Narrow gap laser welding protective method and narrow gap laser welding protective device

A laser welding and protection device technology, which is applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of irreparable, increased welding instability, welding, and dust accumulation, so as to avoid welding defects and facilitate application Promote and improve the effect of shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

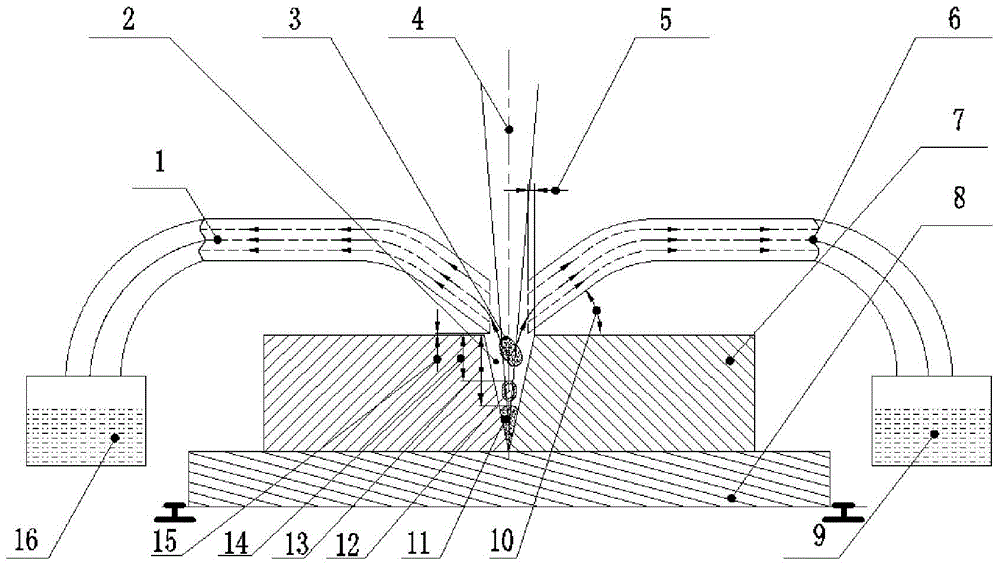

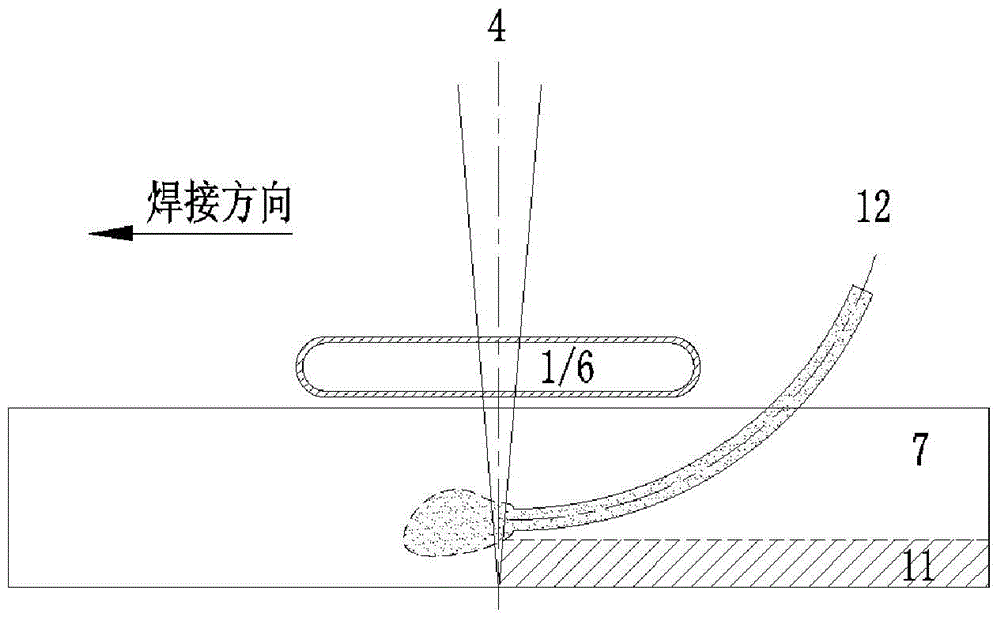

[0039] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

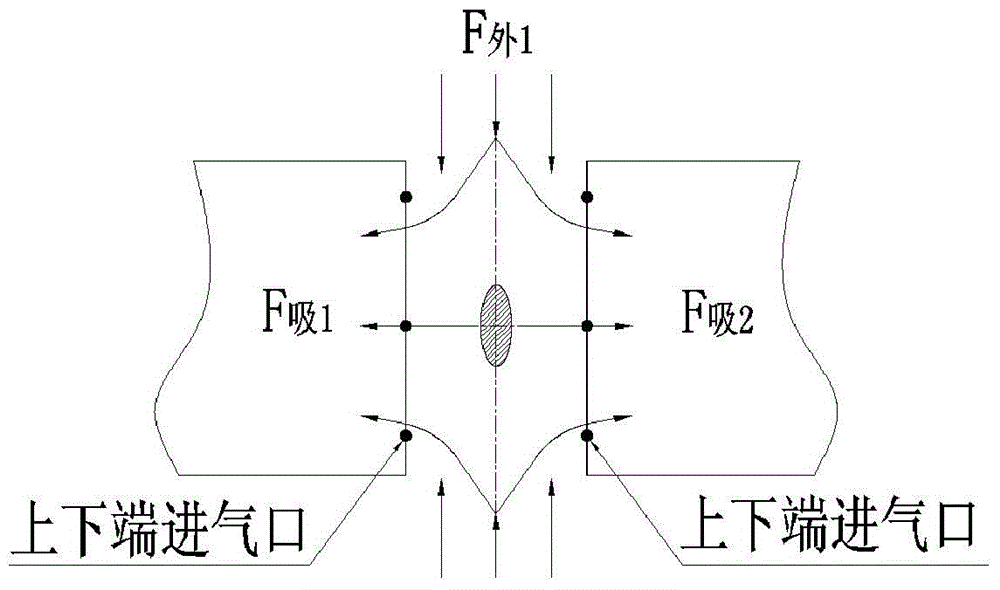

[0040] The inventors have found that when narrow-gap laser welding is implemented in the prior art, due to the ultra-narrow feature of the weld, the smoke and dust generated during the welding process will gather on the side wall of the weld tank; the erupted plasma air mass will strongly absorb the laser energy, limiting The laser energy enters the welding part, thereby shielding the laser energy. Under the action of the two, the welding depth will not be too large, and it is difficult to obtain a good weld seam. And if during the welding process, the shielding gas is blown into the narrow wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com