Patents

Literature

46results about How to "Easy to adjust the flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

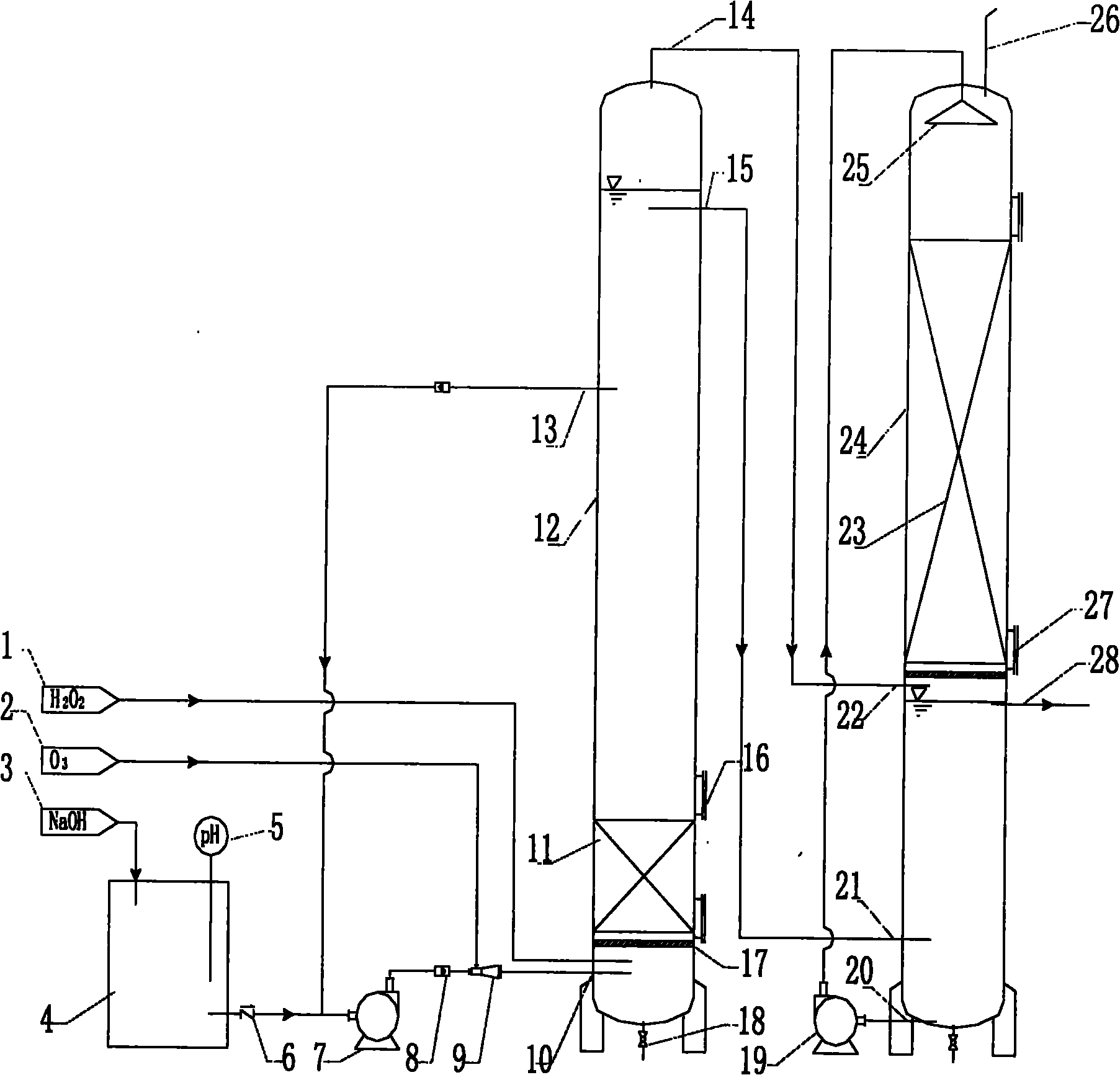

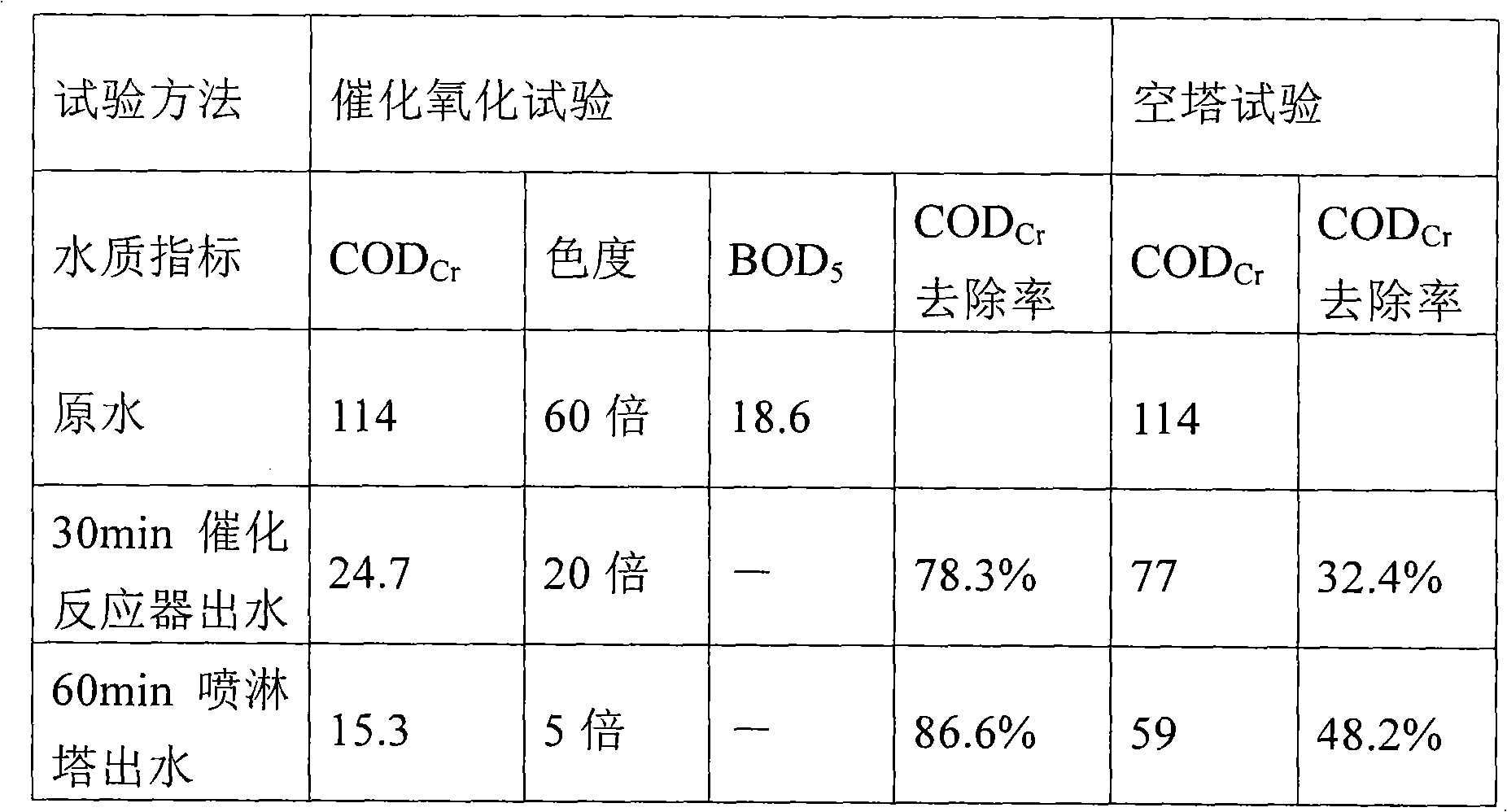

Equipment and method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone

ActiveCN101781036AIncrease contact areaImprove biodegradabilityWater contaminantsMultistage water/sewage treatmentWastewaterPh regulation

The invention provides equipment and a method for treating nondegradable wastewater by utilizing catalytic oxidation of ozone. The equipment comprises a feeding system, an ozone catalytic reaction tower and a spray absorbing tower; the feeding system comprises a wastewater pH regulation device, a wastewater feeding pipeline, a hydrogen peroxide aqueous solution feeding pipeline, an ozone feeding pipeline and a pH regulator feeding pipeline; the wastewater pH regulation device is communicated with the wastewater feeding pipeline and the pH regulator feeding pipeline respectively; the ozone feeding pipeline is communicated with the wastewater feeding pipeline; the ozone catalytic reaction tower is communicated with the wastewater feeding pipeline and the hydrogen peroxide aqueous solution feeding pipeline respectively so that wastewater undergoes once catalytic reaction in the presence of a first catalyst to generate a liquid flow and an ozone tail gas flow which are subjected to initial treatment; and the spray absorbing tower is communicated with a catalytic reaction system, is used for spraying at least one part of the liquid flow which is subjected to the initial treatment, and is contacted with the ozone tail gas flow in the presence of a second catalyst to undergo second catalytic reaction.

Owner:ENN ENVIROTECH CO LTD

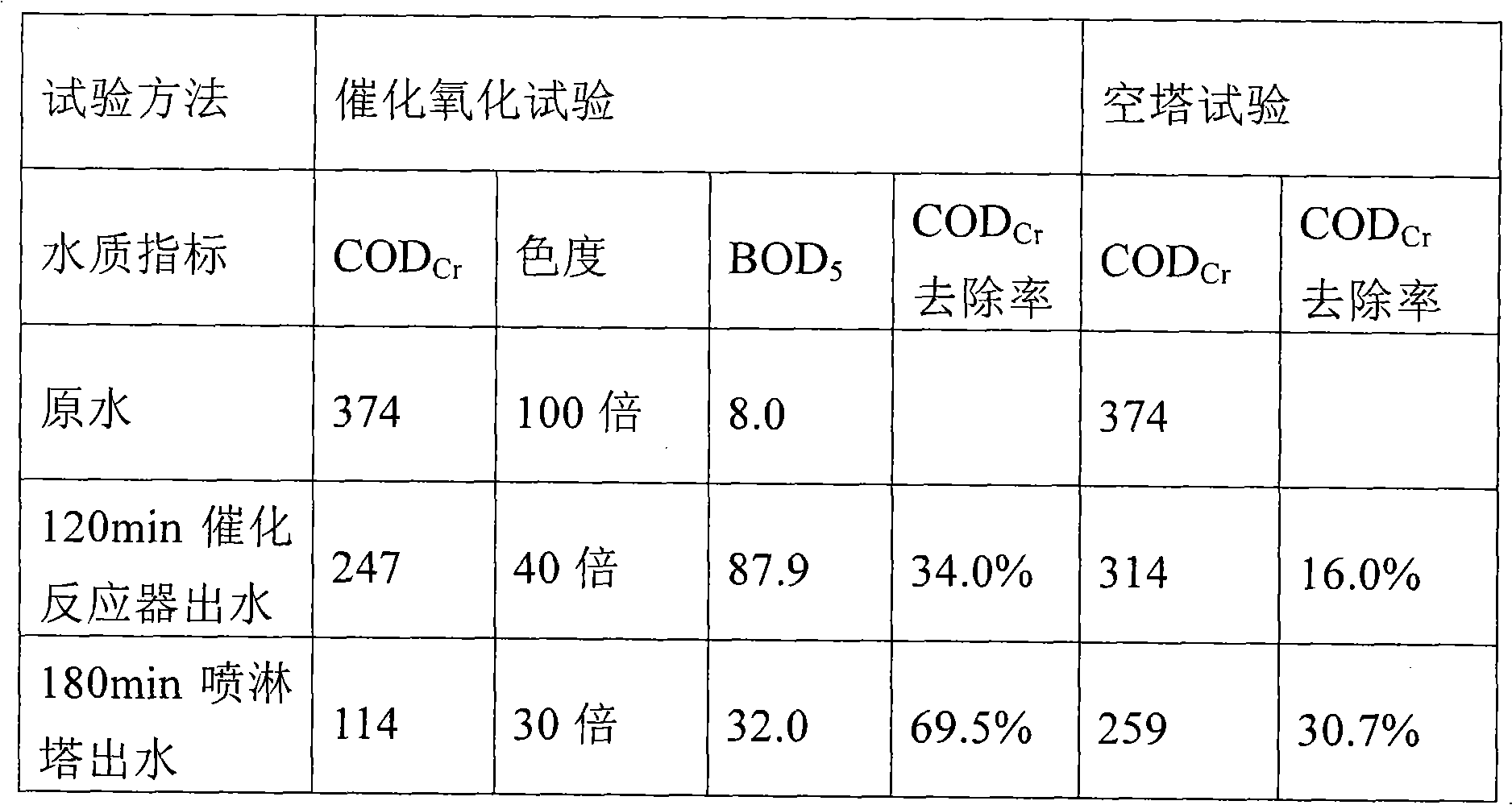

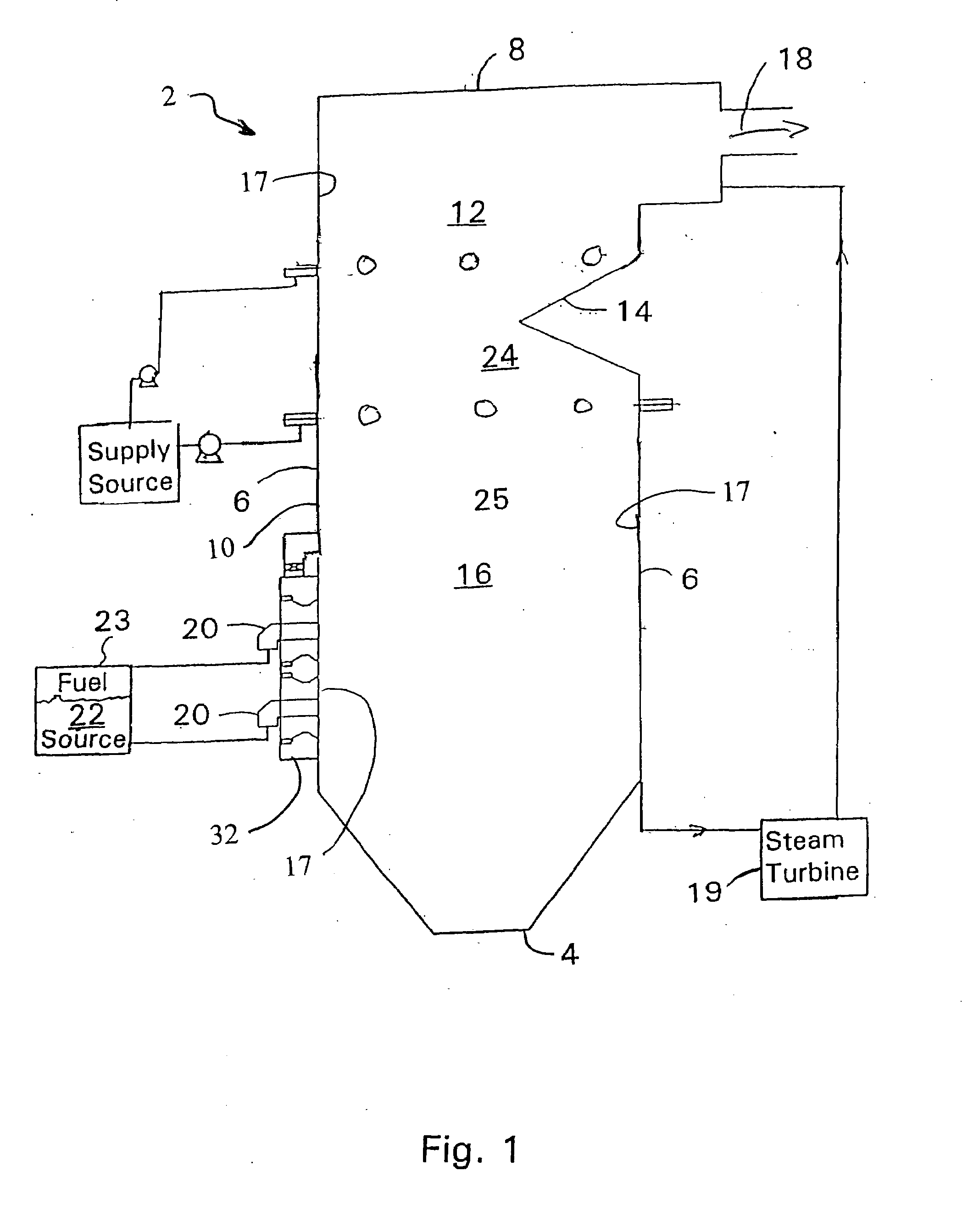

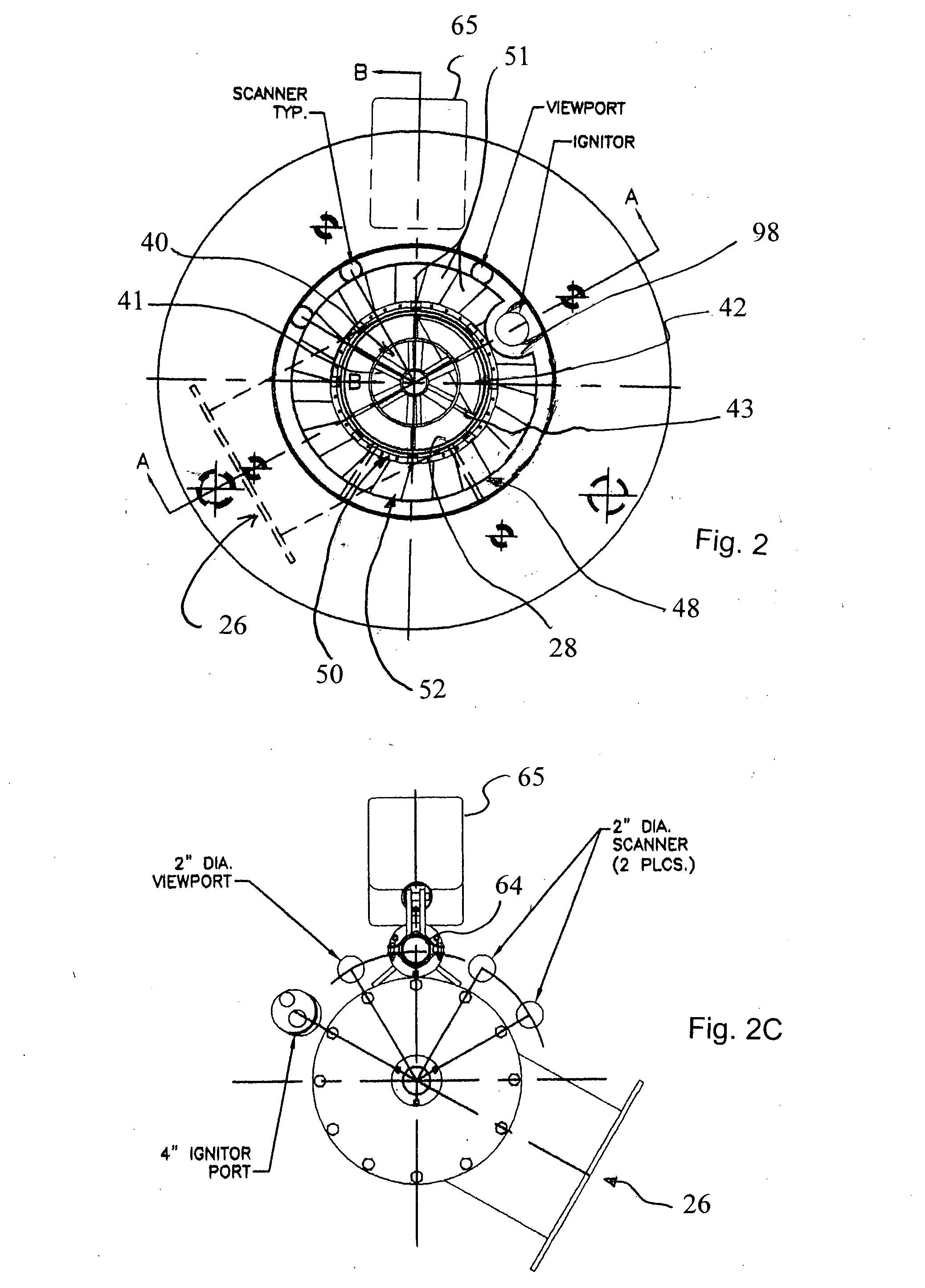

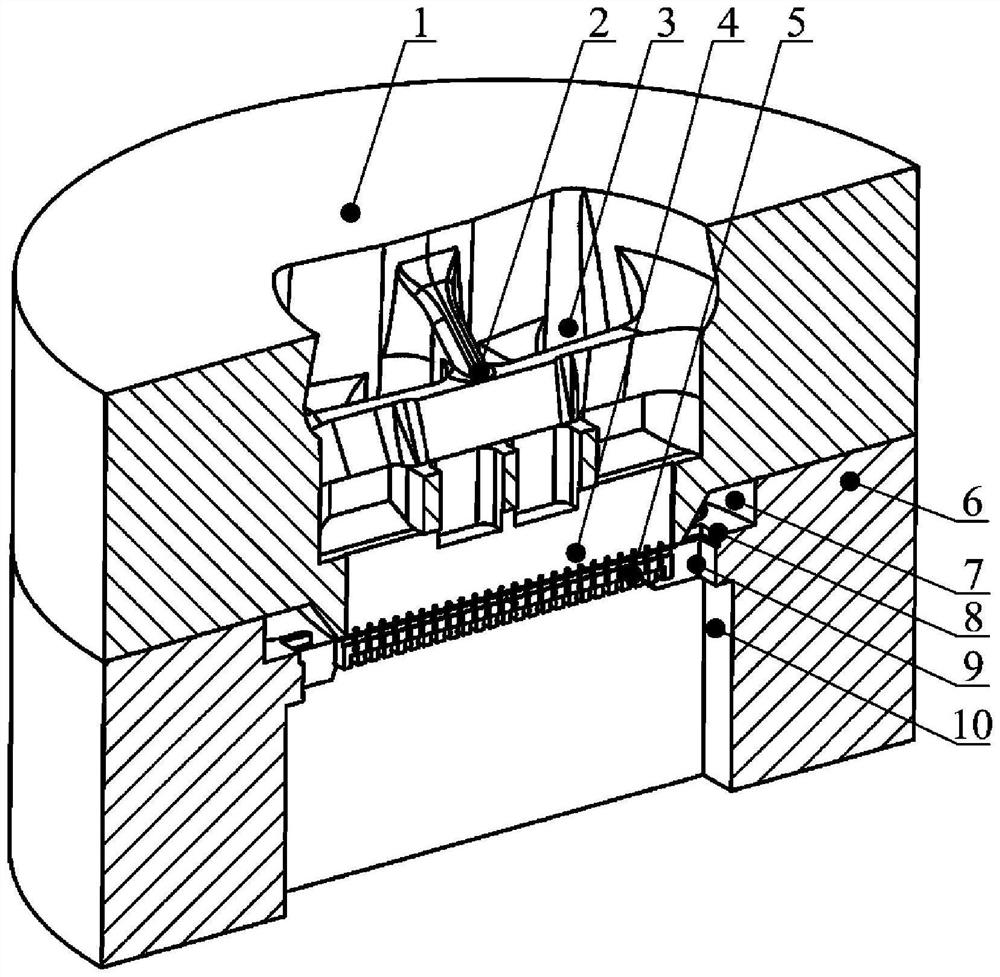

Ultra low NOx burner replacement system

InactiveUS20070272132A1Promote lowerFacilitate fuel flowPulverulent fuel combustion burnersCombustion using lump and gaseous fuelCombustorEngineering

A replacement burner system which facilitates reduction of nitrous oxide produced during combustion of a fuel. The replacement burner system comprising a fuel supply duct having an inlet and an outlet with a fuel deflector located within the fuel supply duct to facilitate redistribution of a flow of the fuel. An adjustable coal nozzle is located within the fuel supply duct between the fuel deflector and the outlet. An exterior surface of the fuel supply duct supports an air swirling device, and the air swirling device obstructs between 65% and 75% of the transverse flow area, located between an exterior surface of the fuel supply duct and the inwardly facing surface of the venturi register, after the replacement burner system is accommodated within the windbox of a combustion boiler. The air swirling device is the only component located in the windbox, between the exterior surface of the fuel supply valve and the inwardly facing surface of the venturi register, for adjusting the flow of the combustion air flowing through the venturi register.

