Dispensing method and system capable of controlling viscosity of photosensitive adhesives

An intelligent control system and photosensitive adhesive technology, which can be used in devices for coating liquid on surfaces, pretreatment surfaces, coatings, etc., which can solve problems such as the limitations of dispensing equipment and laminating equipment, low viscosity of water glue, and helplessness. , to achieve the effect of improving molding efficiency and product quality, simplifying equipment and process routes, and expanding molding processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

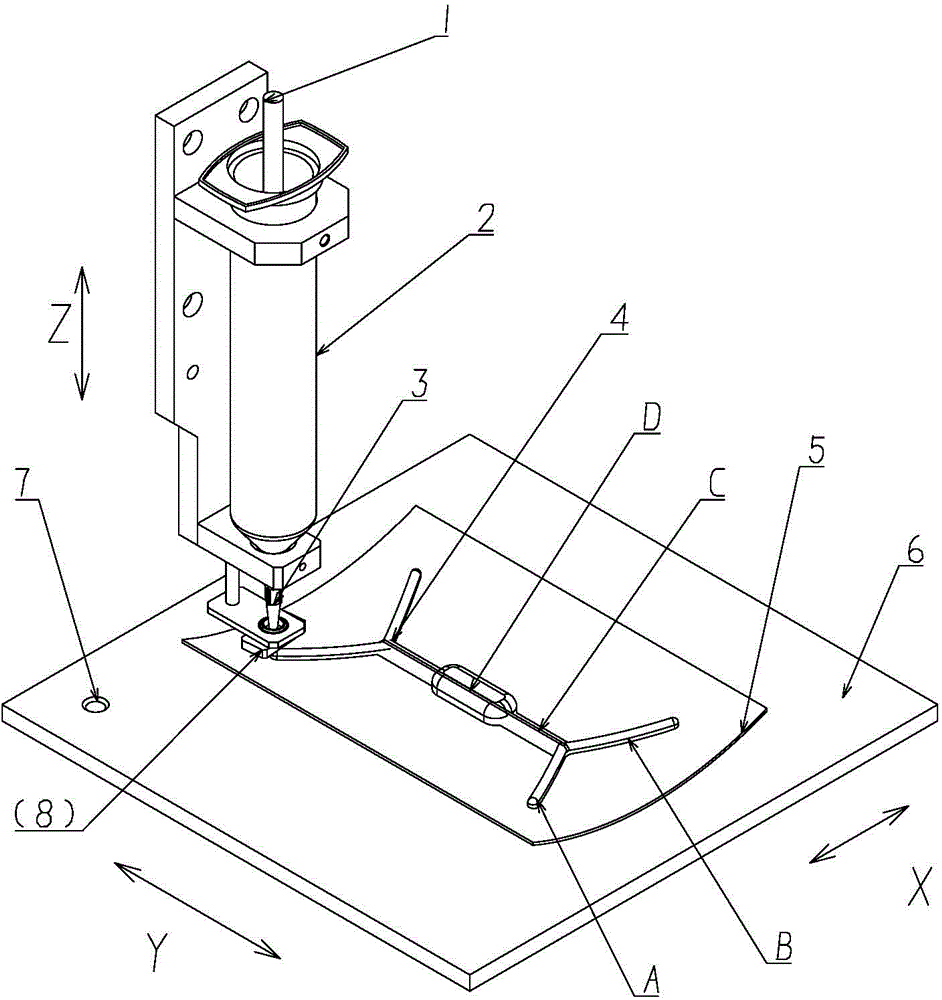

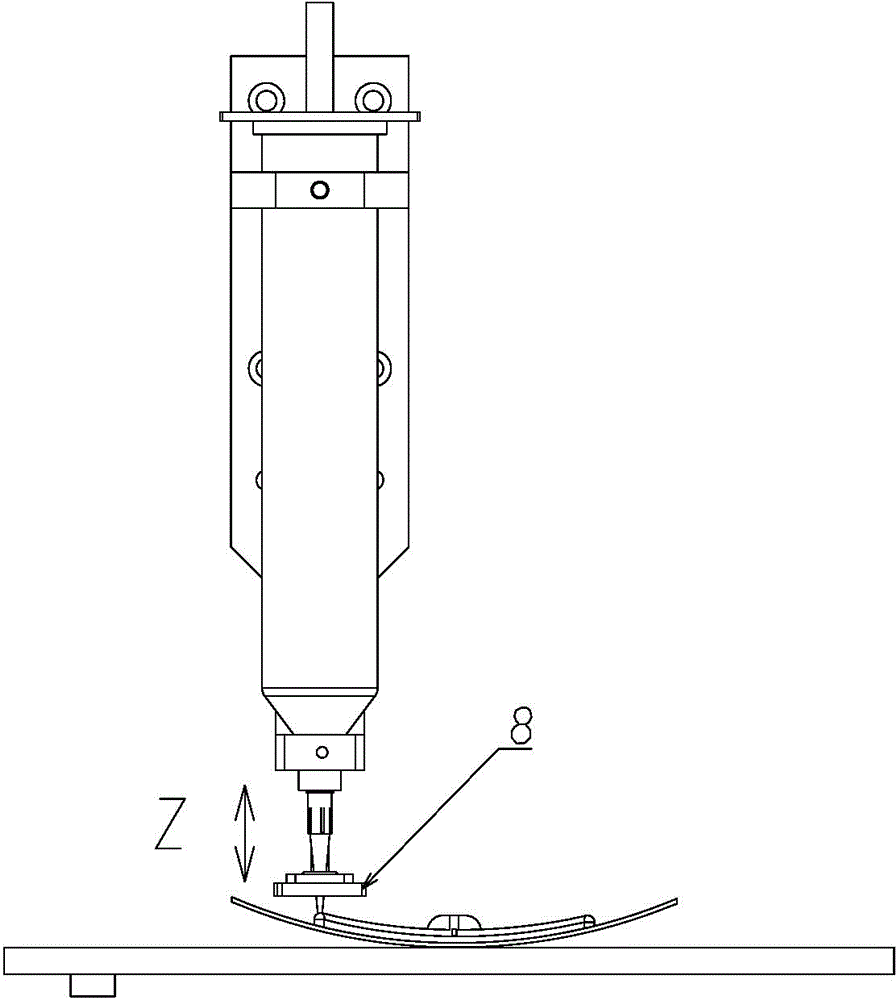

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

