Patents

Literature

247results about How to "Reasonable installation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

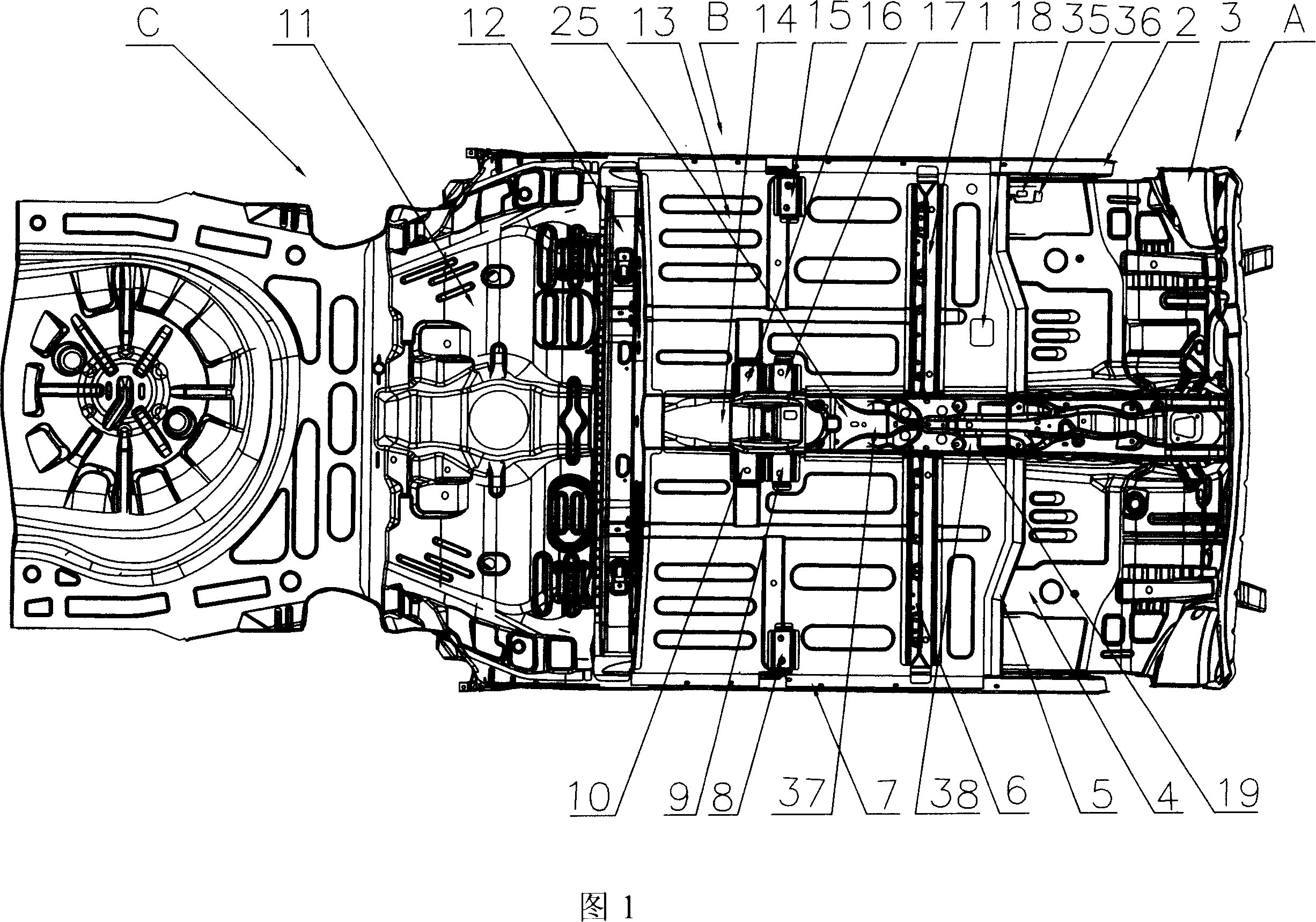

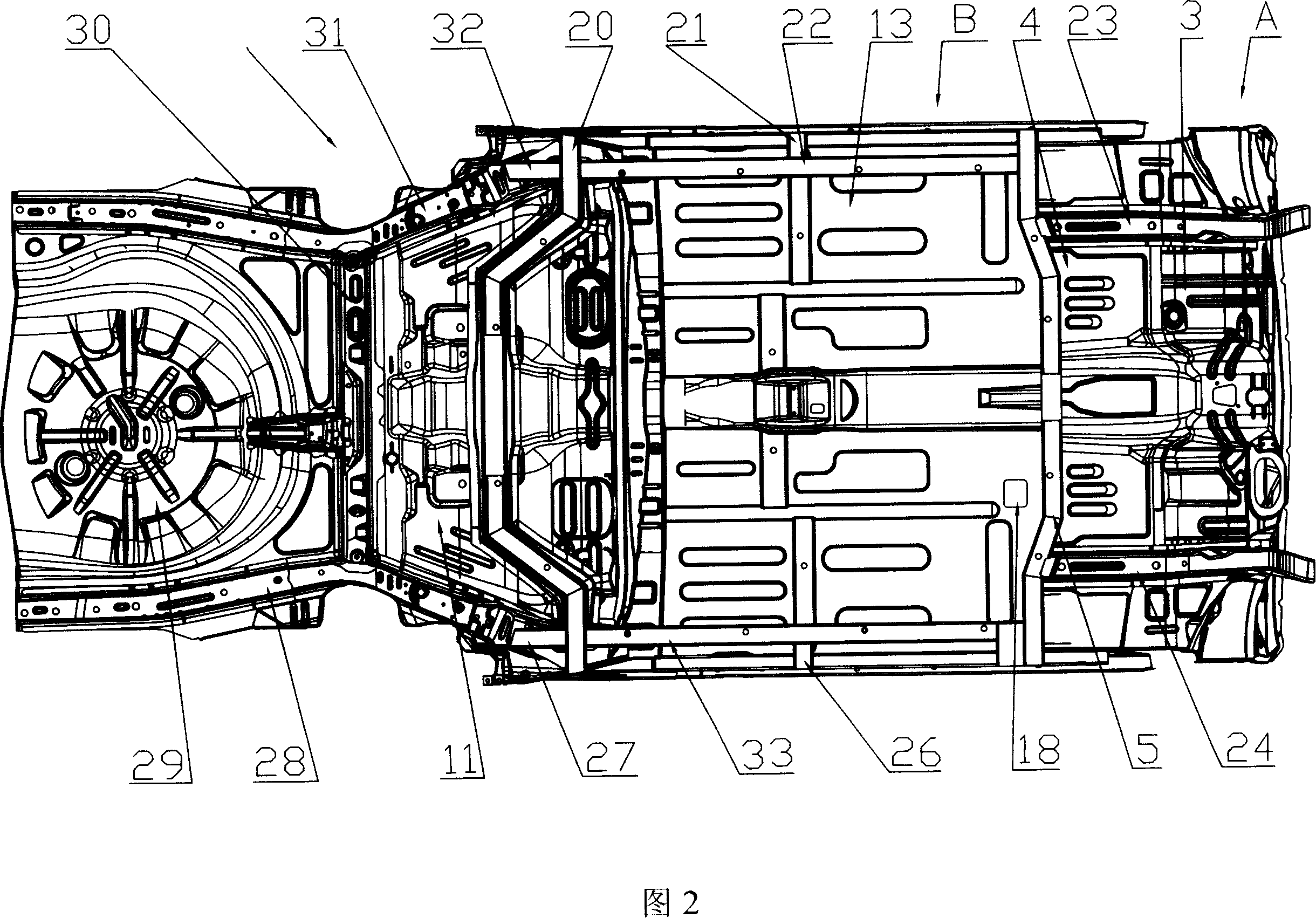

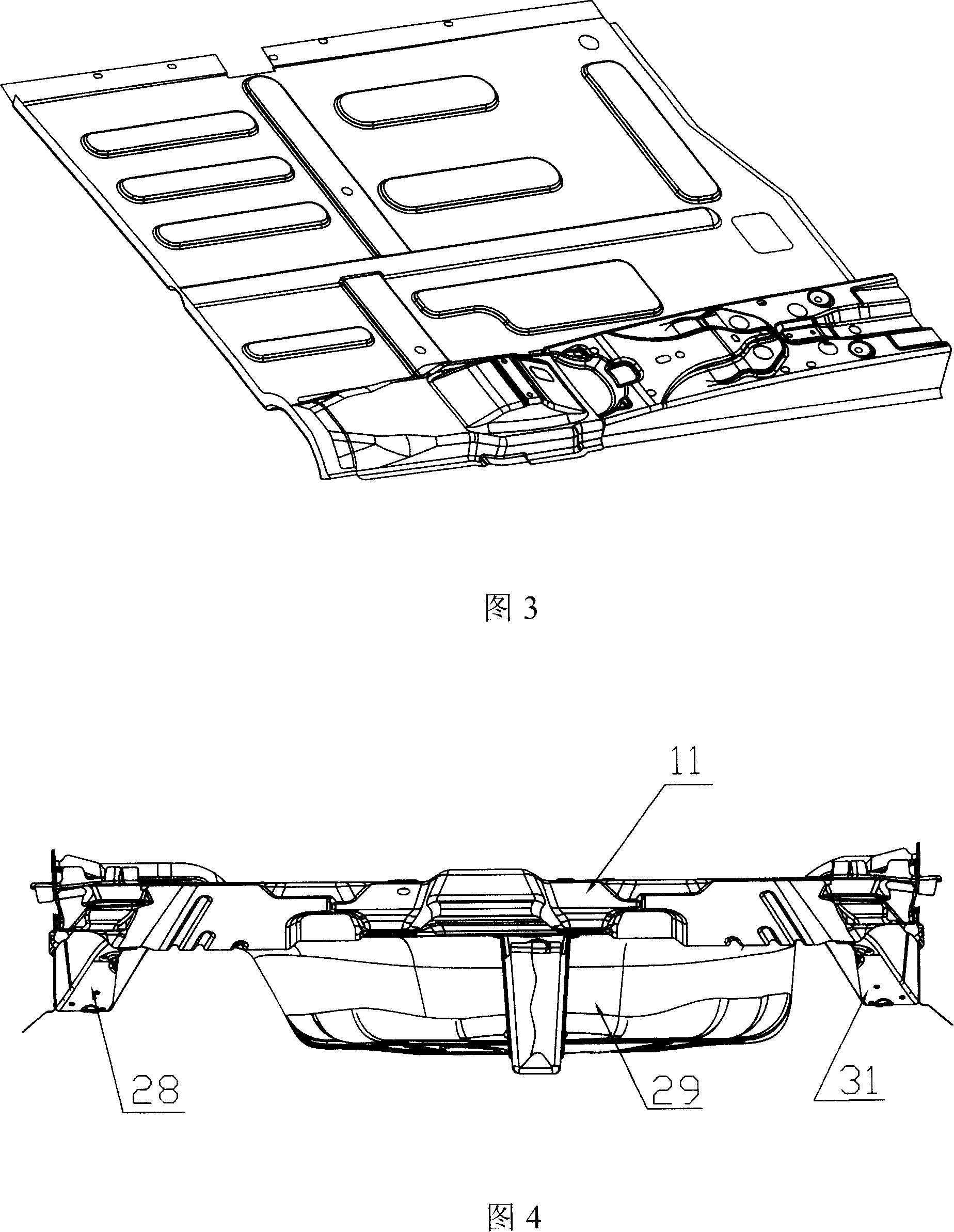

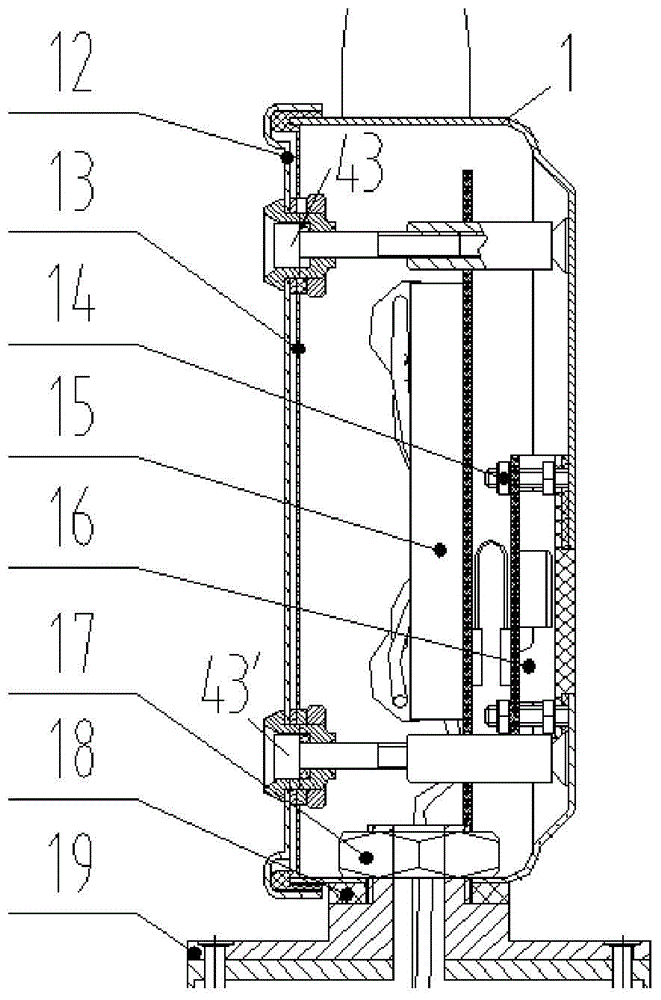

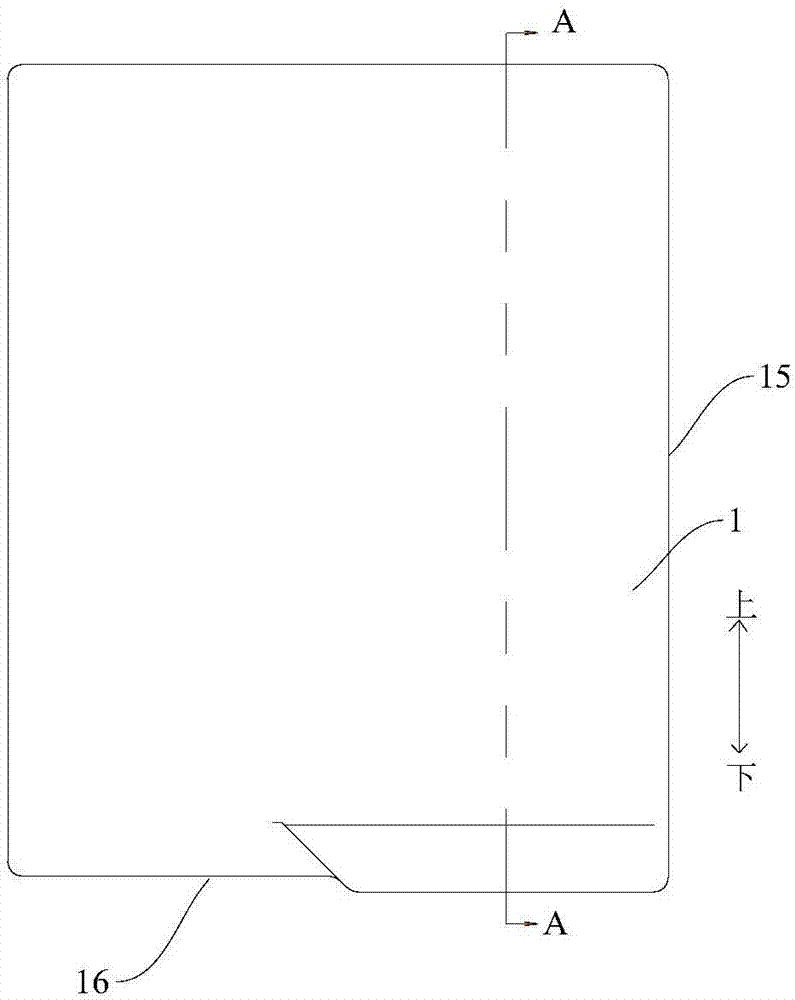

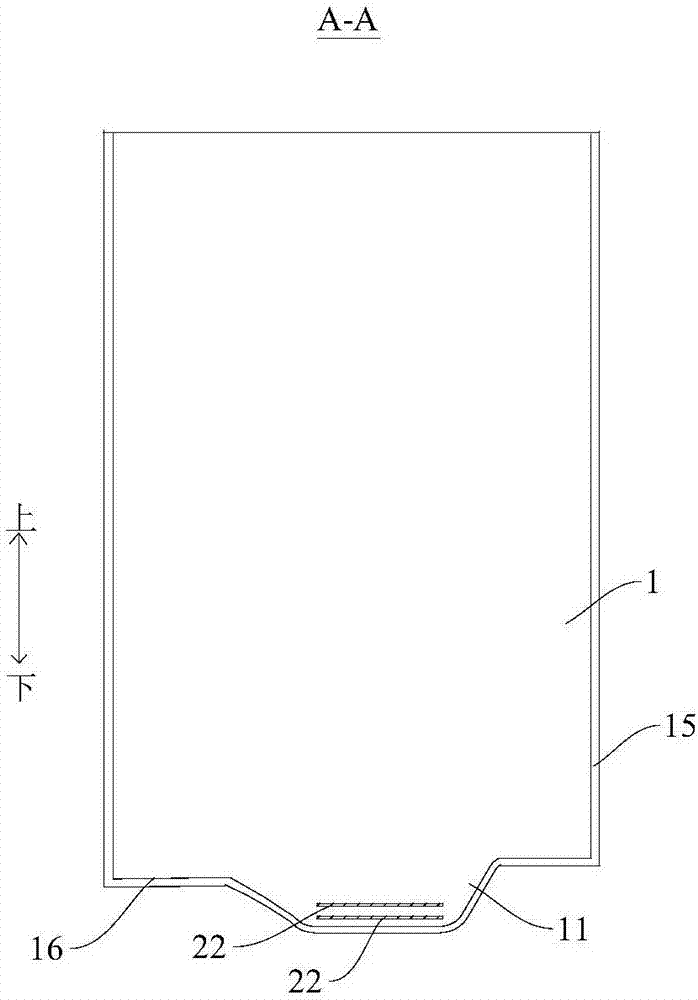

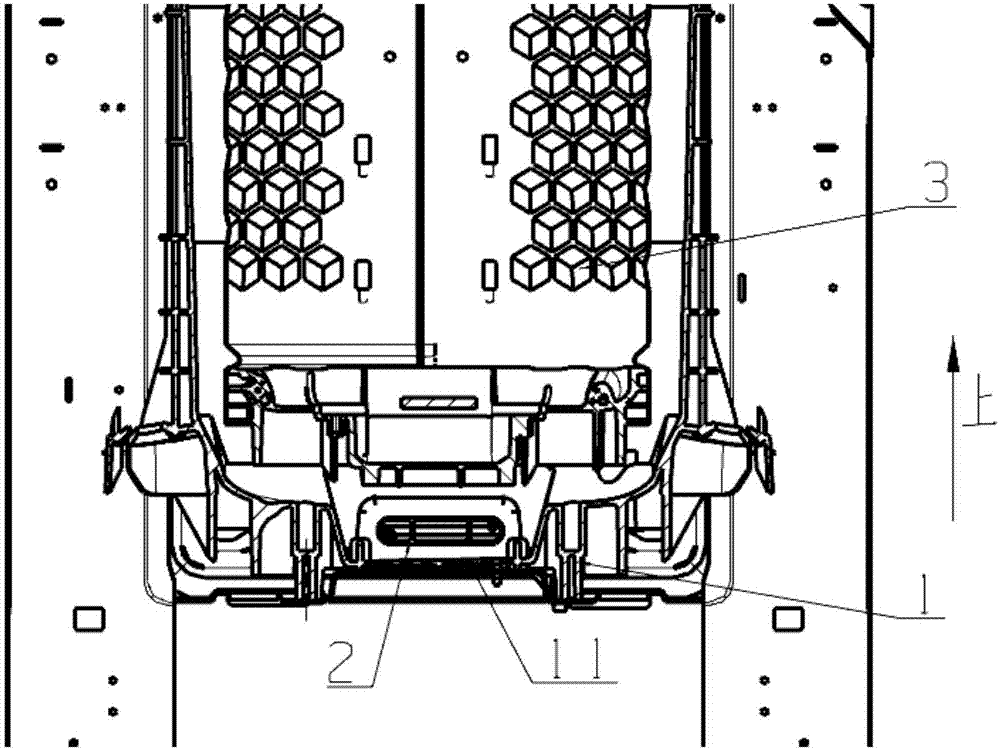

Electric automobile frame

ActiveCN101117135AReasonable installationOptimize layoutElectric propulsion mountingSuperstructure subunitsVehicle framePower battery

The invention discloses an electric automobile frame which consists of three constructional units, namely a front part, a middle part and a rear part. The electric automobile frame comprises a beam, girders and a floor, wherein the beam is laterally arranged on the floor, and the girders intersecting with the beam are longitudinally arranged on the floor. The girders comprise left girders and right girders, wherein the left girders include a front floor left girder and a middle floor left girder, and the right girders include a front floor right girder and a middle floor right girder. The middle floor left girder is positioned between the left edge of the middle floor and the front floor left girder, and the middle floor right girder is arranged between the right edge of the middle floor and the front floor right girder. At least one support is arranged between the floor and the girders, and girder reinforcing blocks are further arranged on two sides of the automobile body. The invention which is novel and smart in design is appropriately provided with a plurality of components to greatly reinforce the rigidity and strength of the entire car, thereby protecting the safety of the inside power battery and passengers in the cabinet in case of critical operating conditions like collision.