Owner:FUEL TECH

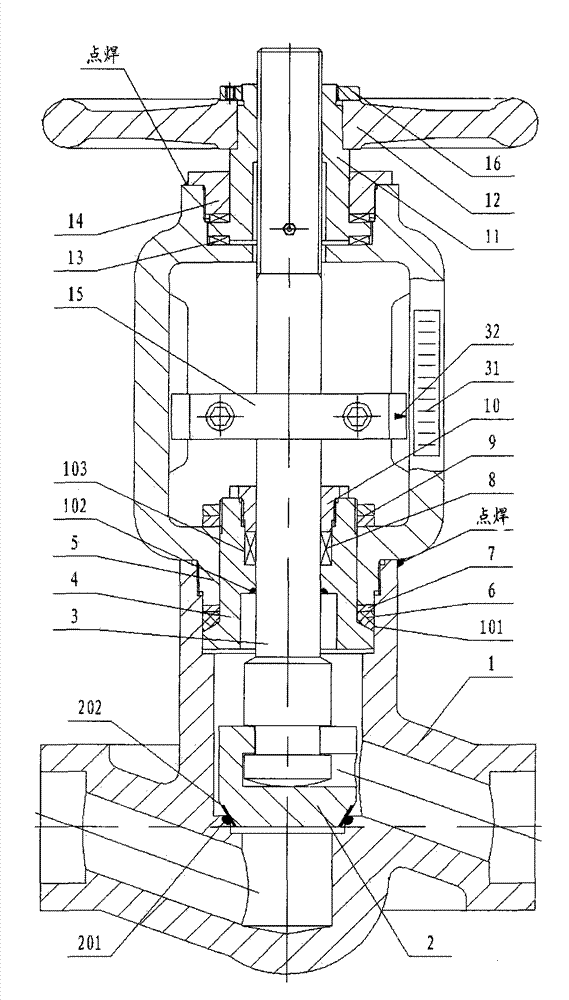

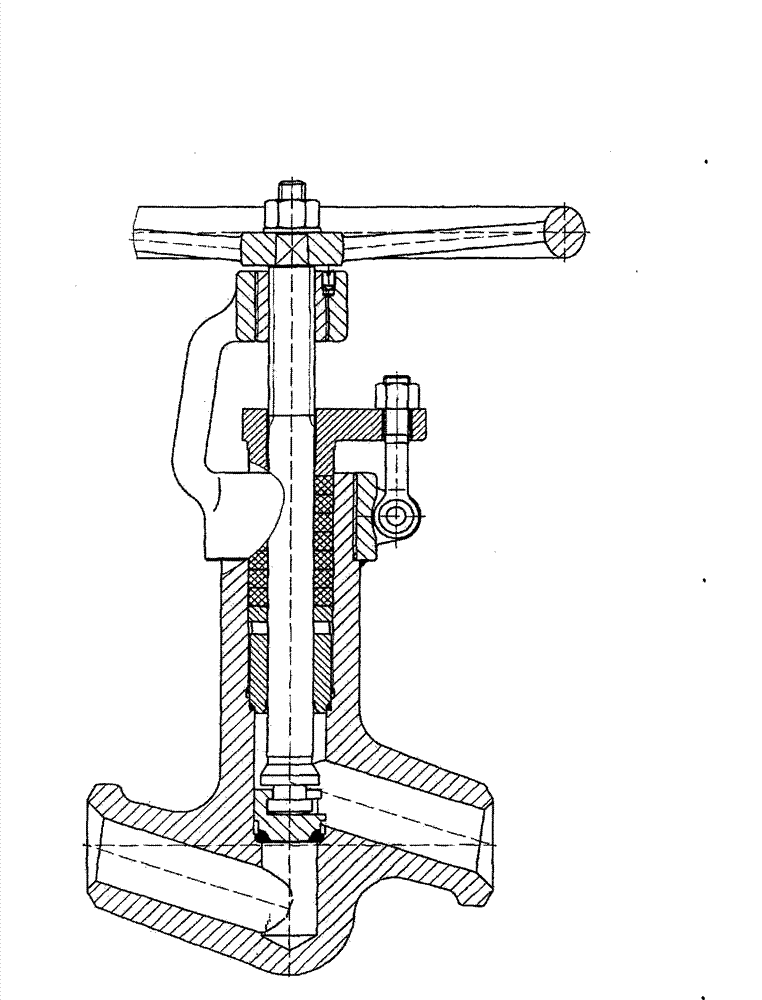

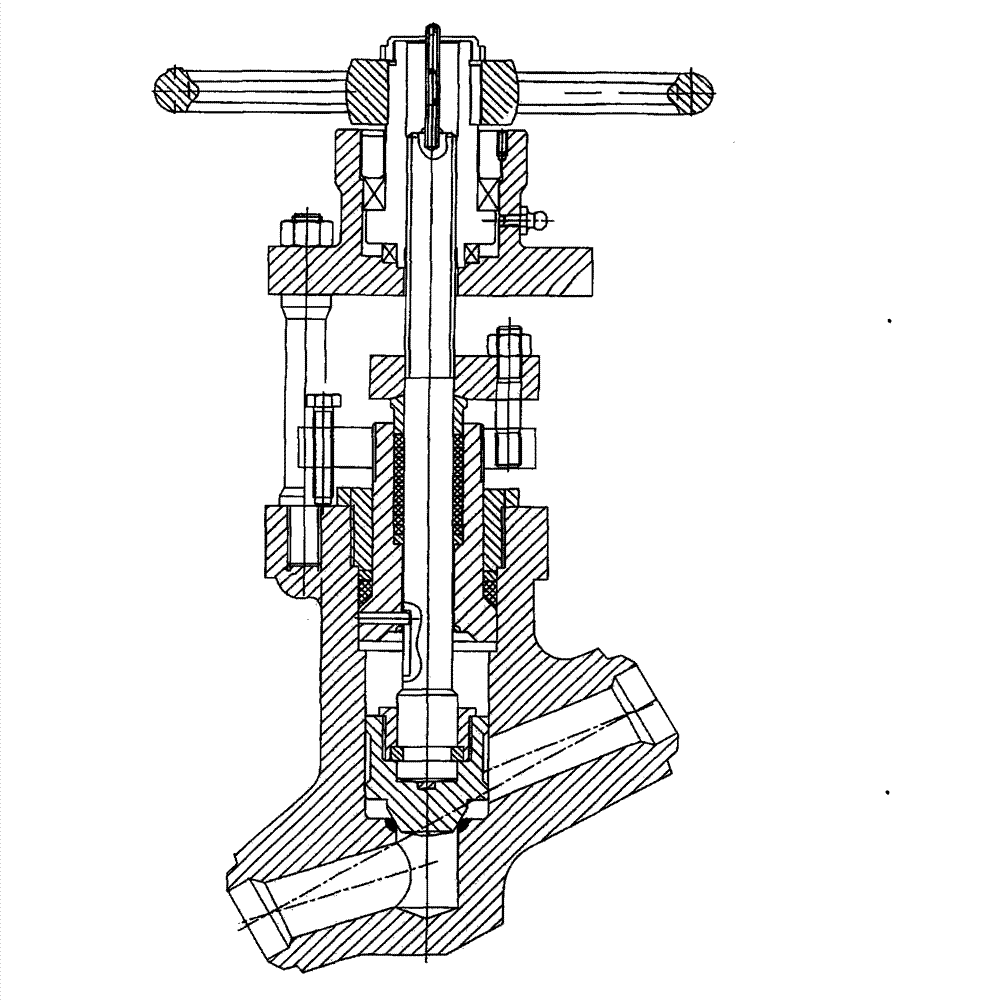

Universal compact type forged steel self-sealing stop valve

InactiveCN102829195AImprove versatilitySmall lumen volumeSpindle sealingsLift valveEngineeringScrew thread

The invention provides a universal compact type forged steel self-sealing stop valve, and is characterized by comprising a valve body, a valve cap, a valve clack, a valve stem, a hand wheel, a valve stem nut, a packing box, a clamping and ranking component, and the like, wherein the valve clack is connected with the lower end of the valve stem; the upper end of the valve stem extends out of the valve cap and is connected with the valve stem nut; the valve stem nut is put into a groove in the upper end of the valve cap; a support gland is connected and fixed with the groove in the valve cap through screw threads; the upper end part of the valve stem nut is connected with the hand wheel; the hand wheel is fixedly connected with the valve stem nut through a lock nut; the valve body is connected and fixed with the valve cap through screw threads; the packing box is arranged between the valve body and the valve cap and extends out of the valve cap to be connected and fixed by the lock nut; packing at a packing case is connected and fixed by a packing gland; and three seals are arranged at the packing, that is to say, firstly, a wedge-shaped sealing ring is arranged between the packing box and the valve body, secondly, back sealing functions are fulfilled by the packing box and the valve stem, and thirdly, the packing case is arranged on the packing box.

Owner:张丽智

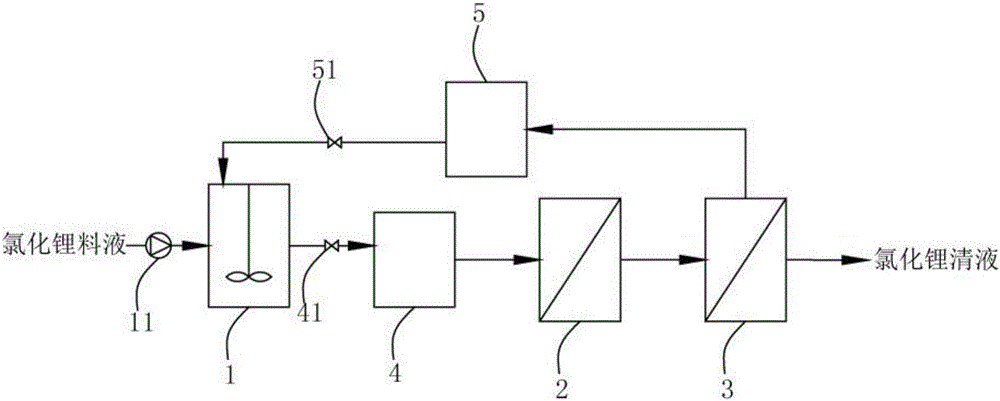

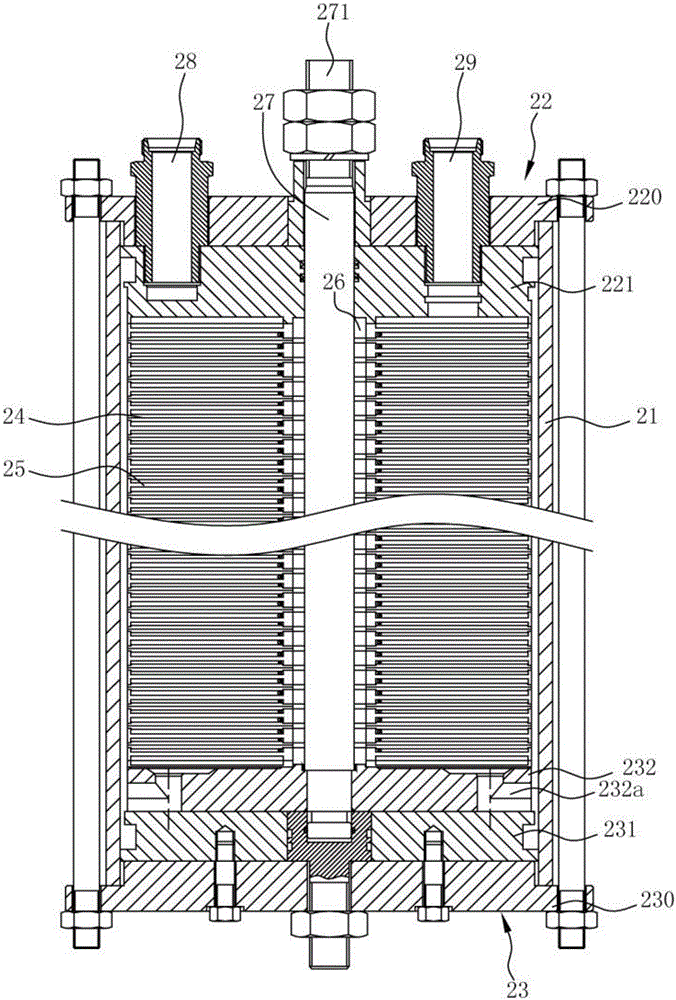

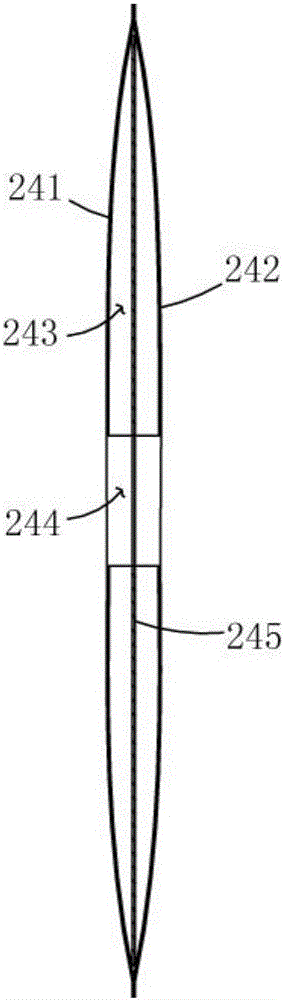

Lithium chloride liquid purification method and lithium chloride liquid purification equipment

InactiveCN106517257ASolve technical problems that are difficult to purifyFacilitate solid-liquid separationLithium halidesFiltration circuitsPurification methodsSulfate radicals

The invention discloses a lithium chloride liquid purification method. The method includes steps: 1) converting sulfate radical ions, calcium ions, magnesium ions and iron ions in lithium chloride liquid into precipitates, and separating the precipitates out to obtain first liquid; 2) allowing the first liquid to pass through first filter equipment being 0.1-50micron in filter particle size to form first filtrate after the first liquid passes through a filter structure of the first filter equipment, wherein the calcium ion concentration of the first filtrate is smaller than or equal to 35ppm, and the magnesium ion concentration of the first filtrate is smaller than or equal to 35ppm; 3) adjusting pH of the first filtrate to 9-12, and allowing the first filtrate to pass through second filter equipment to form clear lithium chloride liquid after the first filtrate passes through a filter medium of the second filter equipment, wherein the second filter equipment is larger than or equal to 99.95% in interception rate of substances with molecular weights larger than or equal to 300, the filter medium of the second filter equipment is a membrane with membrane flux larger than or equal to 15L / m<2>.h, the recovery rate of the clear lithium chloride liquid is larger than or equal to 70%, the flow rate is larger than or equal to 10L / min, the calcium ion concentration of the clear lithium chloride liquid is smaller than or equal to 10ppm, the magnesium ion concentration of the clear lithium chloride liquid is smaller than or equal to 10ppm, and the Li2O loss rate is smaller than or equal to 8.5%.

