A dual combustion chamber scramjet engine and its control method

A scramjet, dual-combustion chamber technology, used in ramjet engines, combined engines, machines/engines, etc., can solve the problems of combination and relay difficulties, reduce the adjustment of additional mass, facilitate combustion organization, and improve engine performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

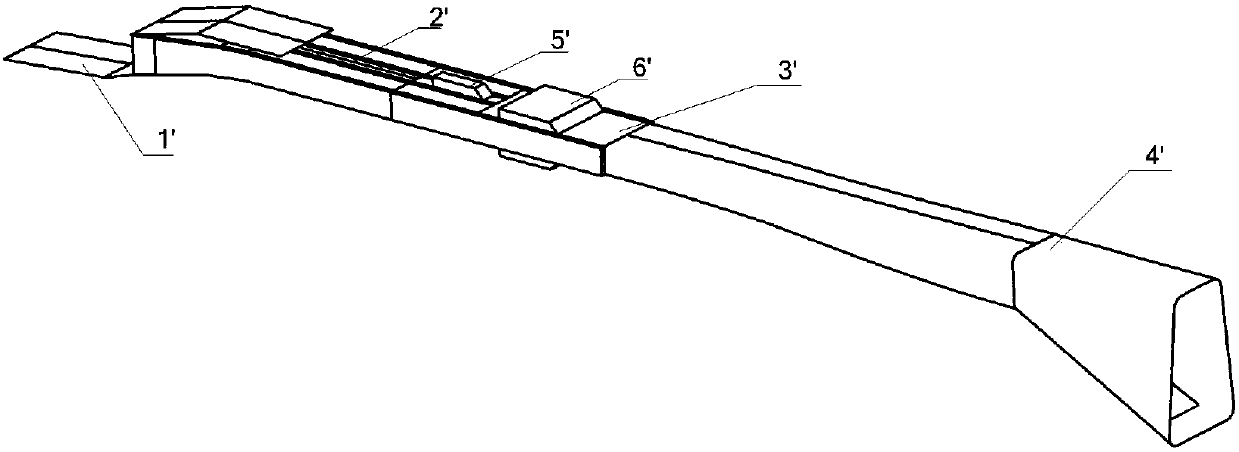

[0045] This embodiment provides a dual combustion chamber scramjet, figure 1 Its structure is shown, the engine is made up of intake port 1', subsonic combustion chamber 2', supersonic combustion chamber 3' and tail nozzle 4', and said subsonic combustion chamber 2' and supersonic combustion chamber 3' Use rectangular parallel layout;

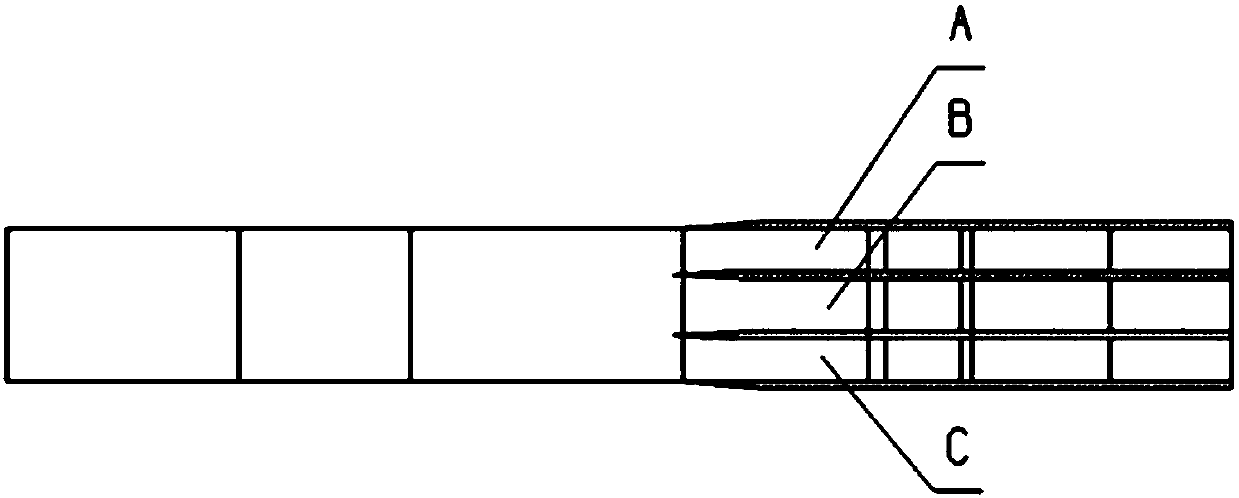

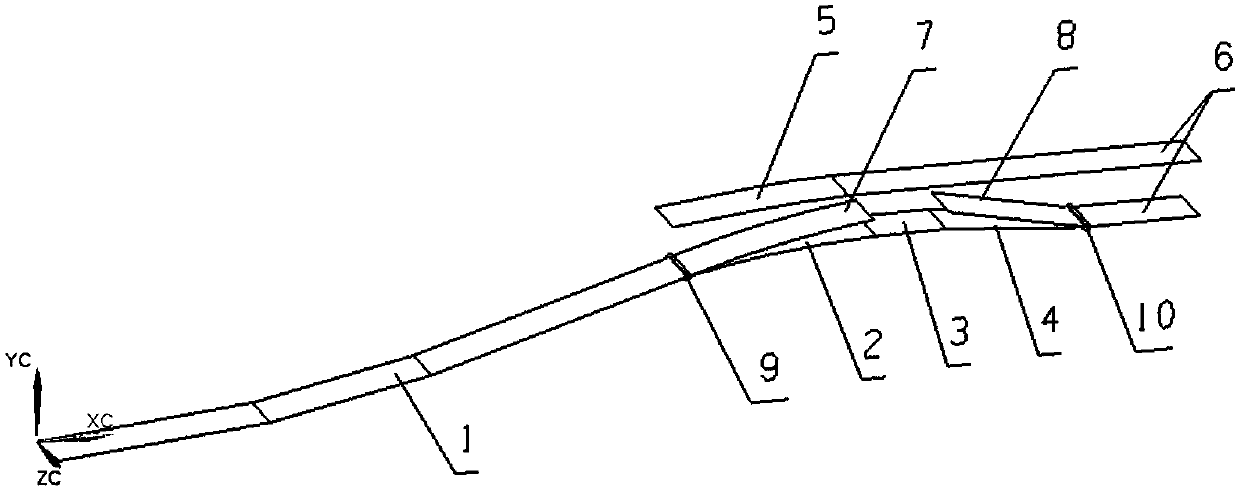

[0046] see figure 2 and image 3 , figure 2 Schematic diagram of the layout of the double inlet runners provided by the embodiment of the present invention; image 3 It is a schematic diagram of the air inlet channel adjustment scheme in the embodiment of the present invention. The inlet channel 1' adopts a binary inlet channel configuration, and is divided into a sub-combustion channel B and a super-combustion channel A and C by a support plate along the flow direction. The B channel is an intermediate channel, which connects In the subsonic combustion chamber 2', the A and C flow channels are distributed on both sides of the B flow cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com