Owner:BYD CO LTD

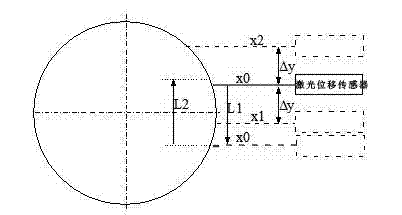

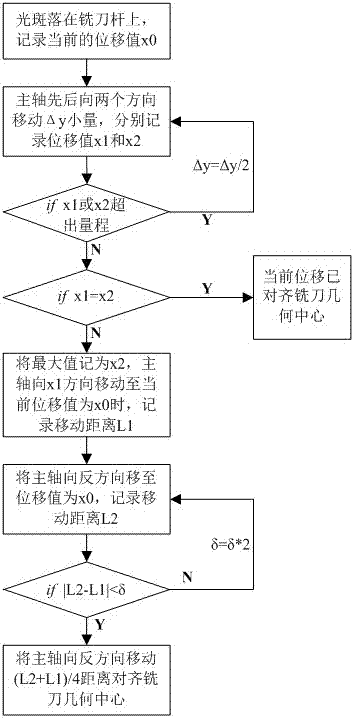

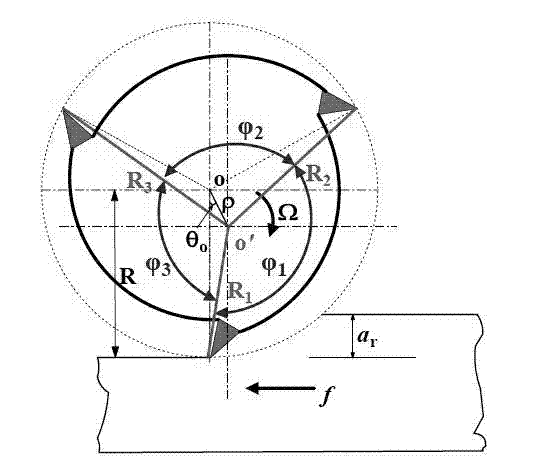

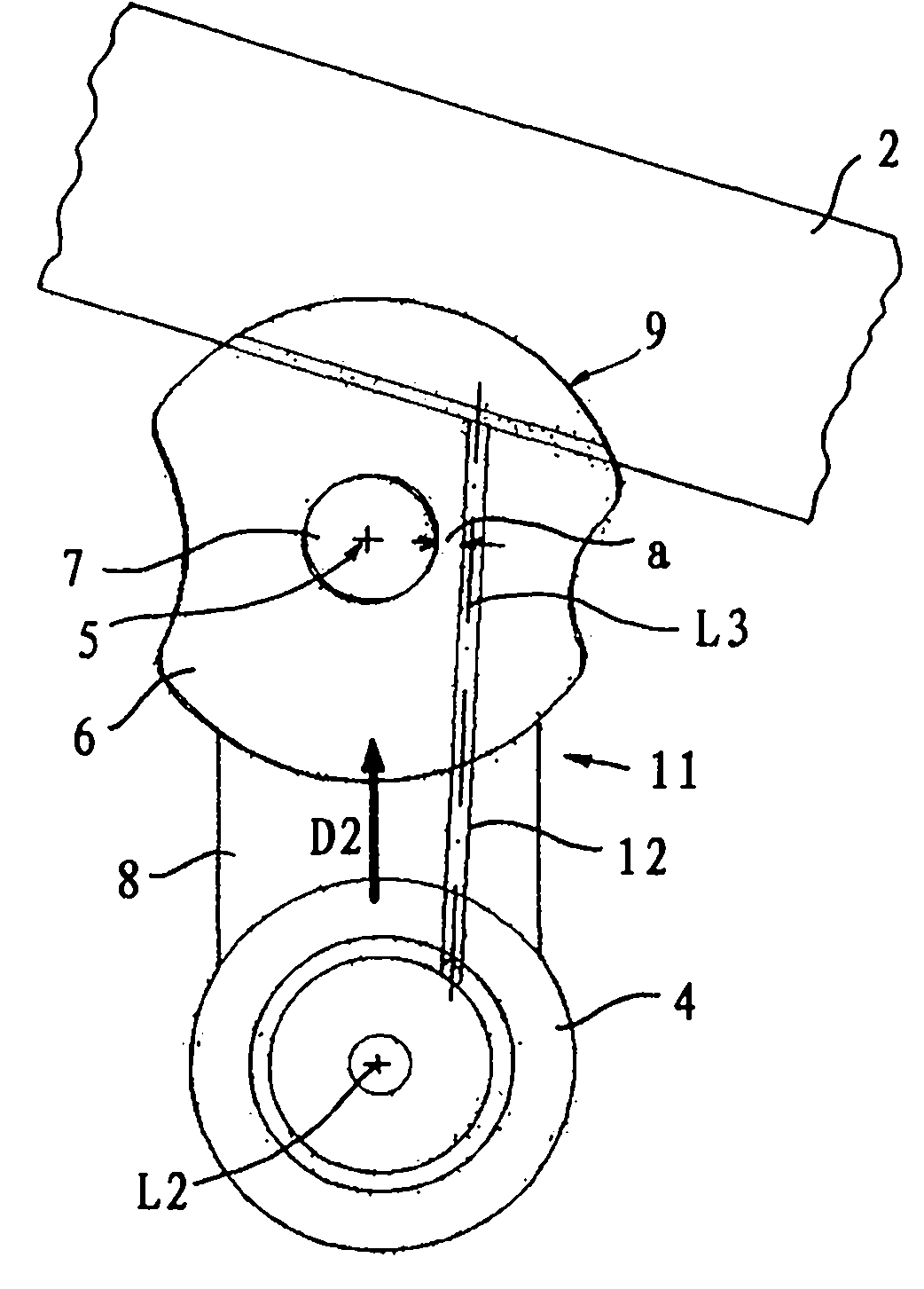

Milling cutter eccentricity rapidly measured non-contact type laser measuring method

ActiveCN103753353AReasonable installationOptimize processing parametersMeasurement/indication equipmentsMilling cutterMathematical model

The invention provides a milling cutter eccentricity rapidly measured non-contact type laser measuring method. The milling cutter eccentricity rapidly measured non-contact type laser measuring method can rapidly obtain the actual cutter eccentricity after a milling cutter is installed, accordingly whether the installation is reasonable or not is judged and efficient machining parameter is confirmed and part accurately and efficiently machining is achieved. The milling cutter eccentricity rapidly measured non-contact type laser measuring method is characterized in that dynamic displacement of the milling cutter during rotation at different rotating speed is collected through a laser displacement sensor; the peak-peak value of the dynamic displacement under different rotating speed through filtering waves are obtained; a mathematical model for solving the milling cutter eccentricity is constructed according to the peak-peak value; the actual milling cutter eccentricity is obtained due to solving of an optimizing model of the milling cutter eccentricity.

Owner:WUXI TURBINE BLADE

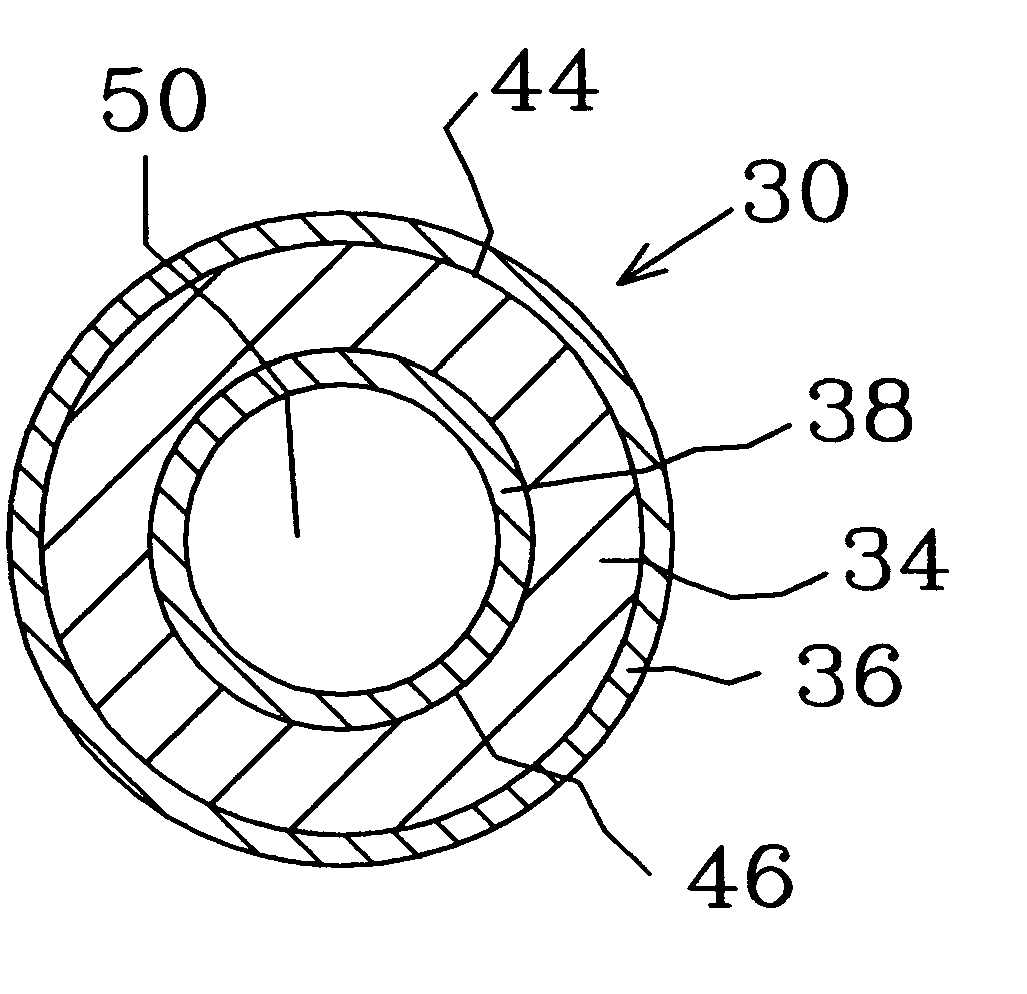

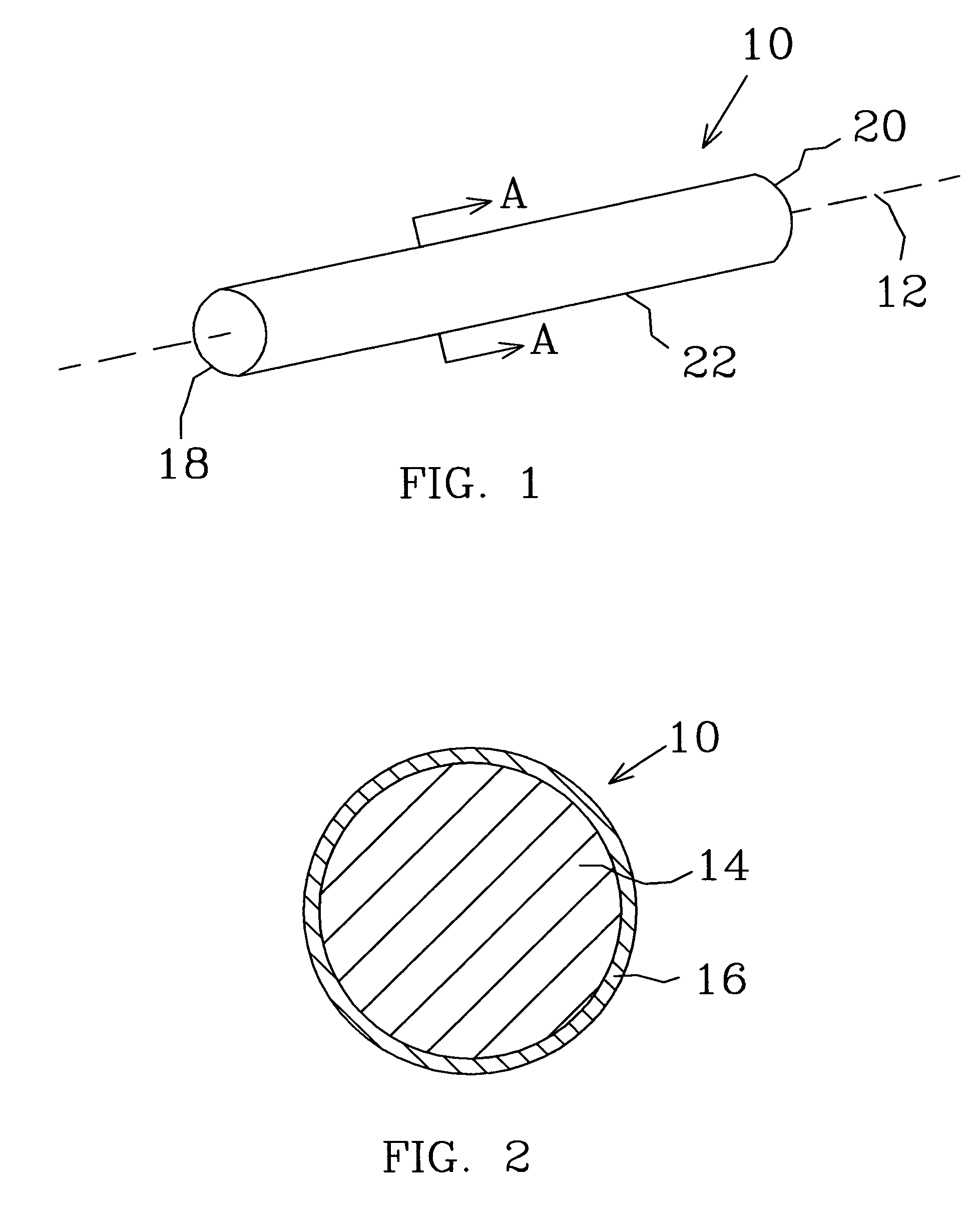

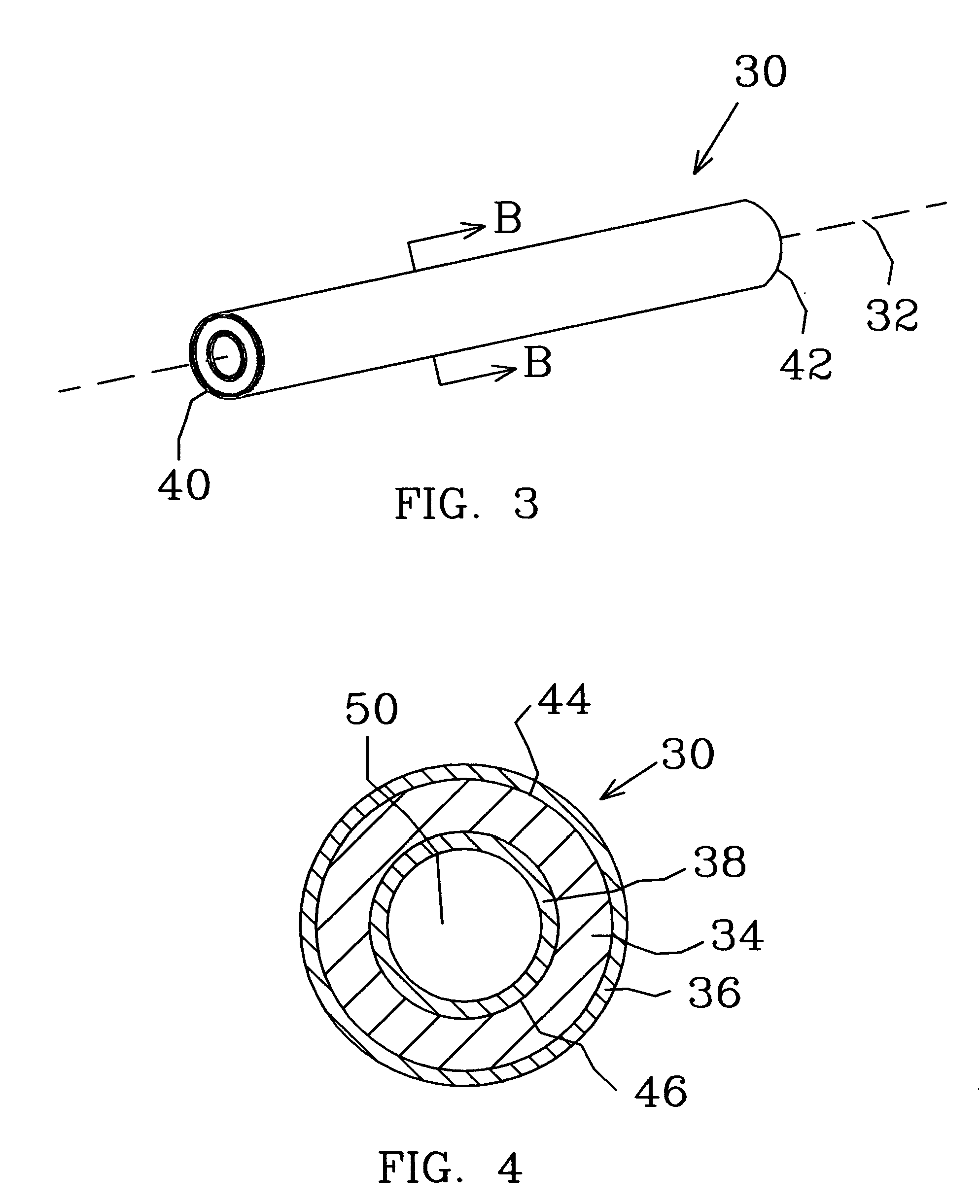

Environmentally protected reinforcement dowel pins and method of making

InactiveUS20050265802A1Maintain integrityMaintain strengthPaving detailsFastener toolsZinc alloysSacrificial metal

Galvanically protected reinforcement dowel pins and methods of producing the same. In one embodiment, the reinforcement dowel pins comprise a bar or tube, the longitudinal exposed surfaces of which are covered by a heavy gauge of a sacrificial metal, such as zinc, zinc alloy, magnesium, magnesium alloy, aluminum, or aluminum alloy. The bar or tube comprises steel, carbon steel, or other ferrous metal. The heavy gauge of sacrificial metal is applied to the ferrous metal by various processes, such as roll bonding, lock seaming, welding, die casting, flame spraying, plasma spraying, dipping, sinking, and drawing. The resulting reinforcement dowel pins resist corrosion without sacrificing structural integrity, and are reasonable in materials and manufacturing costs. These dowel pins may be installed in adjacent concrete panels using conventional methods, and therefore do not introduce additional costs in installation.