Owner:CHENGDU MEIFUTE MEMBRANE TECHNOLOGY CO LTD

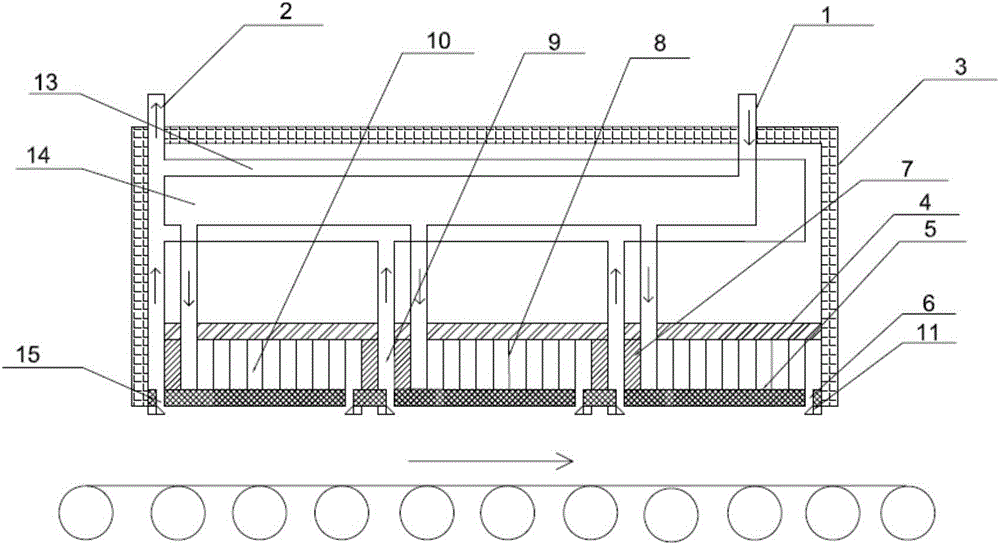

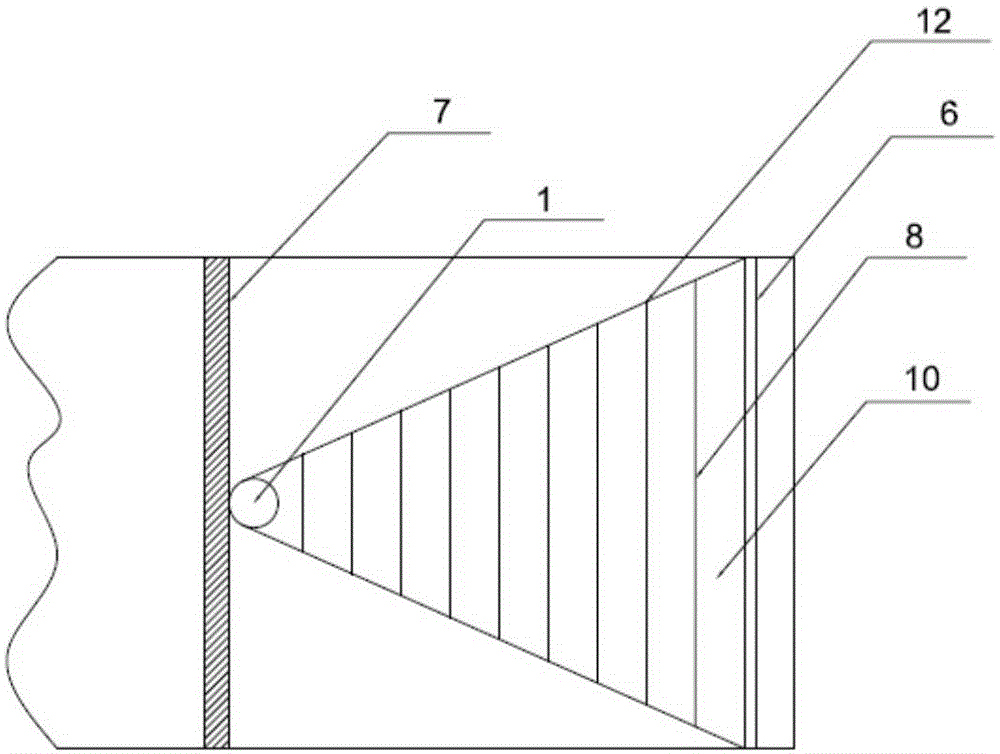

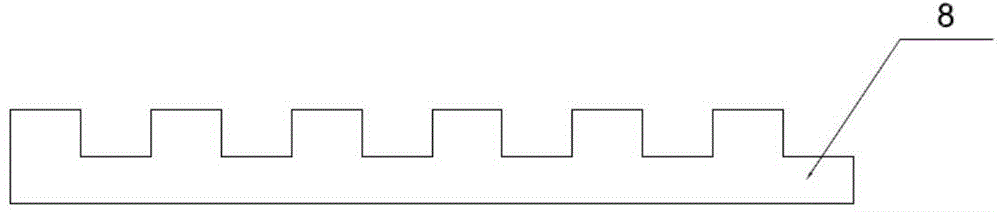

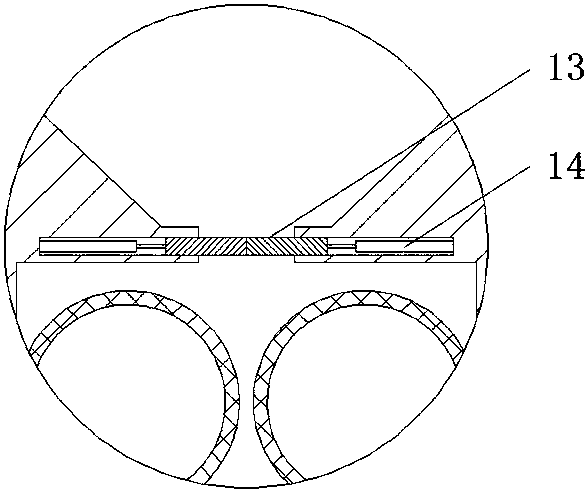

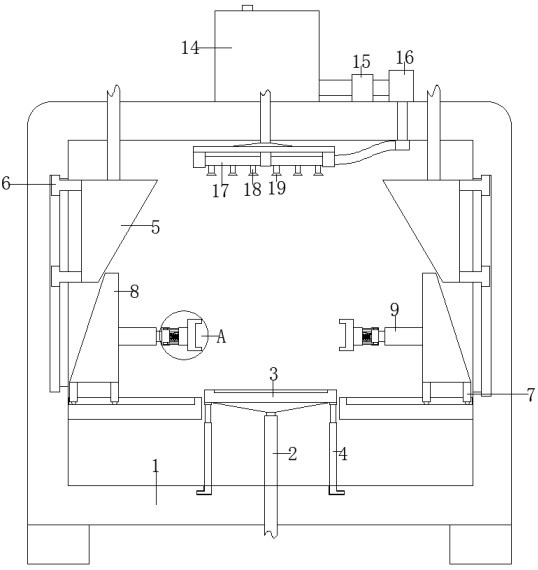

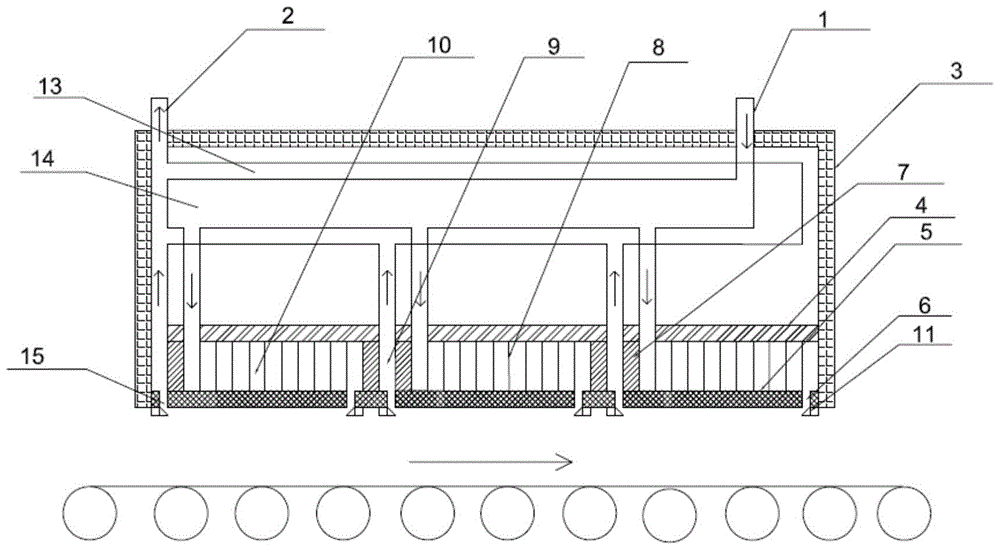

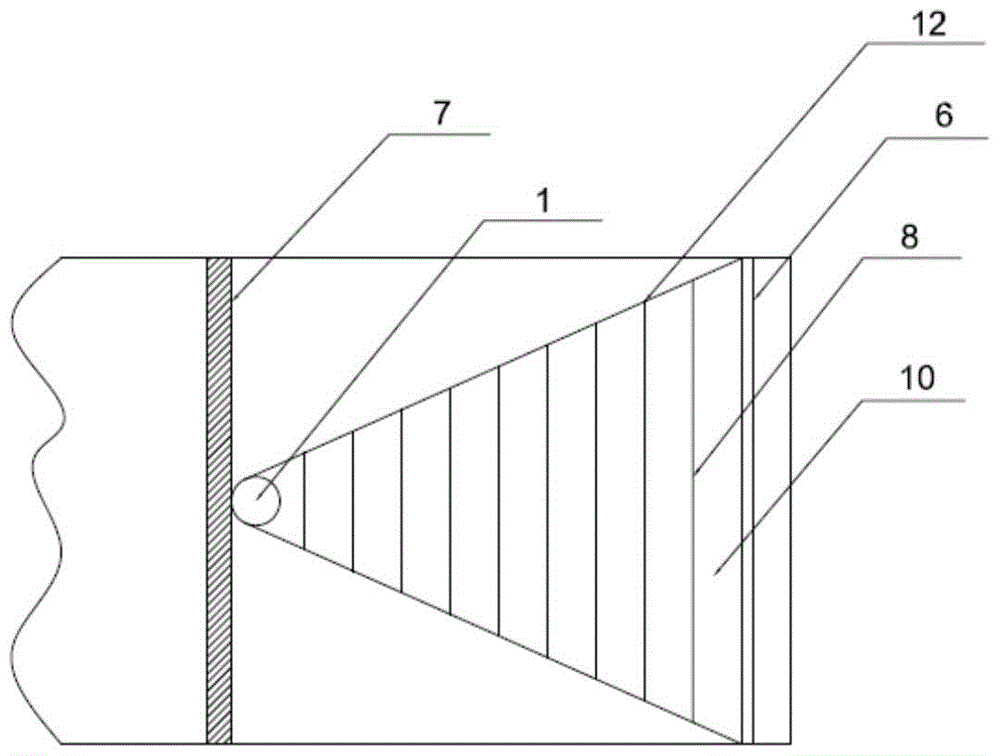

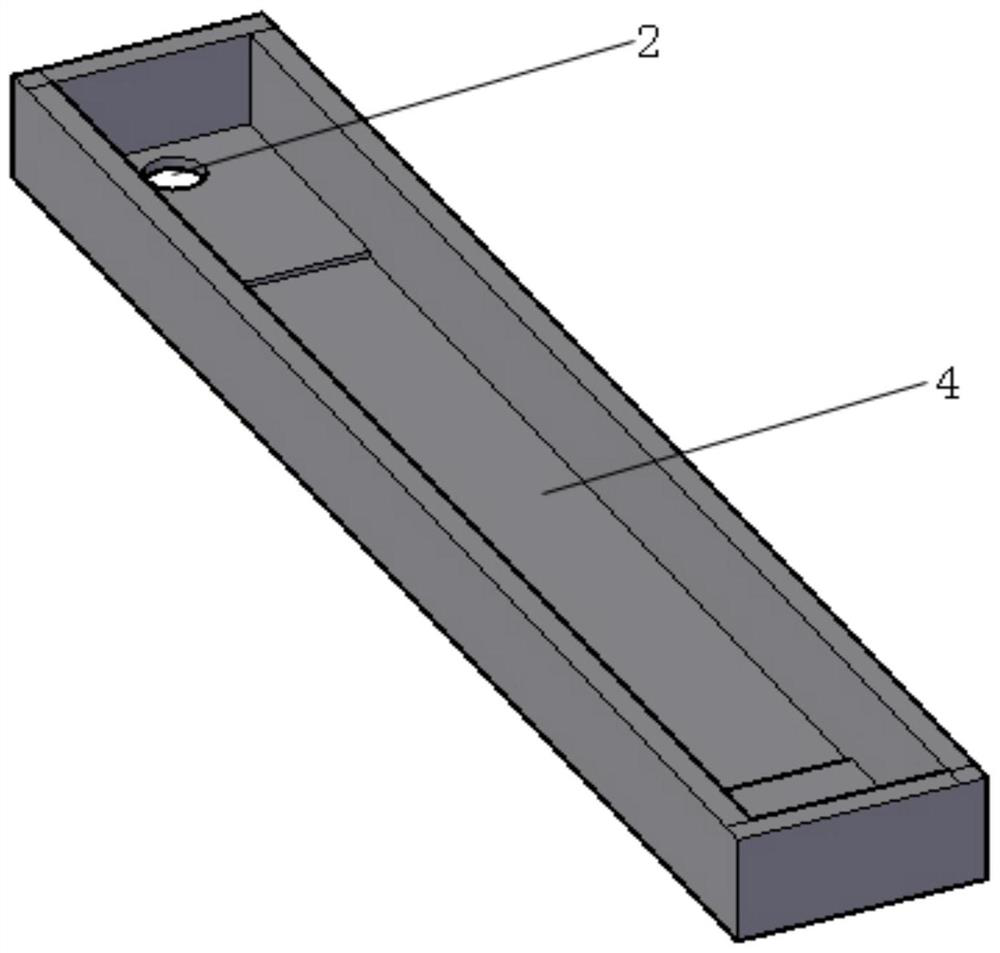

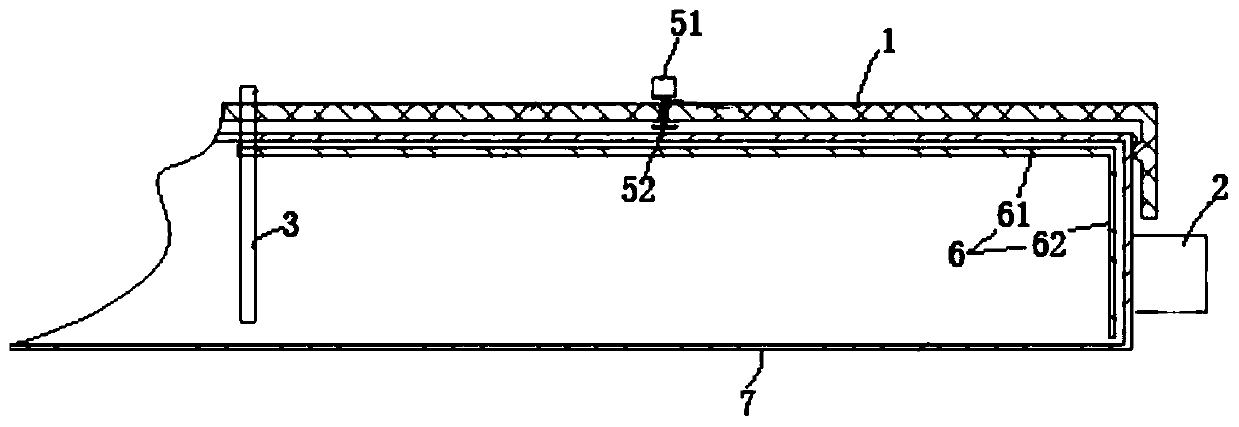

Online normal-pressure chemical vapor deposition film-plating reactor through floatation process

ActiveCN104561938AImprove efficiencyQuality improvementChemical vapor deposition coatingInlet channelWide mouth

The invention discloses an online normal-pressure chemical vapor deposition film-plating reactor through a floatation process. The online normal-pressure chemical vapor deposition film-plating reactor disclosed by the invention comprises a heat preservation shell and a bottom plate, wherein a gas inlet chamber and an exhaust chamber are arranged in the heat preservation shell; a slit communicated with the gas inlet chamber and an exhaust hole communicated with the exhaust chamber are arranged on the bottom plate; a pre-mixing chamber and a waste gas chamber are also arranged in the heat preservation shell; the pre-mixing chamber is connected to a film-plating precursor gas inlet pipe and embedded in the waste gas chamber; the exhaust chamber is connected into the waste gas chamber; the gas inlet chamber is communicated with the pre-mixing chamber through a gas inlet channel; the gas inlet chamber is arranged over the bottom plate and is shaped as a wide mouth gradually widened along the airflow direction; a flow-mixing baffle for forming up and down airflows is installed in the gas inlet chamber; the exhaust chamber is of a structure with a large upper part and a small lower part; and a dust collecting plate is installed in the exhaust chamber. By means of the gas mixing chamber structure in the invention, multi-charge and multi-discharge steady airflow trends are formed easily, pre-heating is strengthened, the flow is convenient to adjust, the film-plating efficiency is increased, and thus, the film-plating quality is increased.

Owner:中玻(陕西)新技术有限公司

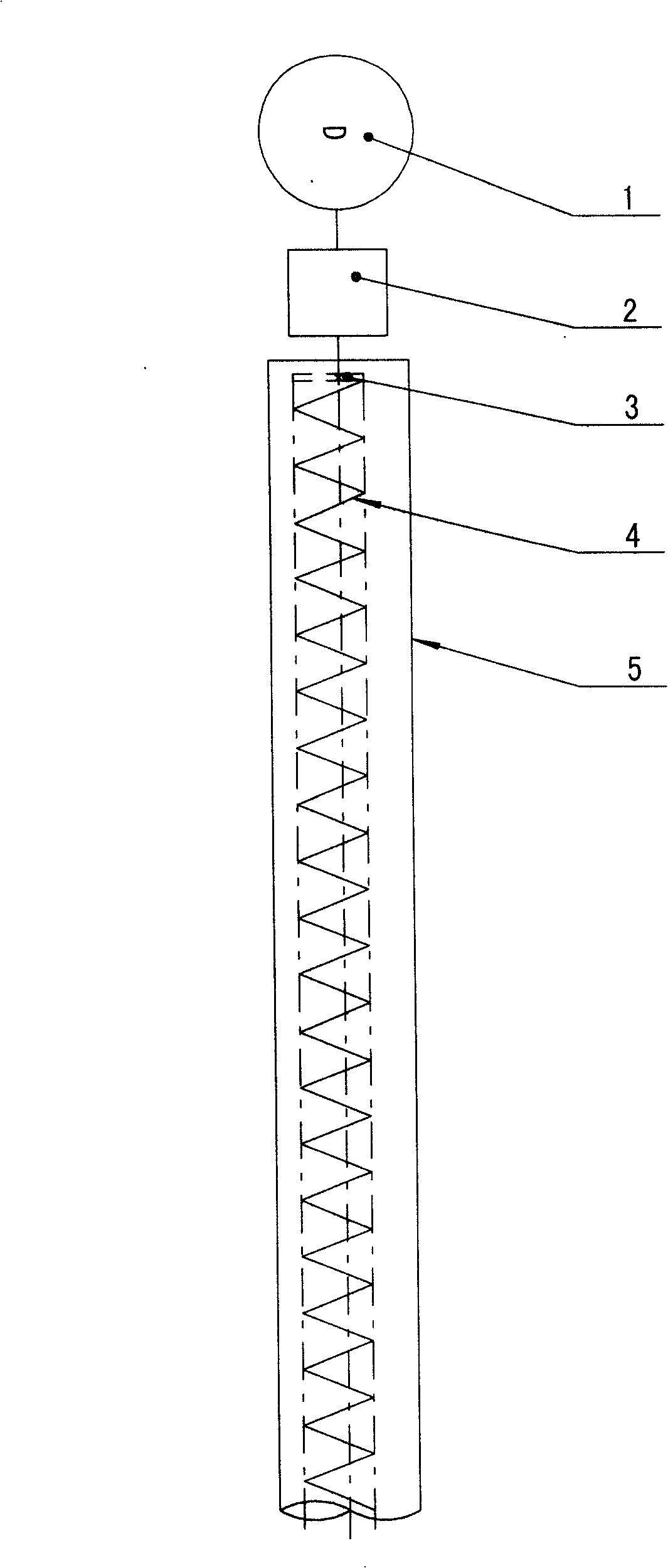

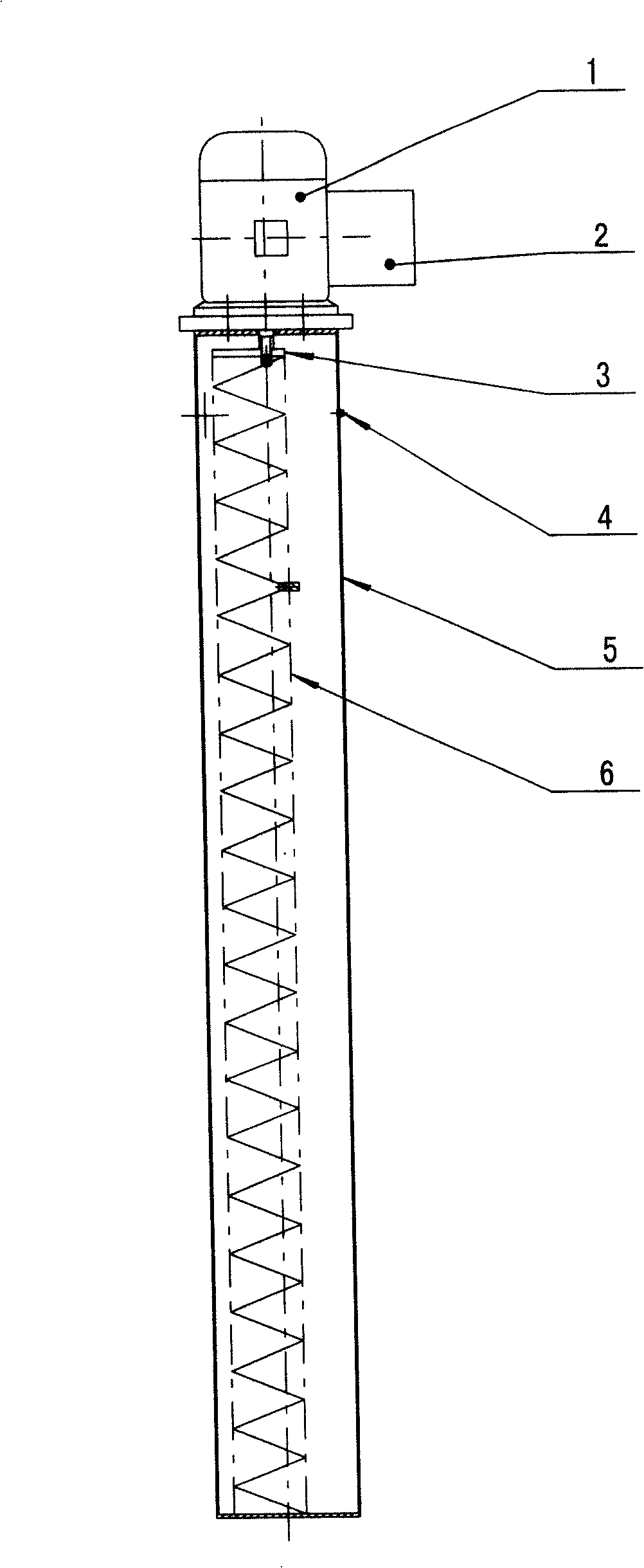

Non-shaft conveyor

The invention provides a conveyer which individually supplies and delivers the material linearly or circuitously for long distance in the production process, which is especially applicable to the supply and delivery of powder-shaped and viscous material. The conveyer rigidly connected with a gearbox system, a delivery pipeline, a connecting part and a no-shaft delivery body by a power source. The no-shaft delivery body is driven to carry out the special motion by a prime mover through the gearbox system, thus realizing the supply and delivery of the material.

