An Easy-to-Remove Formwork Supporting Method of Deformation Seam

A formwork support method and deformation joint technology, applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of affecting the construction period, hidden quality, and difficult to guarantee the structural size, so as to ensure the construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

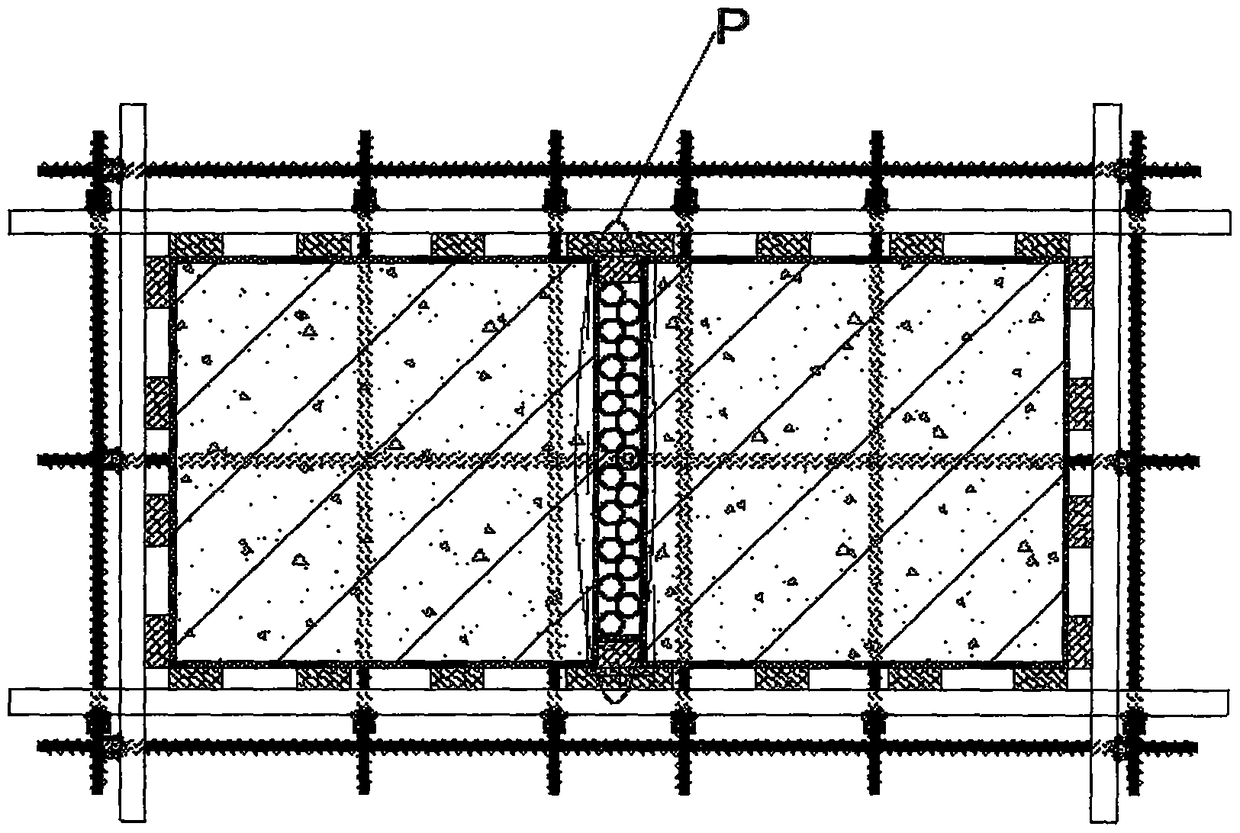

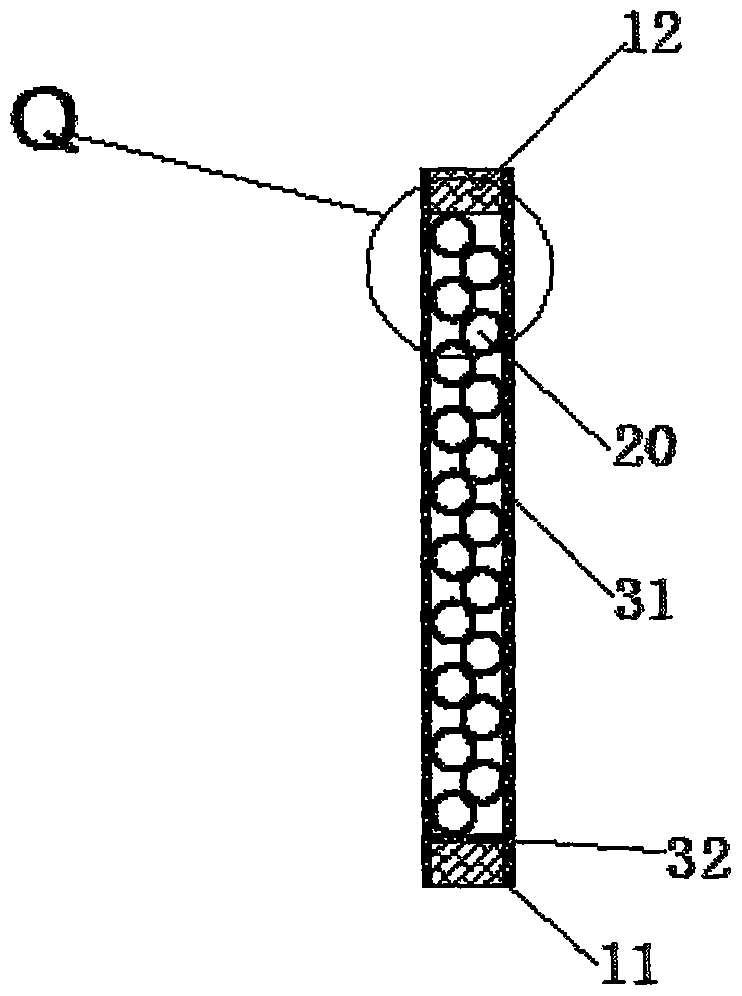

[0036] Such as Figure 1~3 As shown, an easy-to-remove deformation joint formwork method includes the following steps:

[0037] (1), install the first wood plywood 31 with thickness of 10mm respectively on both sides of the deformation joint;

[0038] (2), laying the first wooden side 11 with a thickness of 50mm at the bottom of the deformation joint;

[0039] (3), put into the scaffolding pipe 20 in the deformation seam successively, until the scaffolding pipe 20 is apart from the upper surface 80mm, the outer diameter of the scaffolding pipe 20 is 60% of the deformation seam gap,

[0040] (4), then a second wooden side 12 is set above the scaffolding pipe 20, and the height of the second wooden side is 80mm.

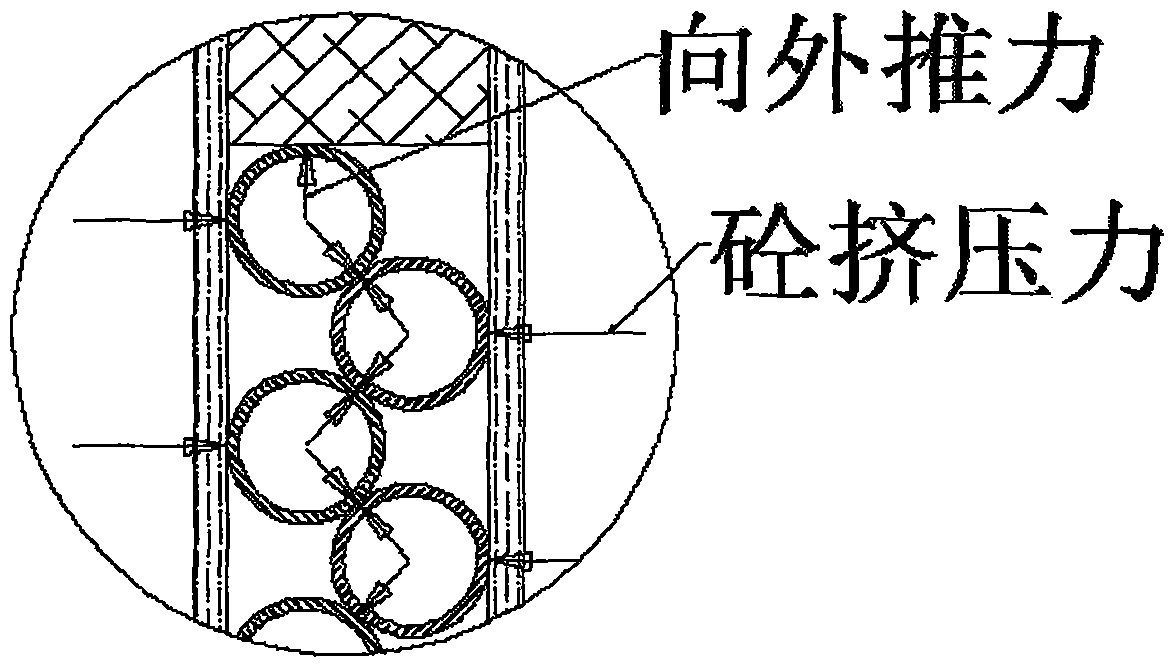

[0041] Further, when under pressure, there is an oblique thrust between adjacent scaffolding tubes 20, and the angle between the oblique thrust is 40°.

[0042] Further, in step (2), a second wood veneer 32 is provided on the upper surface of the first wooden cube 1...

specific Embodiment 2

[0043] An easy-to-remove deformation joint formwork method, comprising the following steps:

[0044] (1), install thickness respectively on the both sides of deformation joint and be the first wood plywood 31 of 12mm;

[0045] (2), laying the first wooden side 11 with a thickness of 50mm at the bottom of the deformation joint;

[0046] (3), put into the scaffolding pipe 20 in the deformation seam successively, until the scaffolding pipe 20 is apart from the upper surface 100mm, the outer diameter of the scaffolding pipe 20 is 55% of the deformation seam gap,

[0047] (4), then set the second wooden side 12 above the scaffold pipe 20, the height of the second wooden side 12 is 100mm.

[0048] Further, when under pressure, there is an oblique thrust between adjacent scaffolding tubes 20, and the angle between the oblique thrust is 50°.

[0049] Further, in step (2), a second wood veneer 32 is also provided on the upper surface of the first wooden cube 11 . The height of the s...

specific Embodiment 3

[0050] An easy-to-remove deformation joint formwork method, comprising the following steps:

[0051] (1), the thickness is respectively installed on both sides of the deformation joint and is the first wood plywood 31 of 11mm;

[0052] (2), laying the first wooden side 11 with a thickness of 50mm at the bottom of the deformation joint;

[0053] (3), put into the scaffolding pipe 20 in the deformation seam successively, until the scaffolding pipe 20 is apart from the upper surface 50mm, the outer diameter of the scaffolding pipe 20 is 65% of the deformation seam gap,

[0054] (4), then the second wooden side 12 is set on the top of the scaffold pipe 20, and the height of the second wooden side 12 is 50mm.

[0055] Further, when under pressure, there is an oblique thrust between adjacent scaffolding tubes 20, and the included angle of the oblique thrust is 45°.

[0056] Further, in step (2), a second wood veneer 32 is also provided on the upper surface of the first wooden cube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com