Owner:JARDEN ZINC PRODS LLC

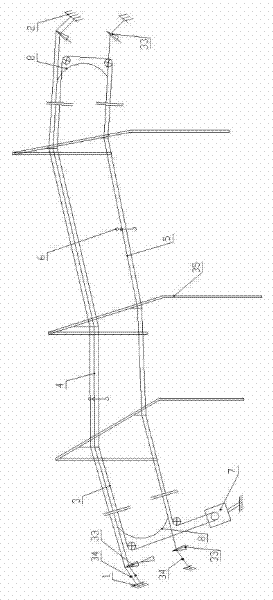

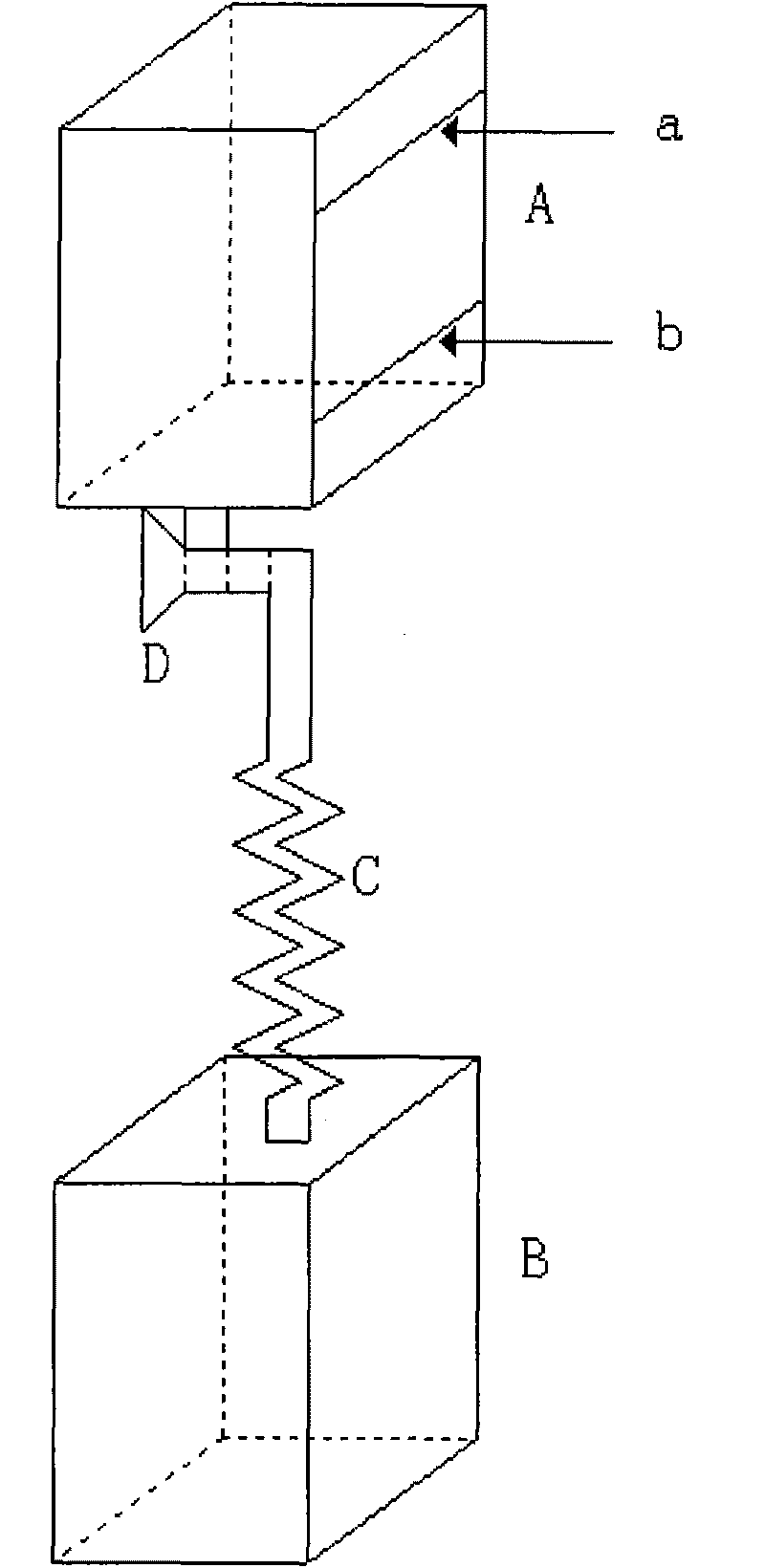

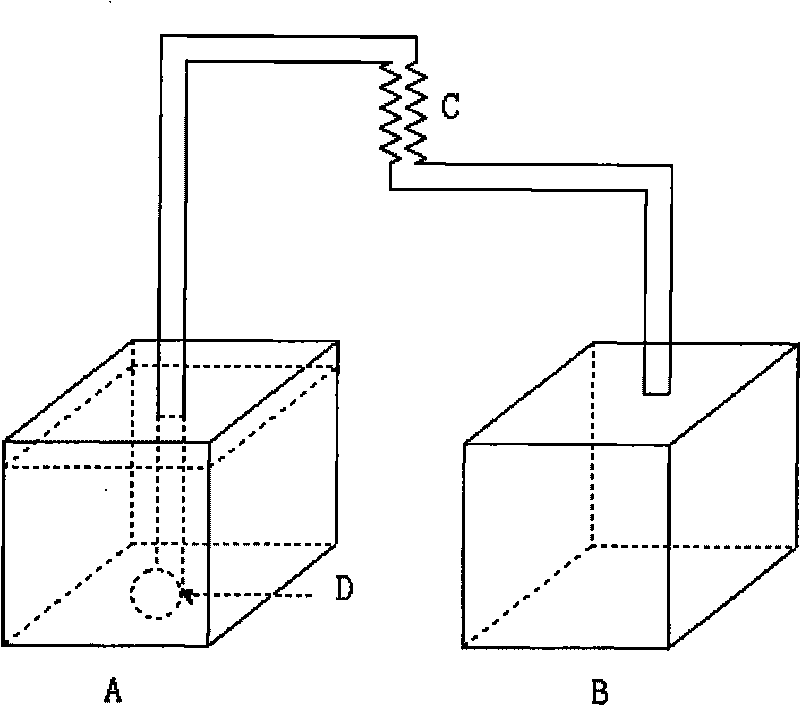

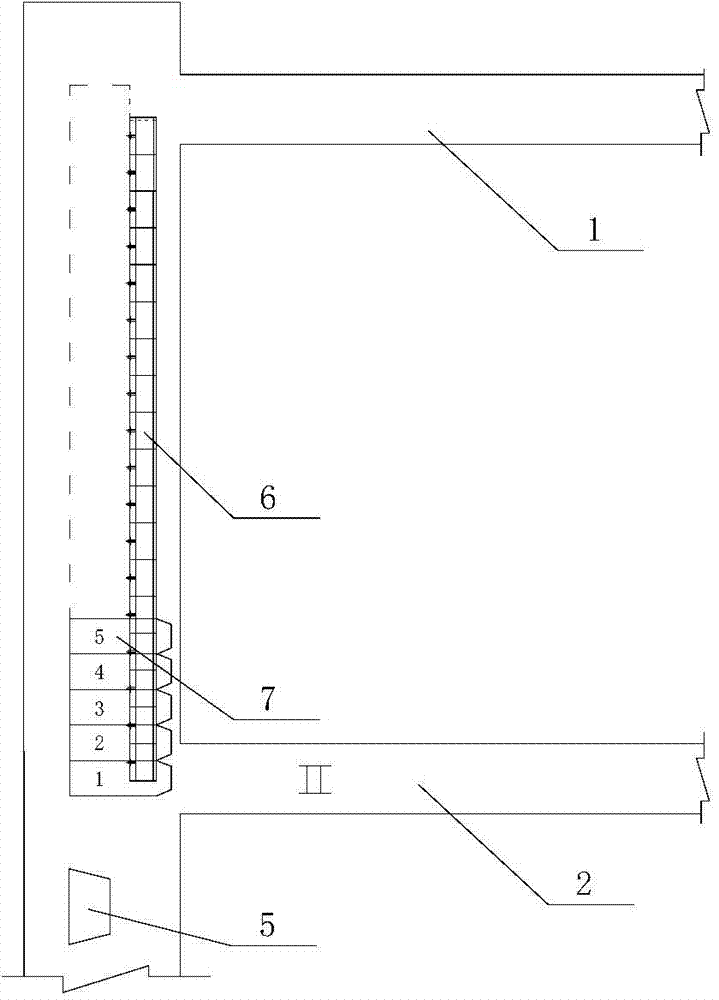

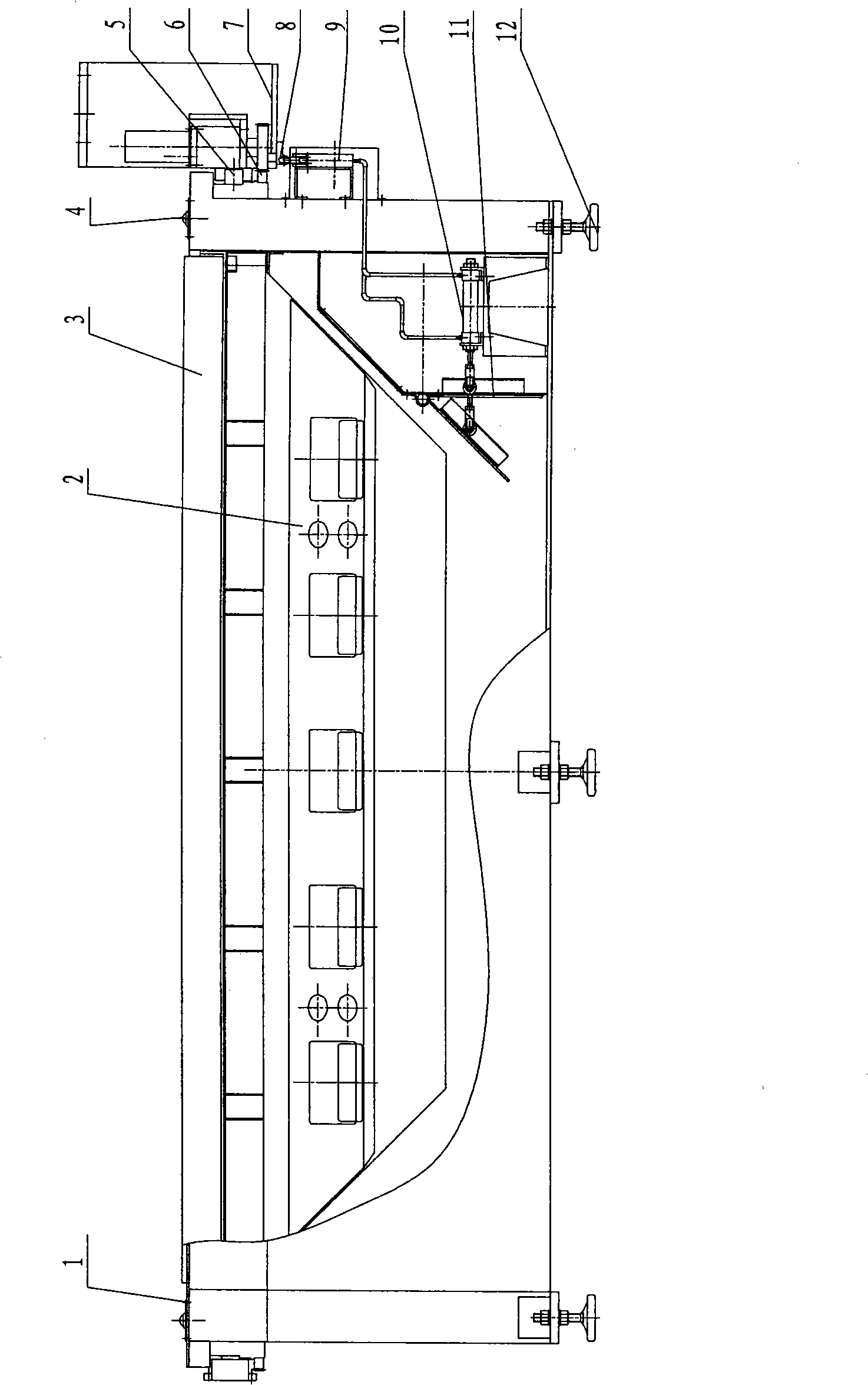

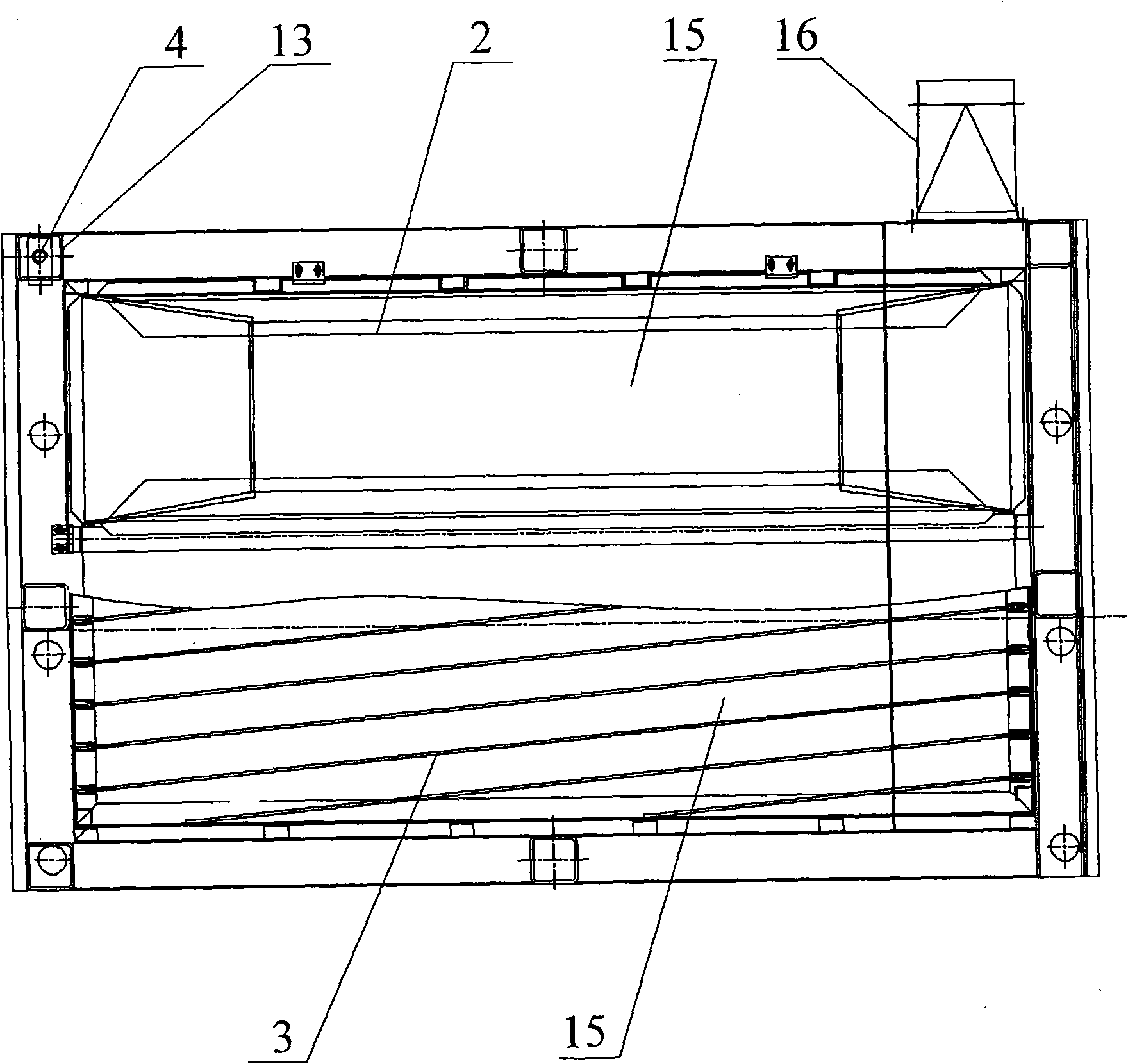

Double-cable circular curved cableway transportation system

ActiveCN102259649AImprove delivery efficiencyImprove securityRope railwaysTransport systemTotal investment

The invention discloses a curve cableway transporting system of double-cable circulating type, which comprises two groups of ground anchors, supporting devices, a dragging cable, two load bearing cables, one or two empty-return cables, a freight trolley and a dragger. The dragging cable is connected with the dragger to form an annular circulating loop, the two load bearing cables are arranged in parallel up and down, the one or two empty-return cables and the load bearing cables are respectively mutually connected at positions near the adjacent two groups of ground anchors through a corner slid rail, the dragging cable is arranged below the two load bearing cables and the one or two empty-return cables, and the load bearing cables or empty-return cables on the two sides of each supportingdevice are provided with an included angle. According to the curve cableway transporting system of double-cable circulating type disclosed by the invention, a cableway construction line is shortened in some regions, and multiple times of loading, unloading, dumping and transporting do not needed during transportation; and the curve cableway transporting system of double-cable circulating type disclosed by the invention has the advantages of reasonable design, convenience for installing, large freight volume, large altitude difference, large span, high transportation efficiency, high safety coefficient, low total investment, low operation cost and the like, and has large popularization and application values.

Owner:STATE GRID CORP OF CHINA +2

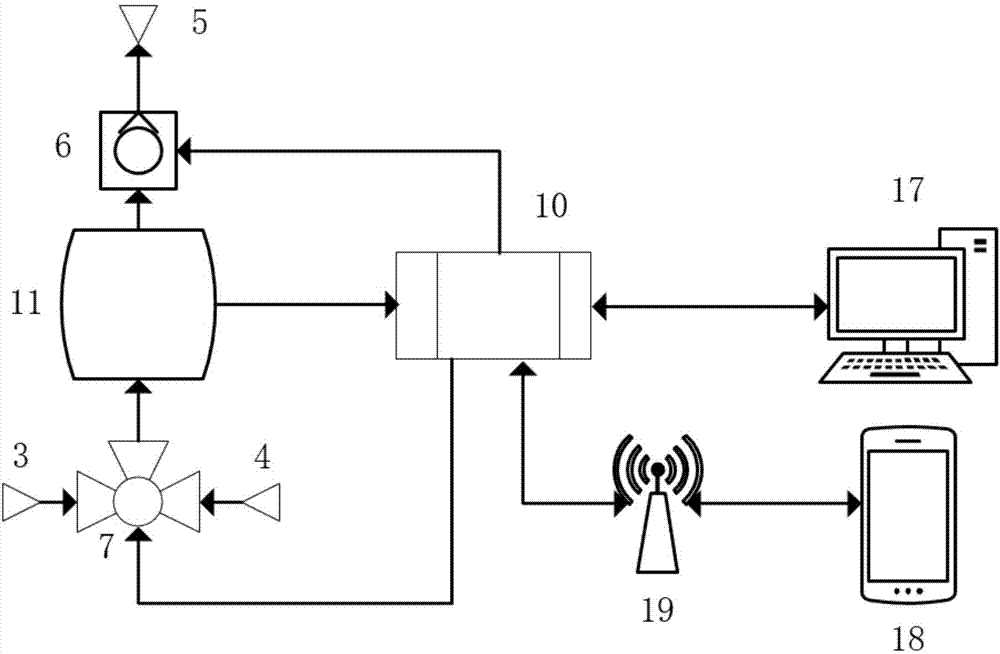

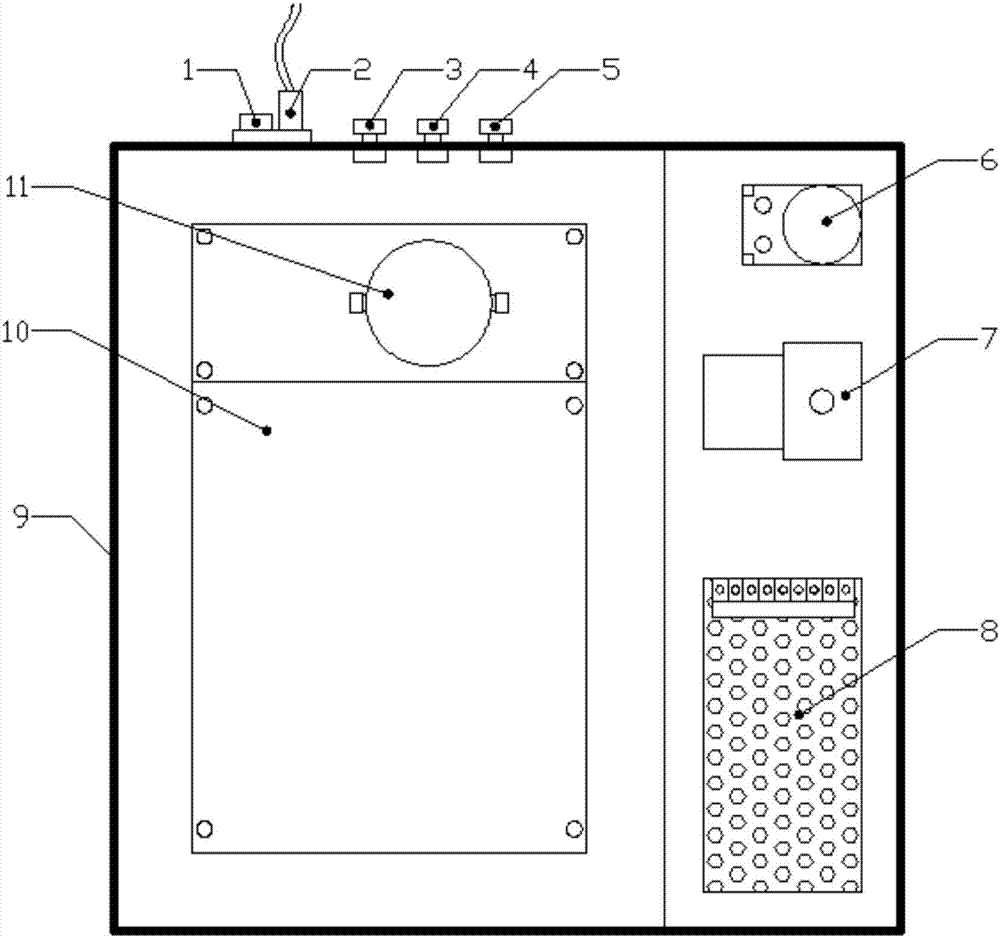

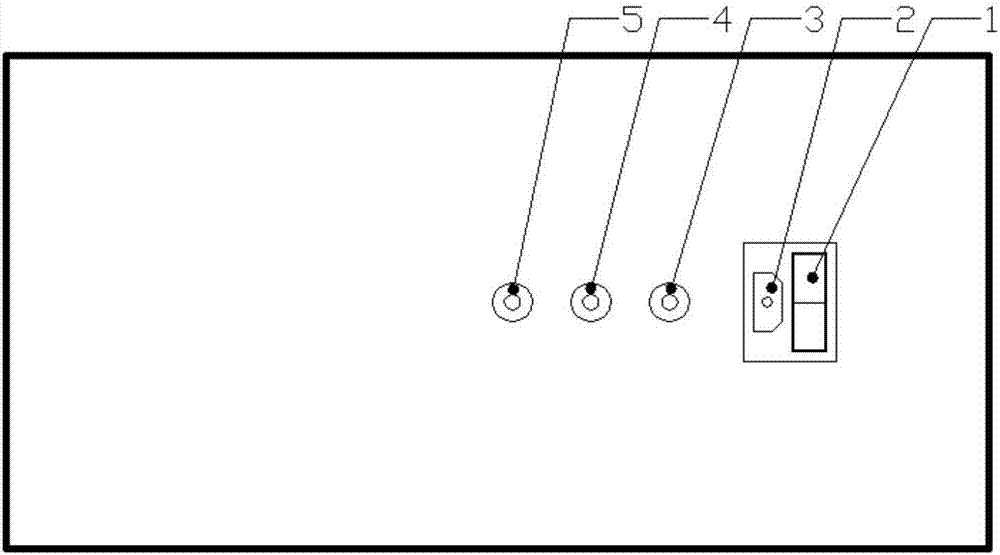

VOCs gas detection system and method

PendingCN107328847AThe measurement results are objective and accurateHigh precisionProgramme controlComputer controlGas detectorEngineering

The invention discloses a VOCs gas detection system and method. The system comprises a VOCs gas detector and an upper computer. The VOCs gas detector comprises a machine case, a sample injection module, a detection module and a control module. The sample injection module, the detection module and the control module are installed inside the machine case; the detection module comprises a gas chamber and a gas detection sensor; the sample injection module comprises a valve and a pump; the control module comprises a master control board and a power module; according to the system, a PID sensor is used for detecting the VOCs gas concentration in the environment to be detected, reasonable analysis is performed through output of the sensor, the concentration of the gas to be detected is determined, on-site online measurement of VOCs gas is achieved, on the basis of upper computer software, and the real-time display and storage function of detection data is achieved. The whole detection process is simple and easy to implement and good in real-time performance, low-concentration detection can be performed without pre-concentration treatment, and the instrument is easy and reasonable to install, and has the good crushing resistance and shock resistance.

Owner:HEBEI UNIV OF TECH

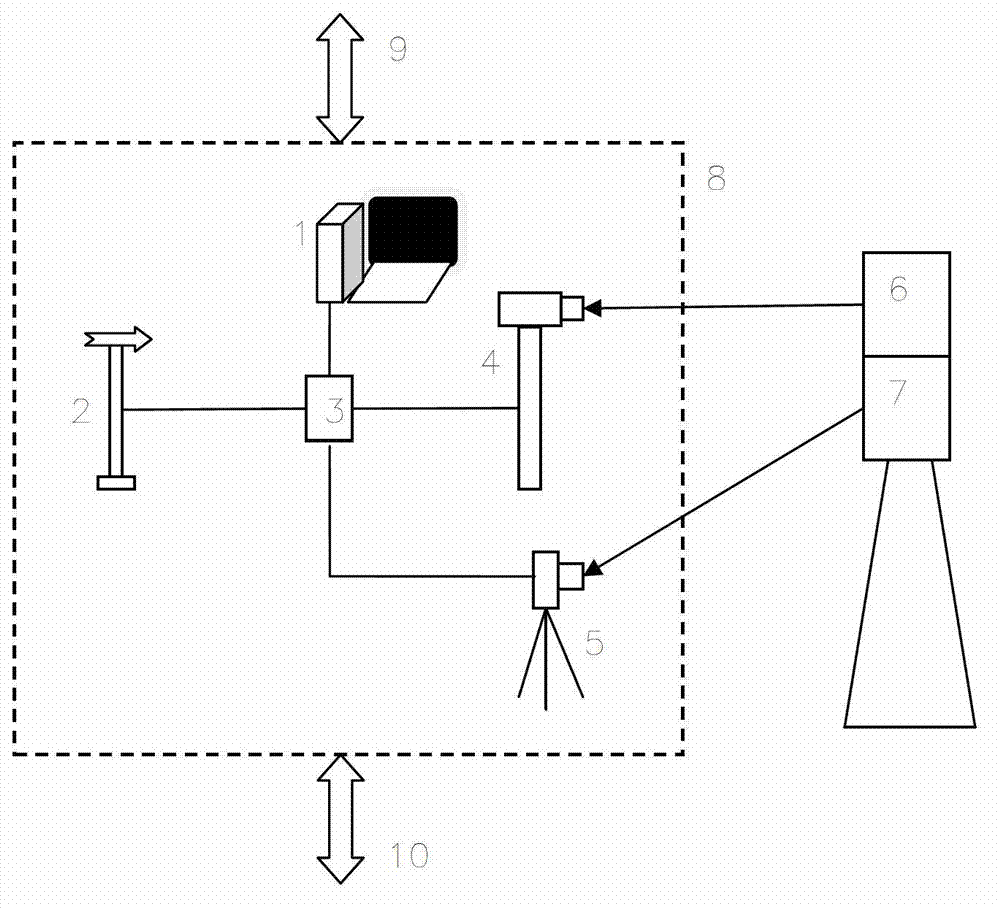

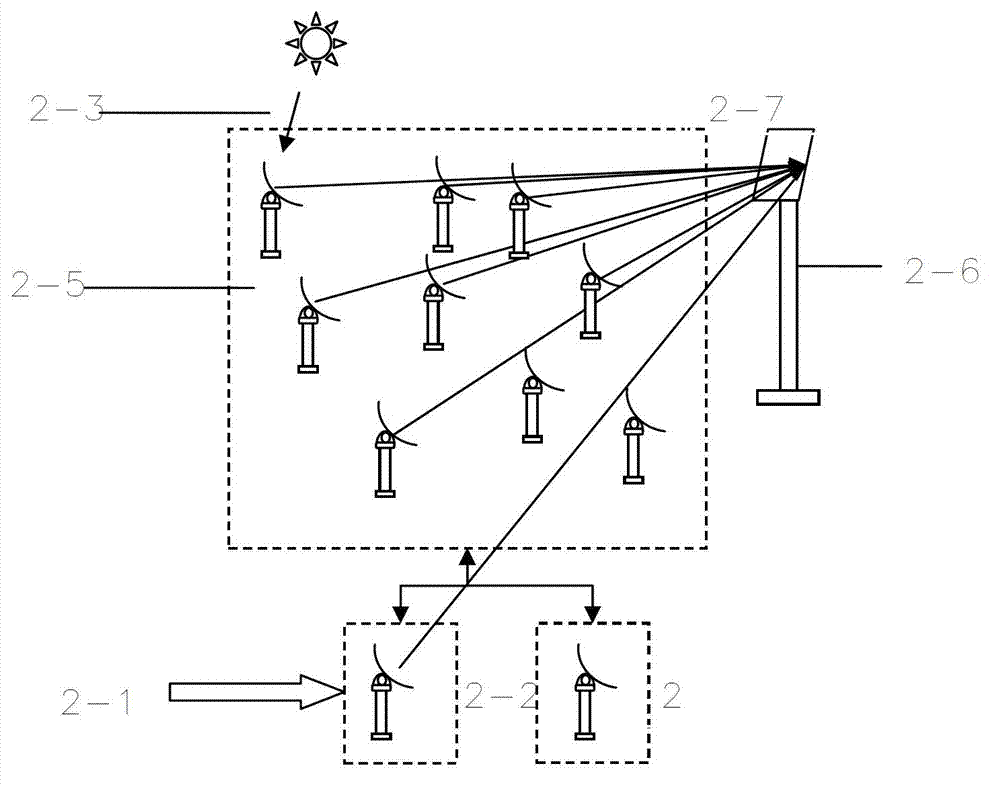

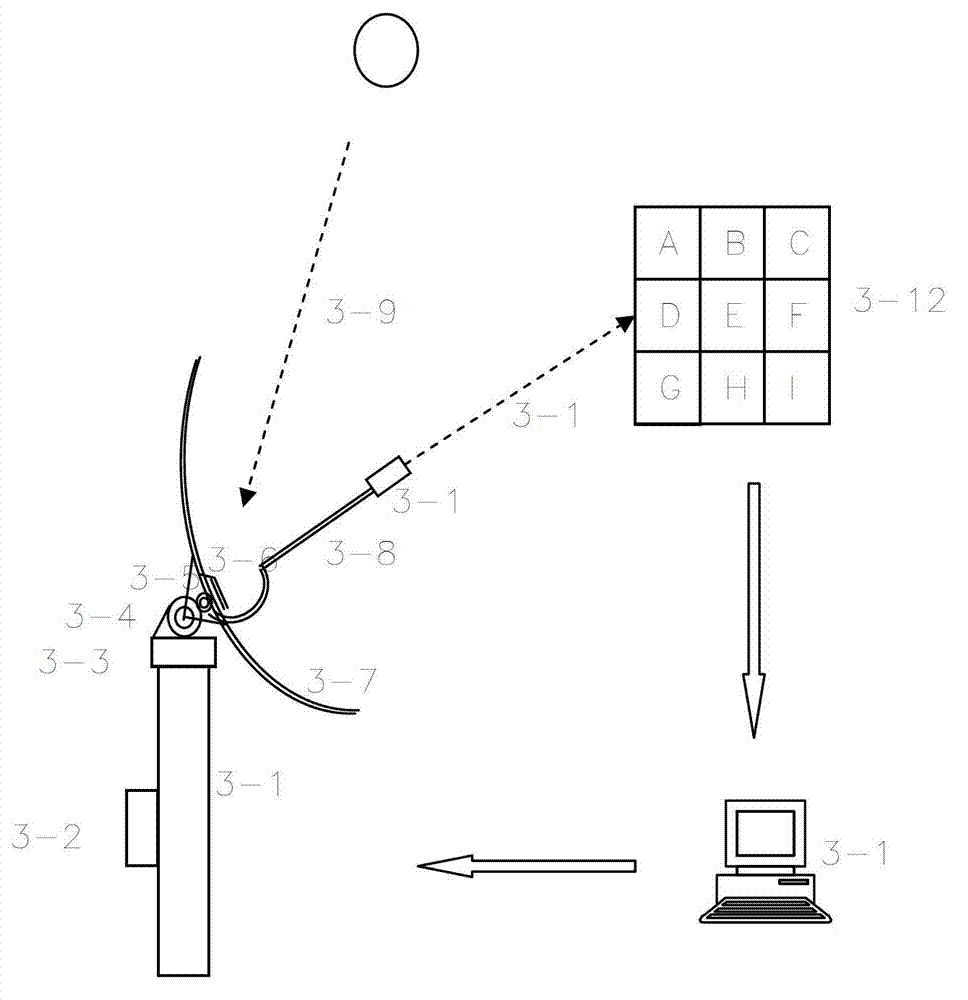

Tower-type solar heat collection heliostat field control system based on multi-layer architecture

ActiveCN102929298AReasonable scheduling methods and devicesReduce manufacturing costControl using feedbackSun trackingWeather monitoring

The invention relates to a tower-type solar heat collection heliostat field control system based on a multi-layer architecture. The system is composed of three control levels including a heliostat field scheduling and controlling layer, a heliostat sub-group controlling layer and a sun tracking device layer from top to bottom, wherein the heliostat field scheduling and controlling layer consists of five parts including a heliostat field controlling machine, a weather monitoring device, a field observation device, a communication interface and a light spot checking device; the heliostat sub-group controlling layer is composed of a controller adopting the two-computer backup redundancy technique, and the controller has the function of a bottom-layer heliostat; and the sun tracking device layer consists of the bottom-layer heliostat used for open-loop control and open-loop / closed-loop mixed control.