Owner:刘辉

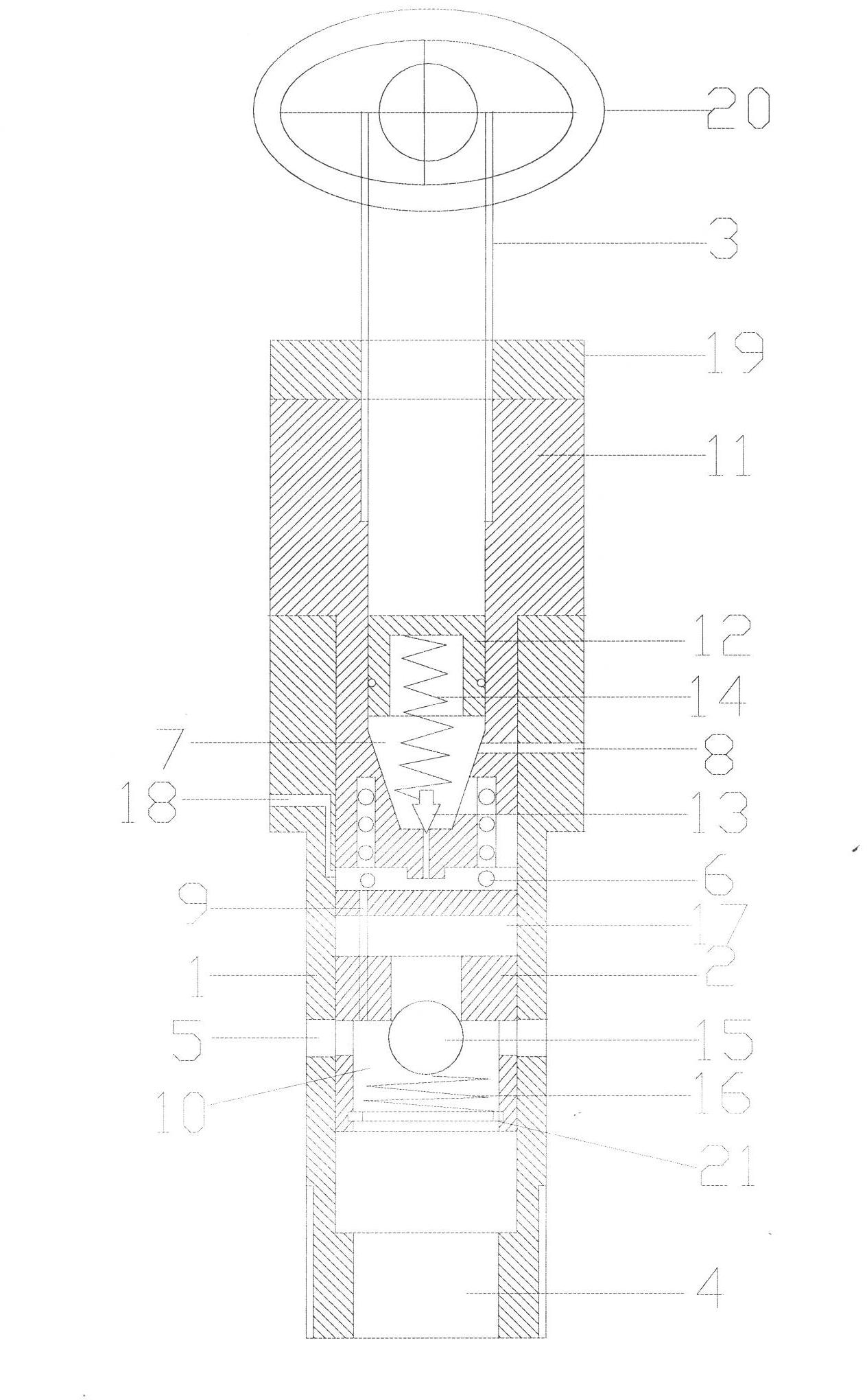

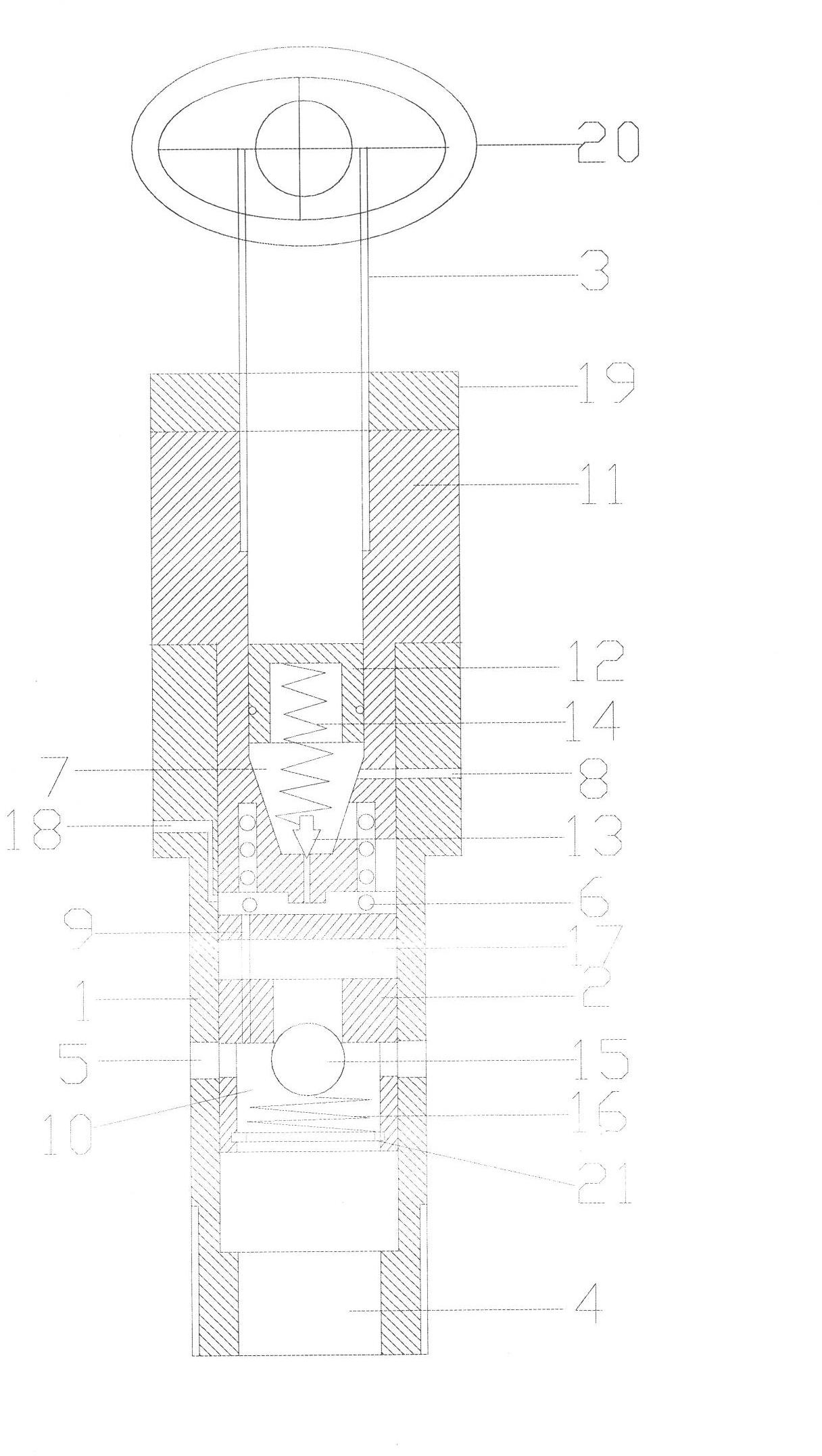

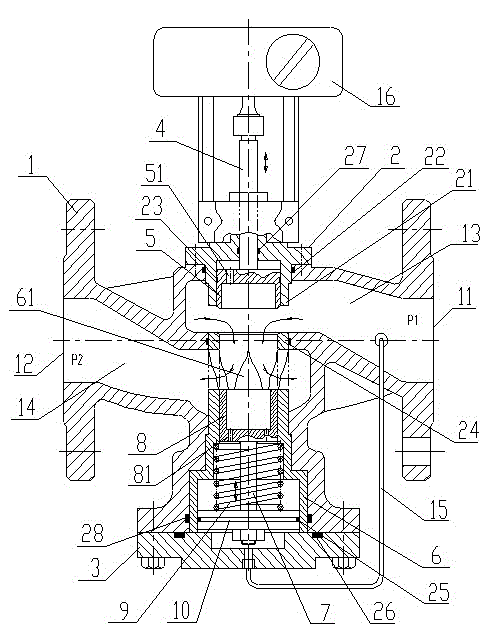

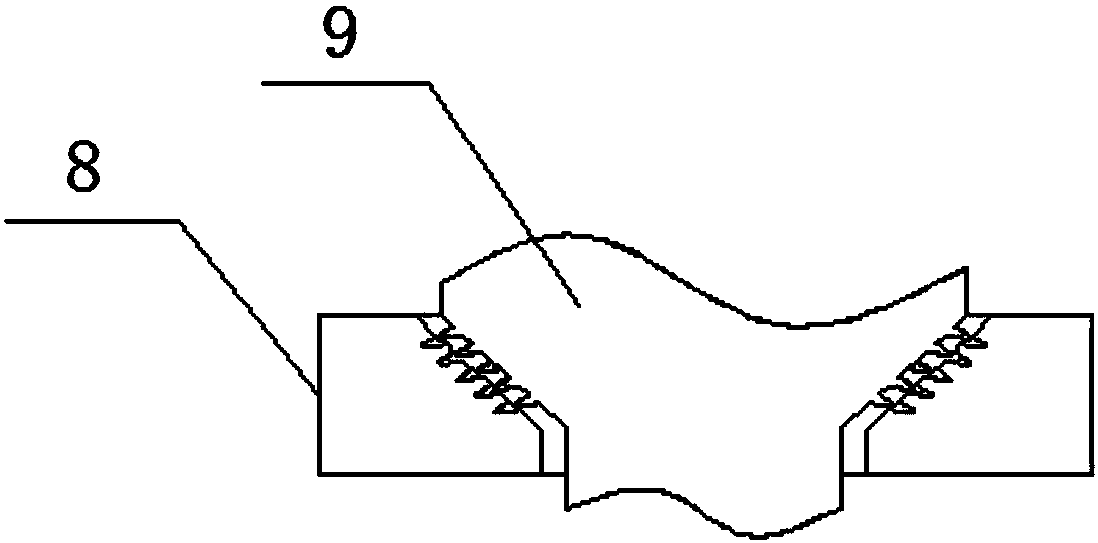

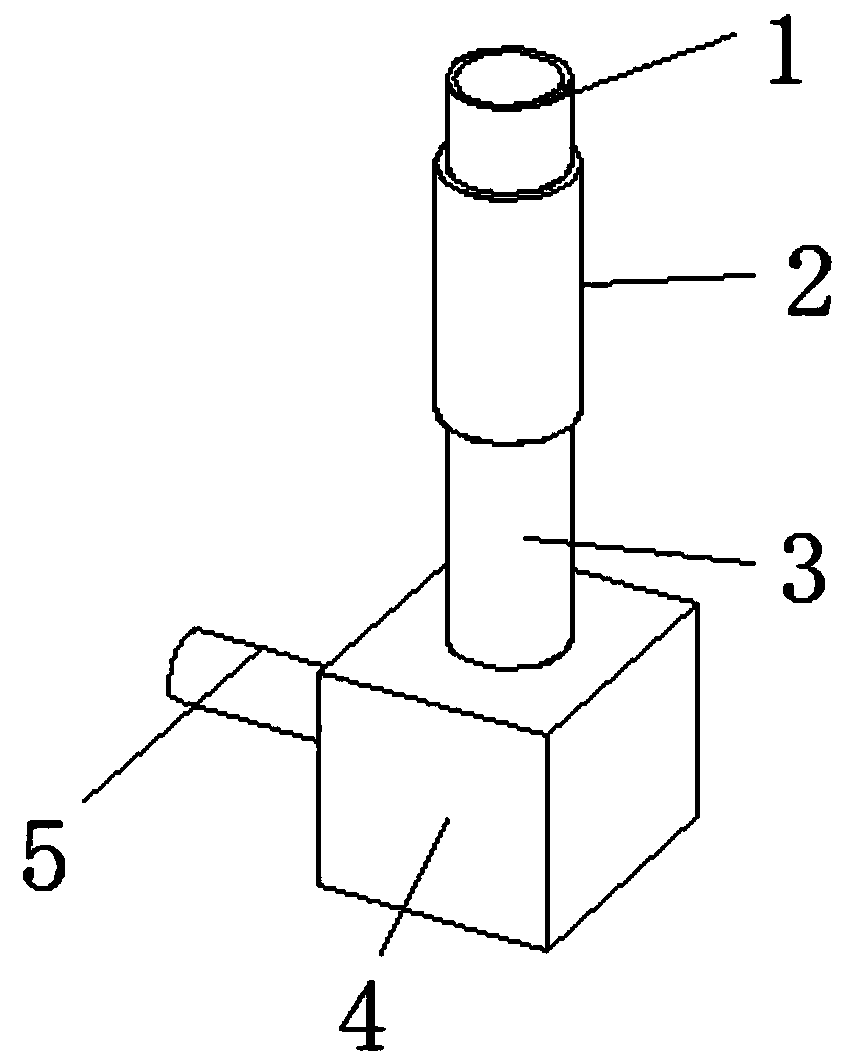

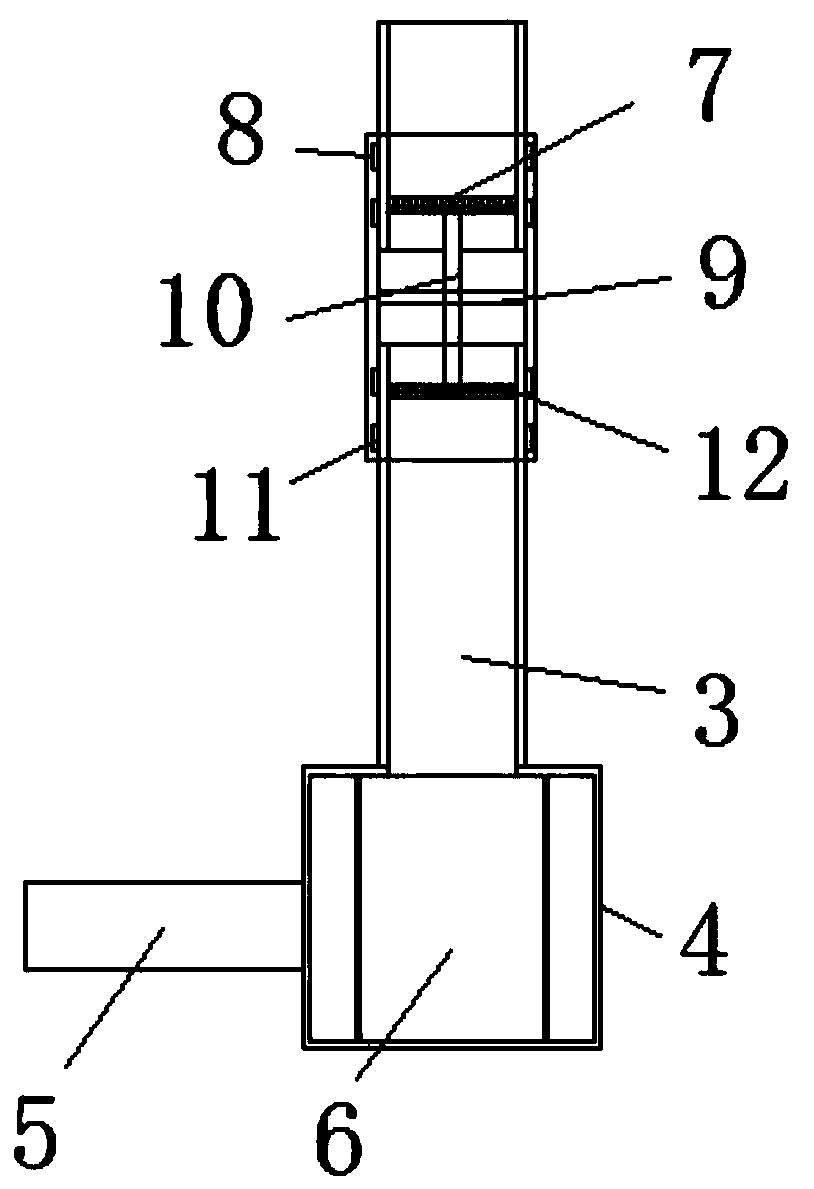

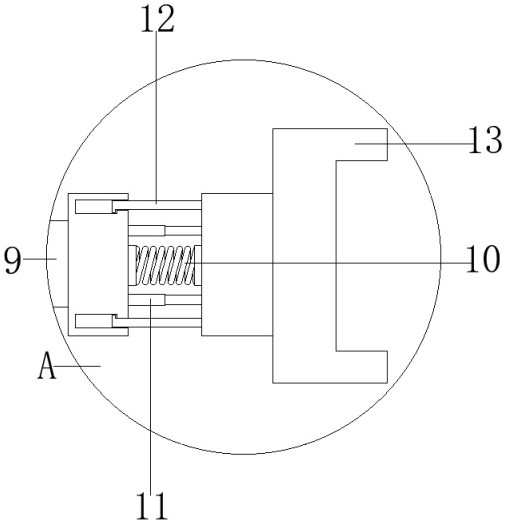

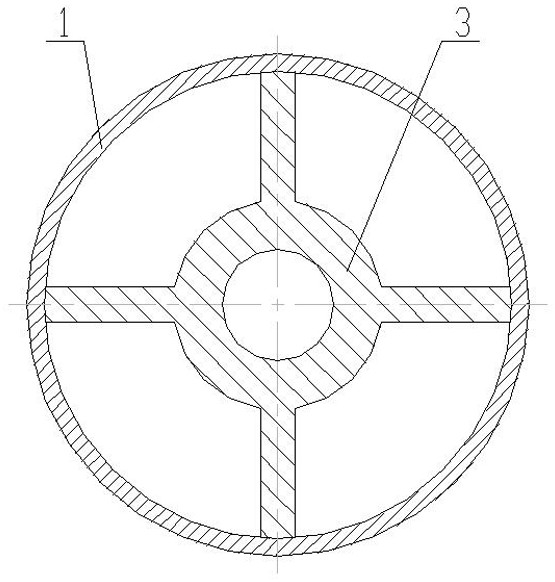

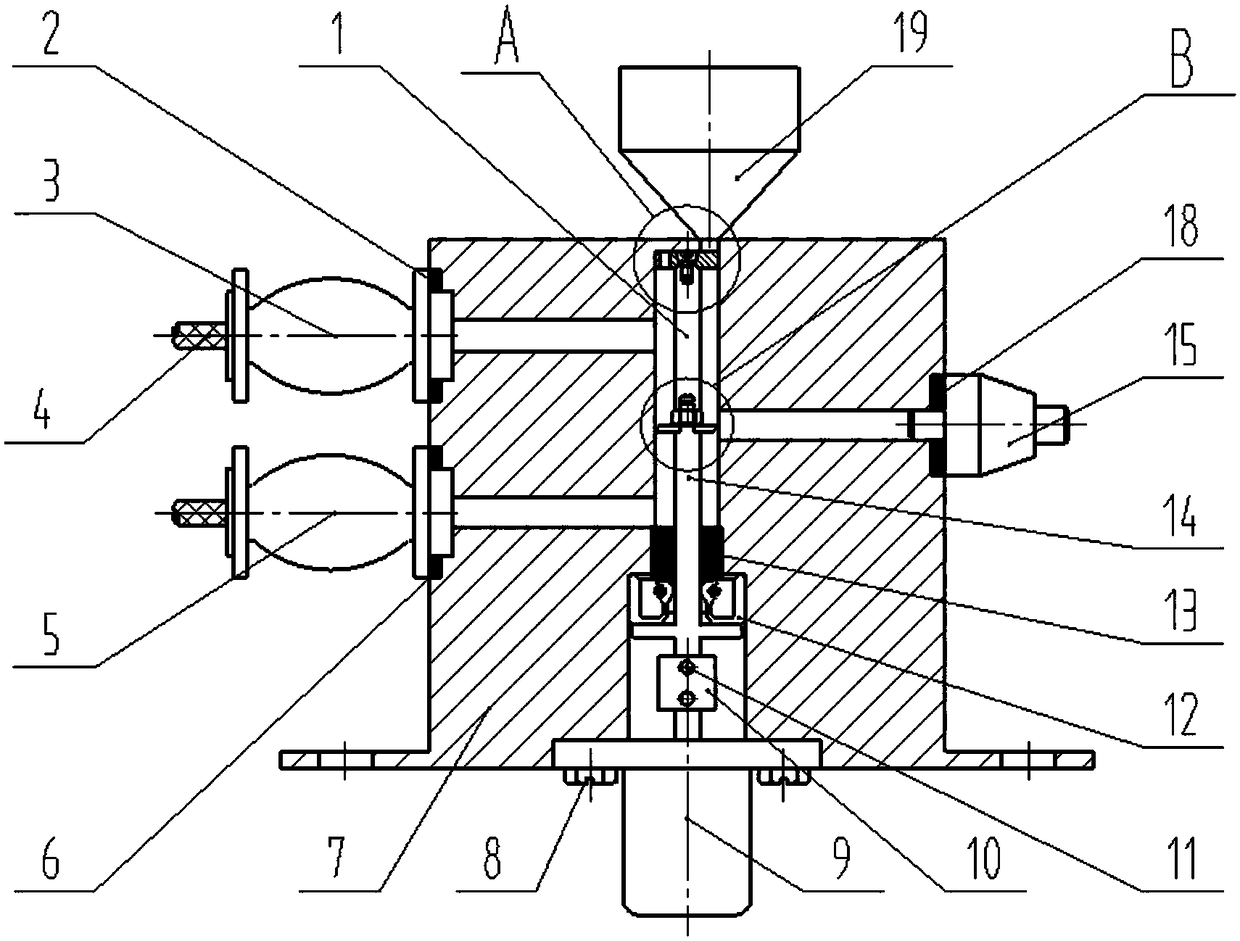

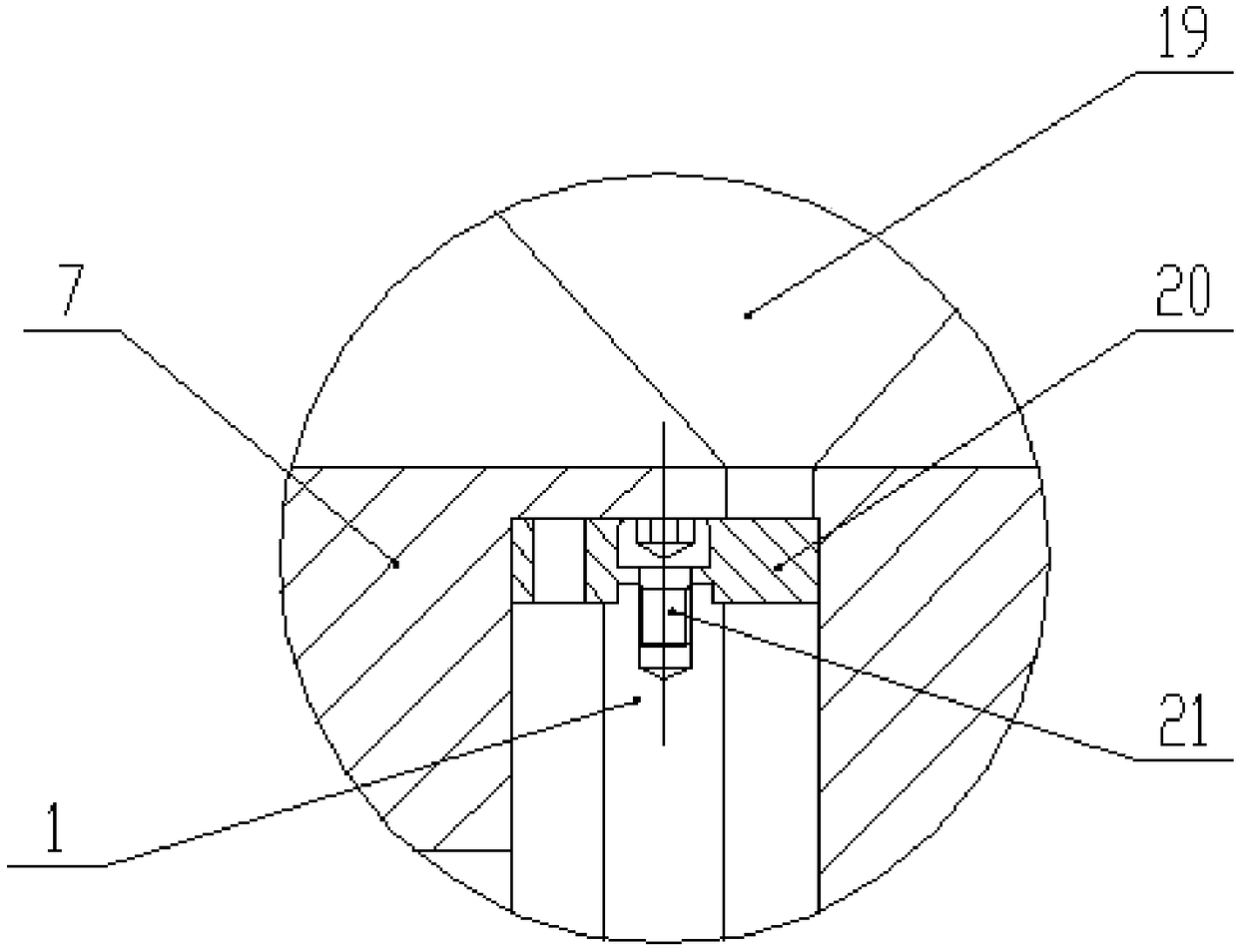

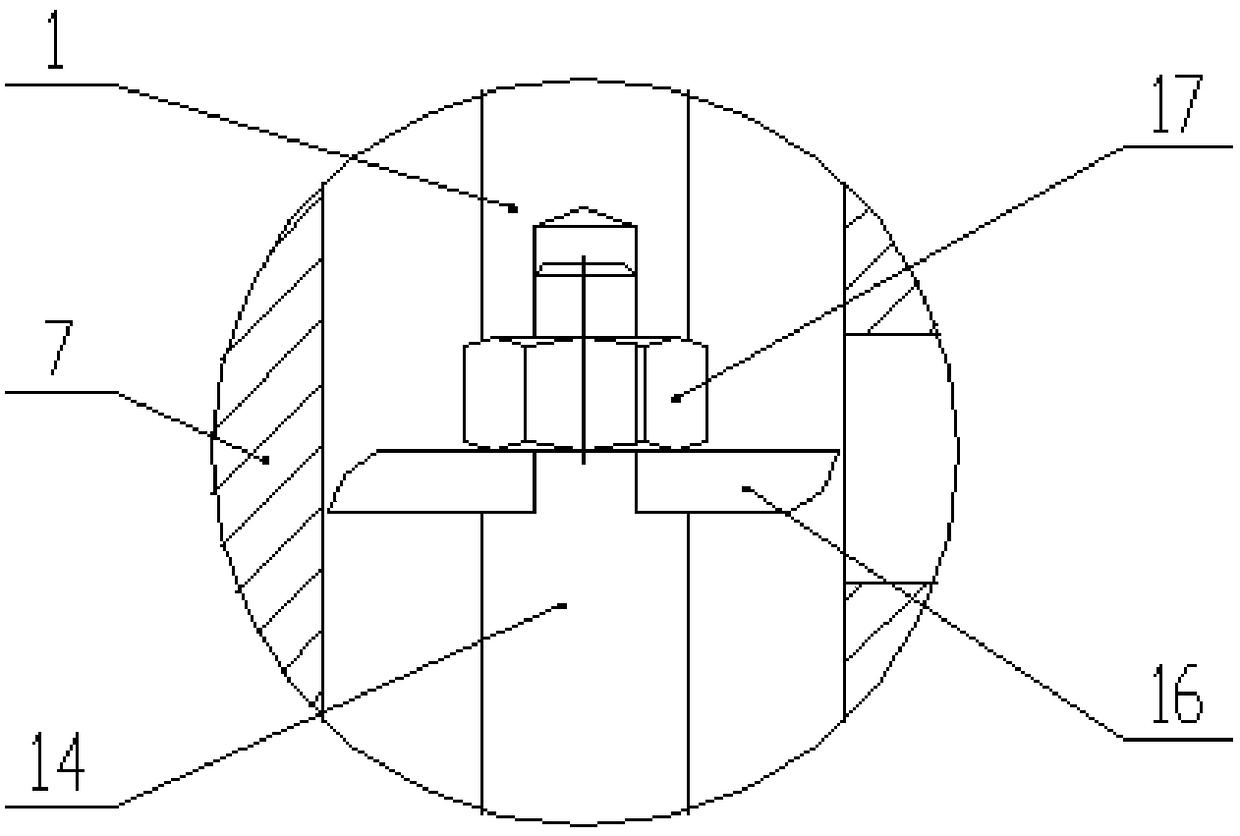

Pilot-operated one-way sequence valve

InactiveCN102563140AFlow is easy to controlPlay a connecting roleCheck valvesValve housingsPilot valveEngineering

The invention discloses a pilot-operated one-way sequence valve, which comprises a valve body (1), a main valve spool (2), a pilot valve and an adjusting rod (3). A liquid inlet (4) and a liquid outlet (5) are arranged on the valve body (1), the main valve spool (2), the pilot valve and the adjusting rod (3) are arranged in the valve body, the outer diameter of the head at the upper end of the valve body is larger than that of a portion below the head, an external thread is arranged on the portion below the head of the valve body which is vertically through, the liquid inlet (4) is arranged at an opening of the lower end of the valve body, the liquid outlet is arranged on the valve wall of the portion below the head of the valve body, a reset spring (6) is connected between the pilot valve and the main valve spool (2), a pilot valve cavity (7) is arranged in the pilot valve and communicated with the outside through a drainage channel (8), and an axial channel (9) is arranged on the main valve spool. The external shape of the valve body is equivalent to that of a hinged bolt, a hydraulic part and a pipeline can be connected by the valve body, and the hinged bolt and the pilot-operated one-way sequence valve are integrated.

Owner:林友根

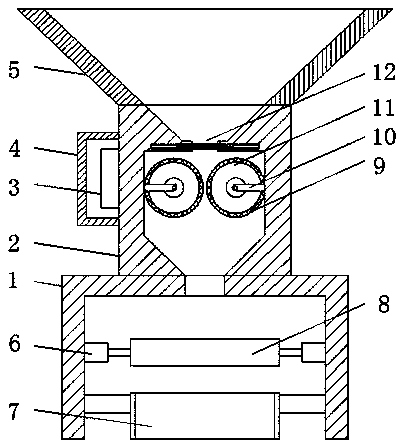

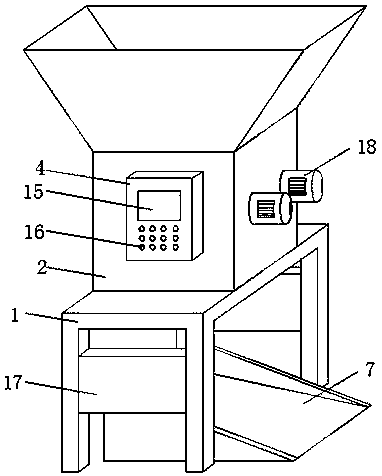

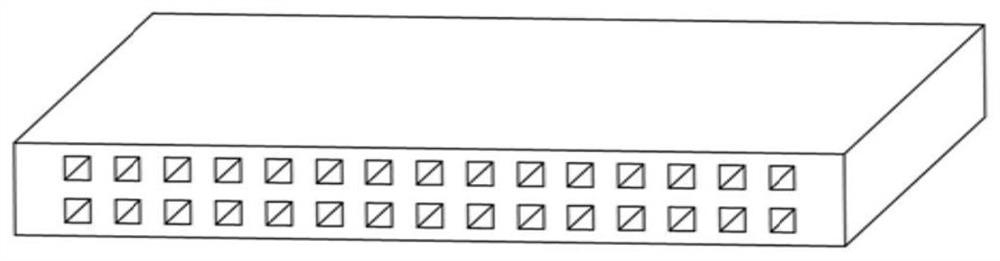

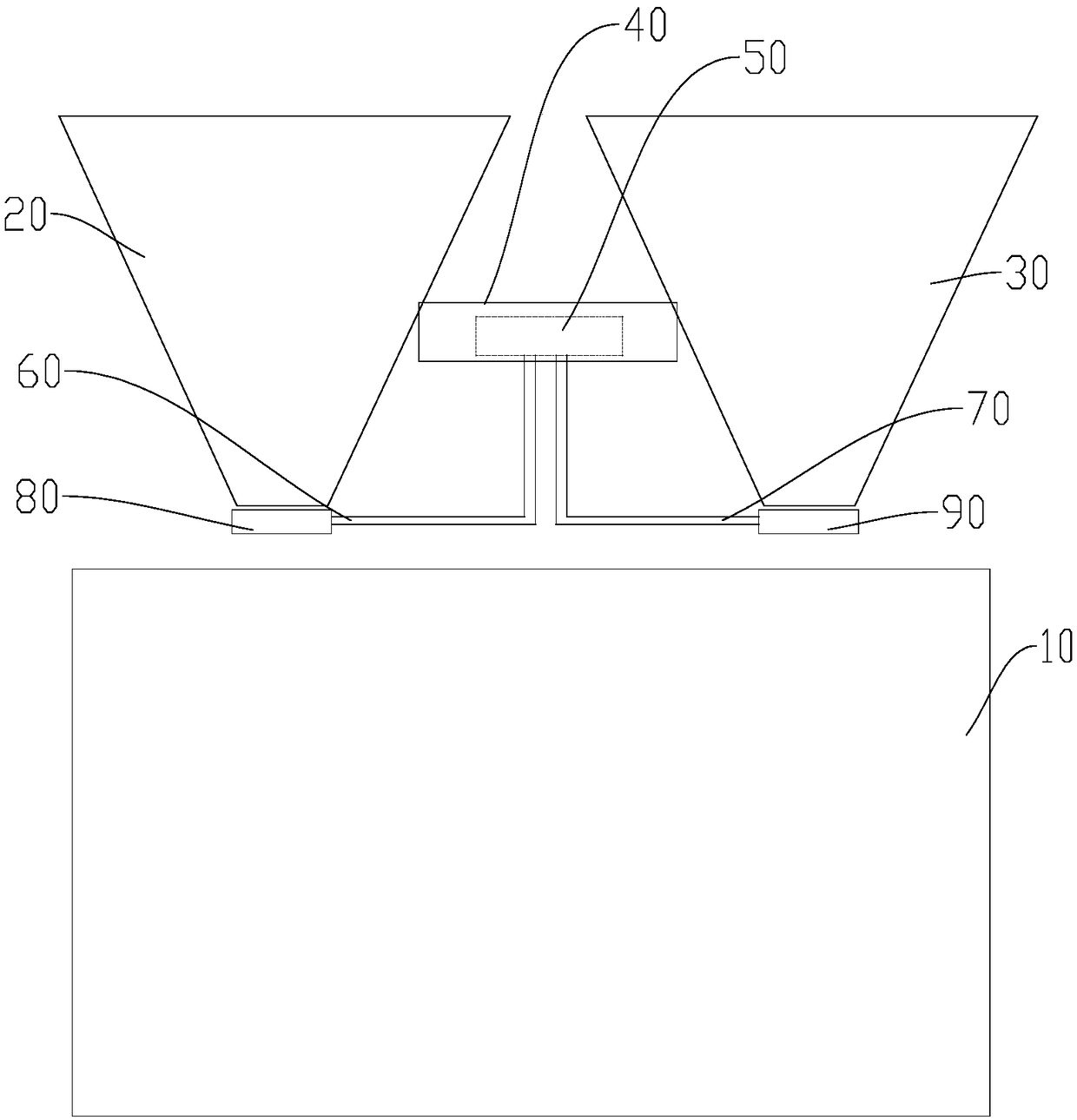

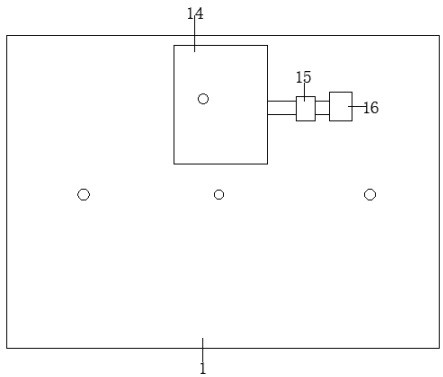

High-efficiency sand screening machine

InactiveCN108722549AHigh trafficEasy to adjust the flowGrain treatmentsElectric machineryEngineering

The invention discloses a high-efficiency sand screening machine. The high-efficiency sand screening machine comprises a support frame. A screening box is mounted at the top of the support frame. An electric control cabinet is mounted at one side of the screening box. A material bin is mounted at the top of the screening box. A discharging opening is formed in the bottom of the material bin. Baffles are mounted at the two sides inside the discharging opening correspondingly and matched for use. One end of each baffle is mounted on a first electric push rod. Servo motors are mounted on the screening box. Supports are mounted on the inner walls of the two sides of the screening box correspondingly. Each support is provided with a rolling roller. An electric heating piece is connected to eachrolling roller in a sleeving manner. Each electric heating piece is composed of an upper aluminum piece, an electric heating wire, heat conduction silica gel and a lower aluminum piece. Partition plates are mounted at the two sides of the support frame correspondingly. The two partition plates are each provided with a second electric push rod. A screening plate is mounted between the two second electric push rods. A screening net is mounted inside the screening plate. An inclined tank is mounted below the screening net. The sand screening machine is compact in structure and high in sand screening efficiency.

