Filler type wet denitration catalyst and preparation method thereof

A wet denitrification and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of complex liquid regeneration, which is not well solved, low investment, low operating temperature and operating costs , The problem of high temperature of the catalyst reaction window, it is easy to adjust the flow rate and gas flow rate, the catalytic effect is good, and the effect of continuous feeding is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1. Preparation of packing type wet denitration catalyst

[0038] Weigh 3g of palladium chloride solid, 2ml of dispersant polyethylene glycol, and 100ml of distilled water into a beaker, heat and mix evenly in a water bath at 50°C; to about 10 to make a colloid; add the treated honeycomb ceramic carrier to the colloid for 3 hours, put it in an oven and dry it at 80°C; after drying, put it in a microwave muffle furnace and bake it at 500°C for 3 hours, and cool it naturally to Room temperature; take the semi-finished catalyst and soak it in the mixture of ethanol and water (volume ratio 3:1), add sodium borohydride to it for full reduction; after the reduction, wash with distilled water, dry at 80°C after washing, Get target catalyst. Wherein the palladium elemental content is 0.72%.

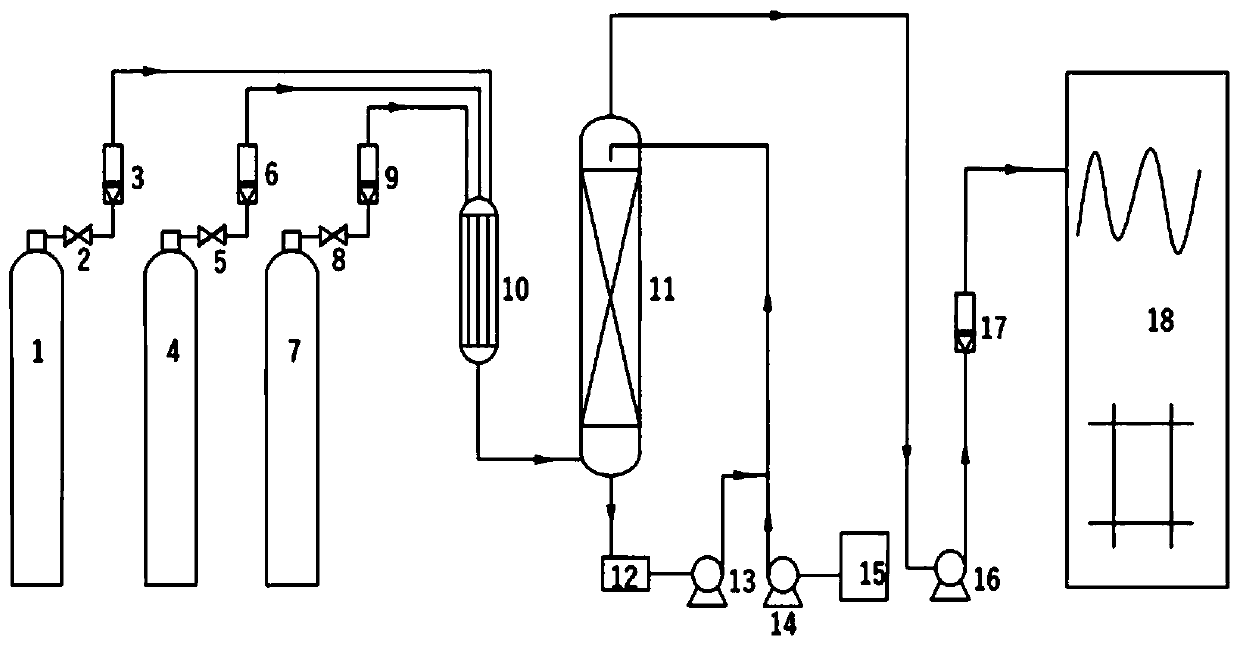

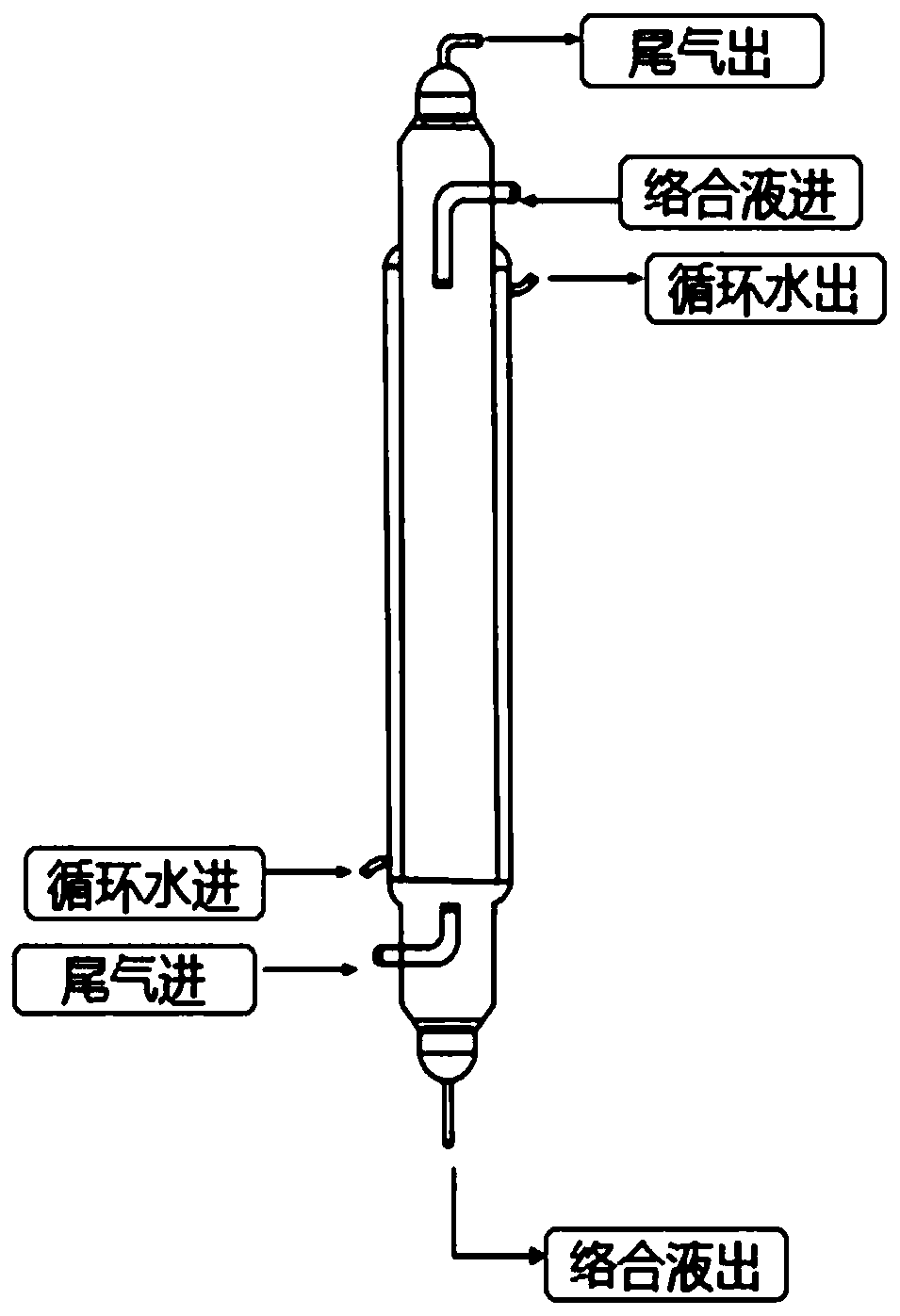

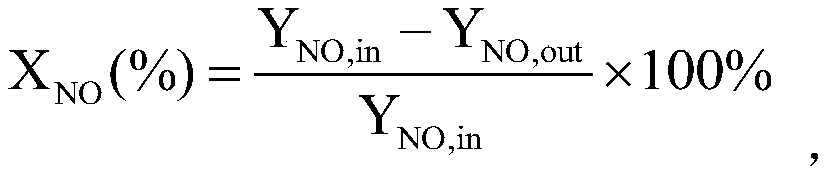

[0039] In this embodiment, the experimental evaluation of NO decomposition is to adopt figure 1 The experimental system shown is carried out, and the process is: use 150g of cat...

Embodiment 2

[0040] Embodiment 2. Preparation of packing type wet denitration catalyst