Owner:陕西西科博尔科技有限责任公司

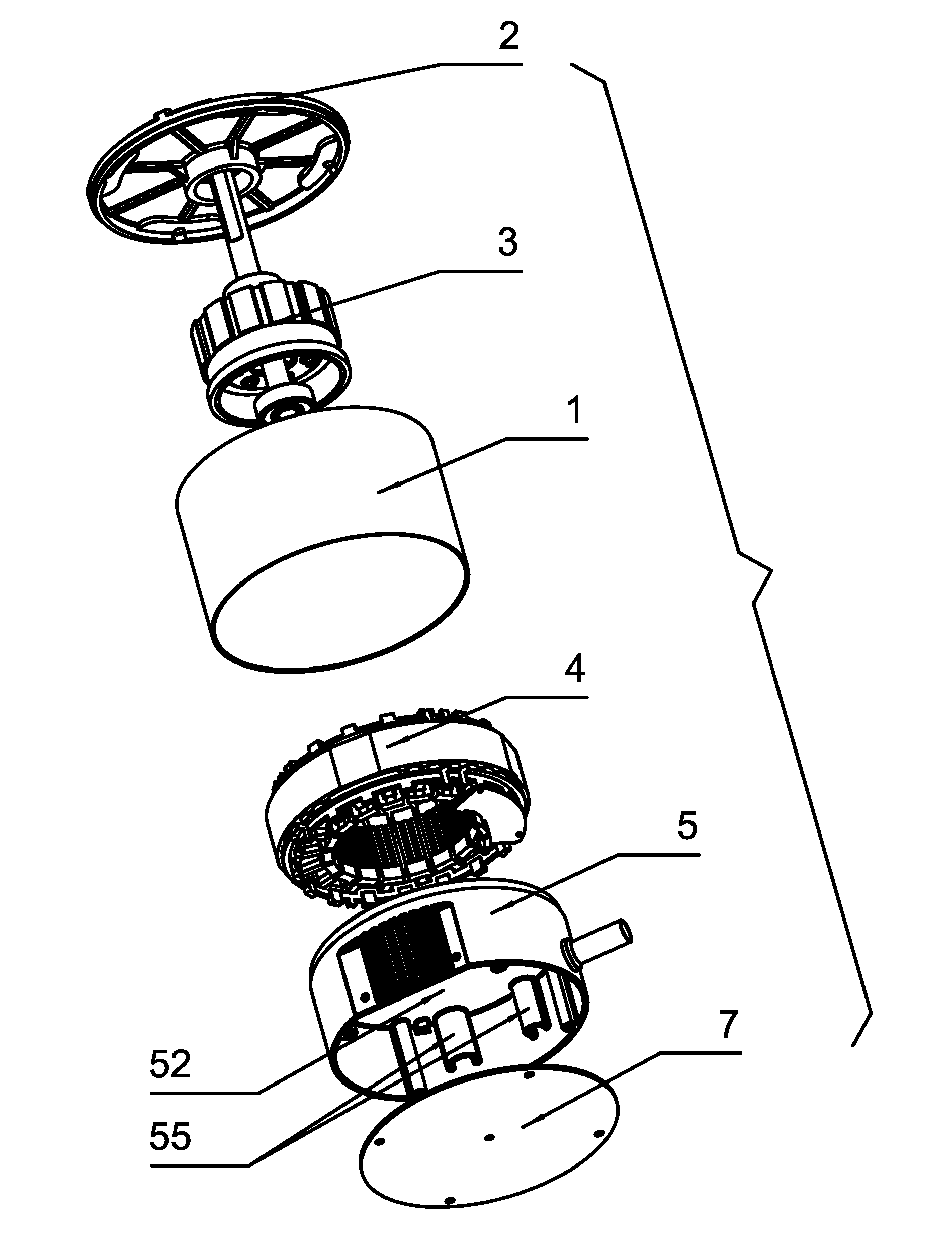

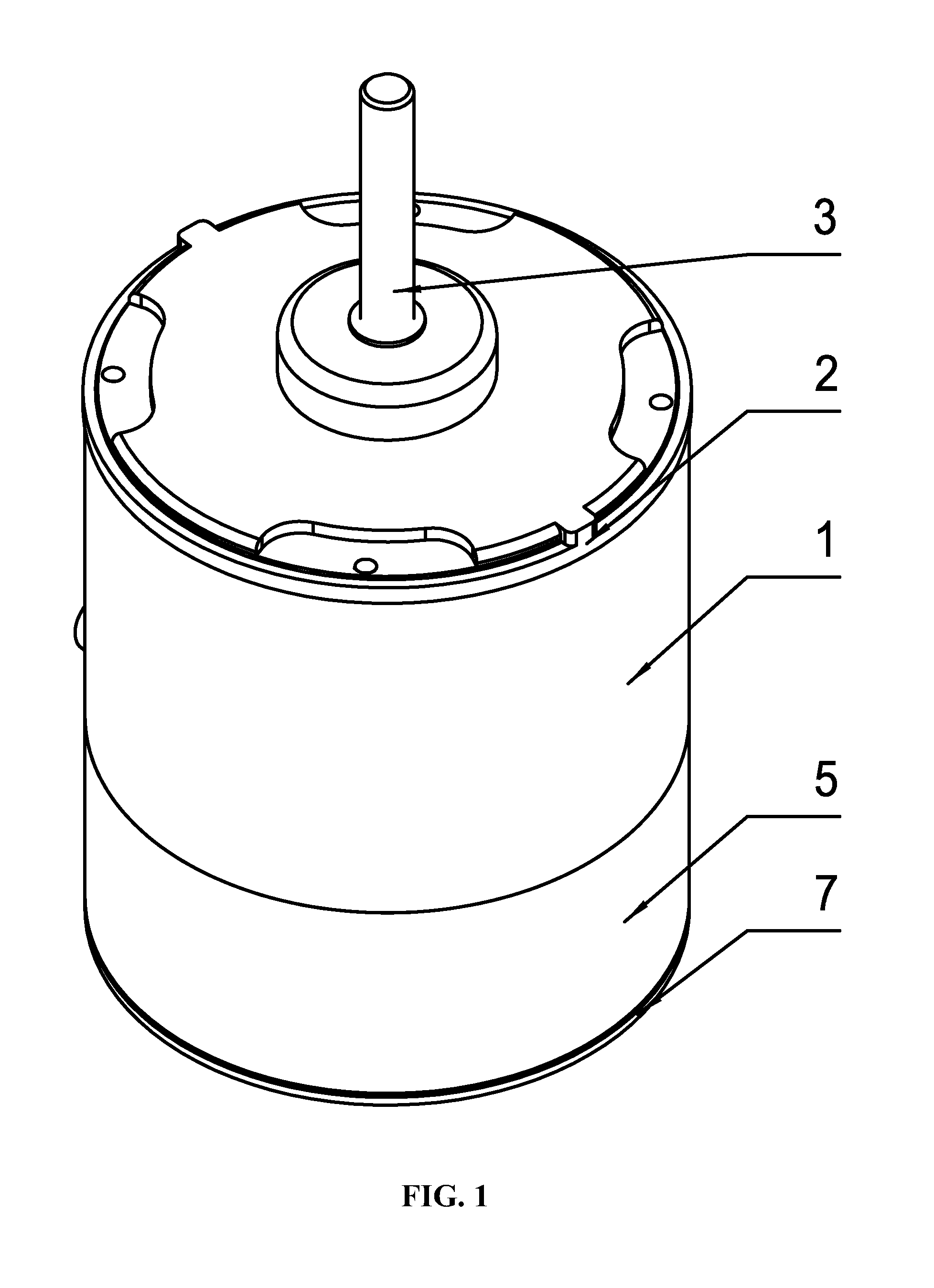

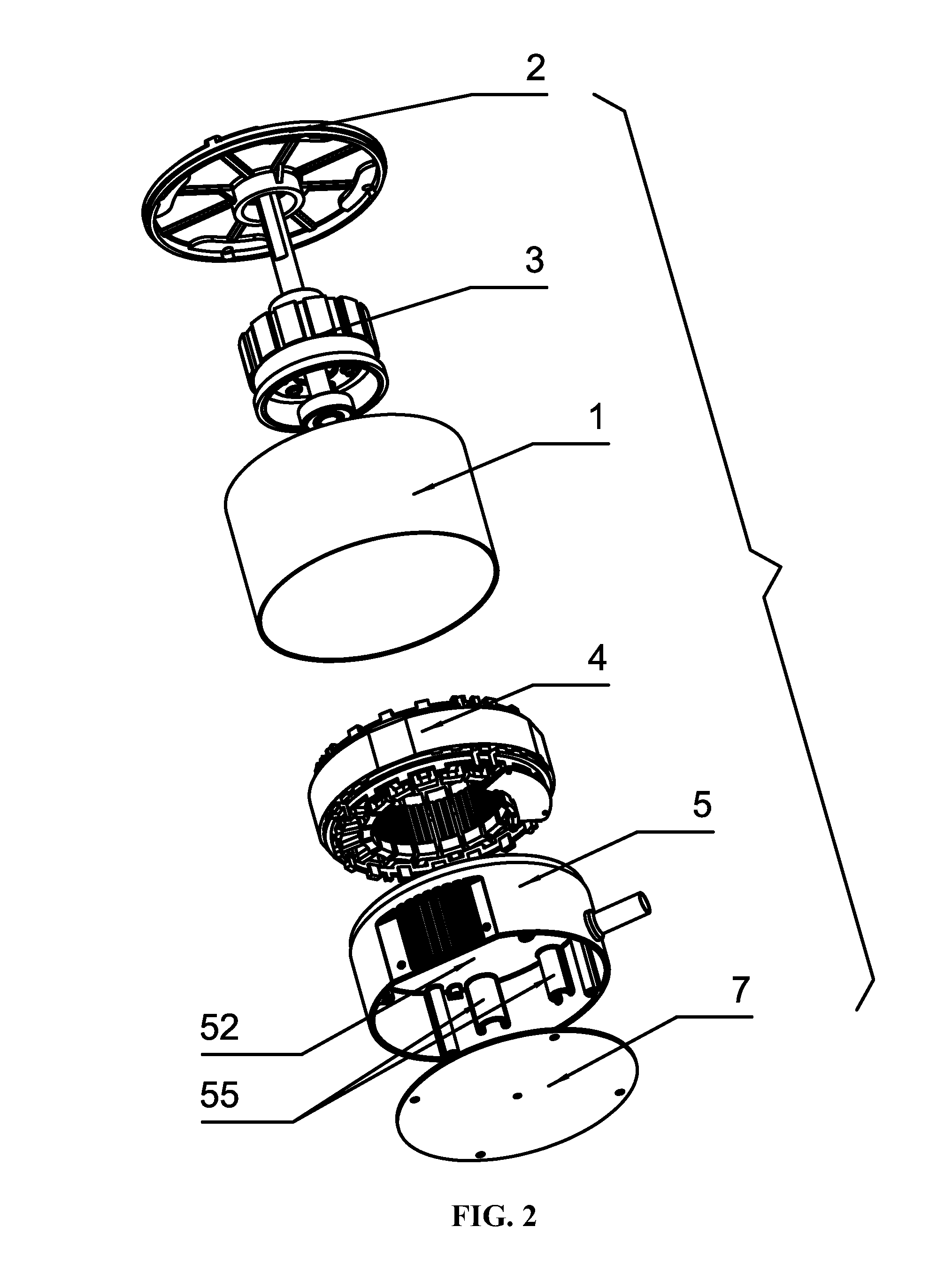

Combination of outer motor and control box therefor

ActiveUS20120104907A1Simple and cost effective production processProlong service lifeAssociation with control/drive circuitsSupports/enclosures/casingsEngineeringControl circuit

A combination of an outer motor and a control box therefor including an upper main body and a lower controller. The upper main body includes a casing, a front end cover, a rotor assembly, and a stator assembly. The controller includes a control box and a control circuit board, and the control box is sheathed in a tail end of the casing. A center of an upper bottom surface of the control box is arranged with a bearing chamber corresponding to that arranged at the front end cover. The control box forms a cavity downwards accommodating the control circuit board. A cover is mounted at the bottom of the control box. A fairlead arranged at an inner wall of the control box extends through the bottom of the motor casing to connect an empty cavity of the casing.

