Micro-channel pipe forming die and method

A forming die and micro-channel technology, applied in the direction of metal extrusion dies, etc., can solve problems such as billet flow imbalance, poor forming quality, and volume reduction, and achieve the goal of reducing material flow resistance, reducing die stress, and increasing feeding speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

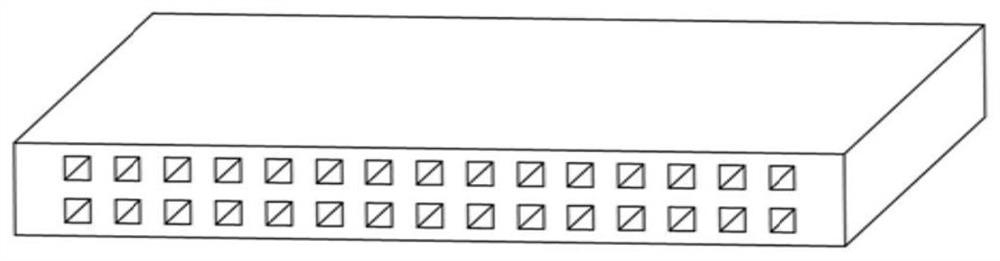

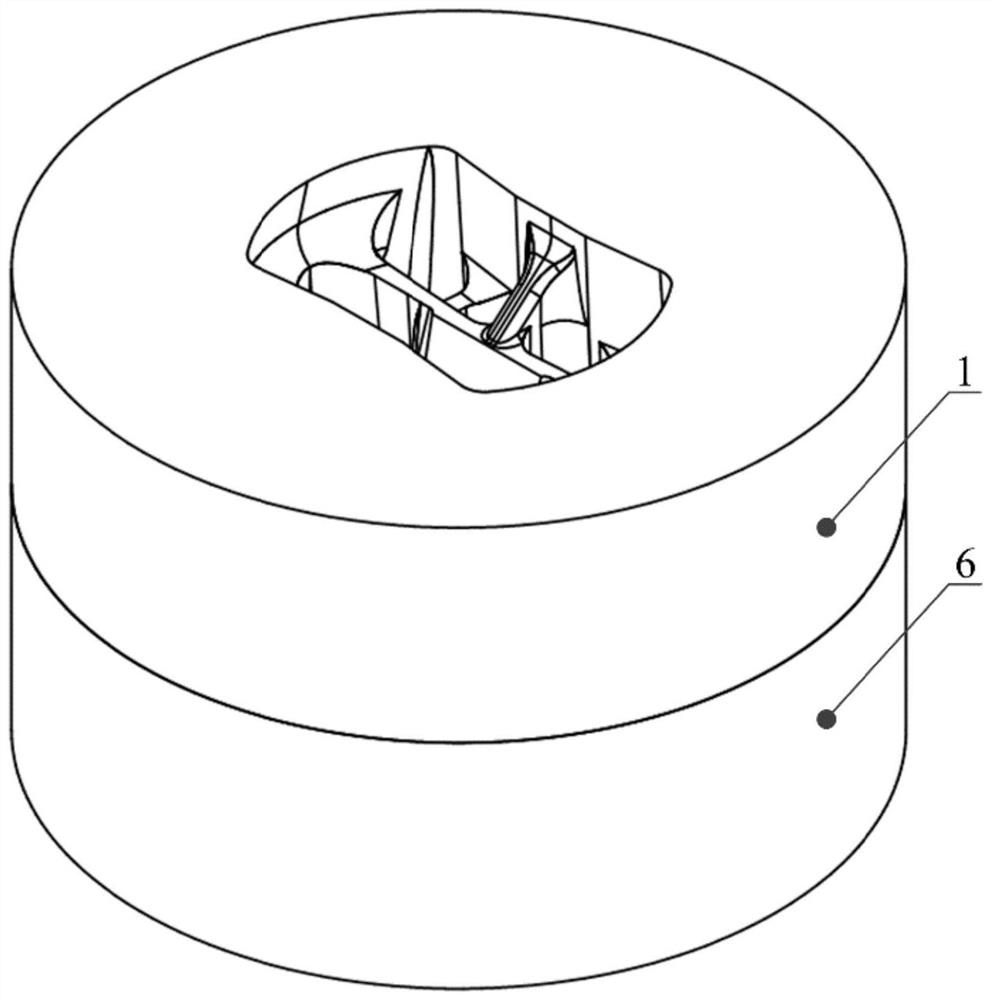

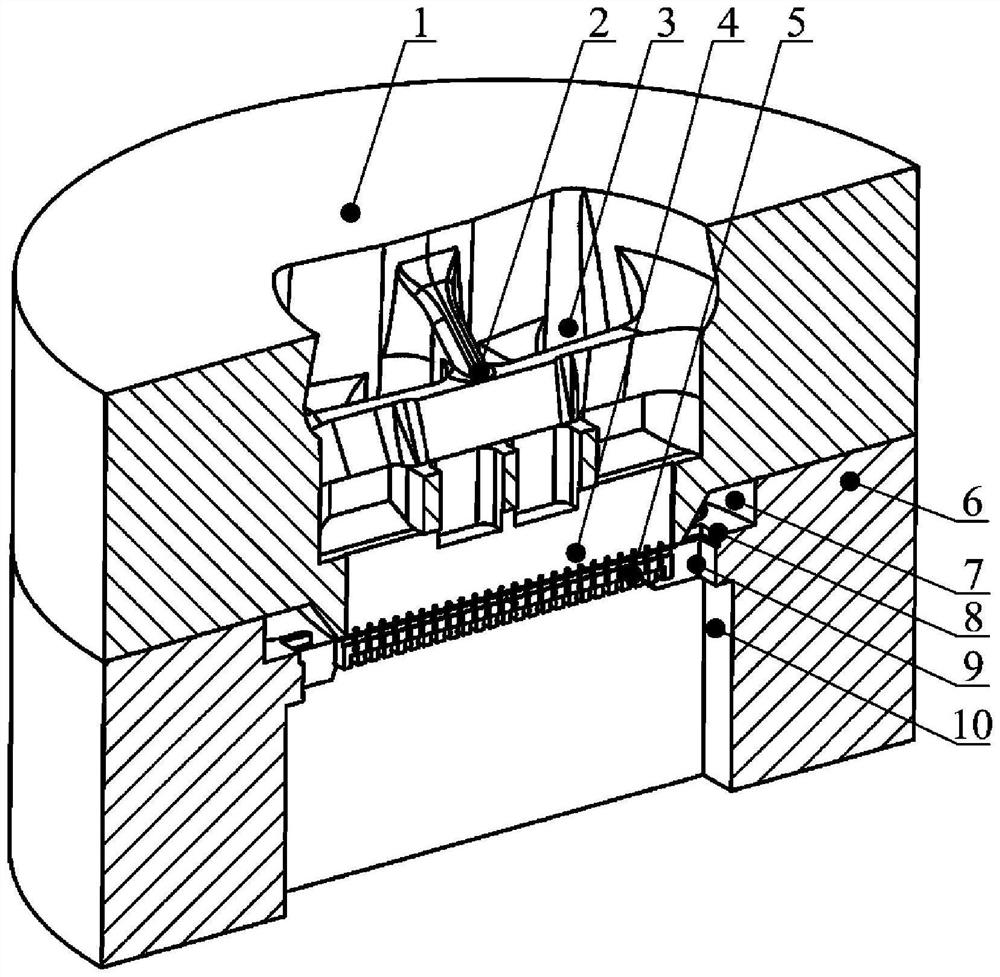

[0040] In a typical embodiment of the present invention, such as Figure 2 to Figure 12 As shown, a microchannel tube forming die is given.

[0041] like figure 2 The microchannel tube forming die shown is used for extrusion forming of microchannel tubes, especially for extrusion forming of multi-row microchannel flat tubes in the refrigeration system, through the shunt channel 3 and welding chamber 7 through which the material flows. And the structural setting of the forming channel 9 solves the problems of high mold stress and unbalanced billet flow in the extrusion forming process of multi-row microchannel flat tubes, thereby achieving the effect of improving the quality of the workpiece and prolonging the life of the mold. The microchannel tube forming mold mainly includes a mold body, and the mold body can be an integrated mold, or can be such as figure 2 , image 3 The split mold shown in , can adopt the form of cooperation of the upper mold 1 and the lower mold 6; ...

Embodiment 2

[0064] In another typical embodiment of the present invention, such as Figure 2 to Figure 12 As shown, a microchannel tube forming method is provided, utilizing the microchannel tube forming die as in Example 1.

[0065] The microchannel tube forming method comprises the following steps:

[0066] Throw the blank into the feed channel and form multiple strands of material under the action of the split channel 3;

[0067] Part of the material enters the gap of the sub-mold core through the inner wall channel to form the inner wall of the workpiece; part of the blank is distributed around the mold core 5 through the outer wall channel to form the outer wall of the workpiece;

[0068] The inner wall of the workpiece and the outer wall of the workpiece are contact welded in the welding chamber 7, and the welded microchannel tube workpiece is output through the forming channel 9.

[0069] The set mold core neck 4 is combined with the welding chamber 7 to form an outer wall channe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com