivity, good PTC strength and resistance reproducibility, and low room temperature resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The composition of the conductive composite material that prepares PTC thermosensitive element is:

[0052] (a) The volume fraction of crystalline polymer is 40%, the melting temperature is 135°C and the density is 0.952g / cm 3 high-density polyethylene;

[0053] (b) The conductive filler is titanium carbide-tantalum carbide-tungsten carbide solid solution, the volume fraction is 60%, its particle size is less than 10 μm, and the volume resistivity is 42 μΩ.cm;

[0054] (c) The coupling agent is monoalkoxy isopropyl dioleate acyloxy titanate, the volume fraction is 0.5% of the volume of the conductive filler, and the density is 0.976g / cm 3 .

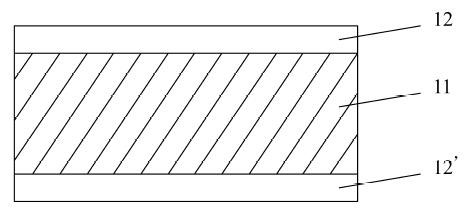

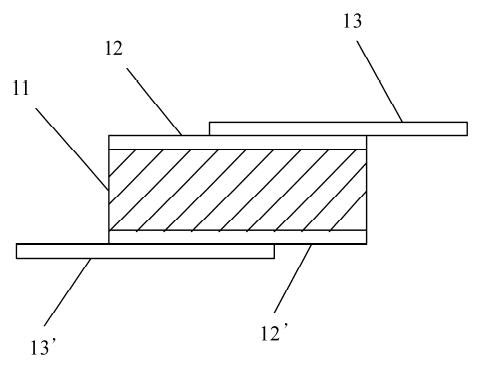

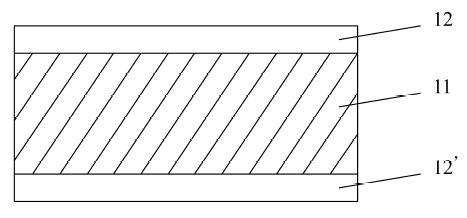

[0055] Set the temperature of the torque rheometer at 180°C and the rotational speed at 30 rpm, first add the crystalline polymer and the coupling agent and banbury for 1 minute, then add the conductive filler, and then continue banbury for 20 minutes to obtain a conductive composite The material is to pass the melted and mixed ...

Embodiment 2

[0060] The steps of preparing the conductive composite material and the PTC thermosensitive element are the same as in Example 1, but the volume fraction of the coupling agent in the conductive composite material is increased from 0.5% to 1.0% of the volume of the conductive filler.

[0061] The electrical characteristics of the PTC thermal element of this embodiment are shown in Table 1.

Embodiment 3

[0063] The steps of preparing the conductive composite material and the PTC thermosensitive element are the same as in Example 1, but the volume fraction of the coupling agent in the conductive composite material is increased from 0.5% to 1.5% of the volume of the conductive filler.

[0064] The electrical characteristics of the PTC thermal element of this embodiment are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com