Owner:ZHONGSHAN BROAD OCEAN

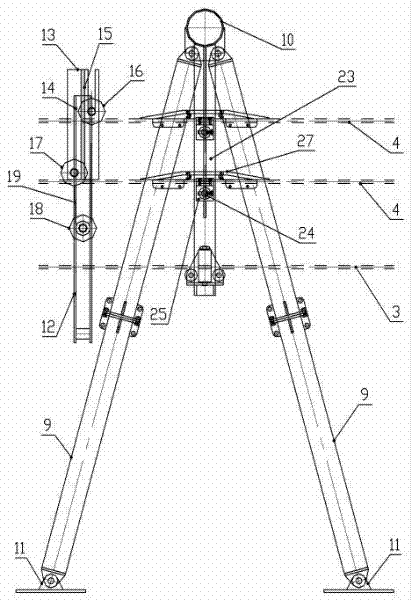

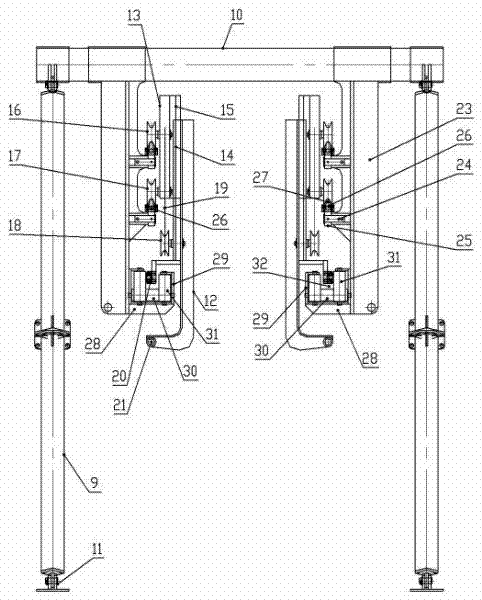

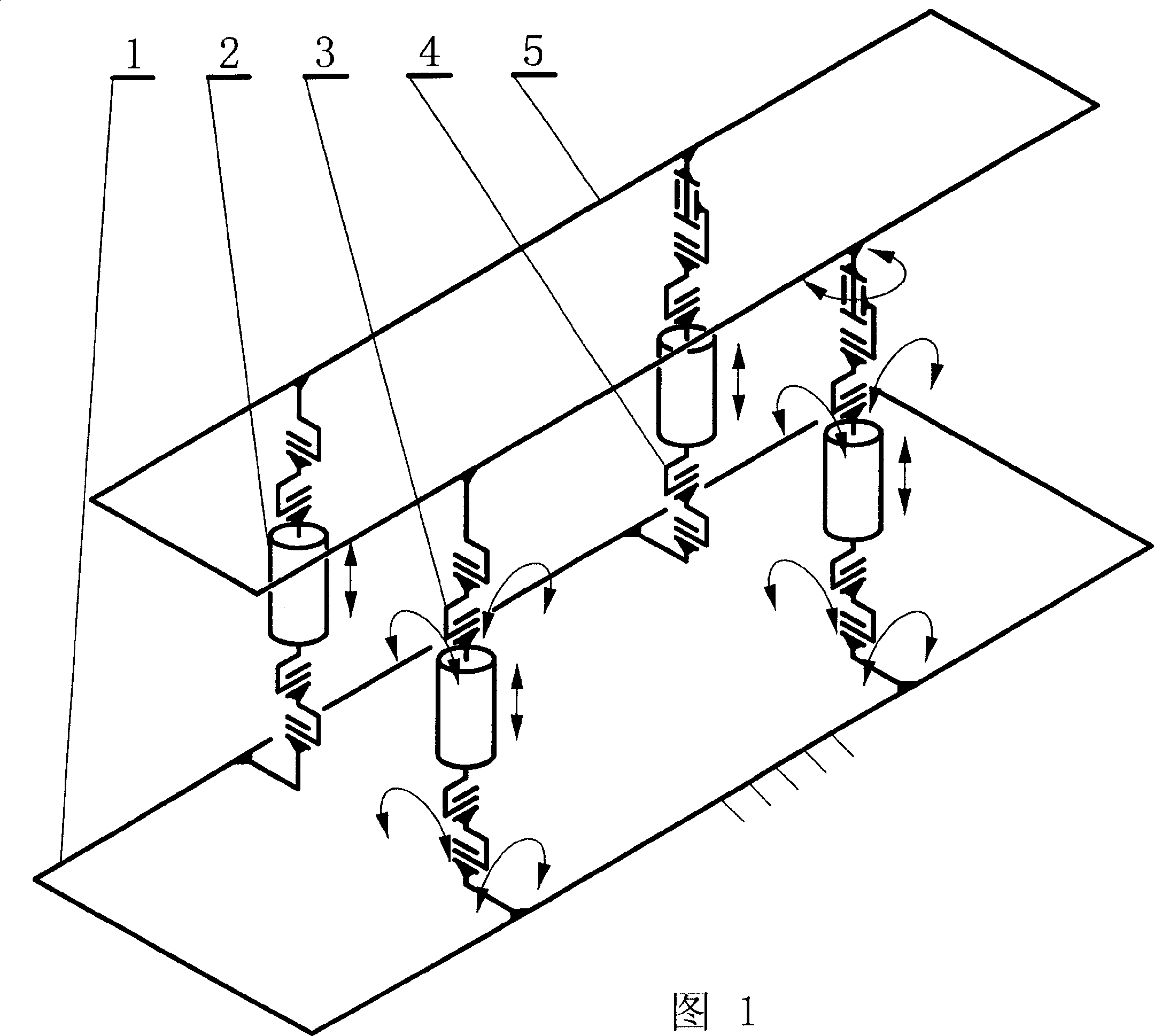

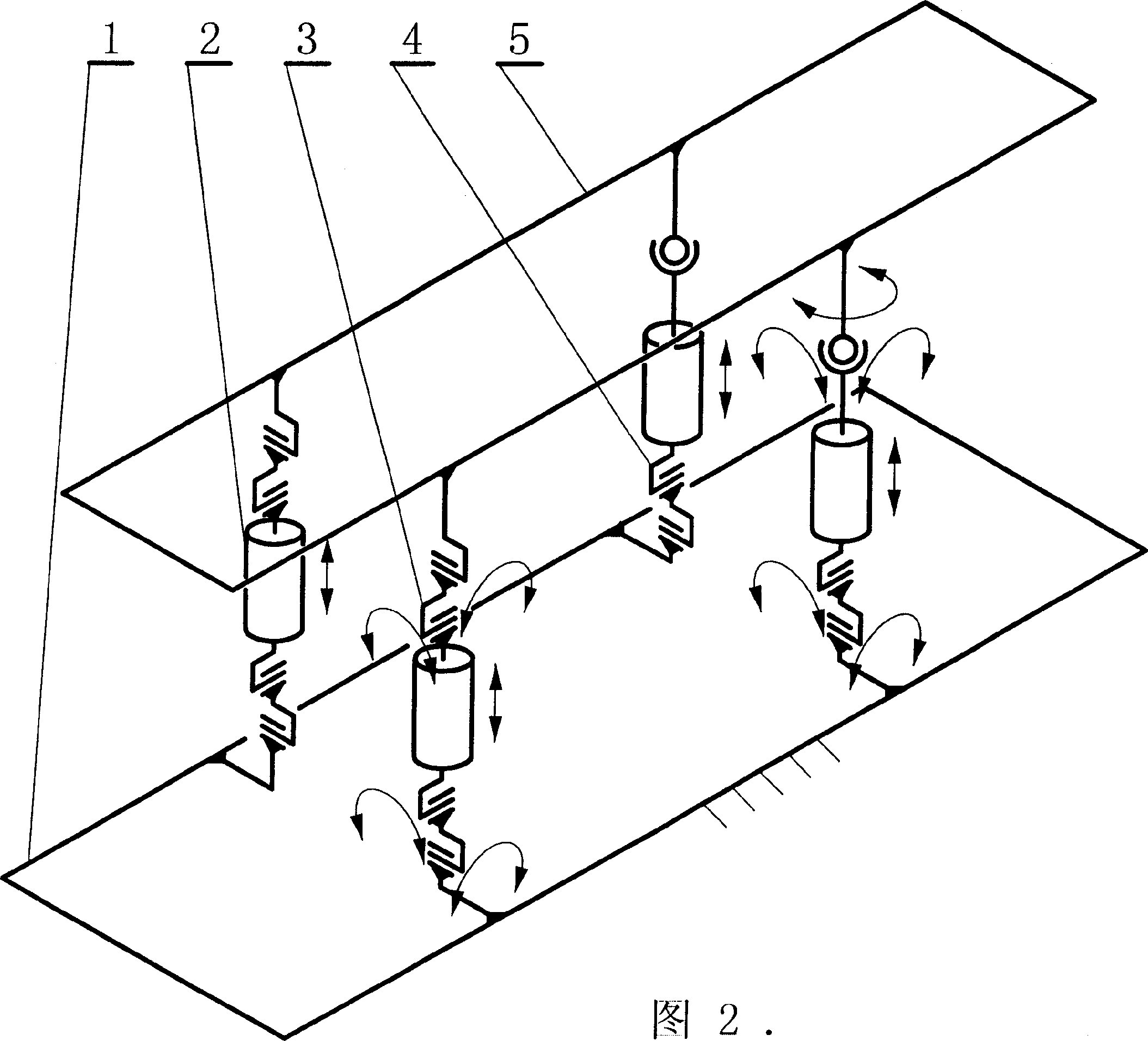

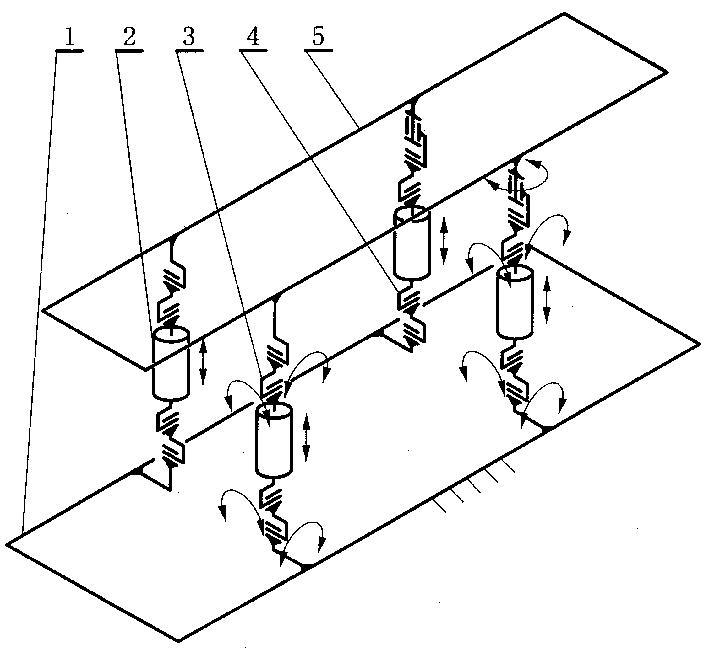

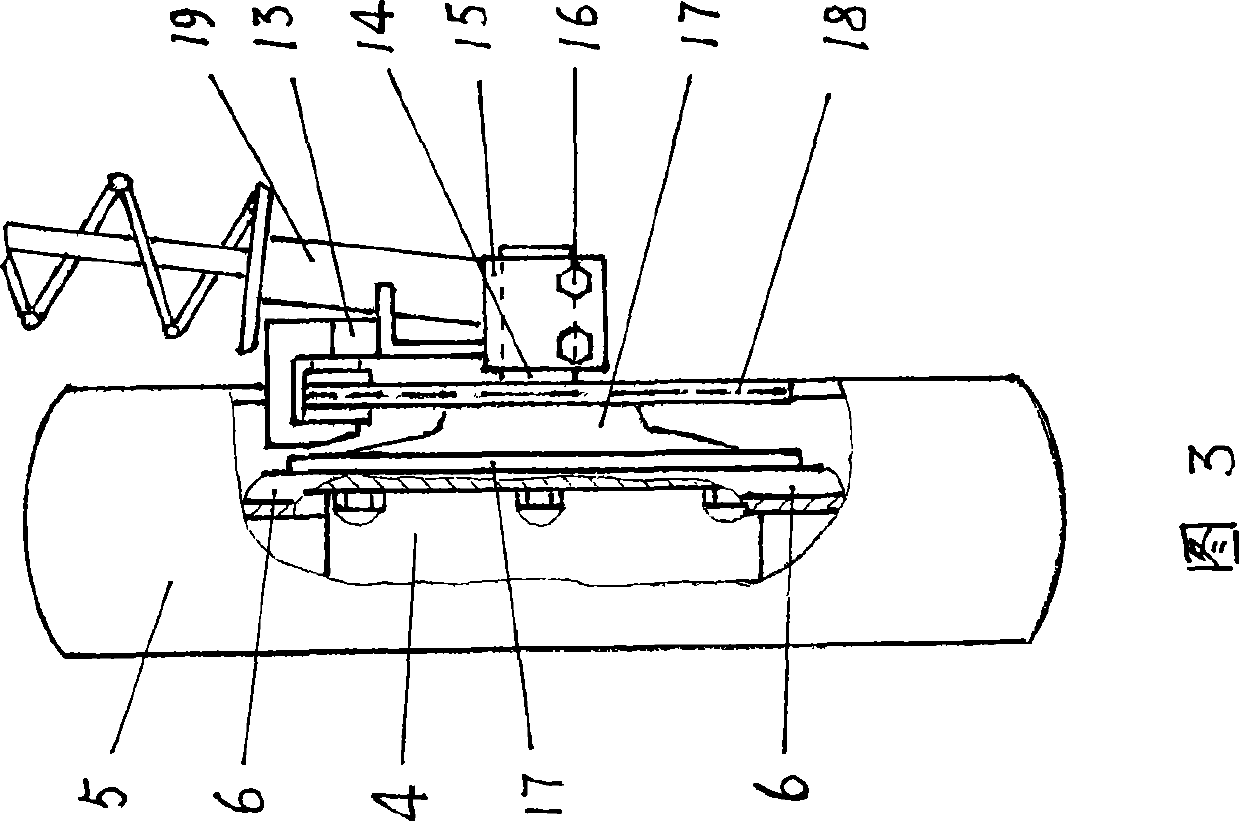

Stand for testing reliablity of electric appliances of four cylinder vehicle

InactiveCN1439555AComparableGood repeatabilityVehicle testingVehicle fittings for lifting and manoeuvringHydraulic cylinderIn vehicle

A reliability tester of electric devices for 4-cylinder driven type vehicle is composed of foundation plate, 4 hydraulic cylinders upper and lower hinged supporters arranged to top and bottom ends of 4 hydraulic cylinders, and chassis beam. Said 4 hydraulic cylinders are divided into front two and back two between said foundation plate and chassis beam. The electric devices to be tested are installed on the chassis beam according to their actual positions in vehicle. Its advantages are simple structure, high reliability and low cost.

Owner:SHANGHAI JIAO TONG UNIV

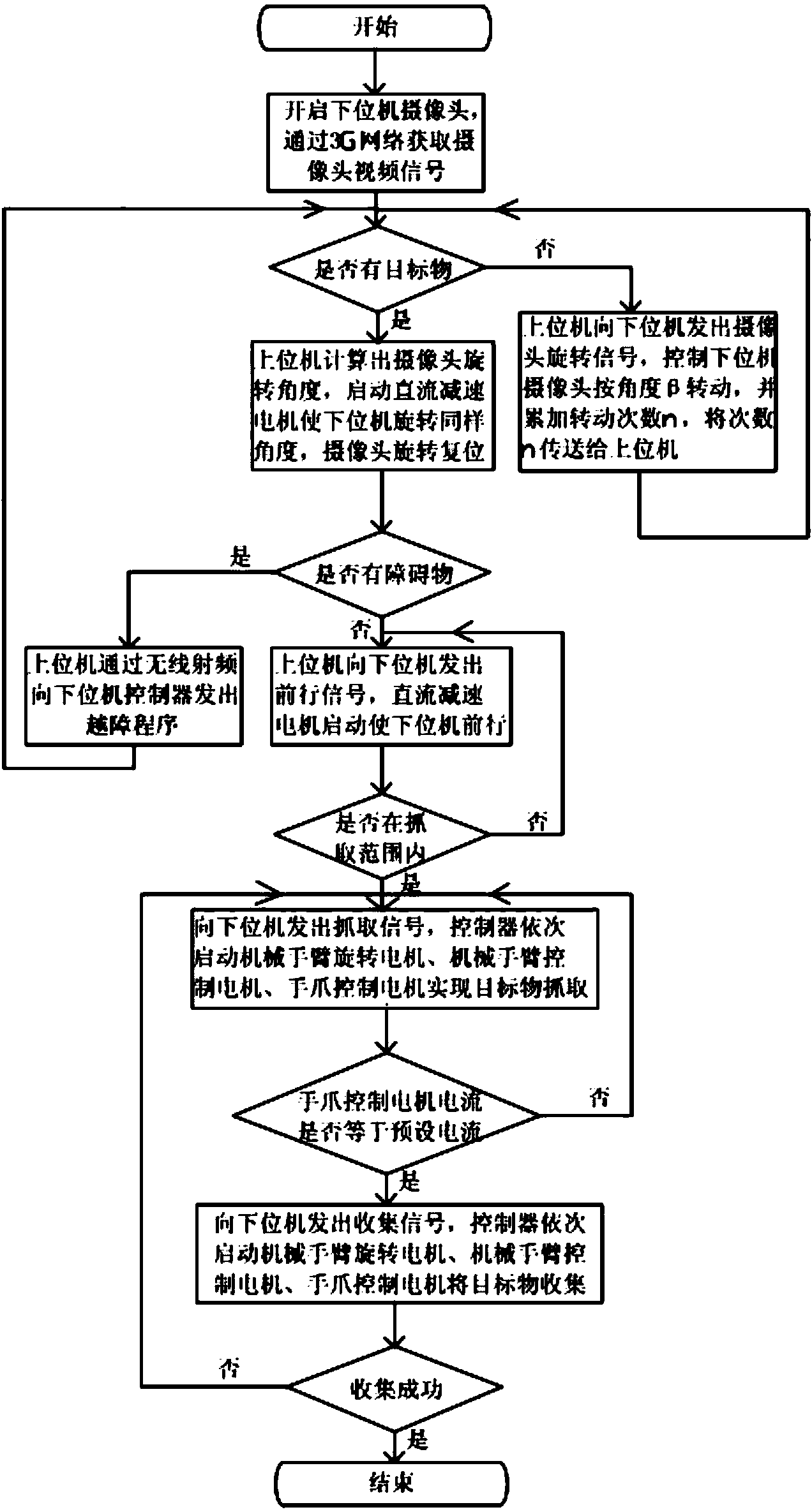

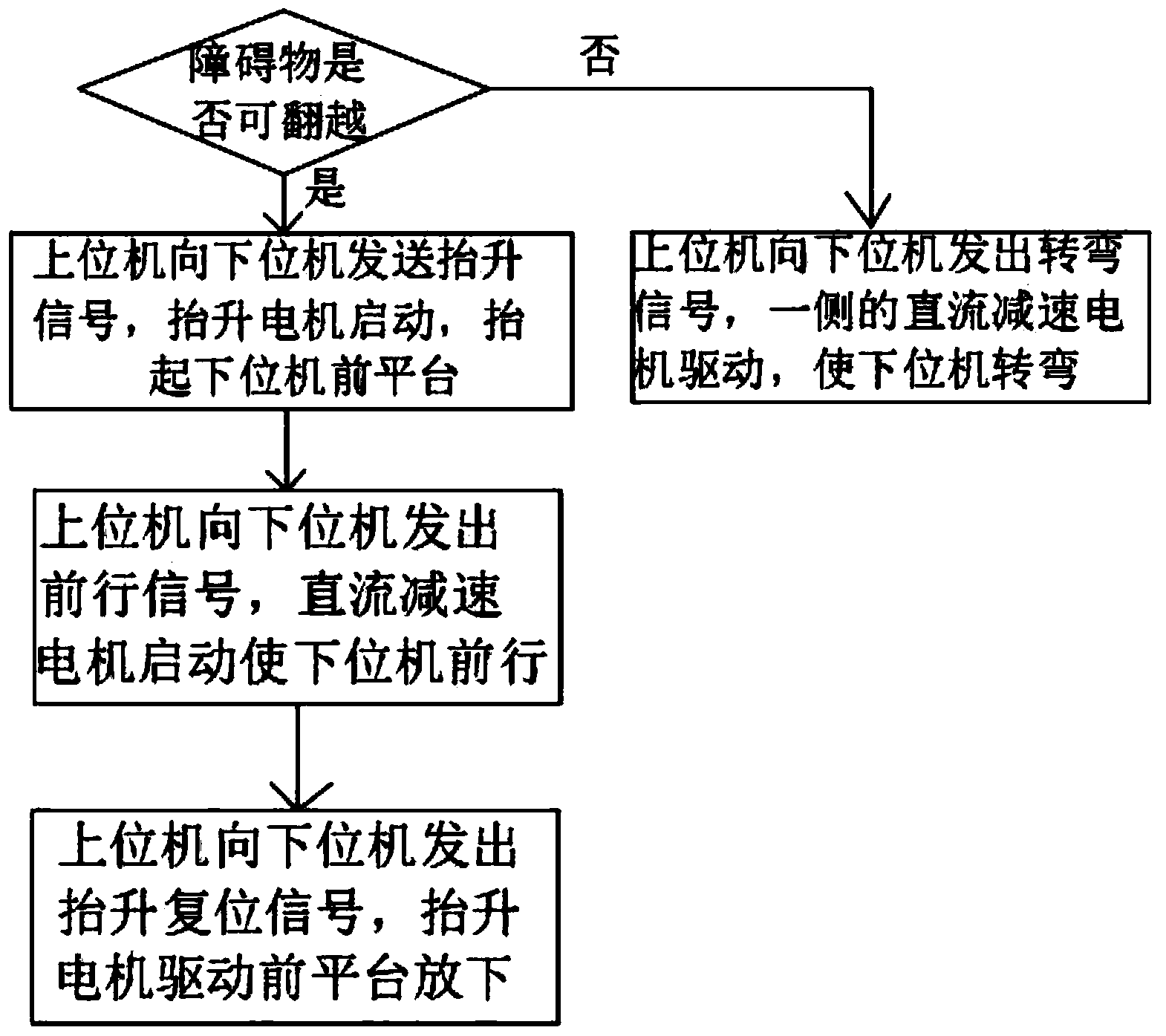

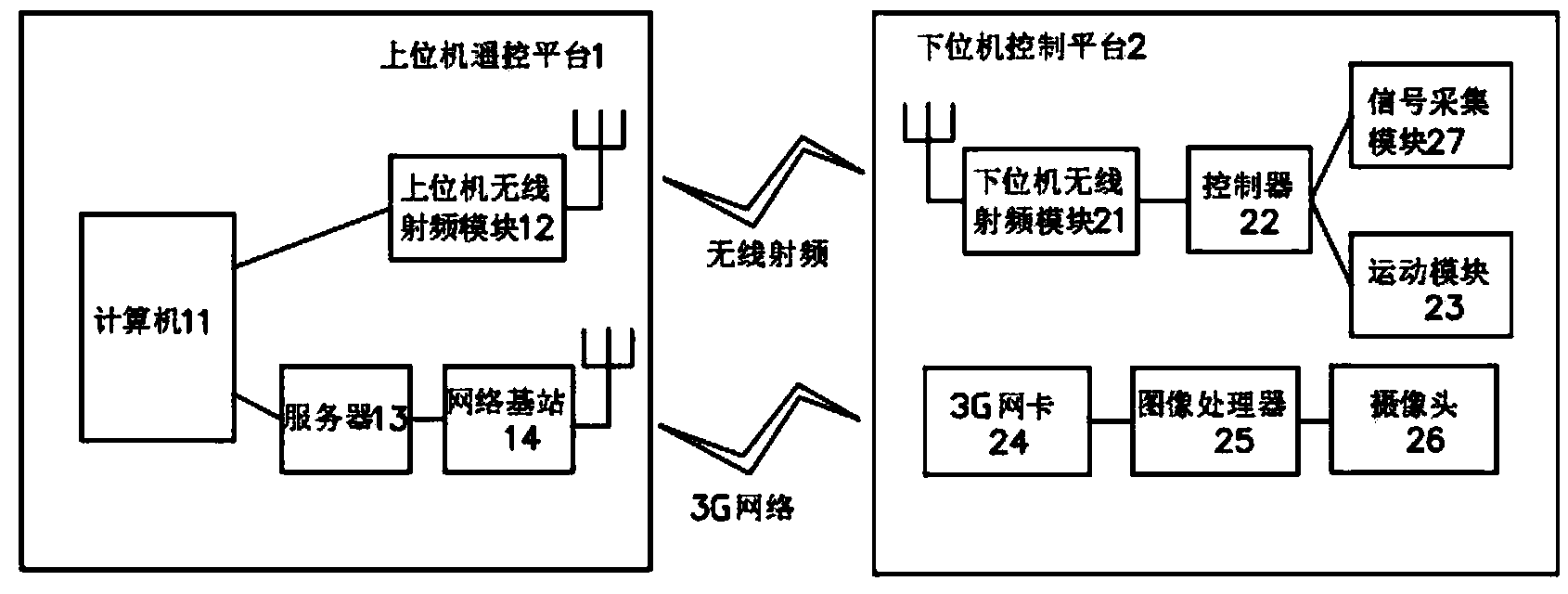

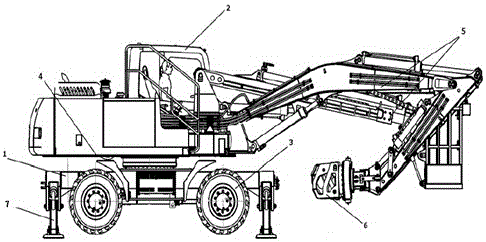

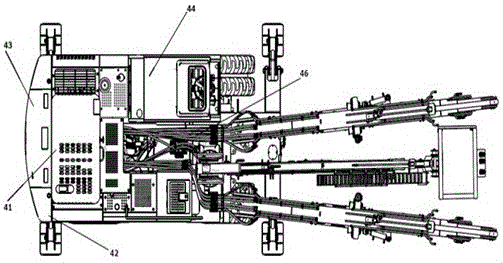

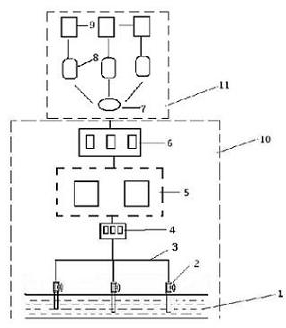

EOD (Explosive Ordnance Disposal) robot control system, EOD robot control method and EOD robot using EOD robot control method

ActiveCN103552084AReduce volumeLess prone to rolloverProgramme-controlled manipulatorRolloverRemote control

The invention discloses an EOD (Explosive Ordnance Disposal) robot control system. The EOD robot control system is characterized by comprising an upper computer remote control platform and a lower computer control platform, wherein the upper computer remote control platform comprises a computer, a server, an upper computer RFID (Radio Frequency Identification) module and a network base station; the lower computer control platform comprises a lower computer RFID module, a controller, a motion module, a 3G (The 3rd Generation Telecommunication) network card, an image processor, a camera and a signal collecting module. The EOD robot control system disclosed by the invention has the beneficial effects that the size of the EOD robot is minimized, the performance is stable, RFID transmission distance is moderate, and simultaneous monitoring by multiple computers or remote monitoring can be realized. The layout of the EOD robot control system is rationalized, and thus the EOD robot is unlikely to be subjected to accidents such as rollover when in operation. The motion module is high in running accuracy, compact in structure, small in size and good in obstacle crossing performance, the EOD robot is enabled to be stable in walking due to three platforms during a walking process, and the motion of the EOD robot is flexible.

