All-three-dimensional two-stage compression double waverider integrated design method based on bending shock wave theory

A bending shock, two-stage compression technology, applied in geometric CAD, ground installation, transportation and packaging, etc., can solve the lack of full three-dimensional two-stage compression double waverider integrated design method, the limited compression performance of double waveriders, Limiting the design scope of dual waveriders to achieve the effects of enriching design ideas, fast design process, and widening the range of working Mach numbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

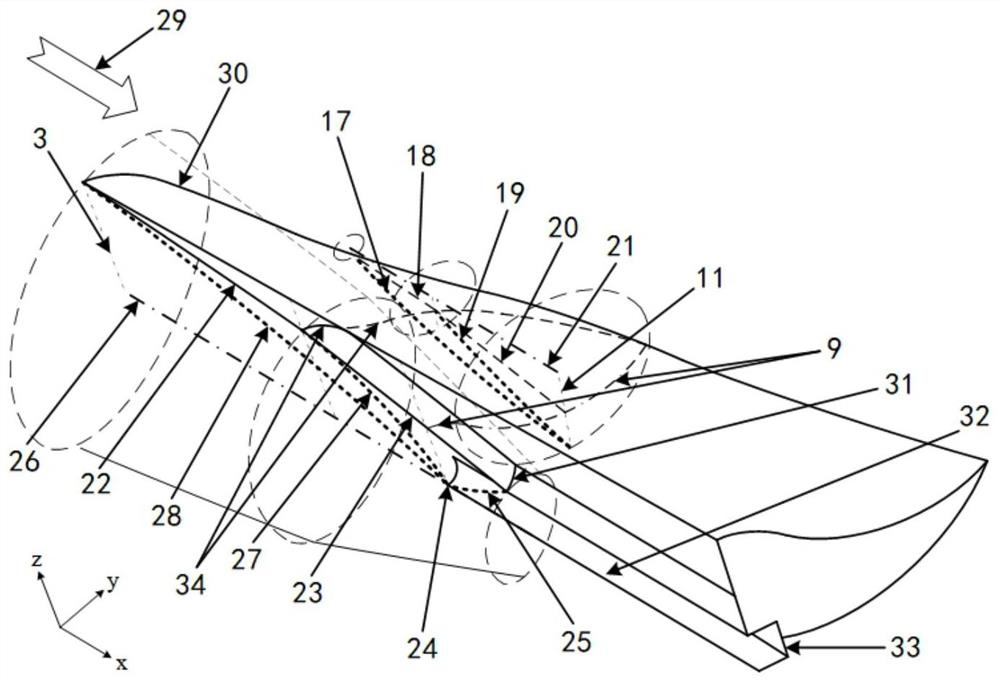

[0022] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

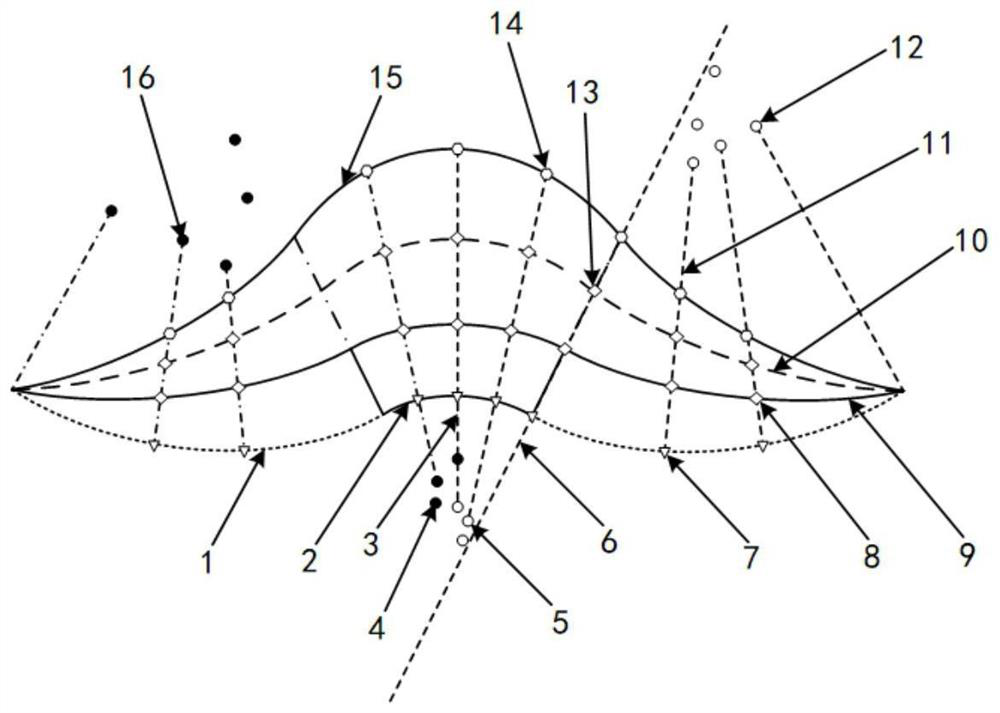

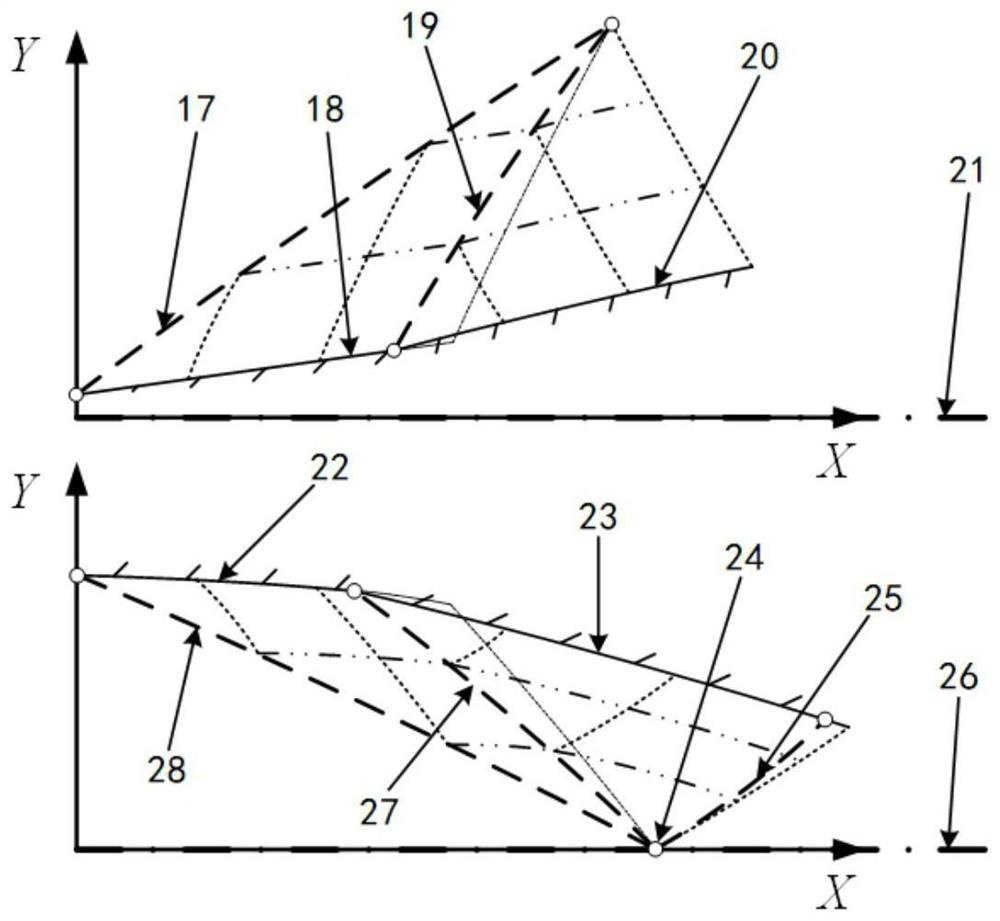

[0023] like Figures 1 to 6 As shown in the figure, the integrated design method of full three-dimensional two-stage compression double waverider based on bending shock theory includes the following steps:

[0024] 1) According to the design requirements, specify the required full three-dimensional shock curve intersected by two full three-dimensional bending shock waves and one full three-dimensional internal flow reflection shock wave in the design section, which includes the full three-dimensional shock curve outer flow section 1 and full three-dimensional shock wave curve. The three-dimensional shock curve has two parts in the flow section 2. The shock curve is designed with an ellipse or other non-axisymmetric shape. According to the curvature characteristics of the two shock waves, the outer flow section 1 and the inner flow section 2 of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com