Owner:梁春峰

Heat supply conveying pipeline of heating tank in chemical plant

InactiveCN104344106AReduce noiseReduce impactLighting and heating apparatusRigid pipesThermodynamicsWater flow

The invention relates to the technical field of chemical equipment, and in particular relates to a heat supply conveying pipeline of a heating tank in a chemical plant. The heat supply conveying pipeline comprises a heat supply pipe which is connected with the heating tank, wherein a hush pipe is arranged inside the wall of the heat supply pipe; hush holes are formed inside the side wall of the hush pipe; a complex number of bulges of which the cross sections are triangular are arranged on the inner wall of the pipe through hole of the hush pipe; the bulges adopt hollow structures filled with sound-proof cotton; a buffer groove which can buffer water flow and takes the shape of a circular arc camber is formed between every two bulges. By adopting the technical scheme, the heat supply conveying pipeline of the heating tank in the chemical plant can alleviate the impact and reduce the noise.

Owner:CHONGQING THRIVE CHEM

Piston type balance valve

InactiveCN104696559AAvoid defectsEliminate distractionsEqualizing valvesSafety valvesRoom temperatureEngineering

The invention discloses a piston type balance valve. An inlet and an outlet are formed in two sides of a valve body of the piston type balance valve; the upper and lower parts of the valve body are respectively closed by an upper valve cover and a lower valve cover; a plurality of piston parts are arranged in a valve cavity; an upper valve rod penetrates through the upper valve cover and is connected with an upper piston type valve clack in an opened barrel of the upper valve cover; a sleeve type step valve seat is arranged in the lower part of the valve body and is closed by using the lower valve cover; a lower piston type valve clack and a driving piston are mounted in the sleeve type step valve seat; the lower piston type valve clack is connected with the driving piston through a lower valve rod; balancing holes are respectively formed in the upper piston type valve clack and the lower piston type valve clack; a plurality of abnormal windows are formed in the upper part of the driving piston; a lower cavity of the driving piston is communicated with the inlet of the valve through a guide pipe; a balancing spring is arranged in an upper cavity of the driving piston. The balance valve disclosed by the invention is used for adjusting the flow of a medium in heating and ventilation pipelines of an air conditioner and automatically eliminating interference among the branch pipelines in the system and eliminating hydraulic disorder of the system, so that the system is stable in operation and accurate to control the room temperature, and the energy consumption can be remarkably reduced.

Owner:KAITAI VALVE GROUP

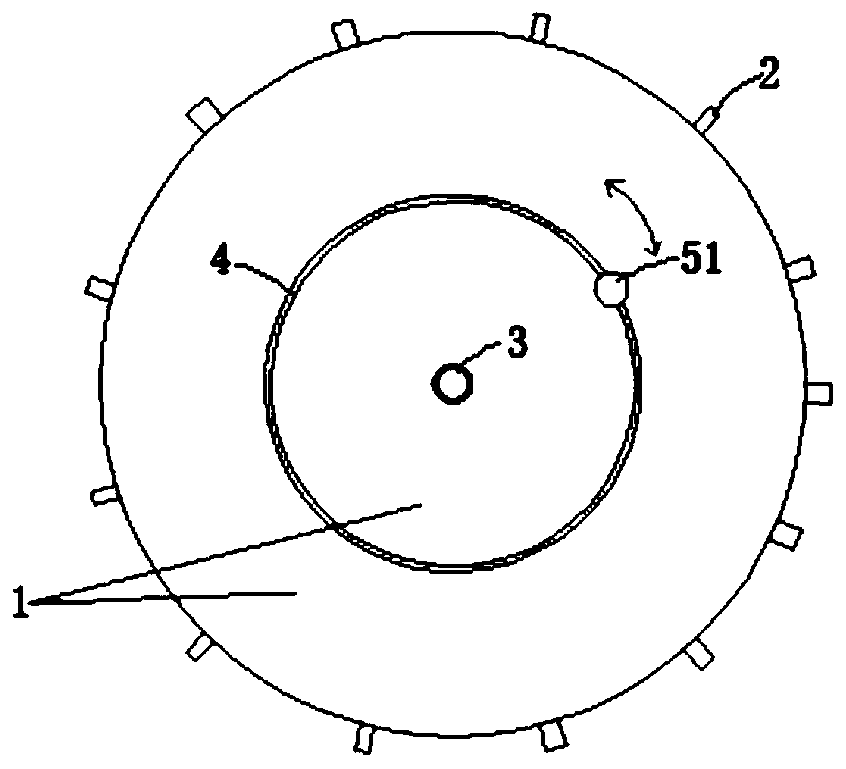

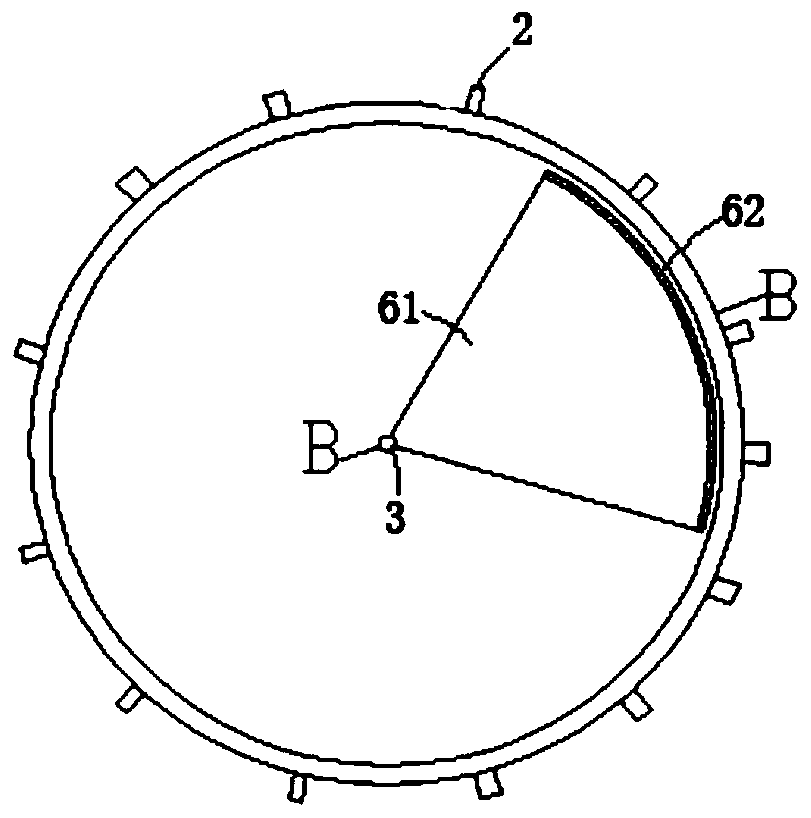

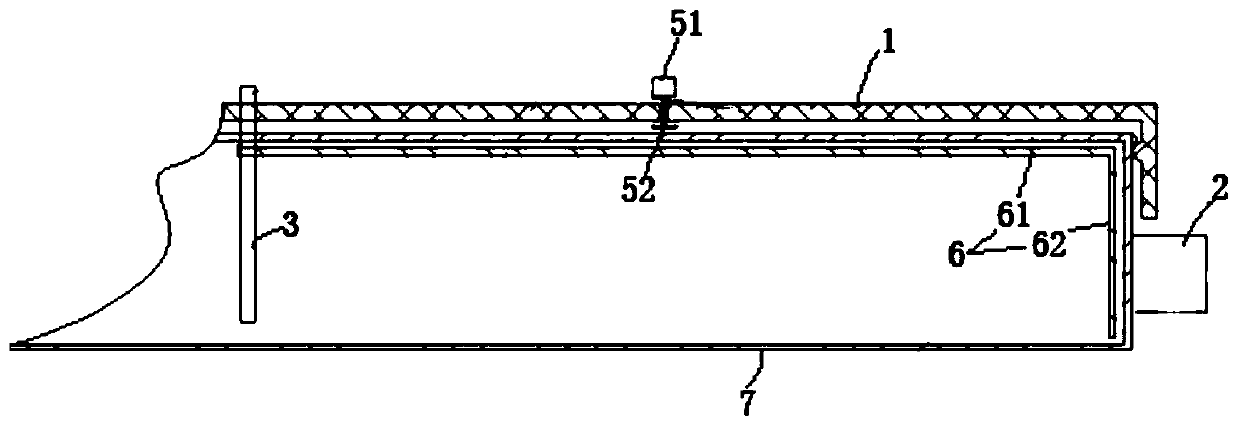

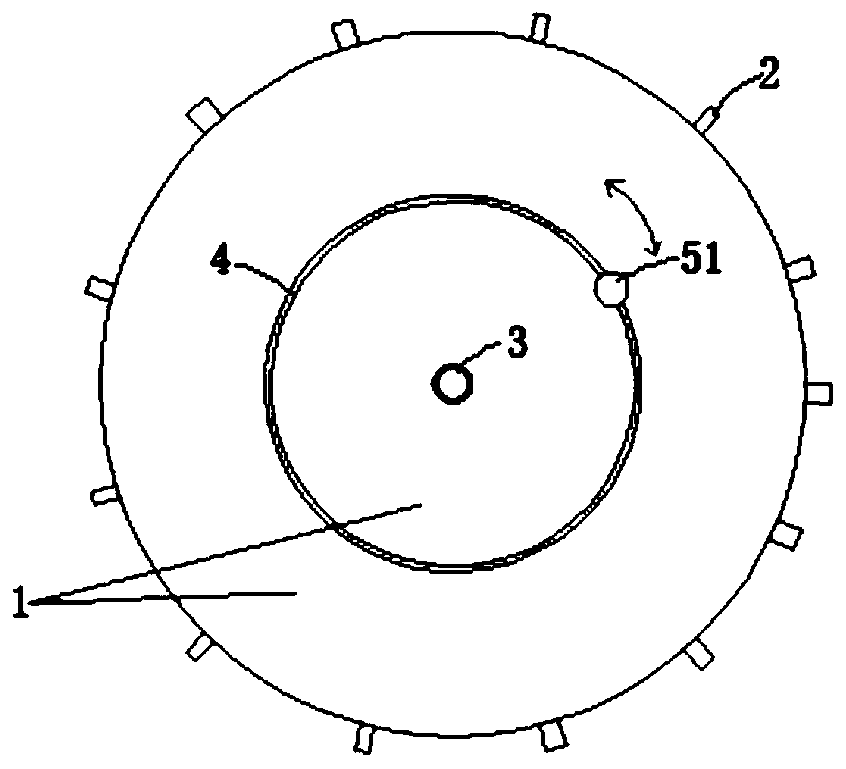

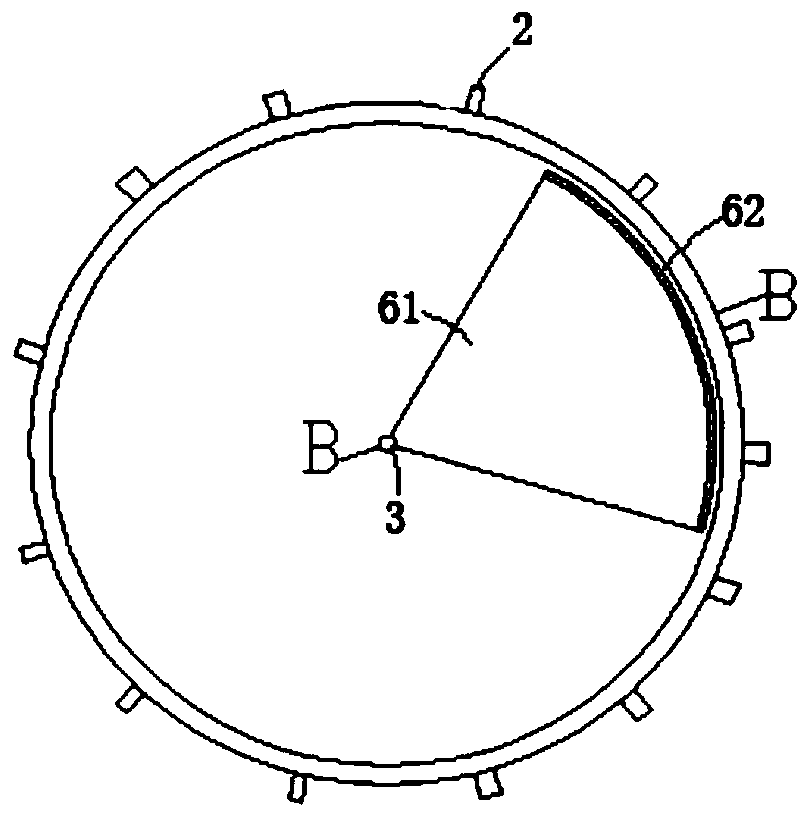

Novel airflow adjusting device

The invention relates to a novel airflow adjusting device. The novel airflow adjusting device comprises a distributor shell and an air inlet pipe, an outer shell is arranged on the outer side of the distributor shell, a plurality of airflow outlets are formed in the peripheral surface of the distributor shell, the air inlet pipe is located in the middle of the outer shell, an annular guide grooveis formed in the side surface of the outer shell, a knob assembly is installed in the annular guide groove, an airflow adjusting baffle assembly is arranged in an inner cavity of the distributor shell, wherein the airflow adjusting baffle assembly comprises an airflow adjusting baffle and an arc-shaped baffle connected with the airflow adjusting baffle, and the end, far away from the arc-shaped baffle, of the airflow adjusting baffle is hinged to the air inlet pipe. A knob drives the airflow adjusting baffle to rotate in the inner cavity of the distributor shell, in the rotating process of theairflow adjusting baffle, the arc-shaped baffle rotates on the inner wall of the outer shell, so that the arc-shaped baffle blocks airflow of a part of the airflow outlets in the outer shell, then the airflow of the part of the blocked outlets is reduced, and the airflow of the part of unblocked outlets is increased, so that the aim of simply adjusting the airflow is achieved.

Owner:CHINA INST FOR RADIATION PROTECTION

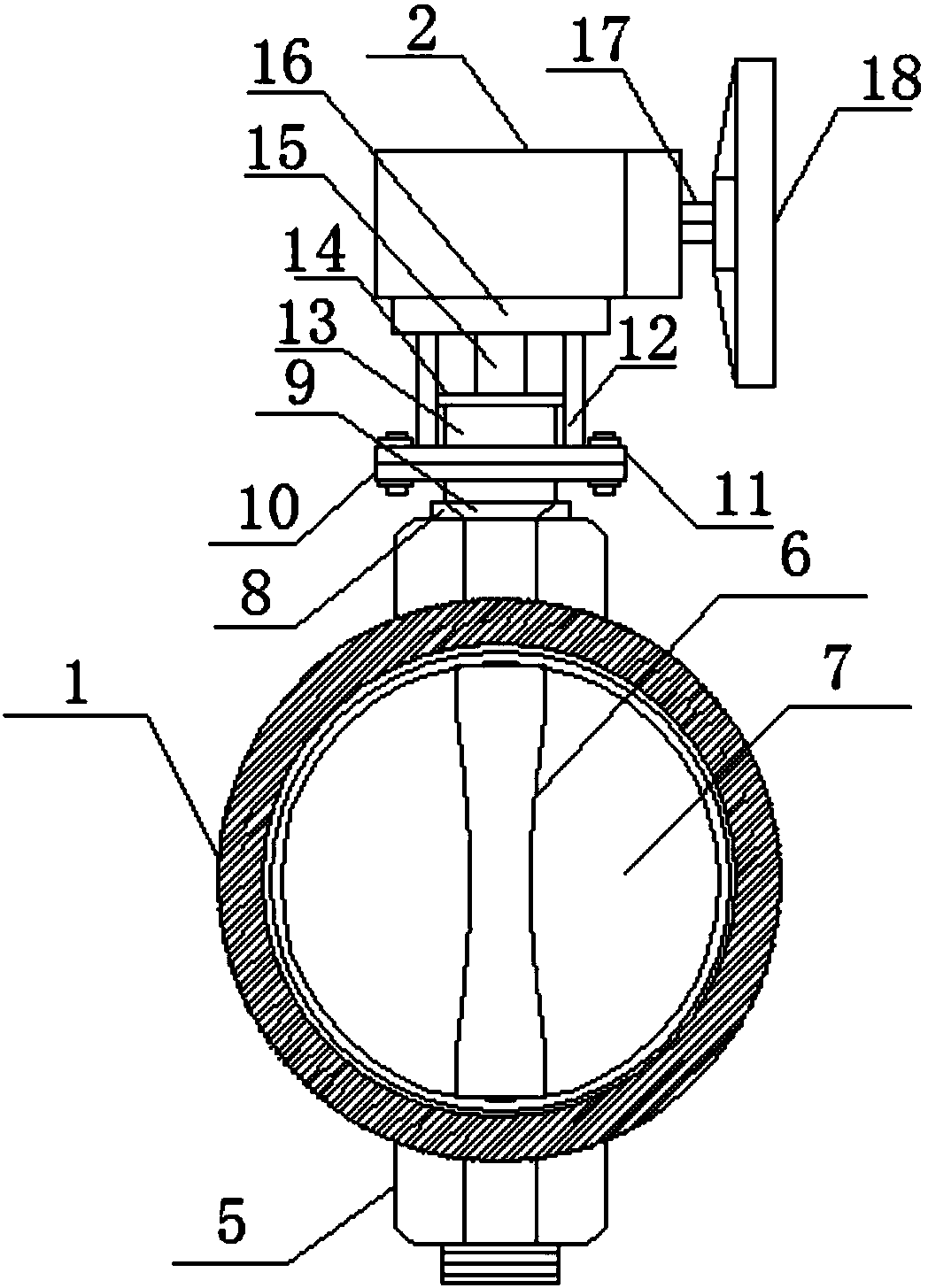

High-performance upper-mounted butterfly valve

ActiveCN108087567AImprove protectionAvoid wastingRotating vibration suppressionSpringsEngineeringButterfly valve

The invention discloses a high-performance upper-mounted butterfly valve which comprises a butterfly valve shell and a box body. The box body is arranged at the top end of the butterfly valve shell. Limiting blocks and a water tank are arranged in the butterfly valve shell. One side of each limiting block is fixedly connected with the inner wall of the butterfly valve shell. Fixed shafts are arranged at the upper end and the lower end of the butterfly valve shell. A rotating shaft is arranged in the butterfly valve shell, and the rotating shaft penetrates the butterfly valve shell and extendsinto the fixed shafts. The rotating shaft and the fixed shafts are movably connected. Flow limiting plates are arranged on the two sides of the rotating shaft and are arranged in the butterfly valve shell. A screw groove column is arranged at the top end of the upper fixed shaft. According to the high-performance upper-mounted butterfly valve, through the arrangement of the limiting blocks, supporting force can be provided for the flow limiting plates easily, and the situation that when the medium flowing speed is too high, the flow limiting plates are impacted to rotate, and consequently thefunction of cutting off media cannot be achieved is avoided; and through the arrangement of a vibration reduction plate, vibration generated when acting force is transmitted can be reduced easily, damage caused by vibration to equipment is avoided, and therefore the aim of the high-performance upper-mounted butterfly valve is achieved.