Owner:北京东美森泰科技有限公司

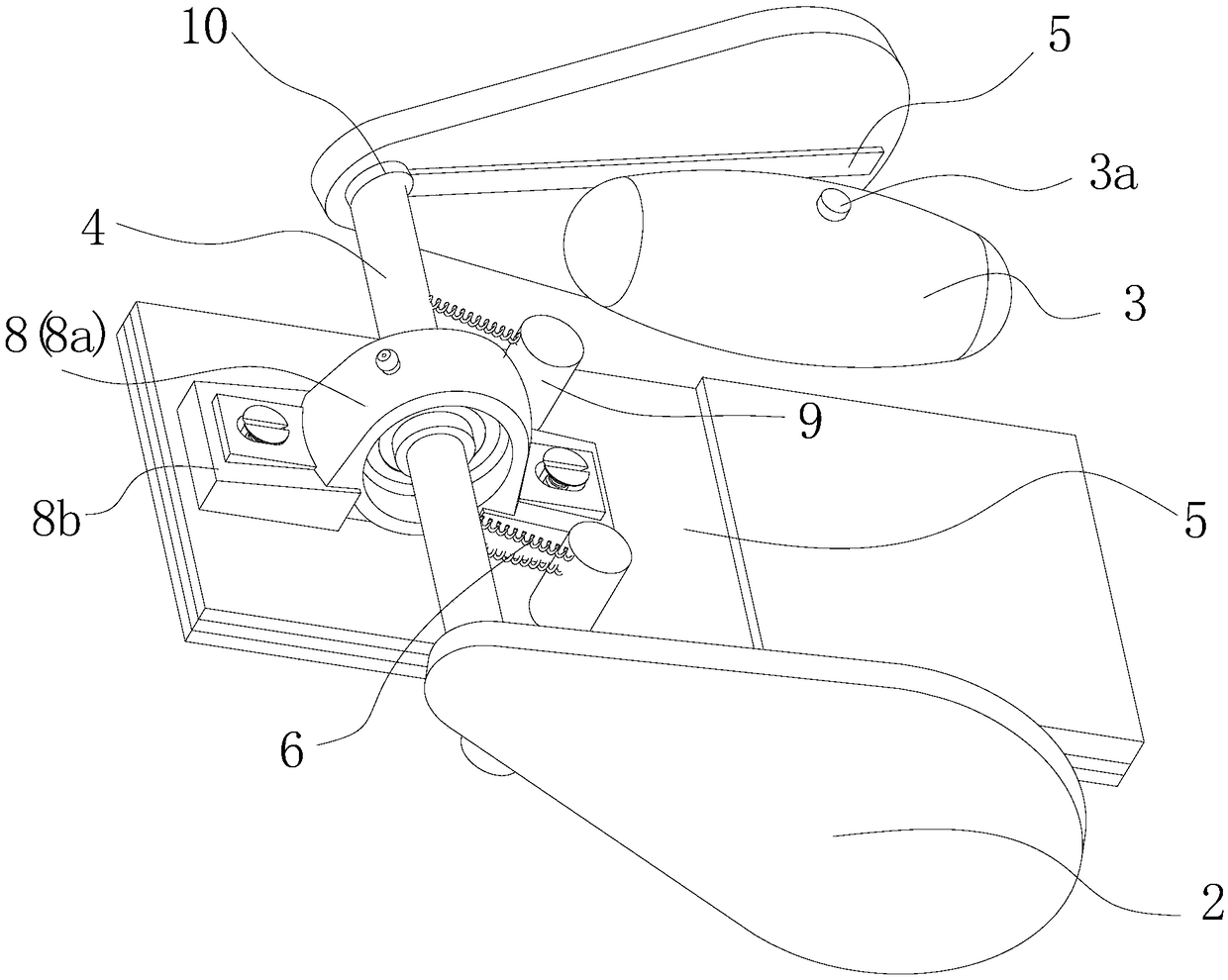

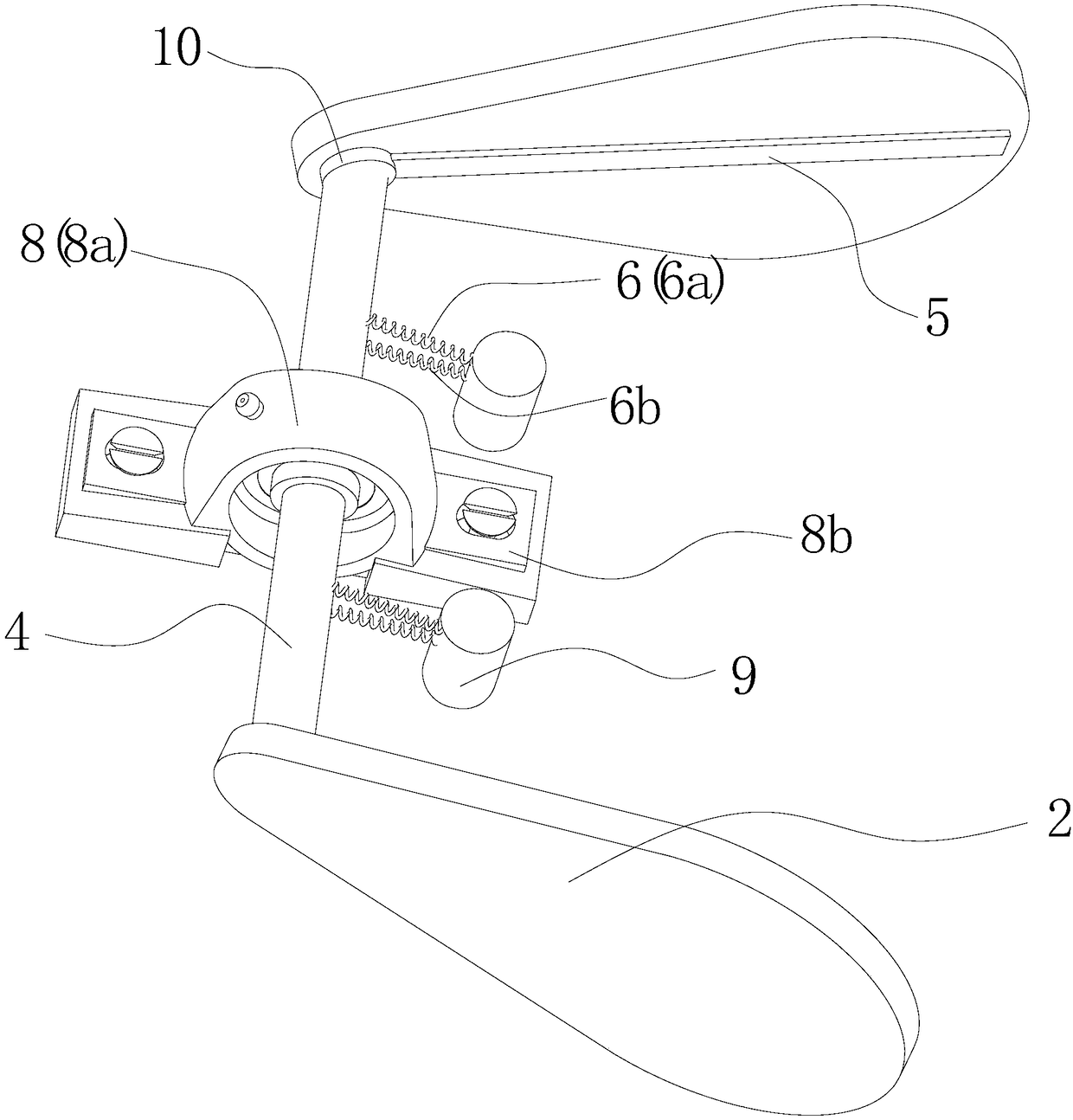

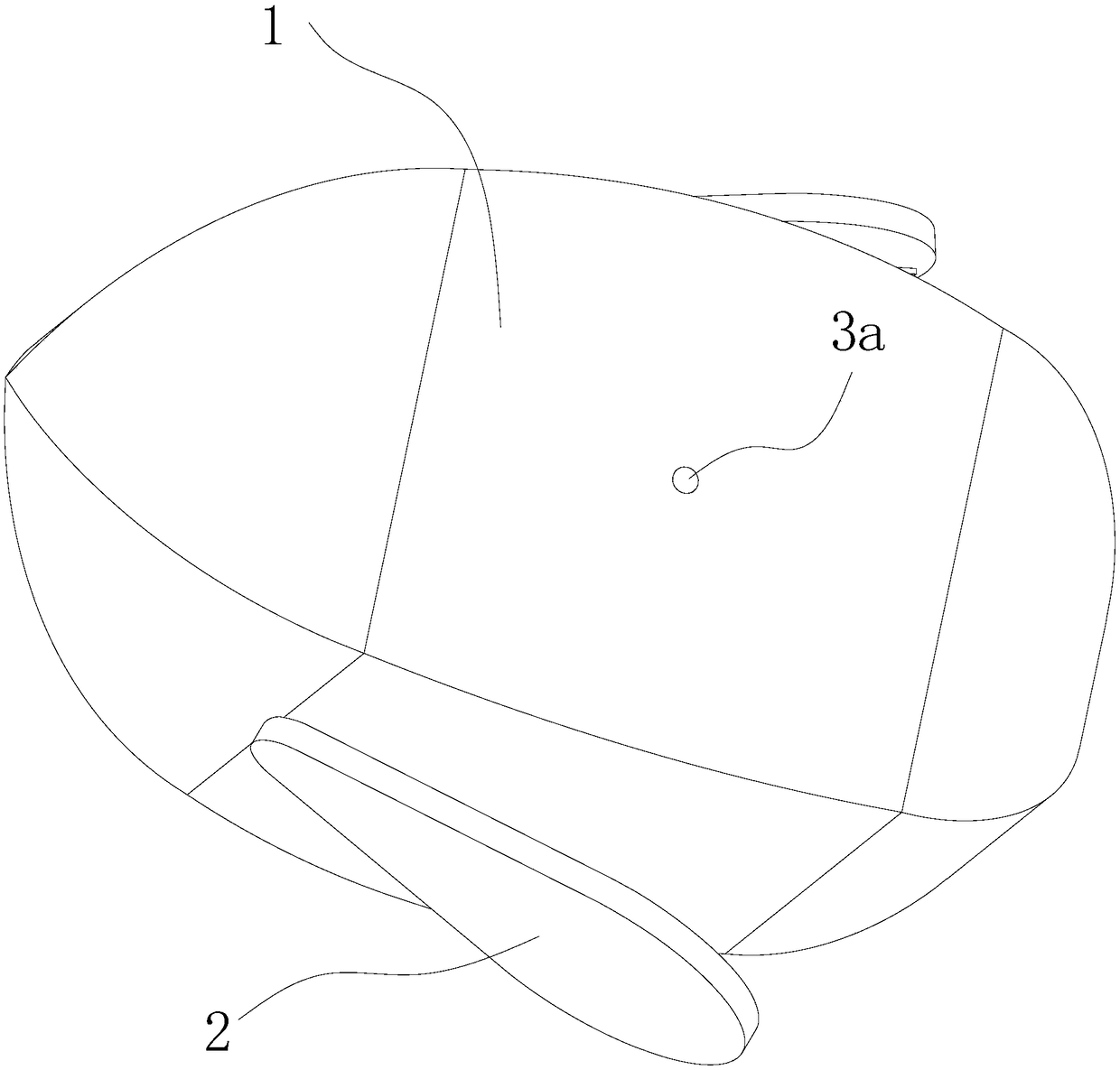

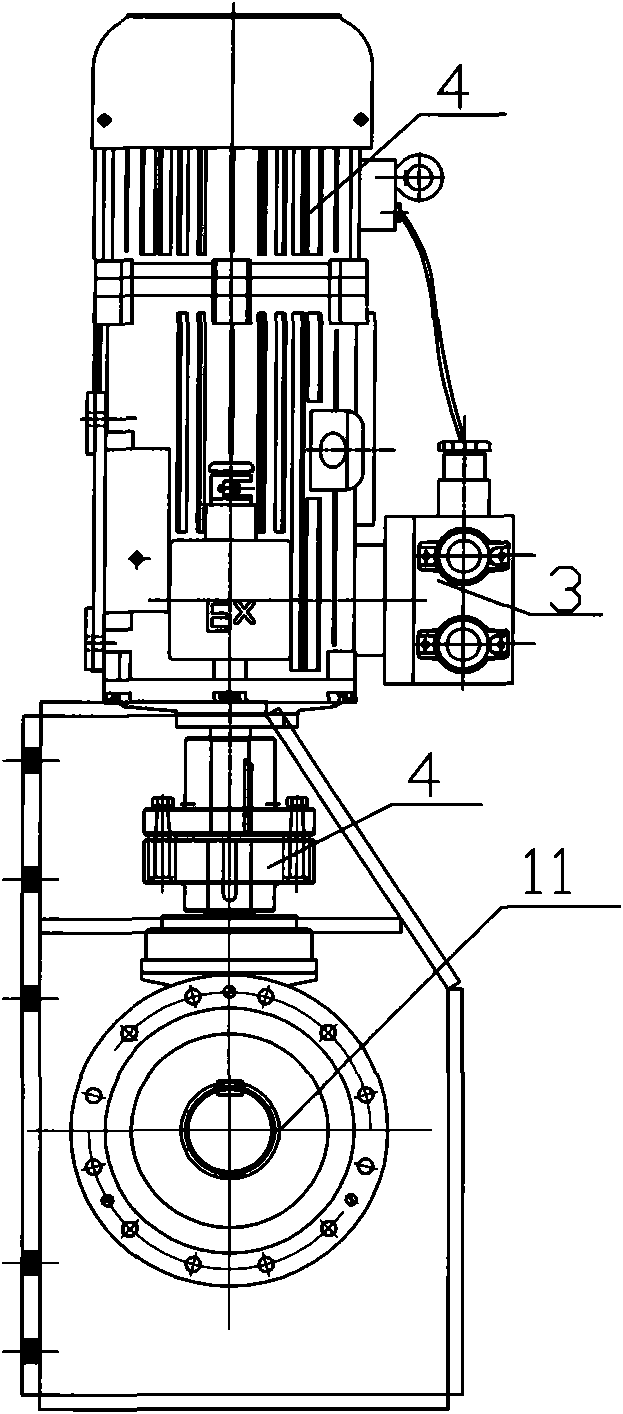

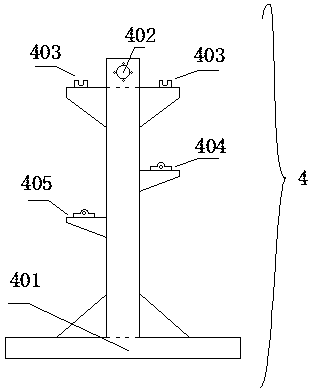

Rotary table of arch installation machine for tunnel

InactiveCN106321122AAchieve free rotationShorten the timeUnderground chambersTunnel liningHanging basketEngineering

The invention discloses a rotary table of an arch installation machine for a tunnel. The rotary table comprises a chassis, a cab 2, a traveling mechanism 3, an upper platform 4, a working arm 5 and a working device 6. The rotary table is characterized in that a rotary platform 45 comprises a bottom plate 451, a cab rotary base 452, two installation arm bases 453 and a hanging basket arm rotary base 454, wherein the bottom plate is used for supporting all assemblies on an installation platform, the cab rotary base is arranged on the front left, the two installation arm bases and the hanging basket arm rotary base are arranged on the front right of the bottom plate and located on the right side of the cab rotary base, and the two installation arms are symmetrically installed relative to a hanging basket arm.

