Welding plant for section-variable aluminum alloy long pipe fittings

A welding device and variable section technology, applied in welding equipment, arc welding equipment, metal processing equipment, etc., can solve the problems of incomplete penetration, failure of welded structural parts, failure of welded joints, etc., to reduce repair rate and scrap rate, Guarantee the effect of product structure size and improve product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

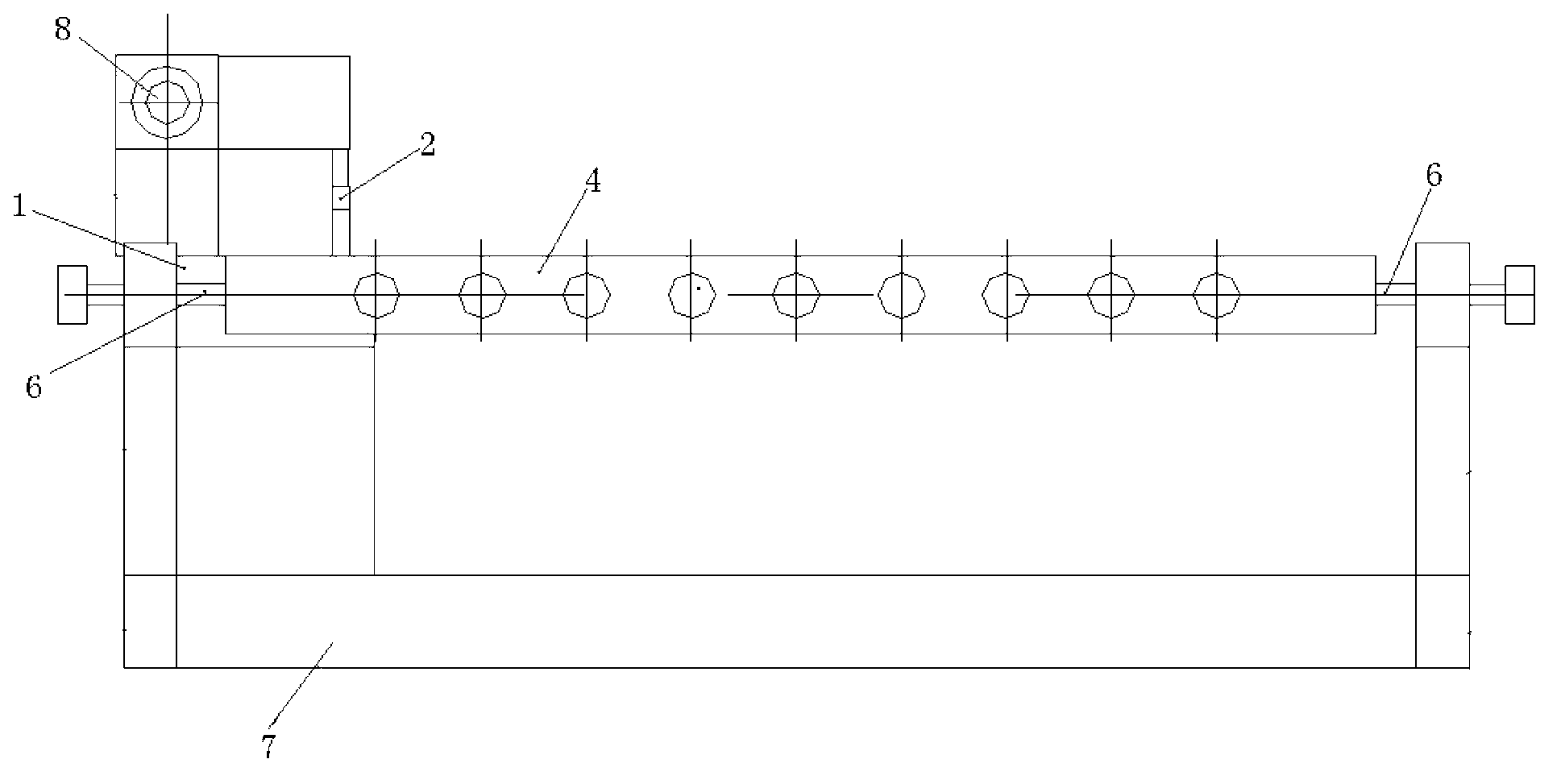

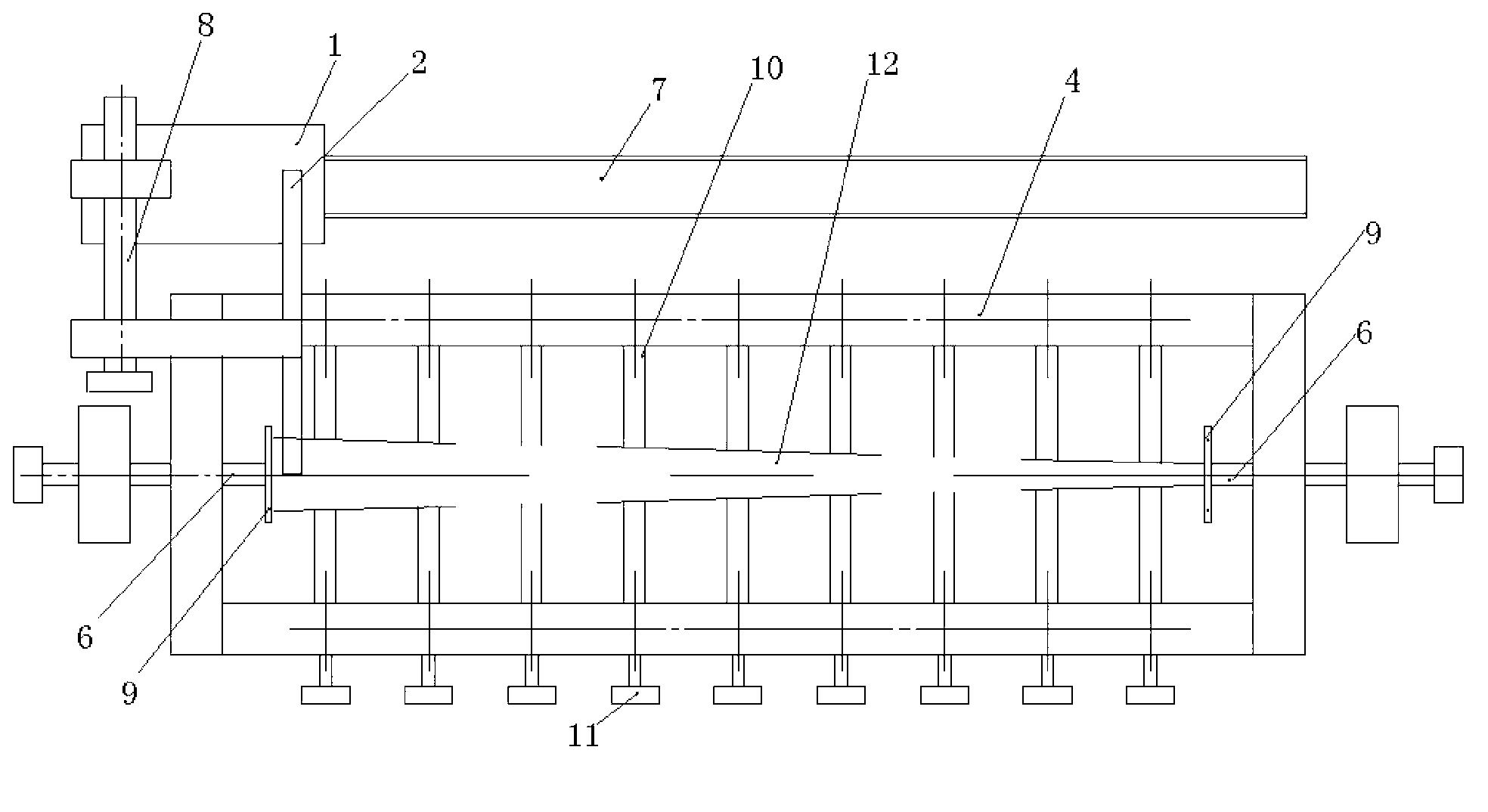