Owner:ANHUI RONGDA VALVE

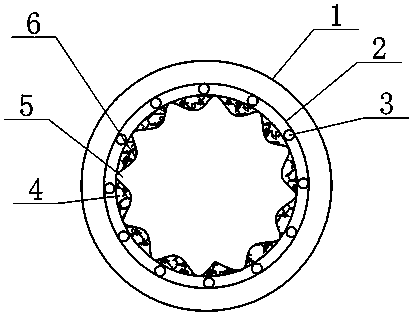

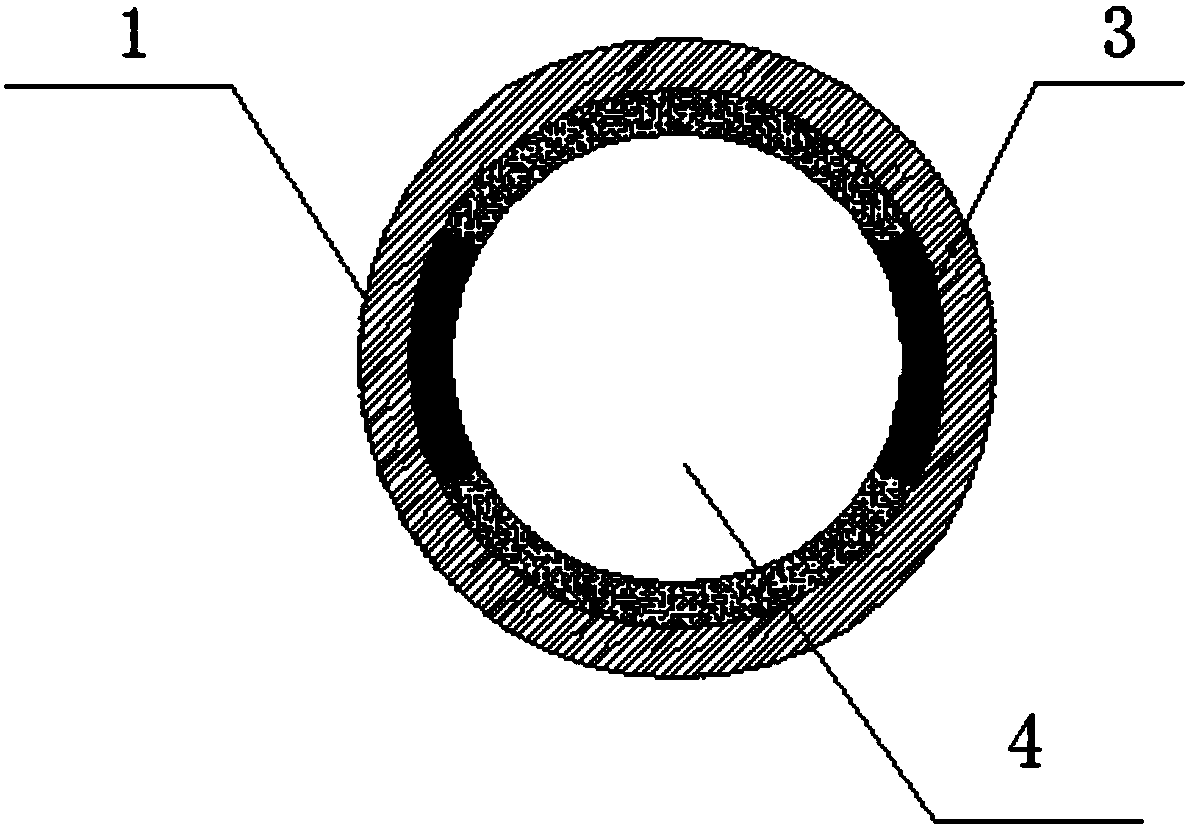

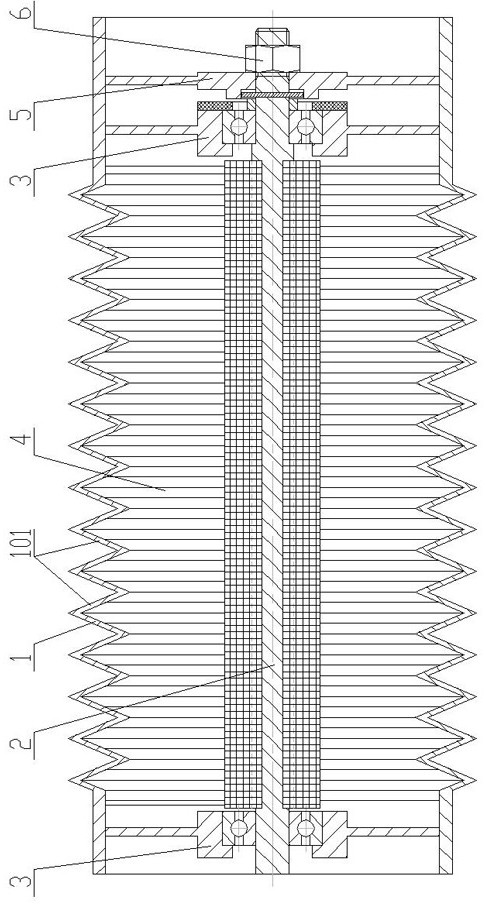

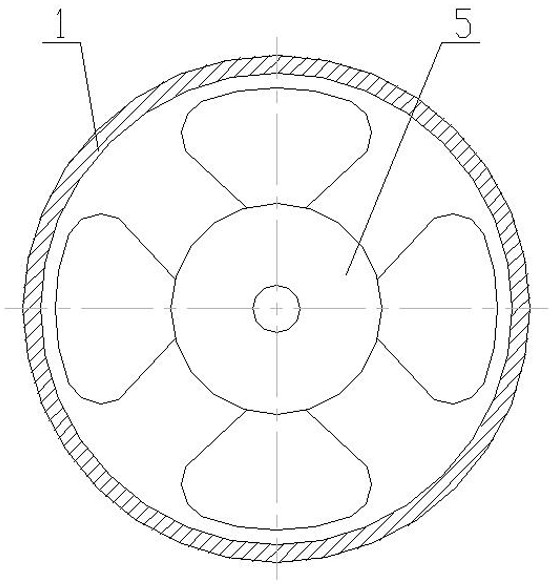

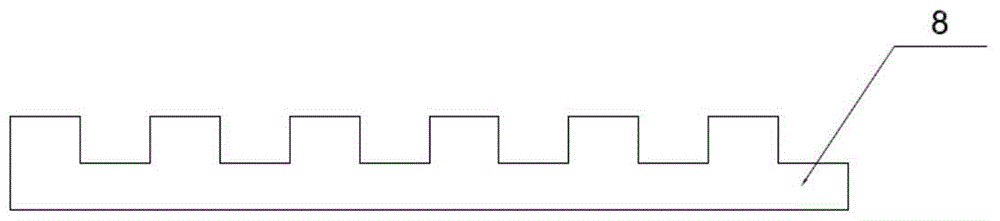

Micro-channel pipe forming die and method

ActiveCN114345971AGuaranteed structural sizeReduce stressExtrusion diesGlass productionEngineeringMechanical engineering

The invention provides a micro-channel pipe forming die and method, and relates to the field of die forming, the micro-channel pipe forming die comprises a die main body, the die main body is provided with a feeding channel, a welding chamber and a forming channel which are communicated in sequence, multiple stages of shunting channels which are communicated in sequence are formed in the feeding channel, and a die core neck is arranged in the welding chamber; one end of the mold core neck is connected with a mold core composed of a series of sub-mold cores distributed in an array mode, the mold core stretches into the forming channel, an inner wall channel communicated with gaps of the sub-mold cores and the flow dividing channel is formed in the mold core neck, and an outer wall channel communicated with the flow dividing channel and the forming channel is formed between the mold core neck and the welding chamber; aiming at the problem that the quality requirement is difficult to meet when the micro-channel pipe is extruded and formed through a die at present, a multi-stage shunting channel is adopted to promote blank flowing so as to reduce the die stress, and meanwhile, flow guide channels are correspondingly arranged on the outer wall and the inner wall of the micro-channel pipe so as to promote the flowing uniformity of a deformation material and reduce the distortion of a profile; and the structural size of the formed micro-channel pipe is ensured to meet the precision requirement.

Owner:SHANDONG UNIV

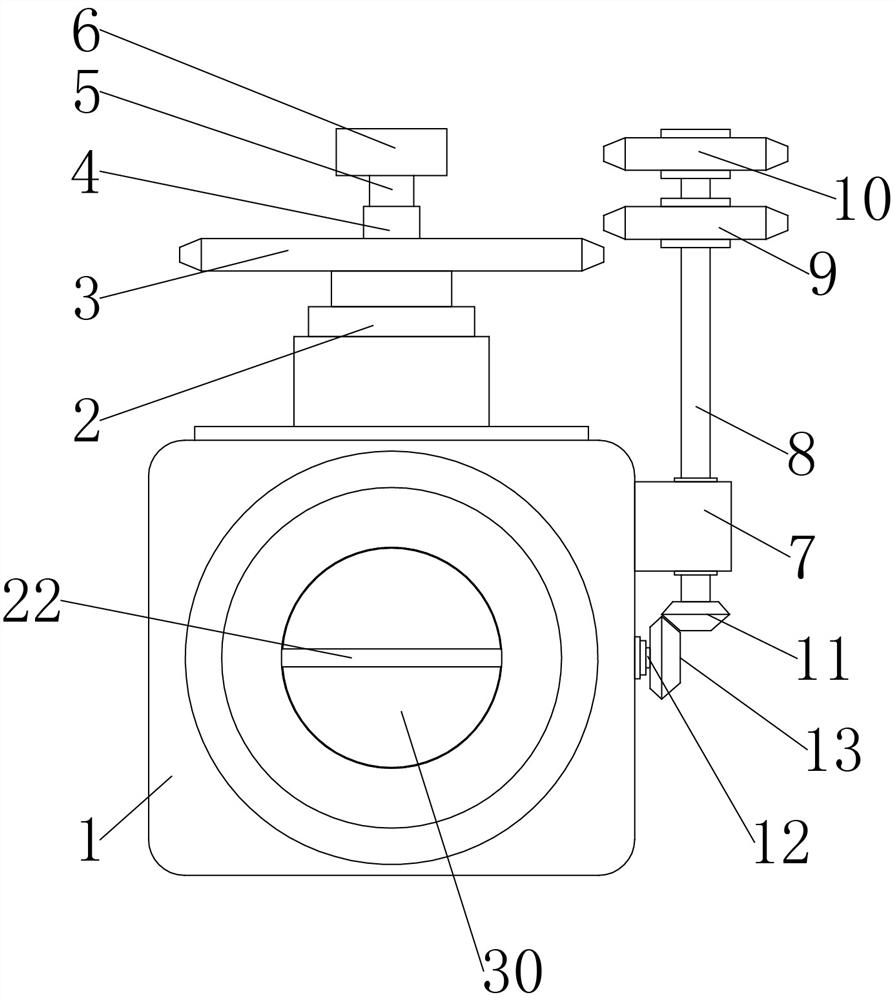

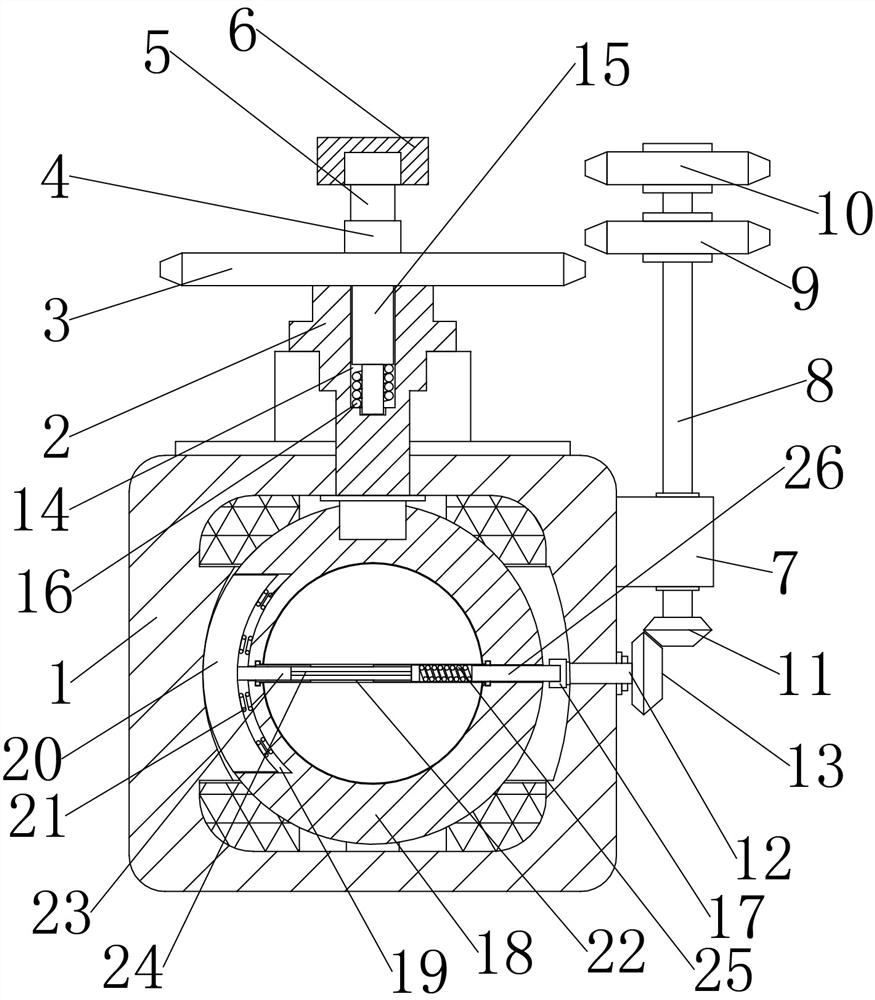

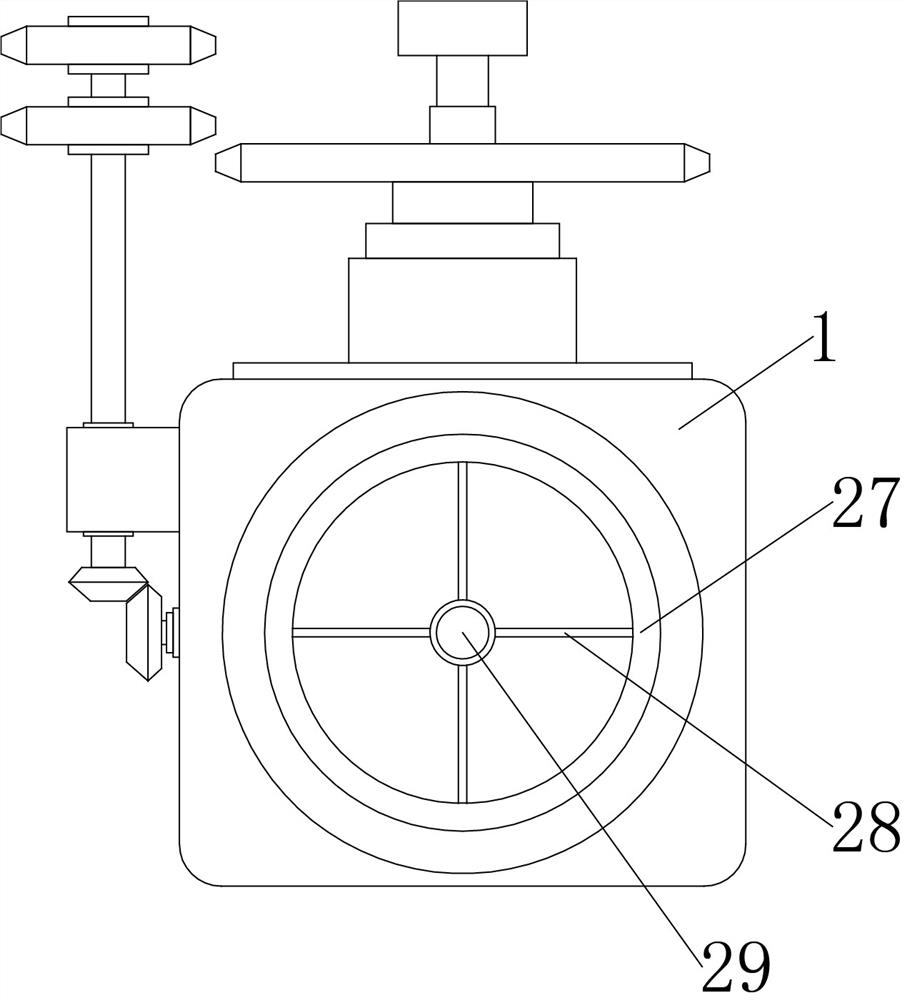

Pressure reduction type ball valve

PendingCN113700889AExtended service lifeAvoid water impact on valve plate activitiesPlug valvesOperating means/releasing devices for valvesPhysicsBall valve

The invention relates to the technical field of ball valves, in particular to a pressure reduction type ball valve. The pressure reduction type ball valve comprises a valve body, a valve rod and a ball, the ball is rotationally connected into the valve body, the valve rod is fixed to the upper end of the ball, the upper portion of the valve rod penetrates through the valve body, an inserting groove is formed in the upper end of the valve rod, an inserting rod is inserted into the inserting groove, the upper end of the inserting rod extends out of the inserting groove and is fixedly provided with a rotating gear, a rectangular lug is fixed to the upper end of the rotating gear, a support is fixed to the rear side of the upper end of the valve body, and a casing is fixed to the tail end of the support. When the valve needs to be opened, the rotating gear is pressed to the bottom and rotates, the rotating gear can drive the valve rod to rotate along with inserting connection of the limiting rod and the limiting groove, the valve rod can drive the ball to rotate at the moment, and therefore the ball valve can be opened and closed; when the ball valve is in the closed state, water pressure impacts a buffer block, the buffer block extrudes a buffer spring, meanwhile, a round rod, a cross rod and a rectangular rod synchronously move backwards, the rectangular rod extrudes a buffer ball, at the moment, the pressure of water pressure to the valve rod can be reduced, and therefore the service life can be prolonged.

Owner:KAISITONG VALVE

Magnetic material mixing device

InactiveCN108636281AEasy to openEasy to closeTransportation and packagingMixer accessoriesEngineeringMechanical engineering

The invention relates to a magnetic material mixing device. The magnetic material mixing device comprises a stirring box, a first storage bin, a second storage bin, a mounting box, a first rotating body, a second rotating body and a controller, wherein the top surface of the stirring box is provided with two feeding ports; the first storage bin is positioned above the stirring box, the bottom endof the first storage bin is provided with a first discharge port, and the first discharge port is provided with a first bin door; the second storage bin is positioned above the stirring box, the bottom end of the second storage bin is provided with a second discharge port, and the second discharge port is provided with a second bin door; the mounting box is arranged on the shell of the first storage bin and the second storage bin and is positioned between the first bin and the second bin; the mounting box is provided with a driving mechanism; a first rotating body is respectively connected with the driving mechanism and the first bin door; a second rotating body is respectively connected with the driving mechanism and the second bin door; the controller includes a control button. The magnetic material mixing device opens and closes the bin door conveniently.

Owner:FOSHAN SUIYUAN HENGKE BUILDING MATERIAL CO LTD

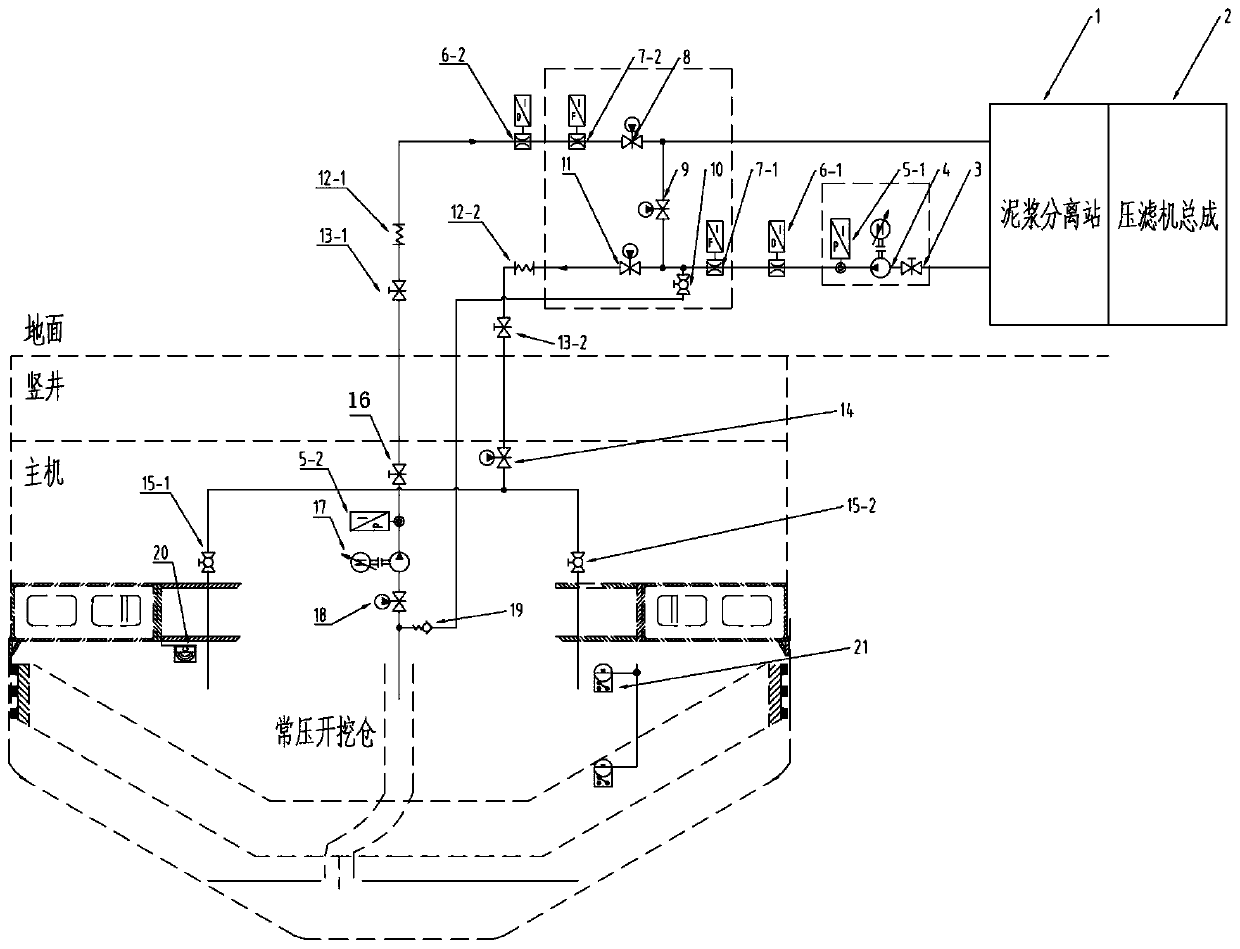

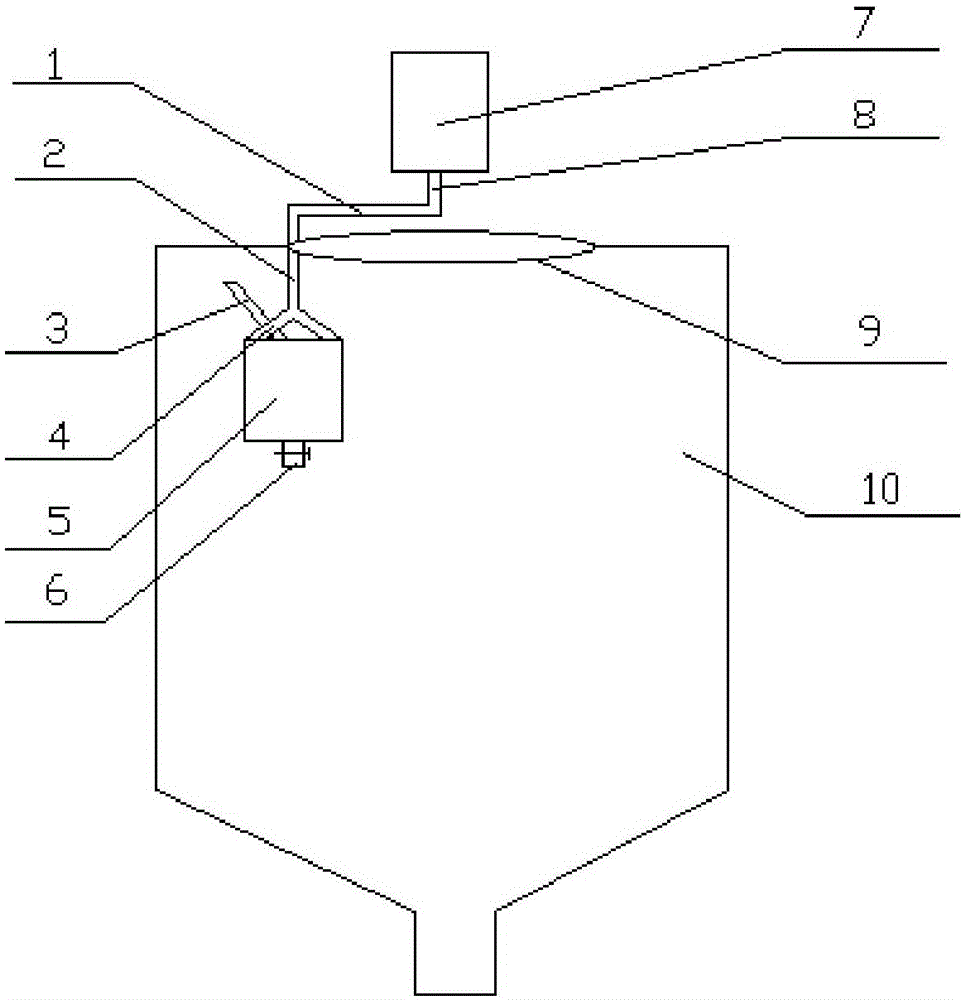

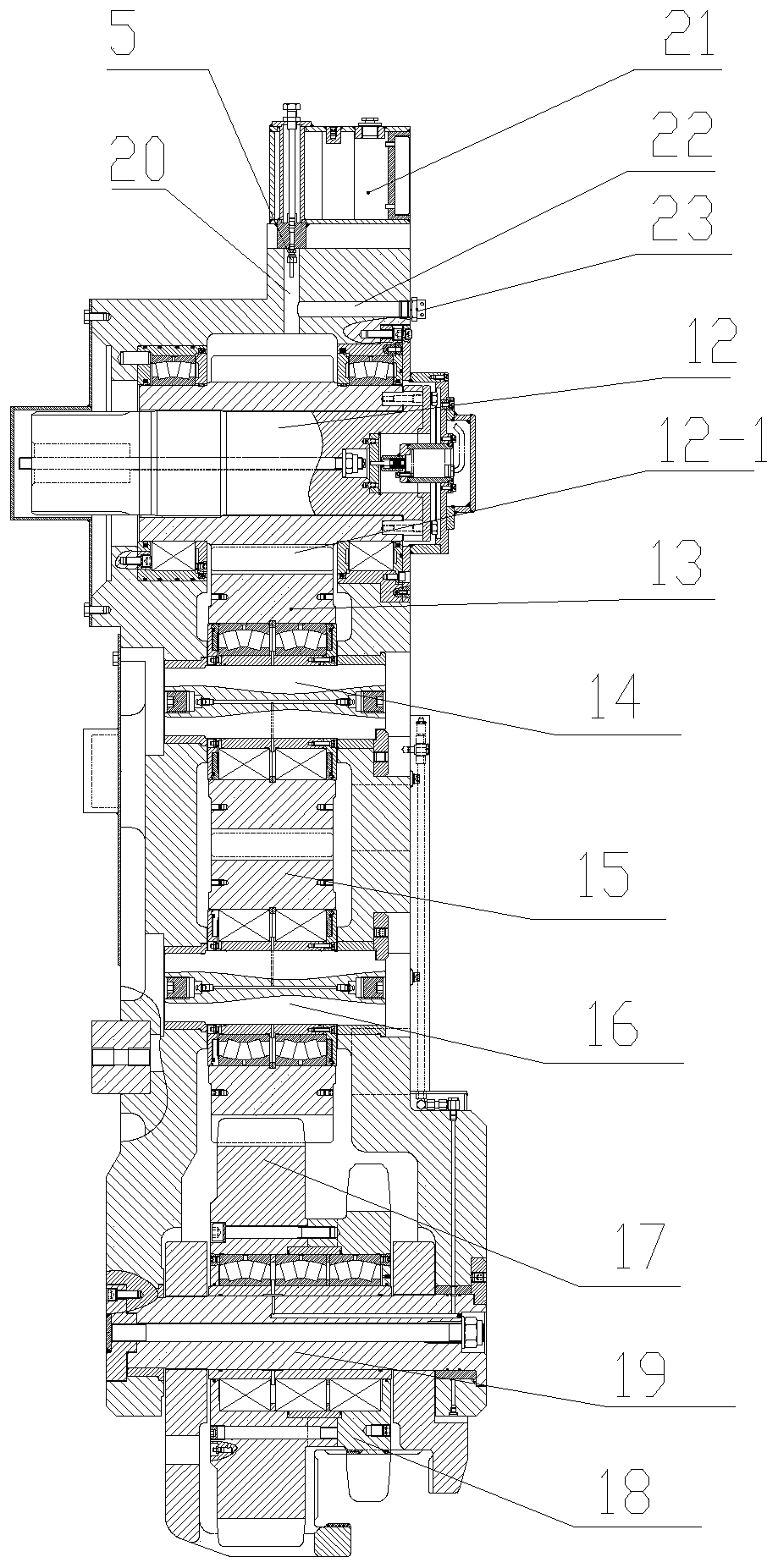

Slurry circulating slag discharging system for shaft heading machine

PendingCN110725683AImprove adaptabilityReduce labor intensityShaft sinkingTunnelsProcess engineeringSlurry