Owner:CHINA RAILWAY NO 5 ENG GRP +2

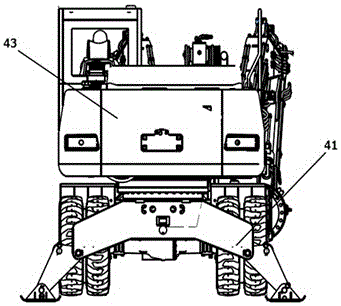

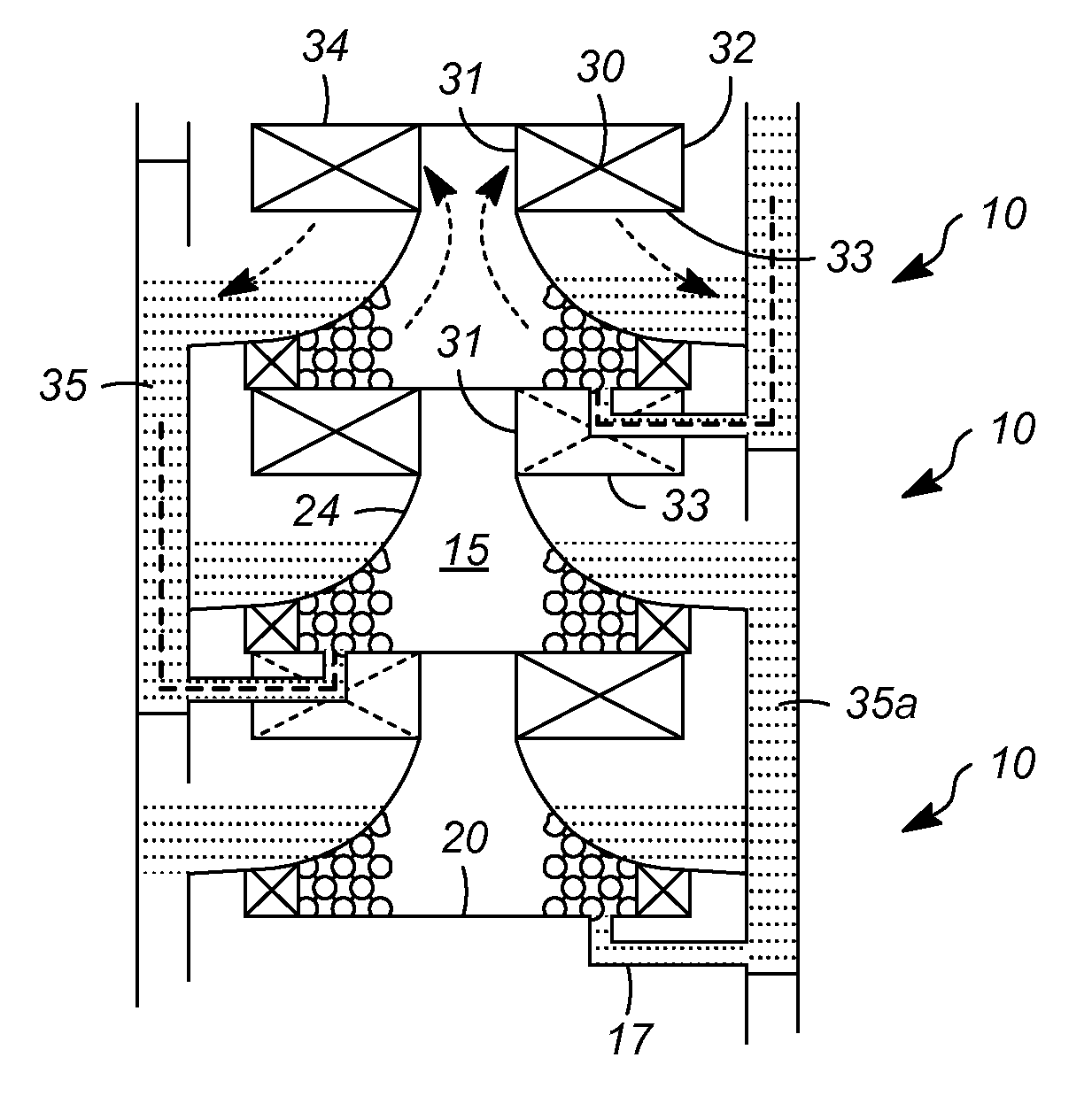

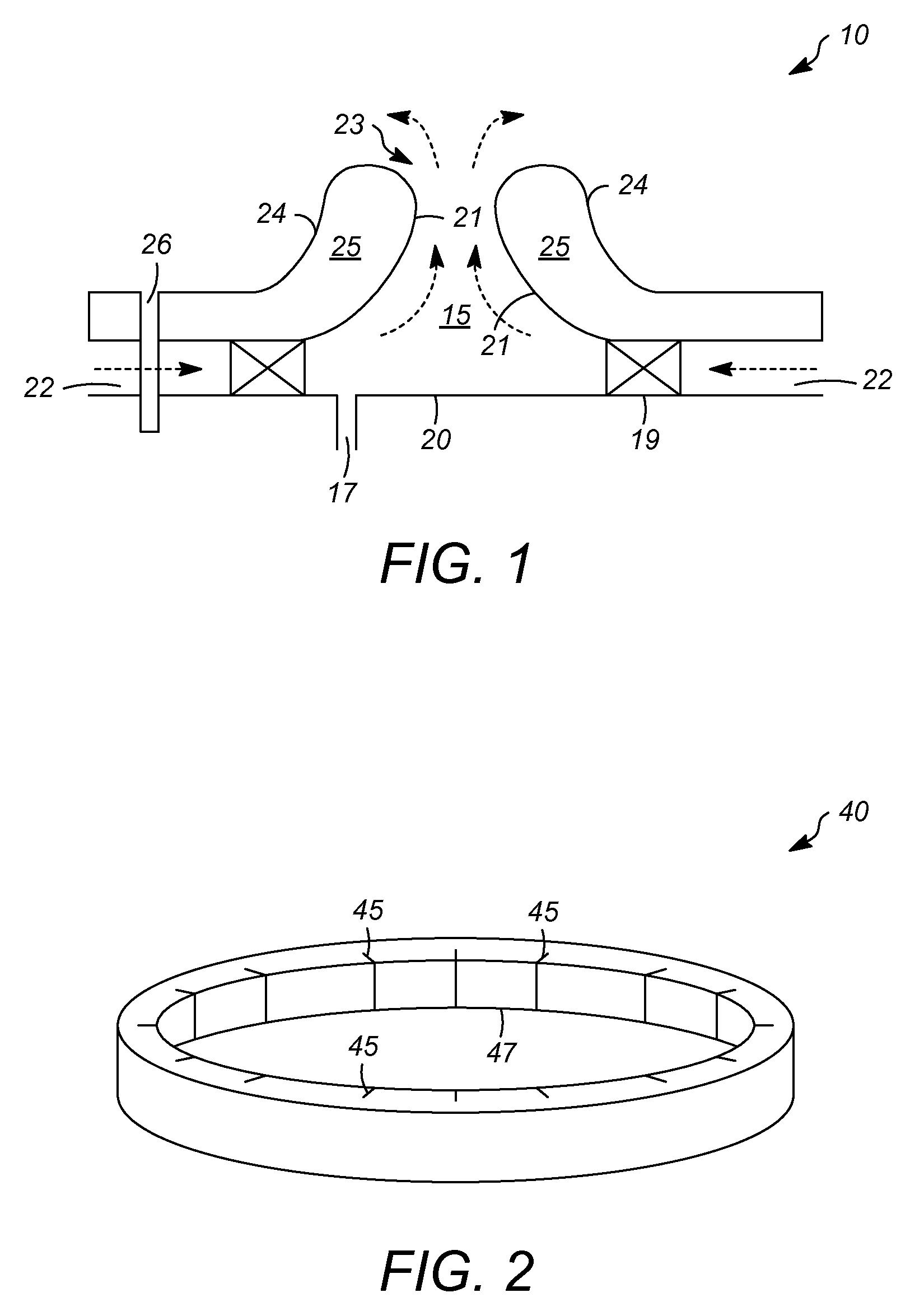

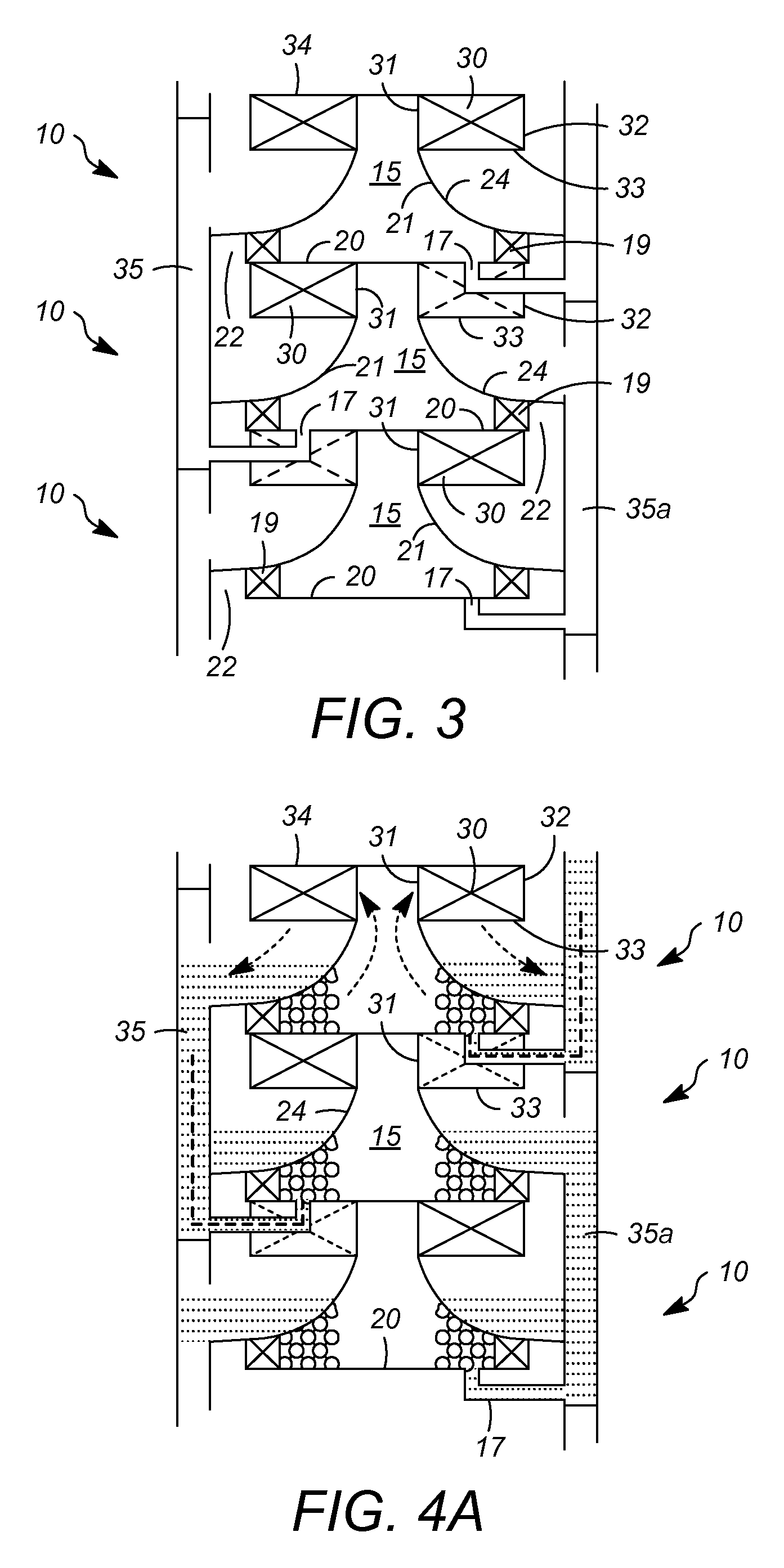

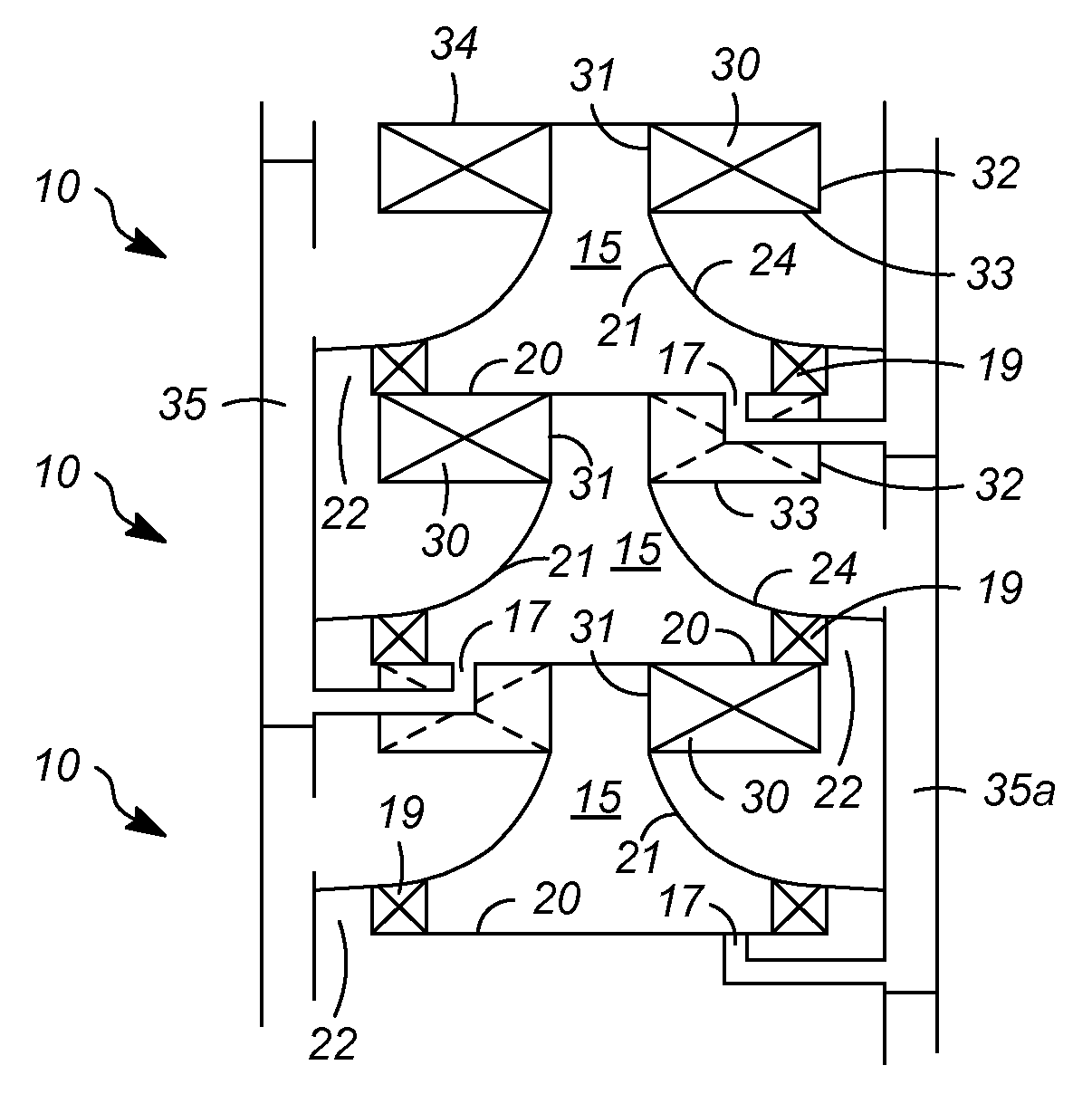

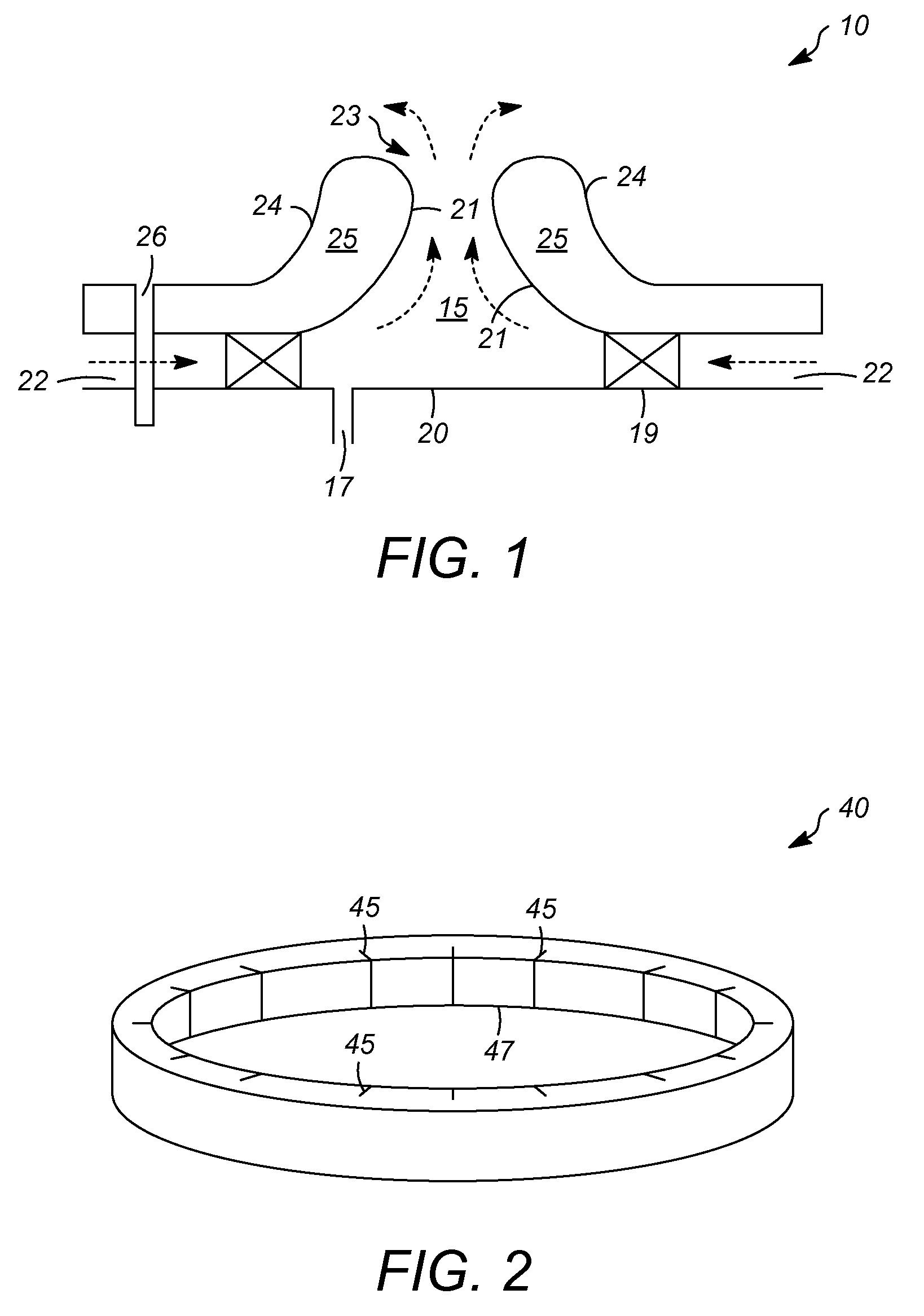

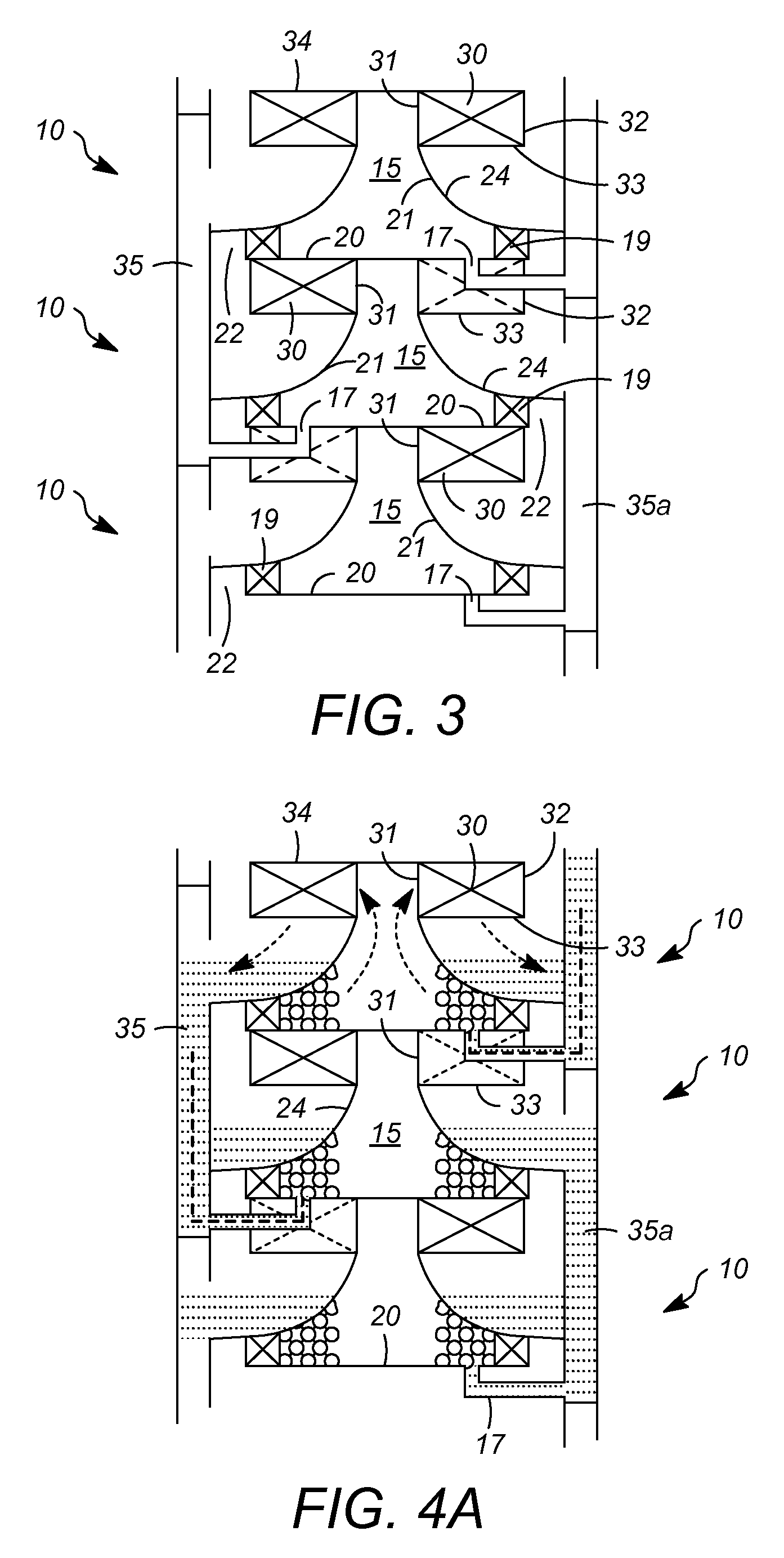

Vapor-liquid contacting apparatuses with vortex contacting stages

InactiveUS20100258427A1Narrow downReduction in stage efficiencyCombination devicesTransportation and packagingVapor liquidReactive distillation

Vapor-liquid contacting apparatuses, for example reactors and distillation columns (as well as reactive distillation apparatuses), comprising a vessel with one or more vortex contacting stages, are described. The one or more stages provide high interfacial area for the effective contacting of the different phases, in addition to the effective disengagement of these phases after contacting.

Owner:UOP LLC

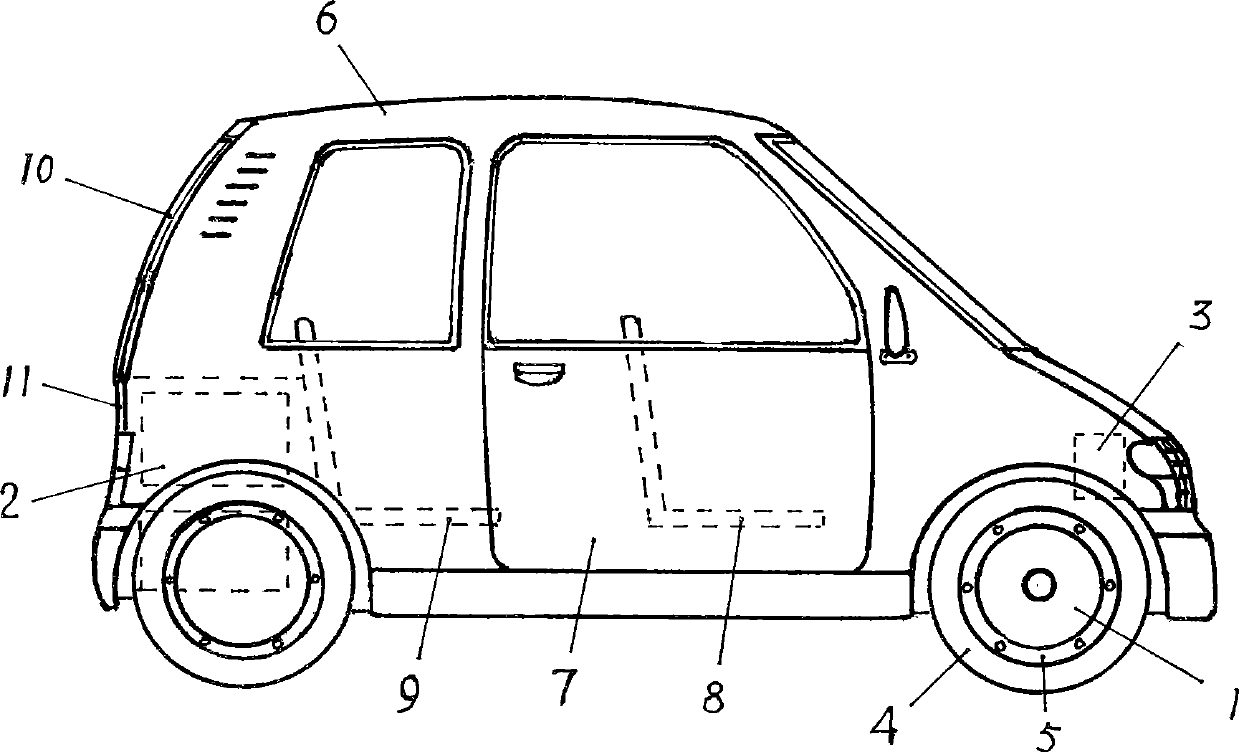

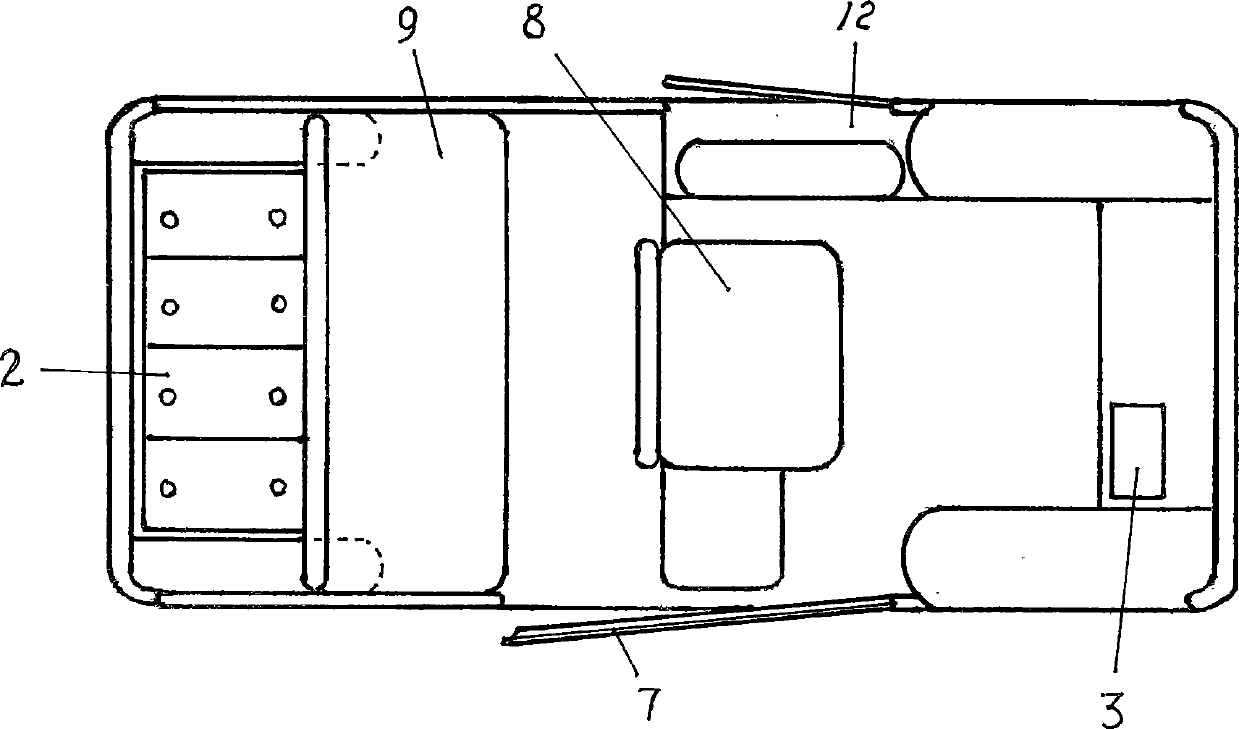

Submicron electric car driven by electric machine with hub

InactiveCN101372205AImprove protectionReduce stressMotor depositionVehicular energy storageLow noiseFrequency changer

The invention provides an ultra-micro electric car driven by a hub motor. Hub motors which are specially designed are installed on wheels of the electric car and directly drive the electric car to run without gearboxes and transmission devices, and the electric car has high energy efficiency ratio, low noise and no exhaust pollution. The combination of the pole changing of the hub motor and the frequency conversion of a frequency inverter is used in variable-speed control of the electric car, so as to ensure the wider scope of speed regulation for the electric car and better performance in climbing, heavy-load startup and low-speed running. The wheels and a brake disc or a brake drum are arranged at the outer edge of an end cover inside the hub motor or on a ring flange inside a motor casing, so as to ensure the outer end of wheel axles to have lower stress, more reasonable stress distribution, better integrity between the wheels and a brake device and stronger impact resistance. The design of an ultra-micro car body with the door opening at one side and two rows with threes seats or two rows with two seats can ensure simpler structure of the whole car and low manufacturing cost, so that the ultra-micro electric car can replace a motorcycle so as to be used in public transport.

Owner:鲁泊凡

Vapor-liquid contacting apparatuses with vortex contacting stages

InactiveUS8047509B2Reduce entrainmentLower overall pressure dropCombination devicesUsing liquid separation agentVapor liquidReactive distillation

Vapor-liquid contacting apparatuses, for example reactors and distillation columns (as well as reactive distillation apparatuses), comprising a vessel with one or more vortex contacting stages, are described. The one or more stages provide high interfacial area for the effective contacting of the different phases, in addition to the effective disengagement of these phases after contacting.

Owner:UOP LLC

A soft-body robotic fish driven by shape memory alloy

PendingCN108974301AImplement differential turnsEase of turning at differential speedsPropulsive elements of non-rotary typeUnderwater vesselsElectricityComputer module

The invention provides a soft-body robot fish driven by a shape memory alloy, which comprises a fish body, two pectoral fins arranged on two sides of the fish body, an air bag arranged in the fish body, a power supply module and a control module. The fish body and the pectoral fin are both of soft structure, A rotary shaft is pierced on the front side of the fish body, two pectoral fins are respectively arranged at two ends of the rotating shaft, A memory alloy plate wound with a resistance wire for control that forward movement of the fish body is arranged at the side part of the pectoral fin, The side wall of the rotating shaft is provided with a memory alloy spring for controlling the rotation of the rotating shaft, the memory alloy plate and the memory alloy spring are respectively electrically connected with the power supply module, and the power supply module is electrically connected with the control module. The soft-body robot fish driven by the shape memory alloy of the technical proposal of the invention has strong applicability, can realize multi-direction travel and turn of the fish body in different water areas, and has simple control structure and strong structural stability.

Owner:GUANGZHOU UNIVERSITY

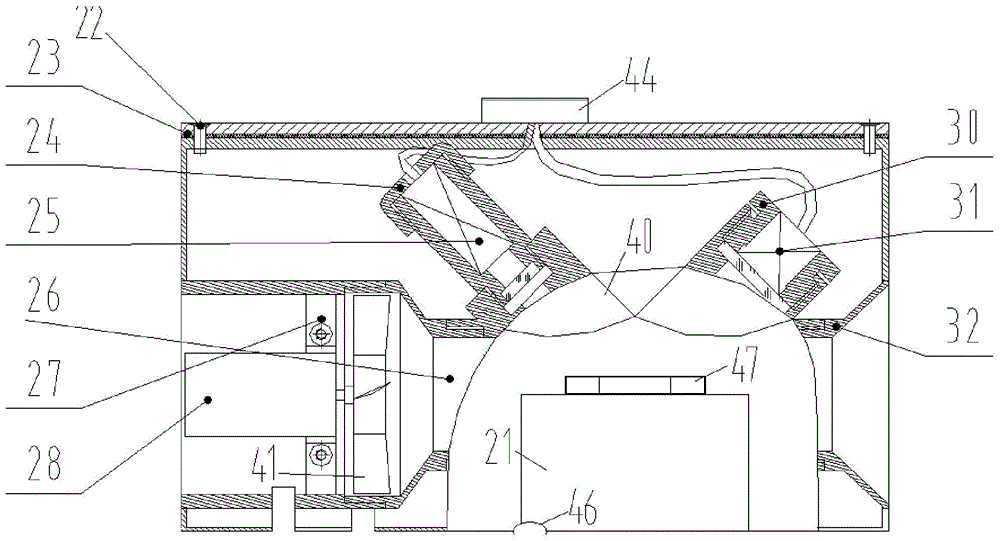

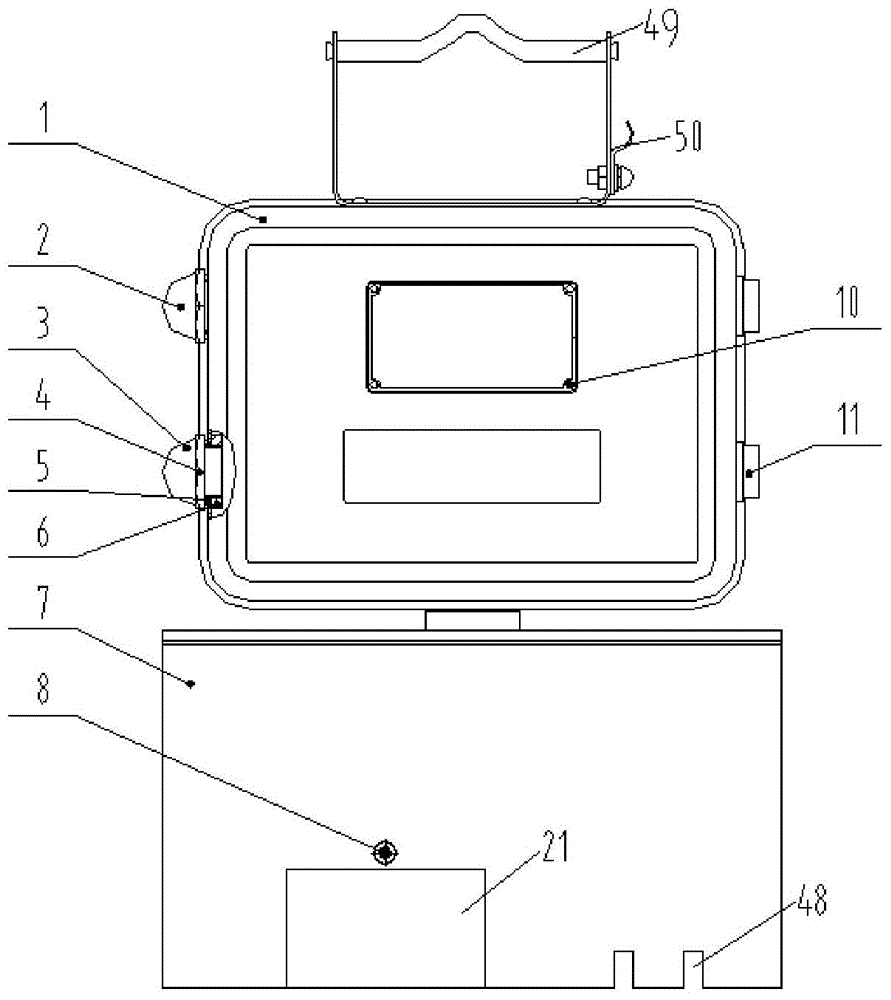

Easily maintainable optical dust concentration detection device

ActiveCN104155222AReduce pollutionEasy to lock and observeParticle suspension analysisMeasuring instrumentElectric machinery

The invention discloses an easily maintainable optical dust concentration detection device. The easily maintainable optical dust concentration detection device is characterized in that an upper shell 1 is coated with an upper shell cover group 12, the periphery of the upper shell cover group 12 is sealed with the upper shell 1 through an upper shell cover group sealing gasket 13 so that the upper shell 1 is formed into a sealed chamber for mounting a dust concentration detection system, the lower part of the upper shell 1 is connected to the upper part of a lower shell 7 through a connecting column 44, an air inlet is formed in one end of the lower shell 7, while an air outlet is formed in the other end of the lower shell 7, an optical measuring instrument 40 is fixed on the lower shell 7 between the air outlet and the air inlet and used for detecting the dust concentration, a fan is mounted at the end of the air outlet and fixed through a fan fixing cylinder 27, a motor 28 is arranged at one end of the fan and connected with an exhaust fan 41, an observing and cleaning opening 21 is formed in the lower part of the lower shell 7, and the shape of the observing and cleaning opening 21 is matched with that of the lower shell 7.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

Impeller type washing machine

ActiveCN107488969AReasonable installationEfficient electrolysisOther washing machinesWater/sewage treatmentImpellerPulp and paper industry

The invention discloses an impeller type washing machine. The impeller type washing machine includes a water bucket, an inner bucket, an impeller and an electrolytic device, wherein the periphery of the water bucket is provided with an opening, the bottom wall of the water bucket is provided with an anticollision groove protruding outwardly, the inner bucket is arranged in the water bucket, the impeller is arranged on the bottom wall of the inner bucket, the electrolytic device includes an installation base and an electrode plate, the electrode plate is arranged on the installation base, the installation base is installed at the position of the opening and extends toward the anticollision groove, the electrode plate is arranged in the anticollision groove, and a wire leading hole is formed in the installation base, By arranging the electrode plate in the anticollision groove, interference between the electrode plate and original parts in the water bucket can be avoided, the space occupied by the impeller type washing machine is less, and the installation reliability of the electrolytic device can be guaranteed.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

