Universal compact type forged steel self-sealing stop valve

A self-sealing and compact technology, used in shaft seals, lift valves, valve details, etc., can solve problems such as affecting sealing performance, increasing costs, and increasing product costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

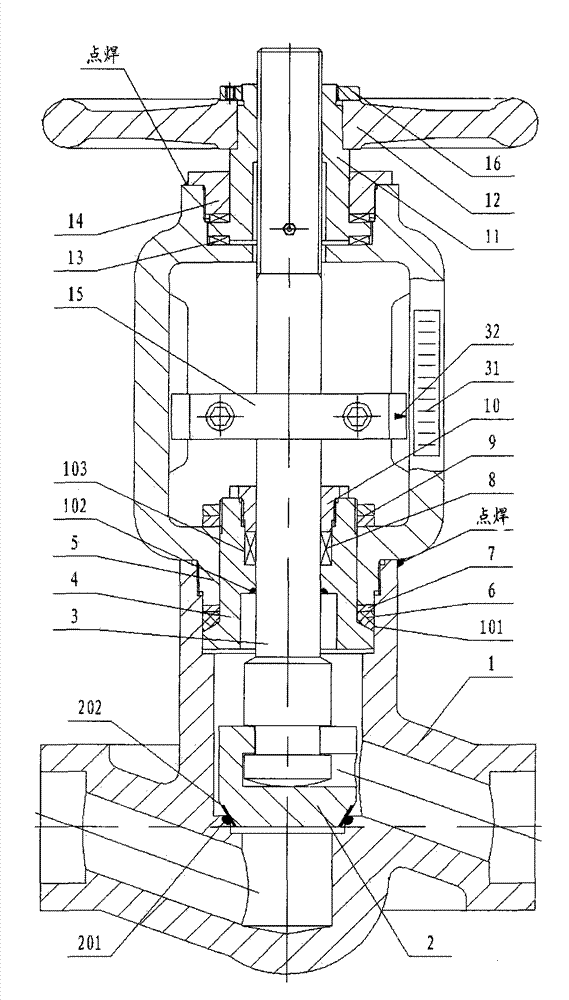

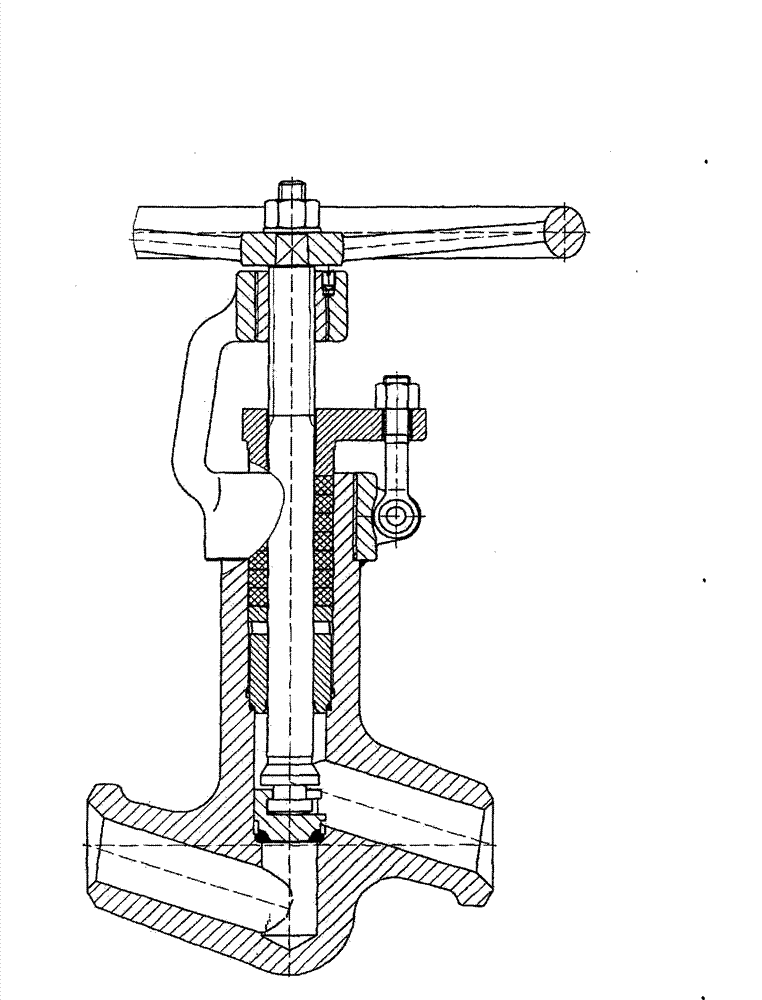

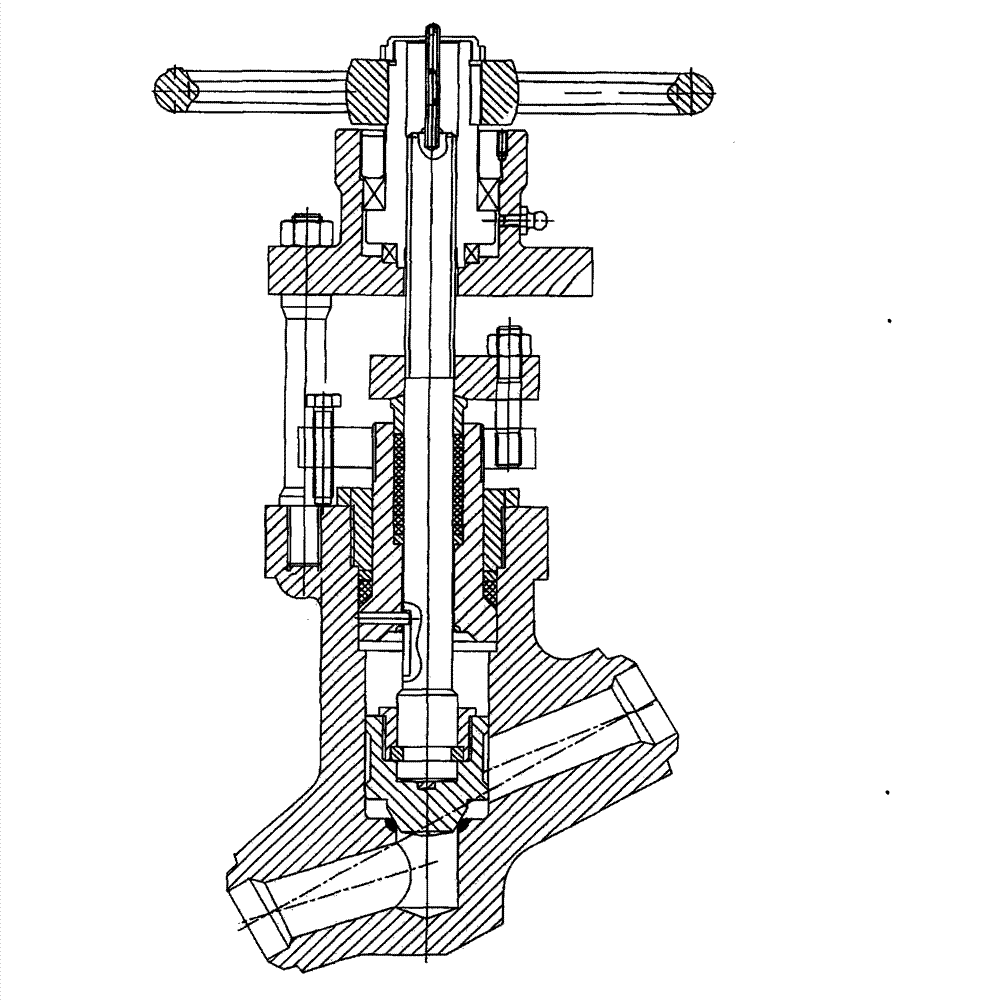

[0012] like figure 1 The universal compact forged steel self-sealing globe valve shown includes valve body 1, valve disc 2, valve stem 3, stuffing box 4, valve cover 5, wedge-shaped sealing ring 6, adjusting pad 7, packing 8, and adjusting nut 9 , Packing gland 10, stem nut 11, hand wheel 12, plane needle roller bearing 13, bracket gland 14, clip row assembly 15, lock nut 16 and other components. The valve disc 2 is fixedly connected with the lower end of the valve stem 3, the upper end of the valve stem 3 passes through the stuffing box 4 and the valve cover 5, and a plane needle bearing 13 is placed on the top and bottom of the valve stem nut 11, and then put into the upper groove of the valve cover 5, and then connected with the The valve stem 11 is connected, and the bracket gland 14 is threadedly connected with the groove of the valve cover 5. The upper end of the valve stem nut 11 is connected with the hand wheel 12. The hand wheel 12 has a lock nut 16 and the upper end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com