The invention provides a slurry circulating slag discharging system for a shaft heading machine, The system comprises a slurry inlet pipeline, a slurry discharge pipeline, a flushing pipeline, a bypass pipeline and a slurry treatment device, wherein one end of the slurry inlet pipeline is connected with the slurry treatment device, the other end of the slurry inlet pipeline is arranged in an excavation bin of the heading machine, slurry treated by the slurry treatment device is conveyed into the excavation bin, one end of the slurry discharge pipeline is arranged in the excavation bin, the other end of the slurry discharge pipeline is connected with the slurry treatment device, the slurry in the excavation bin is conveyed to the slurry treatment device through the slurry discharge pipeline, the flushing pipeline is connected with slurry discharge ports, located in the excavation bin, of the slurry inlet pipeline and the slurry discharge pipeline, the slurry discharge ports are dredgedthrough the flushing pipeline, the bypass pipeline is connected with the slurry inlet pipeline and the slurry discharge pipeline, and a slurry conveying cycle is formed between the slurry inlet pipeline, the bypass pipeline, the slurry discharge pipeline and the slurry treatment device. The slurry circulating slag discharging system integrates circulating slag discharging and slurry discharge portdredging functions, and the bypass pipeline is arranged to facilitate maintenance of the system.

Owner:CHINA RAILWAY CONSTR HEAVY IND

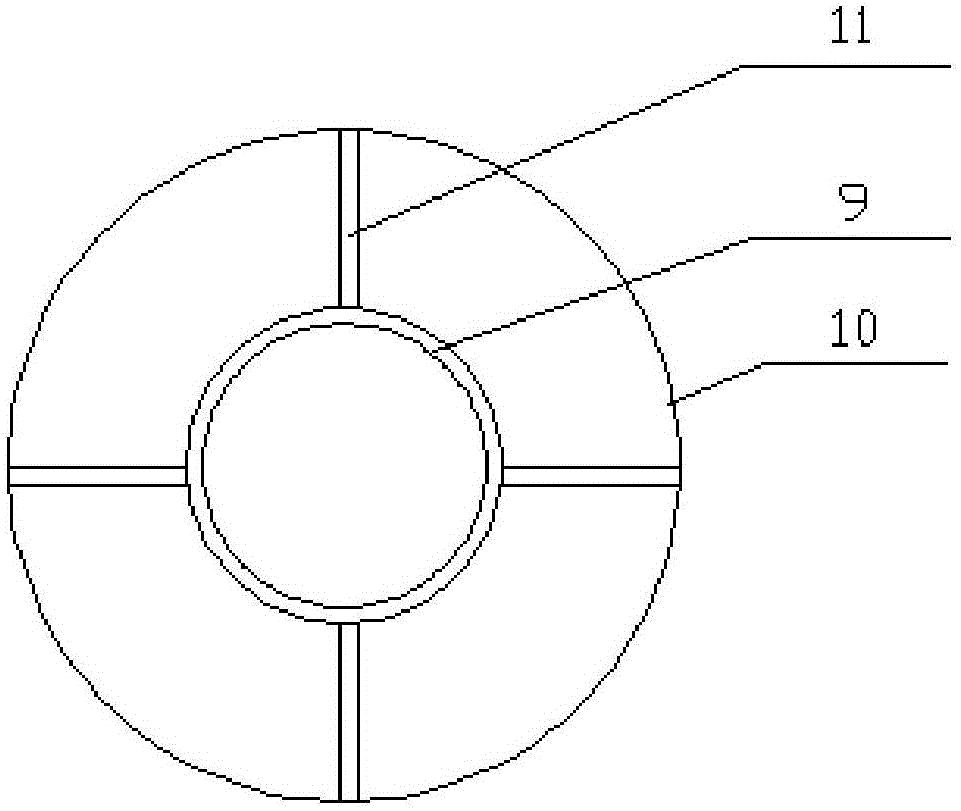

Flow regulator for ophthalmological ultrasound emulsification instrument

InactiveCN108721709ASimple structureSimple and fast operationMedical devicesIntravenous devicesEngineeringCatheter

The invention discloses a flow regulator for an ophthalmological ultrasound emulsification instrument. The flow regulator comprises a connecting box body, wherein a filter screen is welded in the central portions of the upper end and lower end of the inner portion of the connecting box body, an outlet is formed in the center of the upper end of the connecting box body, the upper end of the outletis welded with a connecting duct, a liquid outlet pipe is arranged above the connecting duct, the outer side of the lower end of the liquid outlet pipe and the outer side of the upper end of the connecting duct are both provided with a set of connecting rings, a liquid can be introduced into the connecting box body through a liquid inlet duct, the filter screen in the connecting box body can filter the liquid, the rotation of an adjusting pipe can drive a rotational adjusting plate to rotate, and the rotation of the rotational adjusting plate can stagger through holes in the rotational adjusting plate with through holes in a fixed adjusting plate so as to adjust the size of the through holes. The flow regulator for the ophthalmological ultrasound emulsification instrument has the advantages that the structure is simple, not only can the liquid be filtered, but also the flow adjustment is more convenient, thereby providing convenience for a doctor.

Owner:刘永梅

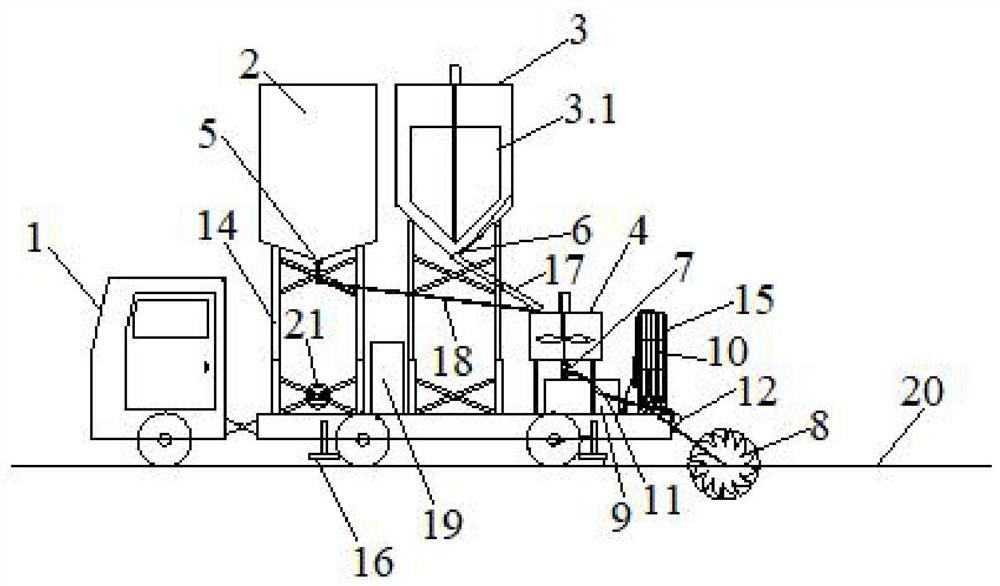

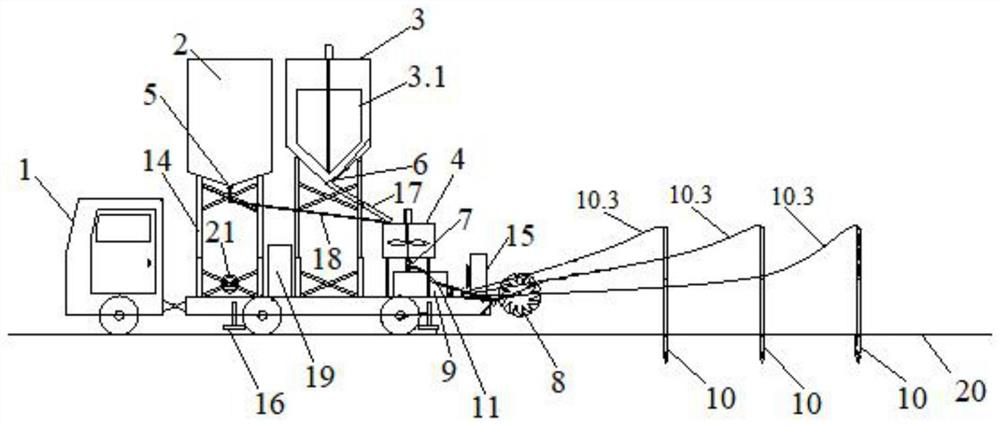

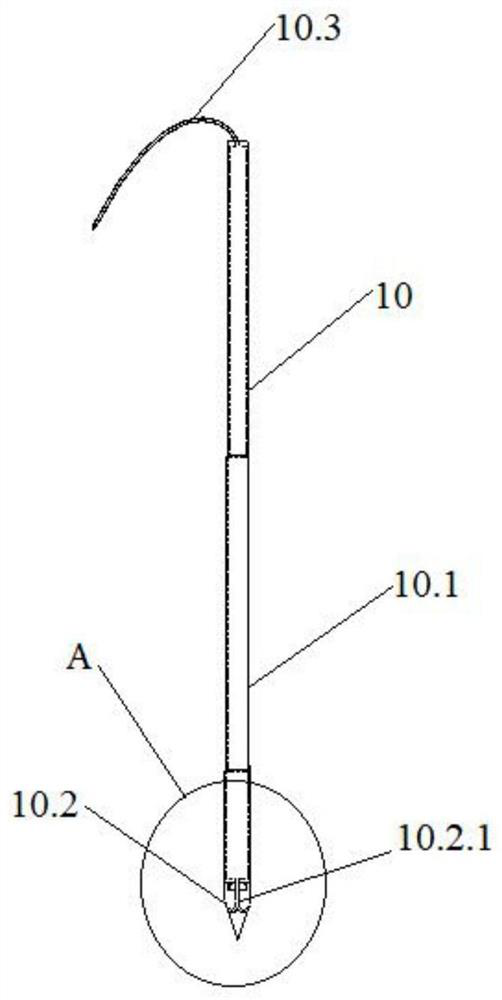

An integrated device for soil in situ remediation

ActiveCN113020240BGood restorativeAvoid wastingContaminated soil reclamationSoil scienceIn situ remediation

The invention provides an integrated device for soil in-situ restoration, which includes a moving mechanism, a shallow soil restoration unit, a deep soil restoration unit, and a liquid medicament silo, a solid medicament powder silo, and a medicament mixing unit arranged on the moving mechanism. Mechanism and power control assembly; the liquid medicament silo communicates with the medicament mixing mechanism, and the solid medicament powder silo communicates with the medicament mixing mechanism; the shallow soil remediation unit includes a soil turning component and a medicament splitting spray assembly; the deep soil remediation The unit includes a booster pump and a plurality of spin medicament injection needles, the spin medicament injection needles include a spin spray head, and the spin spray head includes an even number of nozzles, for the projection of any two opposing nozzles on a vertical plane It is W-shaped, and the projection on the horizontal plane is S-shaped. The invention can realize integrated restoration of shallow soil and deep soil and improves restoration efficiency.

Owner:中铝环保生态技术(湖南)有限公司

Spraying device for refrigerator metal accessory machining

PendingCN112958310AInnovative designEasy to operateLiquid spraying apparatusElectric machineryStructural engineering

The invention discloses a spraying device for refrigerator metal accessory machining, relates to the technical field of refrigerators. Aiming at the problems that in the production process of refrigerator metal accessories, when the surfaces of the refrigerator metal accessories are sprayed with protective liquid, the working procedures are tedious, and the working efficiency is low,the following scheme is provided, specifically, the spraying device comprises a shell, and a lifting rotating mechanism is arranged at the bottom of the shell; extrusion moving mechanisms are arranged on the two sides of the shell, and fixing clamping mechanisms are arranged on the sides, close to each other, of the extrusion moving mechanisms; a lifting spraying mechanism is arranged at the top of the shell, the lifting rotating mechanism comprises a rotating rod rotationally connected with the interior of the shell, and a push rod motor is connected to the top end of the rotating rod; and the output end of the push rod motor is connected with an installation block, and the top of the installation block is connected with a containing plate. According to the spraying device, spraying can be conveniently conducted on refrigerator metal accessories, the flow and hydraulic pressure of liquid can be conveniently adjusted, the positions of the refrigerator metal accessories can be conveniently adjusted, and spraying is facilitated.

Owner:滁州市友邦涂装有限公司

Culturing pond provided with full-automatic artemia culturing feeding device

PendingCN105028344AWell mixedSolve the problem of solid-liquid separationAnimal husbandryArtemia sp.Engineering

The invention discloses a culturing pond provided with a full-automatic artemia culturing feeding device. The culturing pond comprises a pond body, a support, an annular sliding way, a feeding bucket and a transmission rod. The annular sliding way and the edge of the pond body are fixedly connected through the support, the transmission rod penetrates through the upper end and the lower end of the annular sliding way, a speed reducer and the feeding bucket are connected with the two ends of the transmission rod, and the feeding bucket is located at the lower end of the annular sliding way. The culturing pond has the advantages that solid-and-liquid-mixed fish feed can be more evenly mixed, and the problem of solid-and-liquid layering of the fermented fish feed is solved; pollution of the fish feed to a culturing water body is reduced, the culturing cost is saved, and the residual amount of the fish feed is reduced; the working intensity is reduced, the trouble of manual all-day timing multi-time feeding is saved, and the working efficiency is improved; flow can be better regulated when the fish feed is fed into the culturing pond.

Owner:TIANJIN OCEAN PAL CAROL BIOTECH

Filter element with automatic brushing function

InactiveCN111939614AImprove decontamination abilityEasy to adjust flow areaStationary filtering element filtersRotational axisWater flow

A filter element with an automatic brushing function comprises a filter element body of a cylindrical structure, a rotating shaft is installed on the inner side of the filter element body, a brush assembly and a driving fan blade assembly are installed on the rotating shaft in a sleeving mode; the position, corresponding to the brush assembly, of the filter element body is of a folded structure, and the folded structure is composed of a plurality of conical barrel sections in the middle of the filter element body; the conical barrel sections are sequentially connected in the axial direction, the outer circumferential face of the brush assembly is attached to the inner surfaces of the conical barrel sections on the filter element body, the driving fan blade assembly is located on the side,close to the coming direction of back washing water flow, of the brush assembly, the driving fan blade assembly is made to rotate through the back washing water flow, and therefore the rotating shaftdrives the brush assembly to rotate in order to brush the inner surface of the filter element body conveniently. According to the invention, the filter element is flushed by water flow and can be directly brushed by the brush assembly in the backwashing process, the decontamination effect of backwashing on the filter element is greatly improved, and the requirement for long-time use of the backwashing filter after automatic backwashing can be satisfied.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

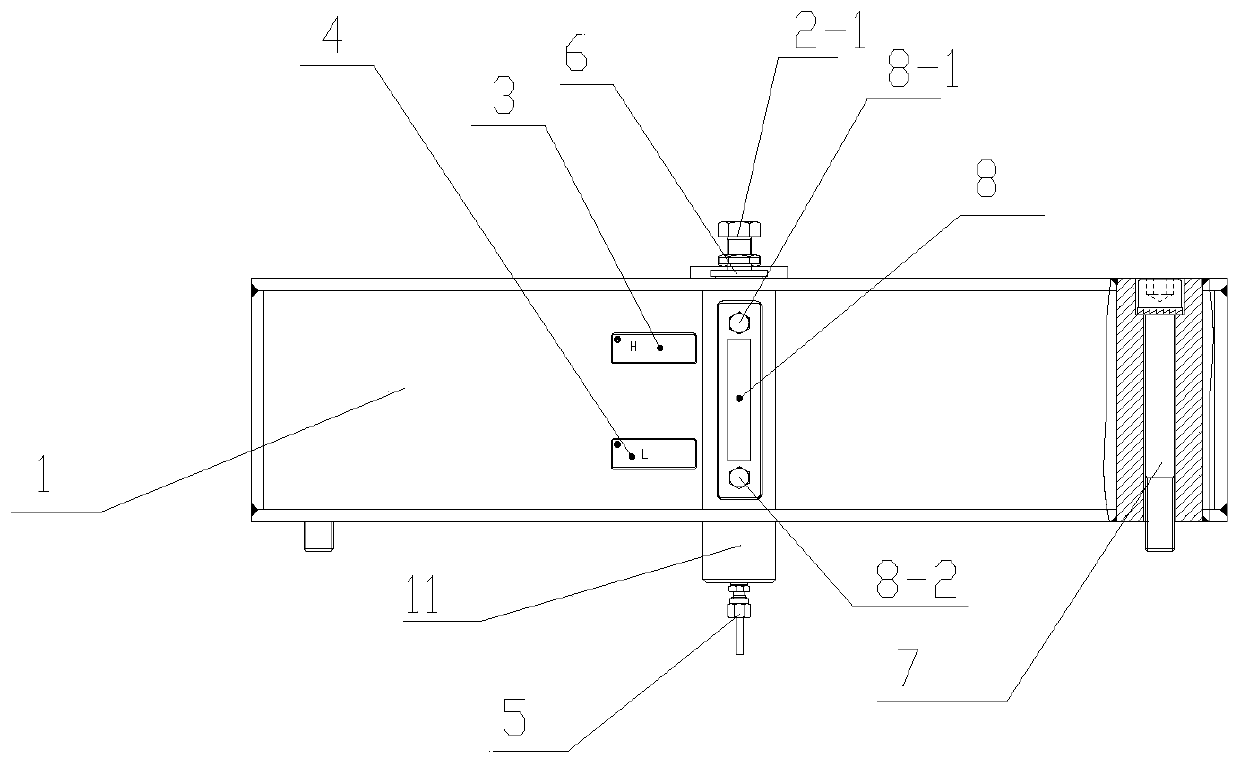

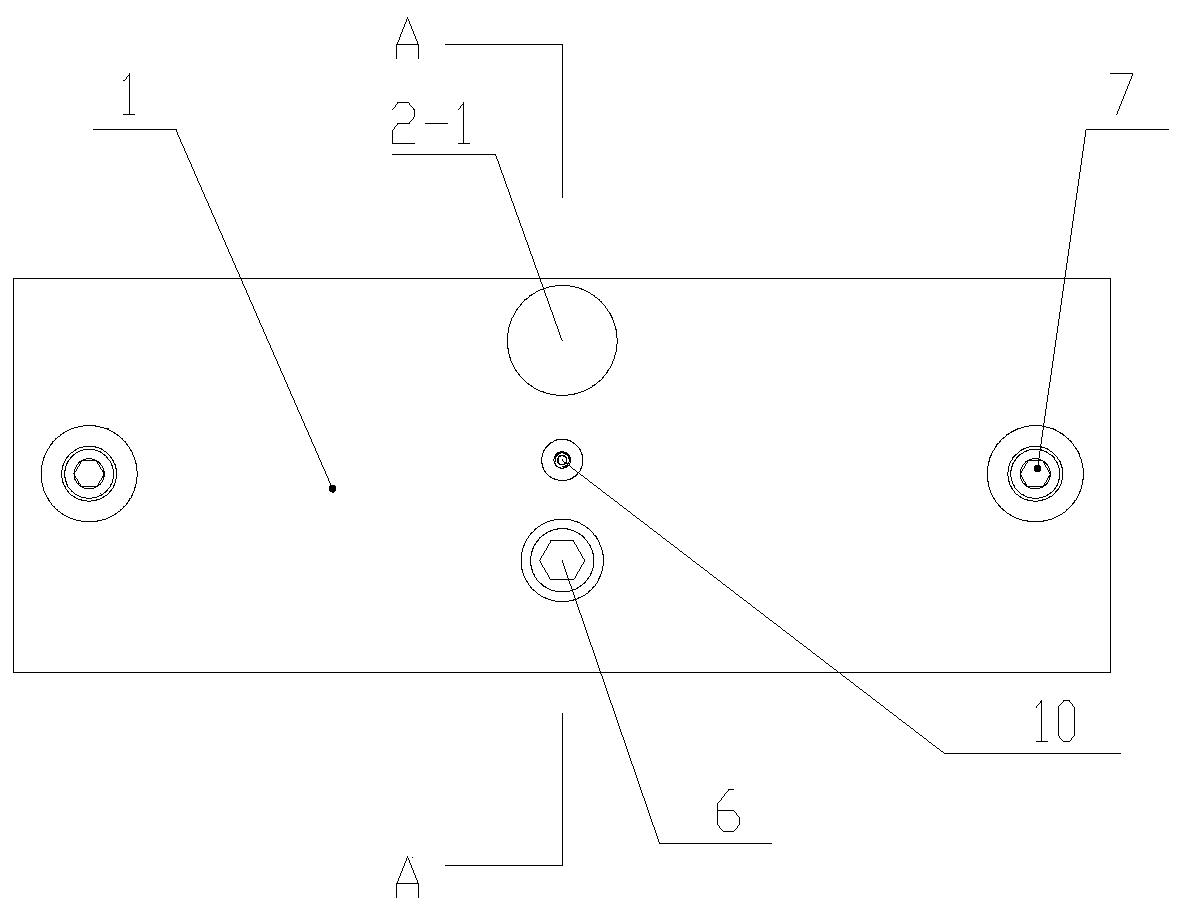

Lubricating and cooling device and method for walking box of coal mining machine

PendingCN110762197ASimple structureReasonable designGear lubrication/coolingPropulsionThermodynamicsGear wheel

The invention discloses a lubricating and cooling device and method for a walking box of a coal mining machine. The device comprises an oil drip lubricating mechanism arranged on the top of the walking box of the coal mining machine and a cooling mechanism arranged on the walking box of the coal mining machine, wherein the oil drip lubricating mechanism comprises an oil drip box body, a drip tubeand an oil drip adjusting part; and the oil drip adjusting part comprises a sealing cover, an adjusting screw rod, a circular protection cylinder and a drip tube. The method comprises the following steps of 1, mounting the oil drip lubricating mechanism and the cooling mechanism; 2, adjusting the oil drip lubricating mechanism and the cooling mechanism; and 3, lubricating and cooling the walking box of the coal mining machine. According to the lubricating and cooling device and method for the walking box of the coal mining machine, lubricating oil and cooling water are mixed to lubricate and cool a transmission gear in the walking box, so that the aims of lubricating and cooling of a walking box inner gear of the super-high-power walking box are achieved.

