Pilot-operated one-way sequence valve

A one-way sequence valve, pilot valve technology, applied in valve details, control valves, valve devices and other directions, can solve problems such as unfavorable maintenance, troublesome procedures, inconvenient use, etc., to facilitate control of liquid flow and pressure adjustment, and reasonable location and installation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

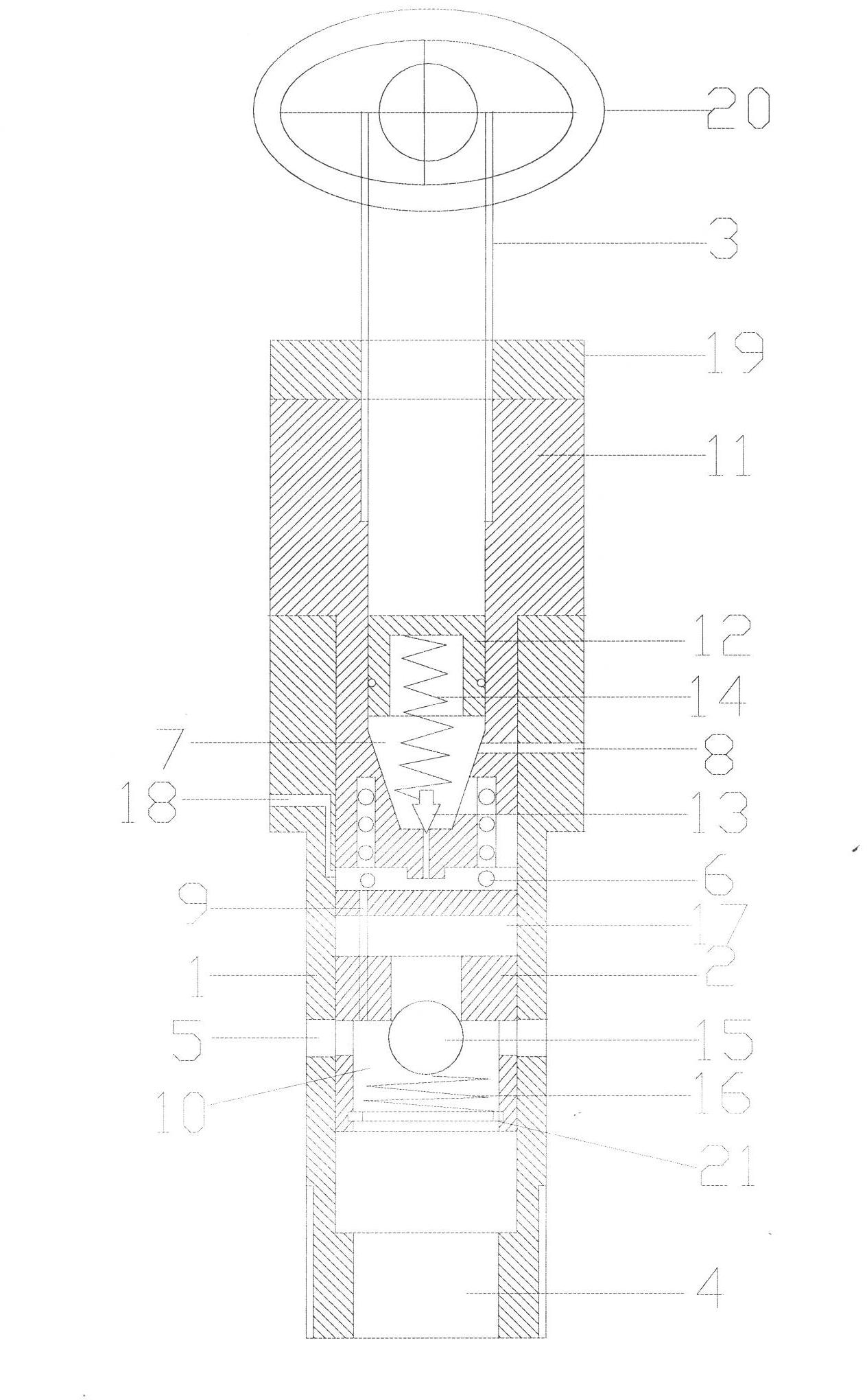

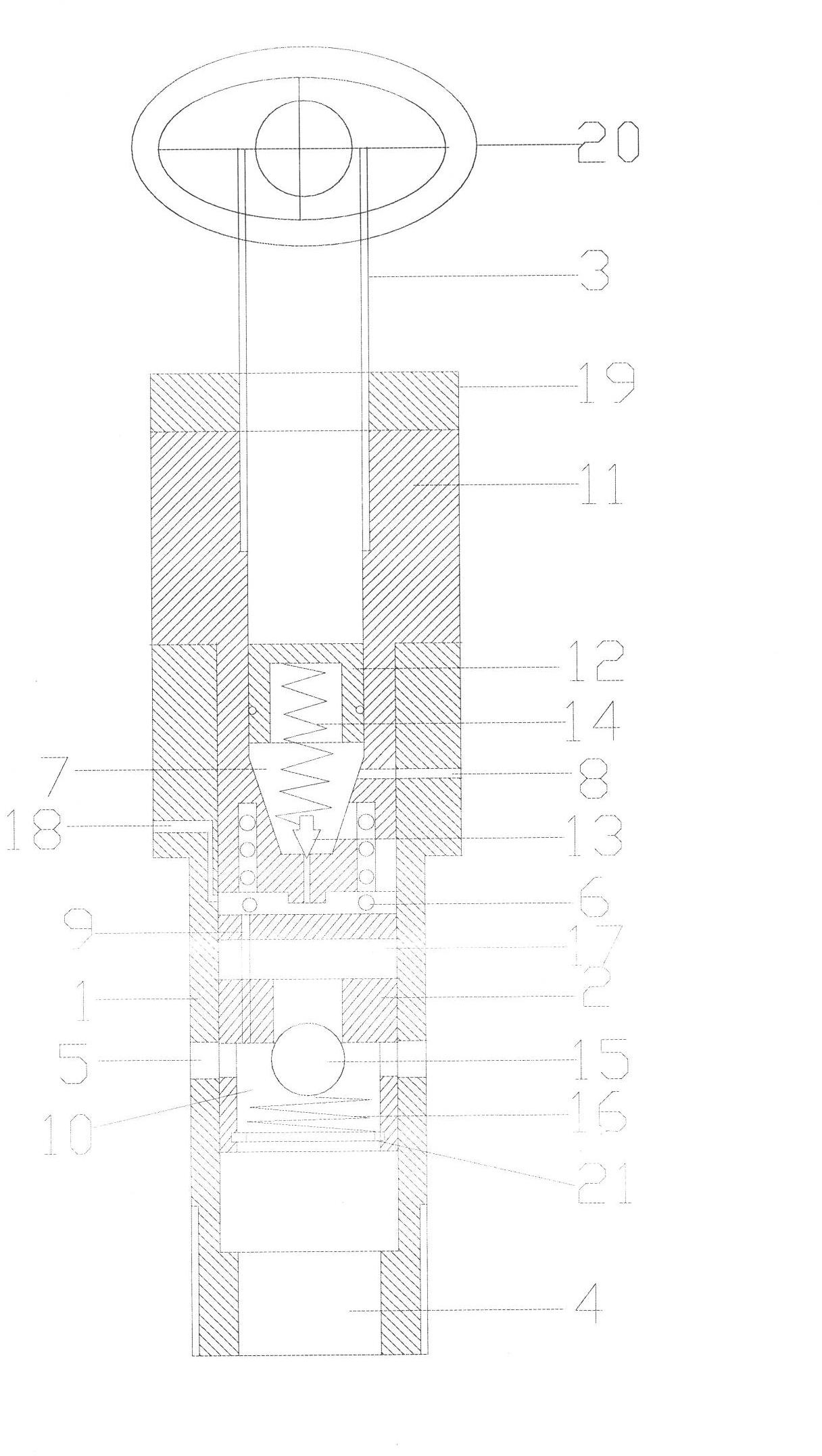

[0016] As shown in the figure, the pilot-operated one-way sequence valve of the present invention includes a valve body 1, a main valve core 2, a pilot valve and an adjusting rod 3, and the valve body 1 is provided with a liquid inlet 4 and a liquid outlet 5 , the main valve core 2, the pilot valve and the regulating rod 3 are arranged in the valve body 1; the outer diameter of the upper end of the valve body 1 (generally an outer hexagon) is greater than the outer diameter of the part below the head, so The part below the head of the valve body 1 is provided with an external thread, the valve body 1 penetrates up and down, the opening at the lower end of the valve body 1 is a liquid inlet 4, and the liquid outlet 5 is arranged on the part below the head of the valve body 1. On the valve wall, a return spring 6 is connected between the pilot va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com