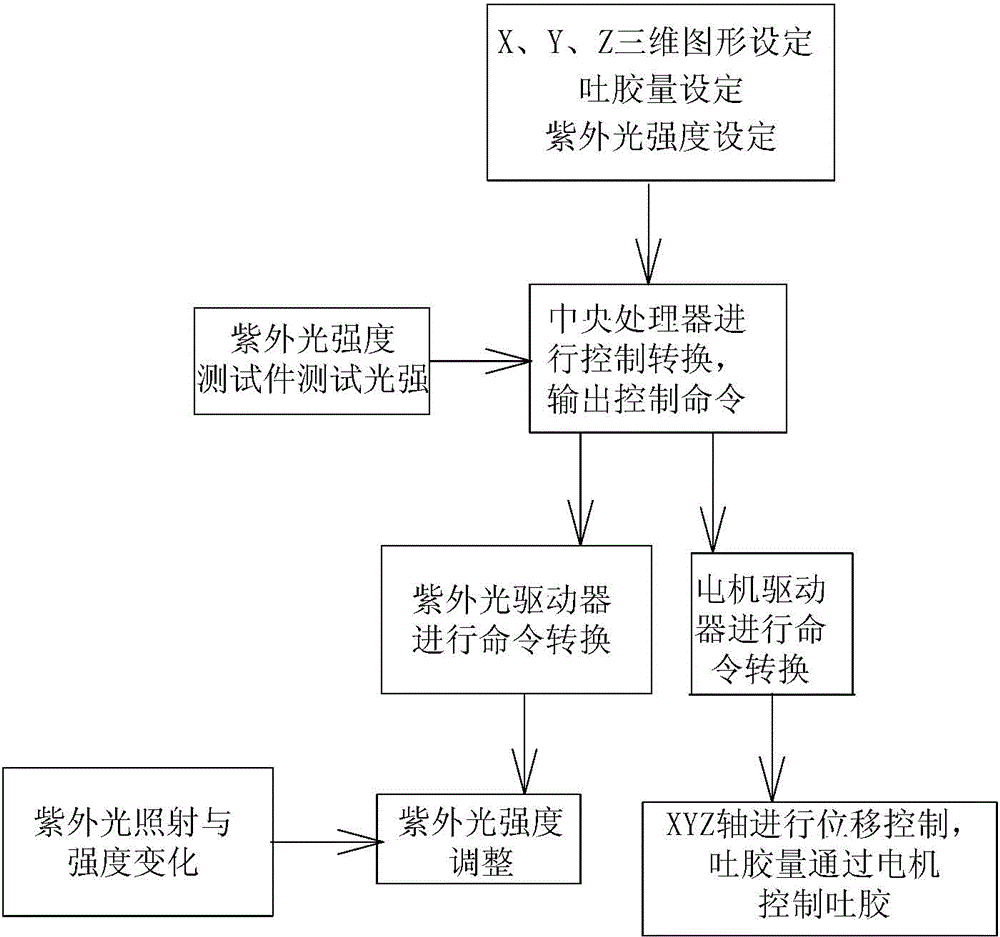

[0033] The present invention proposes a glue dispensing method for controlling the viscosity of photosensitive adhesive. And the dispensing process of the curved screen body. The difference between the present invention and the dispensing method in the prior art is that the dispensing method provided by the present invention changes the viscosity of the photosensitive adhesive by controlling the intensity of ultraviolet light, so that the photosensitive adhesive is in a semi-crosslinked state, and can adjust the photosensitive adhesive in real time. At the same time, the dispensing machine can also be driven by the displacement controller to perform three-dimensional displacement ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com