Owner:XIAN COAL MINING MACHINERY

A Float Online Atmospheric Pressure Chemical Vapor Deposition Coating Reactor

ActiveCN104561938BImprove efficiencyQuality improvementChemical vapor deposition coatingInlet channelWide mouth

The invention discloses an online normal-pressure chemical vapor deposition film-plating reactor through a floatation process. The online normal-pressure chemical vapor deposition film-plating reactor disclosed by the invention comprises a heat preservation shell and a bottom plate, wherein a gas inlet chamber and an exhaust chamber are arranged in the heat preservation shell; a slit communicated with the gas inlet chamber and an exhaust hole communicated with the exhaust chamber are arranged on the bottom plate; a pre-mixing chamber and a waste gas chamber are also arranged in the heat preservation shell; the pre-mixing chamber is connected to a film-plating precursor gas inlet pipe and embedded in the waste gas chamber; the exhaust chamber is connected into the waste gas chamber; the gas inlet chamber is communicated with the pre-mixing chamber through a gas inlet channel; the gas inlet chamber is arranged over the bottom plate and is shaped as a wide mouth gradually widened along the airflow direction; a flow-mixing baffle for forming up and down airflows is installed in the gas inlet chamber; the exhaust chamber is of a structure with a large upper part and a small lower part; and a dust collecting plate is installed in the exhaust chamber. By means of the gas mixing chamber structure in the invention, multi-charge and multi-discharge steady airflow trends are formed easily, pre-heating is strengthened, the flow is convenient to adjust, the film-plating efficiency is increased, and thus, the film-plating quality is increased.

Owner:中玻(陕西)新技术有限公司

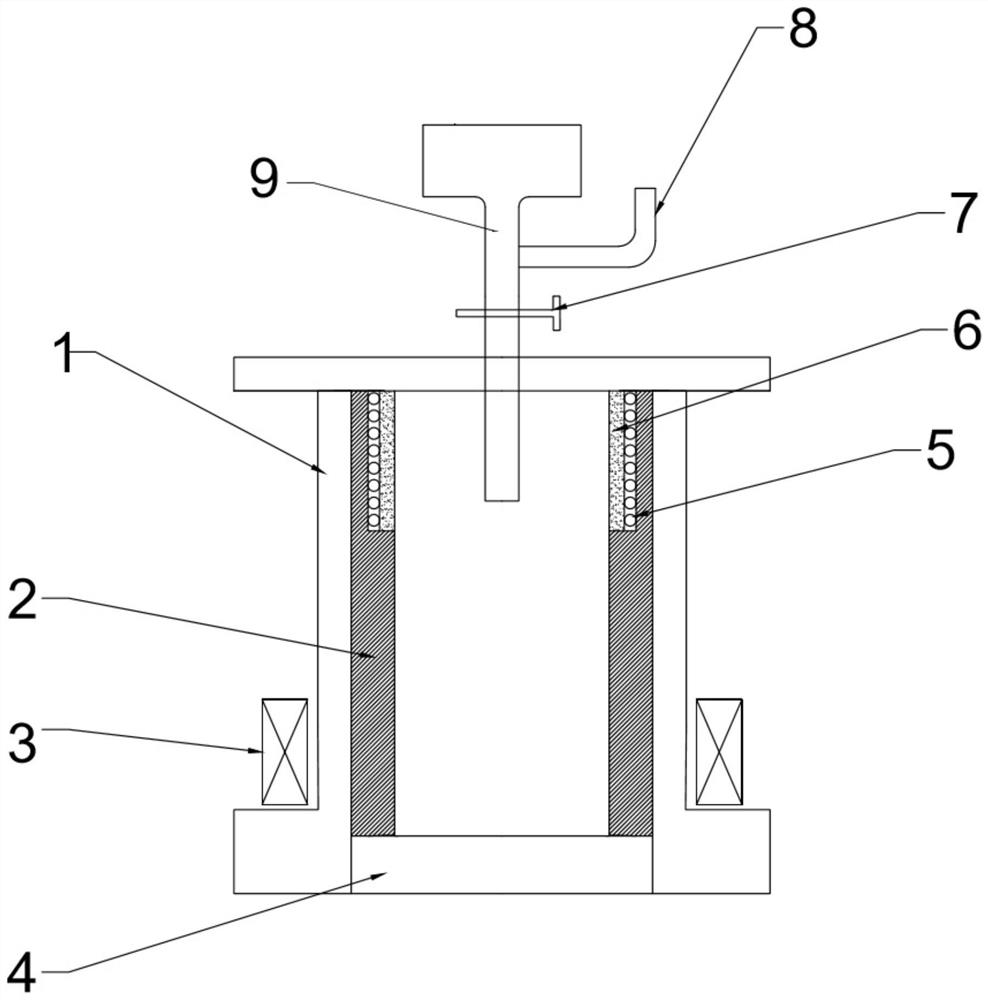

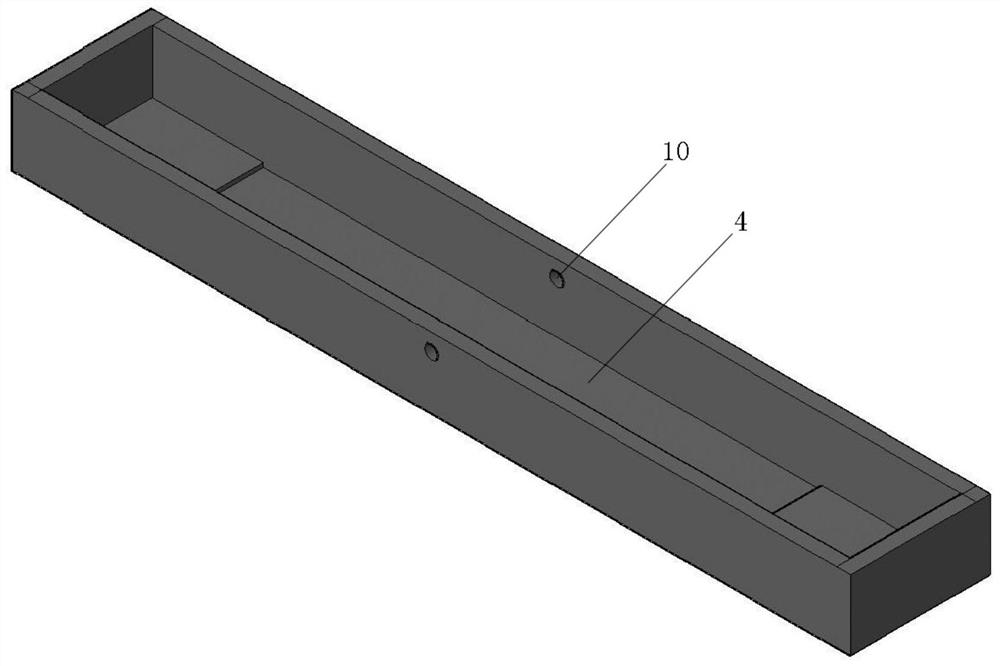

Device and method for preparing foamed aluminum based on electromagnetic stirring under the action of composite magnetic field

ActiveCN113186420BReduce contact pressureReduce sliding frictionStirring devicesTemperature controlPhysical chemistry

The device and method for preparing aluminum foam based on electromagnetic stirring under the action of a composite magnetic field belongs to the technical field of porous metal foam materials. The device includes: a reactor shell, a mold, an electromagnetic stirring device, a temperature control device, an induction coil, a filling material, a valve, Vent and feed piping. The method includes: proportioning, heating, feeding thickener and foaming agent, electrified stirring and foaming reaction. The invention proposes a device and method for preparing foamed aluminum based on electromagnetic stirring under the action of a composite magnetic field. The invention uses an induction coil to generate an alternating magnetic field, and the alternating magnetic field interacts with the induced current in the foamed aluminum to generate a direction perpendicular to the mold wall surface. The electromagnetic pressure in the center of the foamed aluminum melt reduces the contact pressure and sliding friction between the foamed aluminum and the mold wall, reduces the non-slip phenomenon, and makes them reach a soft contact state, so that the foamed aluminum melt flows smoothly. Therefore, the effect of electromagnetic stirring in the preparation process of foamed aluminum is improved.

Owner:NORTHEASTERN UNIV LIAONING

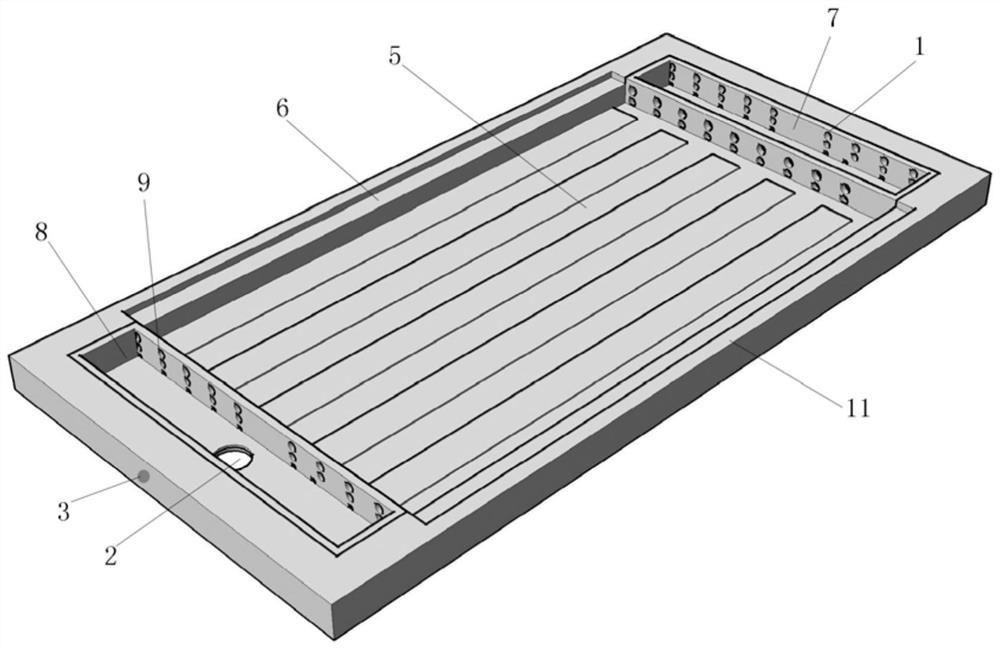

Soilless culture device with liquid levels capable of being adjusted

PendingCN111837927AImprove work efficiencyLow costAgriculture gas emission reductionCultivating equipmentsWater flowEnvironmental engineering

The invention relates to the field of plant culture devices, in particular to a soilless culture device with liquid levels capable of being adjusted. The soilless culture device with the liquid levelscapable of being adjusted comprises culture bed bodies, liquid supply devices and liquid discharge devices; and each culture bed body is in a concave shape as a whole, liquid-pouring grooves are formed in the bottoms of the culture bed bodies, both ends of the bottom of each culture bed body are provided with concave-shaped sedimentation tanks, liquid overflow openings and liquid outlets are formed in the culture bed bodies, the levels of the liquid overflow openings are higher than those of the liquid outlets, the liquid supply devices and the liquid discharge devices are placed in the culture bed bodies, water flow adjusting holes are formed in the liquid supply devices, liquid level adjusting holes / seams are formed in the liquid discharge devices, and through a synergistic effect of the liquid supply devices and the liquid discharge devices, the flow uniformity of liquid in culture beds is improved. The soilless culture device with the liquid levels capable of being adjusted is simple in structure, reasonable, simple and convenient to operate and wide in application range, the problem of uneven water quantities in the culture beds is solved, the flowing uniformity of the liquidin the culture beds is effectively improved, elimination of sediment of waste dregs is facilitated, and blocking of the liquid outlets is avoided.

Owner:FUJIAN SANAN SINO SCI PHOTOBIOTECH CO LTD

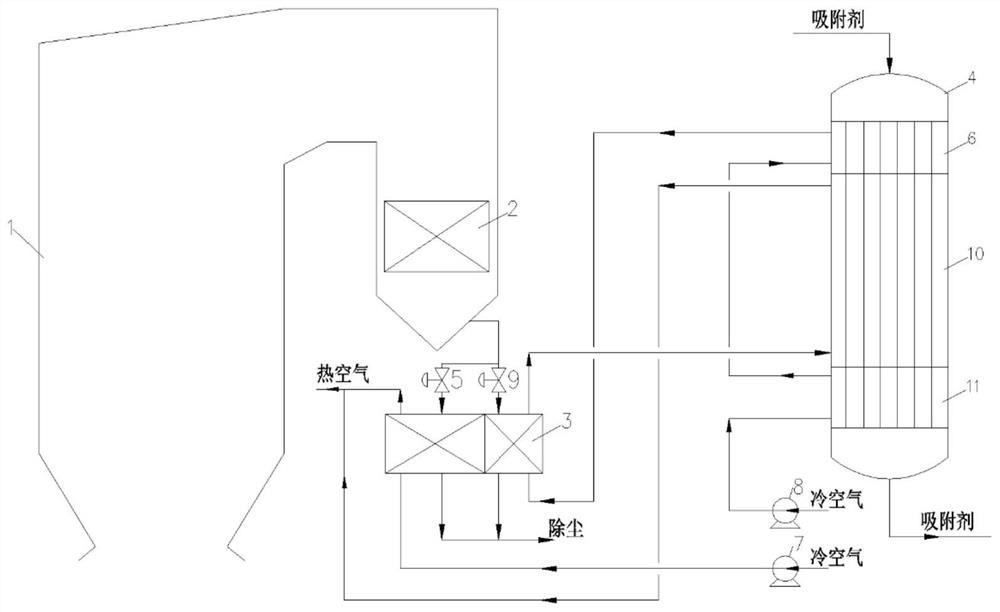

Regeneration system and method for synergistically removing multiple pollutants in flue gas

PendingCN112892511AReduce consumptionLow running costGas treatmentCombustion processAir preheaterCold air

The invention discloses a regeneration system and method for synergistically removing multiple pollutants in flue gas; after boiler flue gas passes through a primary economizer, one path of flue gas is connected to a flue gas inlet of a main area of an air preheater, and the other path of flue gas is connected to a flue gas inlet of a regeneration area; one path of cold air is connected to an air inlet of the main area through a main air blower, and the other path of cold air is connected to an air inlet of a cooling section through a regenerated air blower; an air outlet of the cooling section is connected to an air inlet of a preheating section, an air outlet of the preheating section is connected to an air inlet of the regeneration area, and an air outlet of the regeneration area of the air preheater is connected to an air inlet of a heating section; and the air outlet pipeline of the heating section and the hot air outlet pipeline of the main area are gathered and then enter a boiler. The flue gas at the tail of the boiler is used for heating air for regeneration treatment of an adsorbent, heat is recycled in a stepped mode, utilization is sufficient, the operation cost is reduced, a back flushing system does not need to be additionally arranged, and the initial investment of the device is reduced.

Owner:HUANENG CLEAN ENERGY RES INST +1

A new type of air conditioning device

The invention relates to a novel airflow adjusting device. The novel airflow adjusting device comprises a distributor shell and an air inlet pipe, an outer shell is arranged on the outer side of the distributor shell, a plurality of airflow outlets are formed in the peripheral surface of the distributor shell, the air inlet pipe is located in the middle of the outer shell, an annular guide grooveis formed in the side surface of the outer shell, a knob assembly is installed in the annular guide groove, an airflow adjusting baffle assembly is arranged in an inner cavity of the distributor shell, wherein the airflow adjusting baffle assembly comprises an airflow adjusting baffle and an arc-shaped baffle connected with the airflow adjusting baffle, and the end, far away from the arc-shaped baffle, of the airflow adjusting baffle is hinged to the air inlet pipe. A knob drives the airflow adjusting baffle to rotate in the inner cavity of the distributor shell, in the rotating process of theairflow adjusting baffle, the arc-shaped baffle rotates on the inner wall of the outer shell, so that the arc-shaped baffle blocks airflow of a part of the airflow outlets in the outer shell, then the airflow of the part of the blocked outlets is reduced, and the airflow of the part of unblocked outlets is increased, so that the aim of simply adjusting the airflow is achieved.

Owner:CHINA INST FOR RADIATION PROTECTION

Three Phase Flow Regulator

InactiveCN106040059BAdjust densityEasy to adjust the flowRotary stirring mixersTransportation and packagingThree-phaseEngineering

The invention relates to the technical field of coalbed methane exploitation, in particular to a three-phase flow regulator, comprising: a gas proportional valve, a liquid proportional valve, a base, a solid addition unit, a mixing unit and an outlet plug. A first channel, a second channel, a third channel and an inner cavity are opened in the base. The gas proportional valve communicates with the inner cavity through the first channel; the liquid proportional valve communicates with the inner cavity through the second channel; the outlet plug communicates with the inner cavity through the third channel; the solid addition unit is connected with one end of the inner cavity, and the mixing unit is set In the inner cavity, gas, liquid and powder are mixed by the mixing unit and then output through the outlet plug. The three-phase flow regulator provided by the present invention inputs gas, liquid and solid respectively through the gas proportional valve, liquid proportional valve and liquid proportional valve, so as to facilitate the regulation of the flow or concentration of gas, liquid and solid in the three-phase flow, and realize the control of the three-phase flow regulator. Accurate control of three-phase flow parameters.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

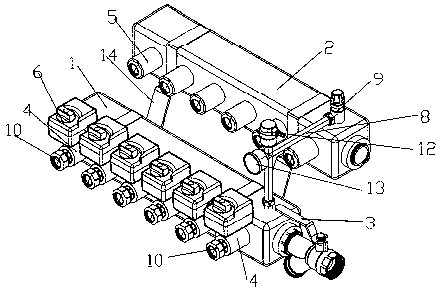

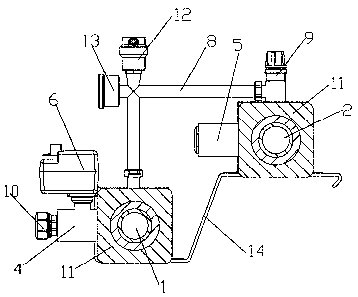

Water-circulating central air conditioner flow homogenizer

InactiveCN109838853AGuaranteed to open normallyEasy to open and closeMechanical apparatusLighting and heating apparatusAdjustable pressure limiting valveEngineering

The invention discloses a water-circulating central air conditioner flow homogenizer. The water-circulating central air conditioner flow homogenizer comprises a water supply cavity and a water returncavity, and a water inlet of the water supply cavity is provided with a manual valve; a set of water supply flow diversion channels are arranged on the water supply cavity, and a set of water return flow diversion channels in one-to-one correspondence with the water supply flow diversion channels are arranged on the water return cavity; each water supply flow diversion channel is provided with anelectric ball valve, and the electric ball valve is connected to a chamber controller; and a bypass flow stabilization pipe is arranged at the inlet end of the water supply cavity and the outlet end of the water return cavity, and an adjustable pressure limiting valve is arranged on the bypass flow stabilization pipe. According to the water-circulating central air conditioner flow homogenizer, theflow in each water supply flow diversion channel can be effectively adjusted, and constant-pressure heat supply and cold supply are guaranteed. The water-circulating central air conditioner flow homogenizer can be widely applied to the field of water-circulating central air conditioner pipeline installation.

Owner:南京大东机电设备有限公司

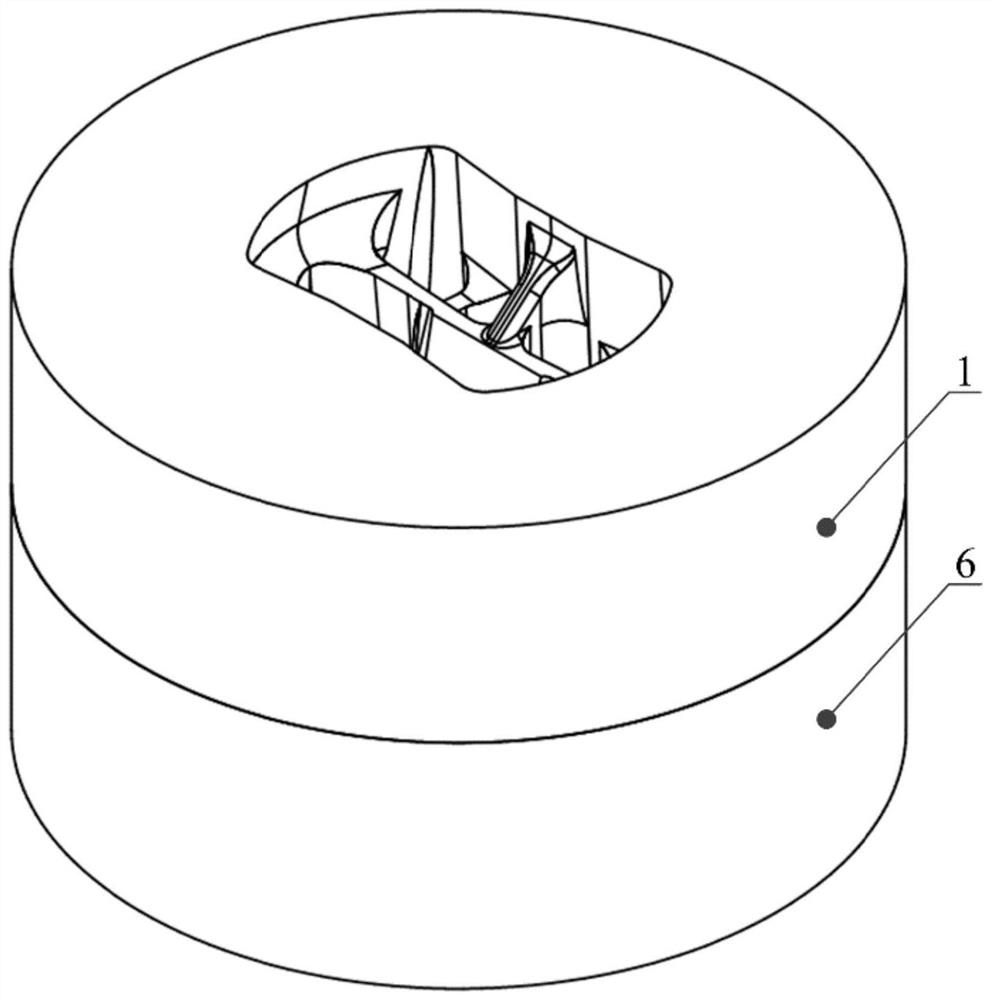

Rectifier of gas turbine

ActiveCN107620980AIncrease the effective areaEasy to adjust the flowContinuous combustion chamberEngineeringGas turbines

The invention discloses a rectifier of a gas turbine. The rectifier comprises a sleeve cover, an end plate and a flow guide cylinder; the sleeve cover is provided with a first end and a second end, and air inlet groove holes are formed in the sleeve cover; the end plate is provided with a center hole, the end plate is installed at the first end of the sleeve cover, an imaginary column body is formed by extending the center hole in the direction towards the second end of the sleeve cover, and an annular channel is formed between the sleeve cover and the column body; and a plurality of holes areformed in the flow guide cylinder, the flow guide cylinder is located in the annular channel, and the flow guide cylinder is arranged on the column body in a sleeving mode and is separated from the column body and the sleeve cover. According to the rectifier of the gas turbine, the effective area is large, air uniformity can be conveniently adjusted so that loss of air flow can be reduced, and overall performance of the whole gas turbine can be improved.

Owner:CHINA UNITED GAS TURBINE TECH CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com