[0041] Weigh 1g of palladium chloride solid, 2ml of dispersant polyethylene glycol, and 100ml of distilled water into a beaker, heat and mix evenly in a water bath at 50°C; after the palladium chloride is completely dissolved, add an appropriate amount of aluminum sol, and drop ammonia to adjust Make a colloid at about 10°C; put the catalyst loaded with 0.72% active components into the beaker for impregnation for 3h, put it in an oven and dry it at 80°C; after drying, put it in a microwave muffle furnace and bake it at 500°C for 3h , naturally cooled to room temperature; take the semi-finished catalyst, and soak it in the mixed solution of ethanol and water (volume ratio 3:1), add sodium borohydride to it and carry out sufficient reduction; °C to obtain the target catalyst. Wherein the palladium simple substance content is 0.81%.

[0042] In this embodiment, the experimental evaluation of NO decompos...

Embodiment 3

[0043] Embodiment 3. Preparation of packing type wet denitration catalyst

[0044] Weigh 1g of palladium chloride solid, 2ml of dispersant polyethylene glycol, and 100ml of distilled water into a beaker, heat and mix evenly in a water bath at 50°C; after the palladium chloride is completely dissolved, add an appropriate amount of aluminum sol, and drop ammonia to adjust Make a colloid at about 10°C; put the catalyst loaded with 0.81% active components into the beaker for immersion for 3 hours, put it in an oven and dry it at 80°C; after drying, put it in a microwave muffle furnace and bake it at 500°C for 3 hours , naturally cooled to room temperature; take the semi-finished catalyst, and soak it in the mixed solution of ethanol and water (volume ratio 3:1), add sodium borohydride to it and carry out sufficient reduction; °C to obtain the target catalyst. Wherein the palladium simple substance content is 0.93%.

[0045] In this embodiment, the experimental evaluation of NO d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com