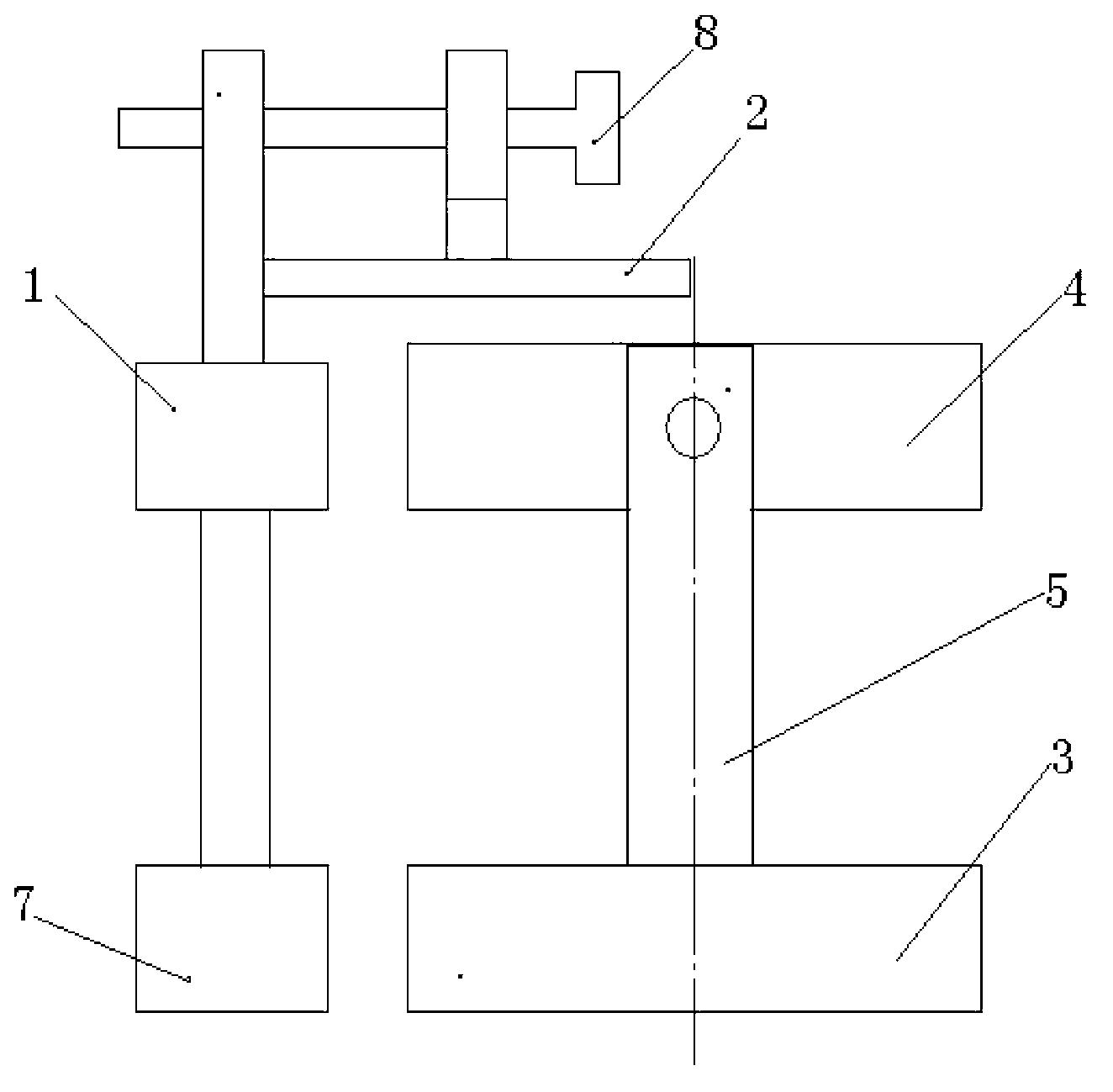

[0023] Such as Figure 4 , Figure 5 As shown, the variable cross-section aluminum alloy long pipe fittings (hereinafter referred to as pipe fittings) are longer in size (2050mm), the maximum section width of the pipe fittings is 45.5mm, the minimum section width is 18.5mm, and the pipe wall is thinner (2.5mm); pipe fittings group butt welding After the completion, the straightness of the weld seam is required to be no more than 0.5mm, and both sides of the pipe fittings need to be welded, and the weld seams on both sides are required to realize single-sided welding and double-sided forming.

[0024] According to the above requirements, a rotary welding device is designed and manufactured. This device ensures the product structure size and joint welding quality, reduces the deformation of variable-section pipe fittings, and realizes double-sided welding of pipe fittings in one clamping. When using a welding trolley to complete variable-section pipe fittings After welding on o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com