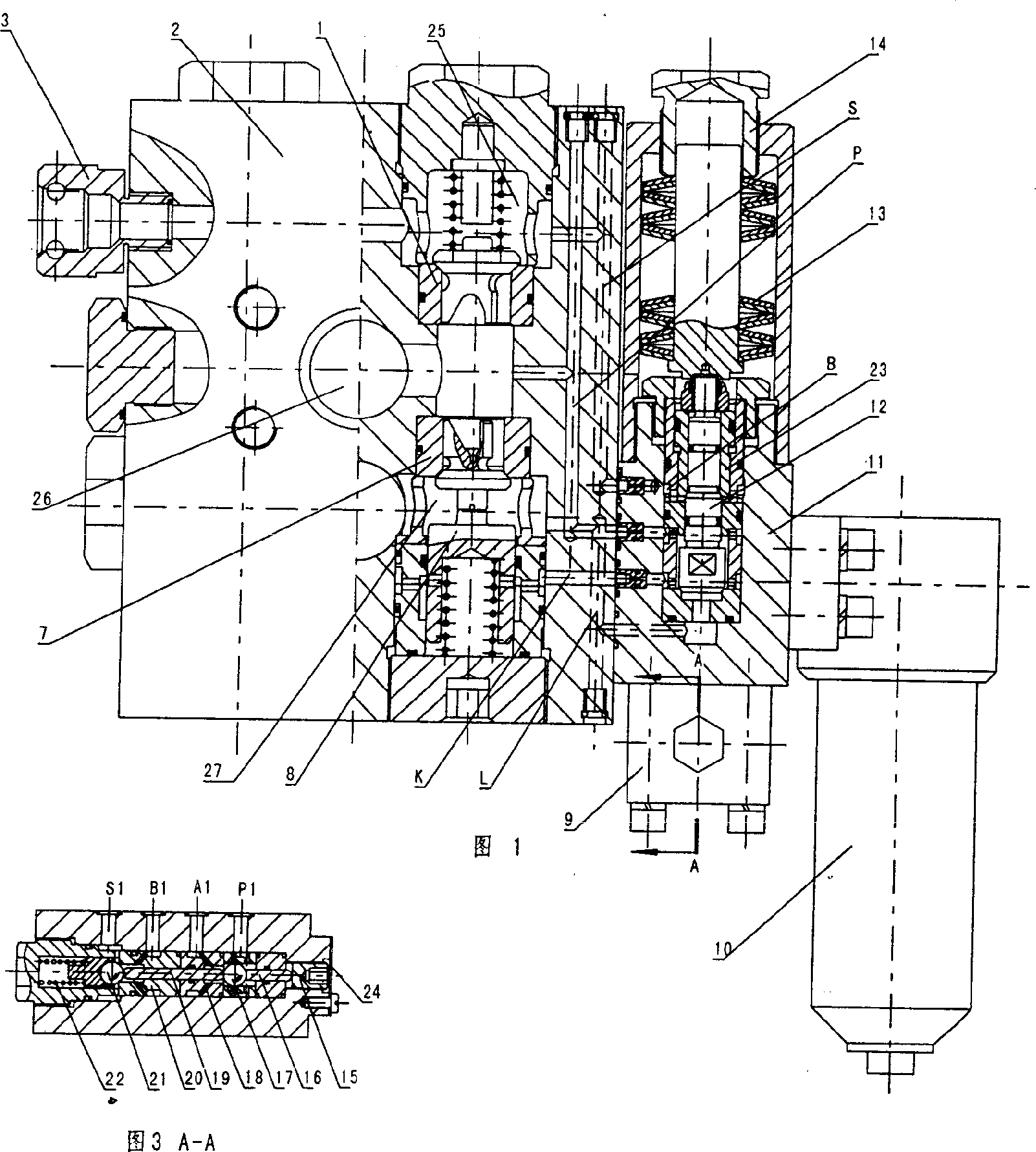

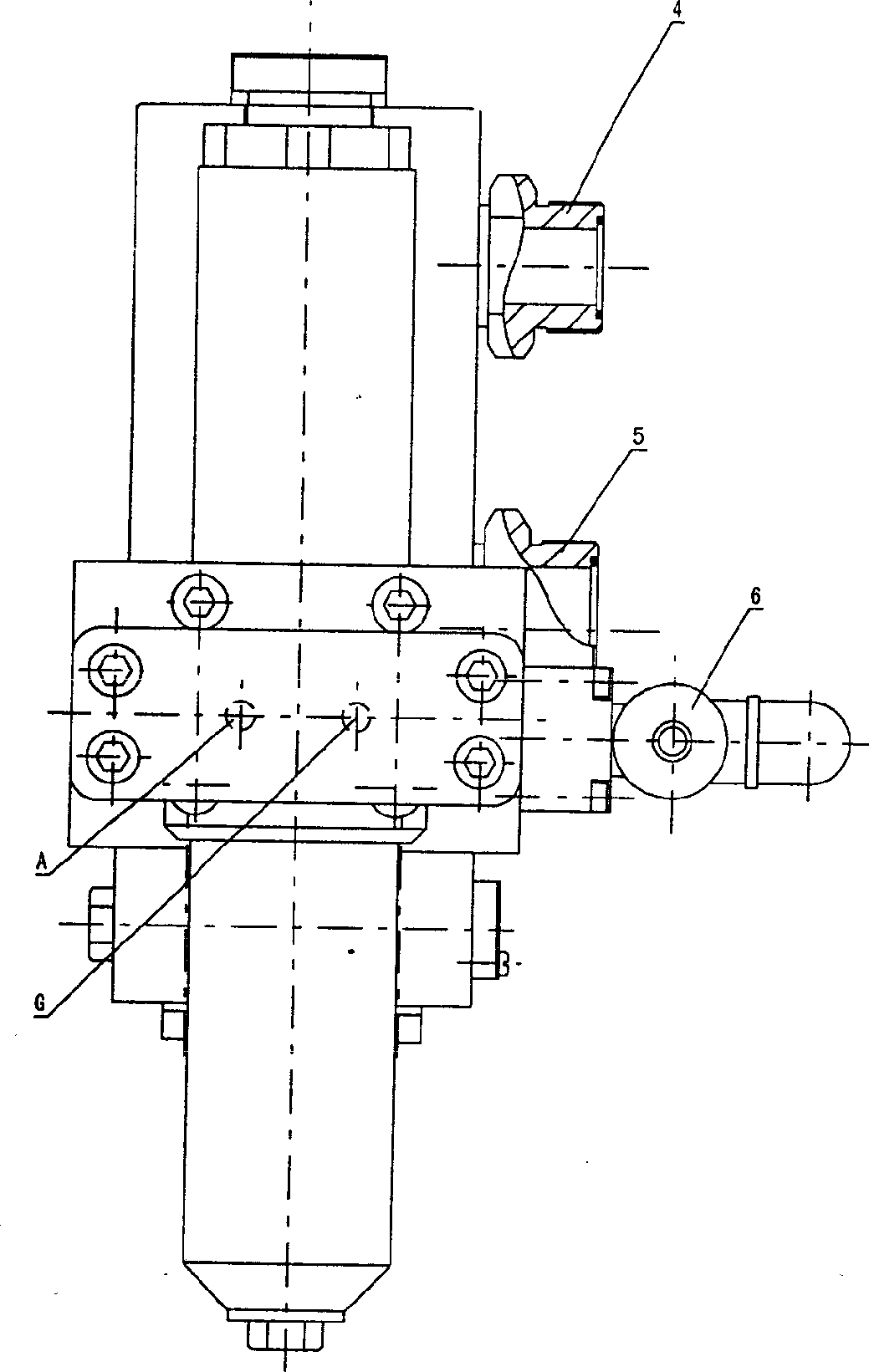

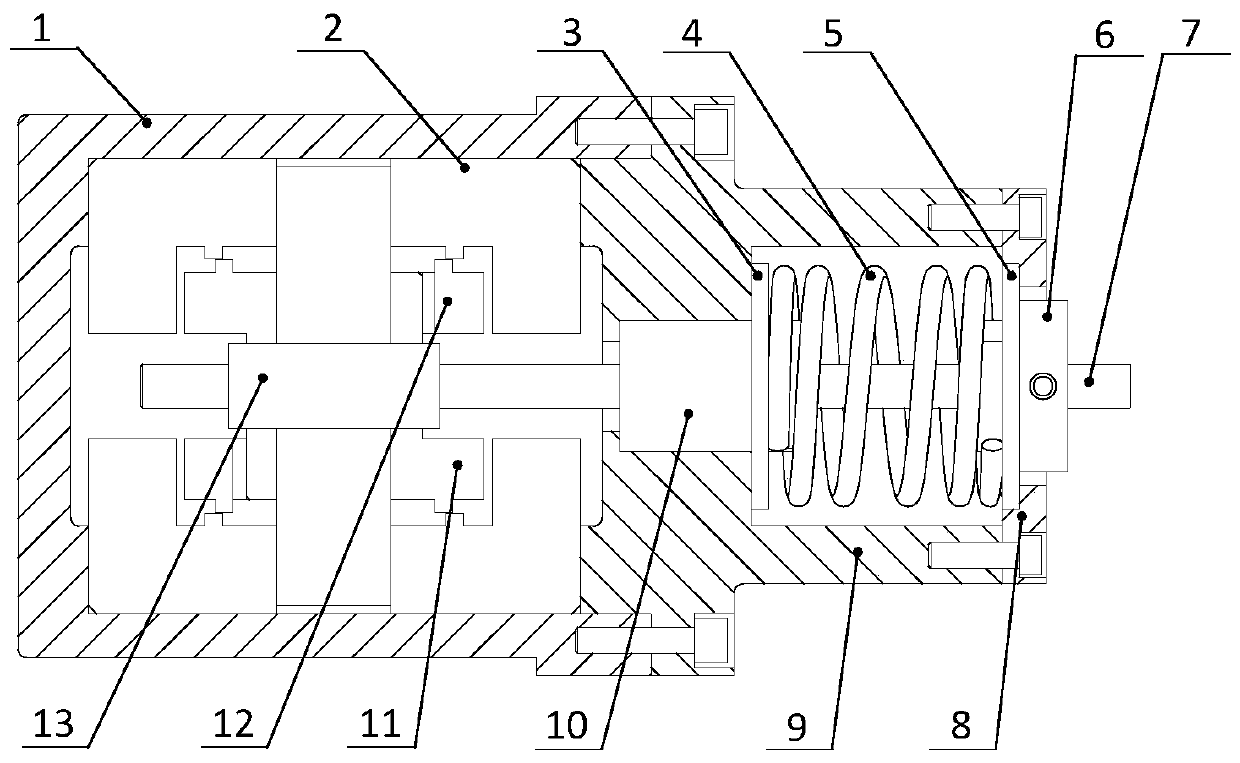

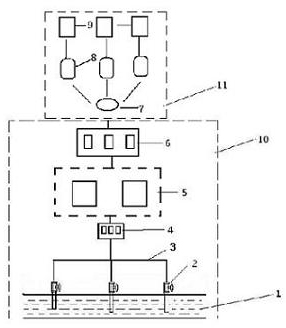

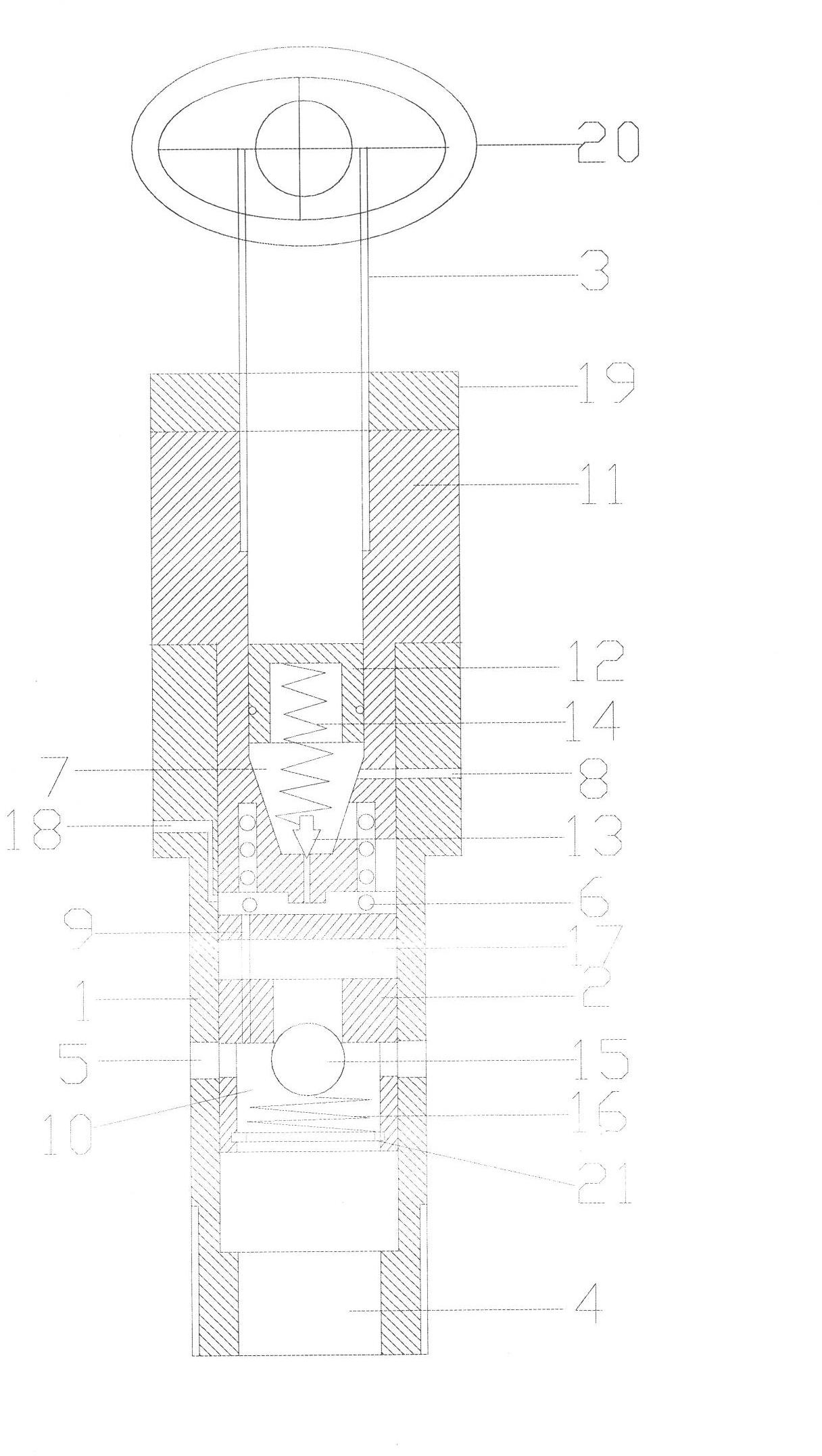

Electrohydraulic unloading valve with both hydraulic control mode and electrohydraulic control mode

InactiveCN1811202AReasonable installationImprove reliabilityServomotor componentsProps/chocksEmulsionControl manner

The electrohydraulic unloading valve with both hydraulic control mode and electrohydraulic control mode consists of mainly a main valve body, a pilot operated valve and a filter. The main valve body is provided with non-return valve assembly, main valve assembly and thrust piston, as well as energy accumulator joint, high pressure liquid outlet joint, unloading back liquid joint and solenoid valve; and the pilot operated valve has electrohydraulic switching valve with communicated liquid path in the bottom. The electrohydraulic unloading valve has two functions, including conveying high pressure emulsion during the operation of the work face support and loading the emulsion pump during stopping the work face support. It has expanded use range in both fully mechanized coal winning work face and common coal winning work face, high reliability, simple and compact structure and simple operation.

Owner:CHINA UNIV OF MINING & TECH

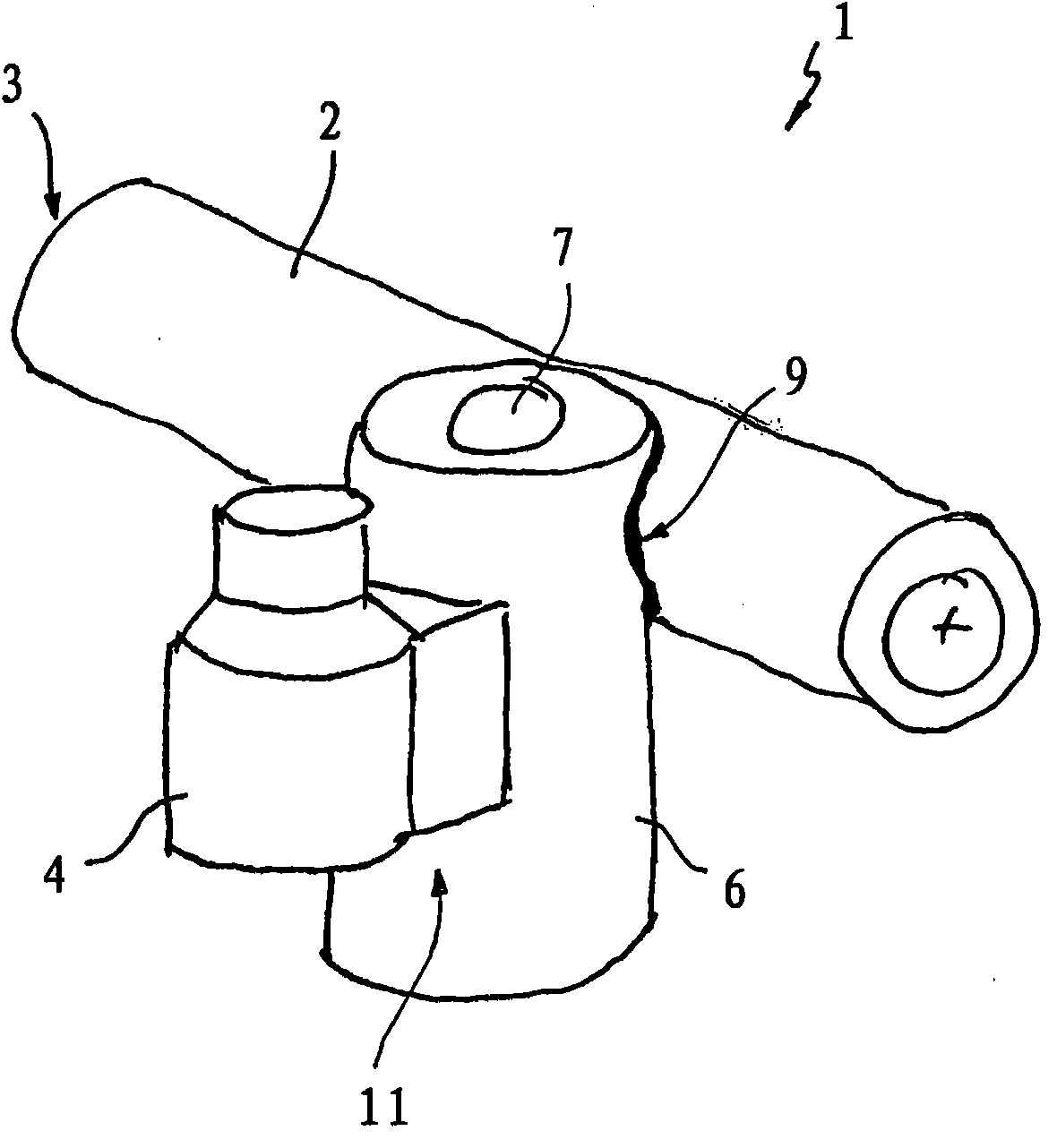

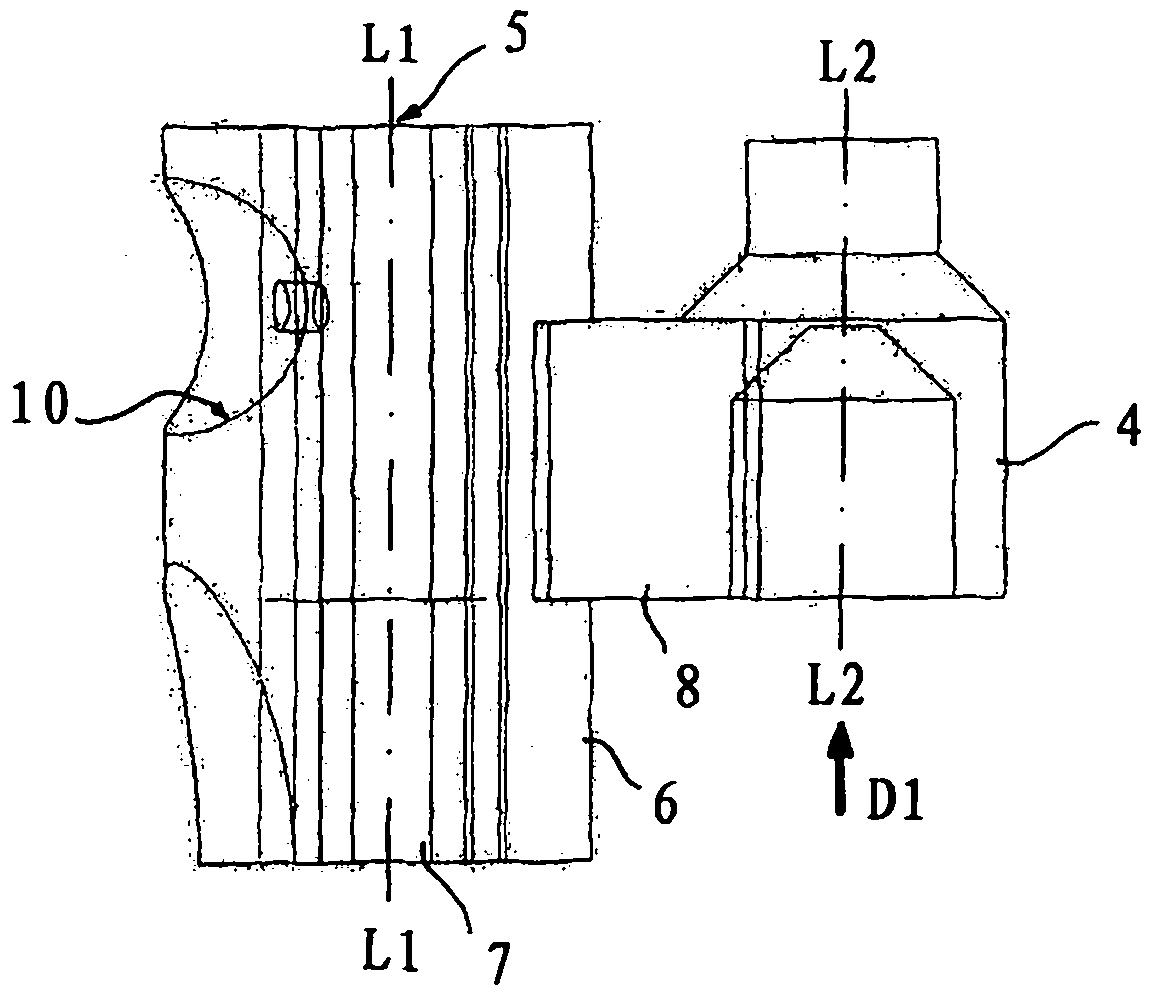

Fuel distributor

InactiveCN101793214AReduce leakageClose acceptanceMachines/enginesSpecial fuel injection apparatusExternal combustion engineInternal combustion engine

A fuel distributor for conveying fuel to an injection valve of the internal combustion engine, is provided with a distributing pipe (2) for accommodating fuel at normal voltage and at least one injector accommodating part (4), wherein the distributing pipe has a fuel inlet (3), the injector accommodating part is connected to the distributing pipe through a connecting passage and the distributing pipe can be fixed on the internal combustion engine through at least one fixing element perforating the fixture unit accommodating part (6), the fixture unit accommodating part is connected to the distributing pipe through a brazing interconnecting piece (9) and the injector accommodating part is provided on the lateral surface (11) of the fixture unit accommodating part opposite to the brazing interconnecting piece, the connecting passage perforates the fixture unit accommodating part and the longitudinal axis of the connecting passage is transversal to the longitudinal axis of the perforation hole (7) perforating the fixture unit accommodating part.

Owner:BENTELER AUTOMOBILTECHNIK GMBH

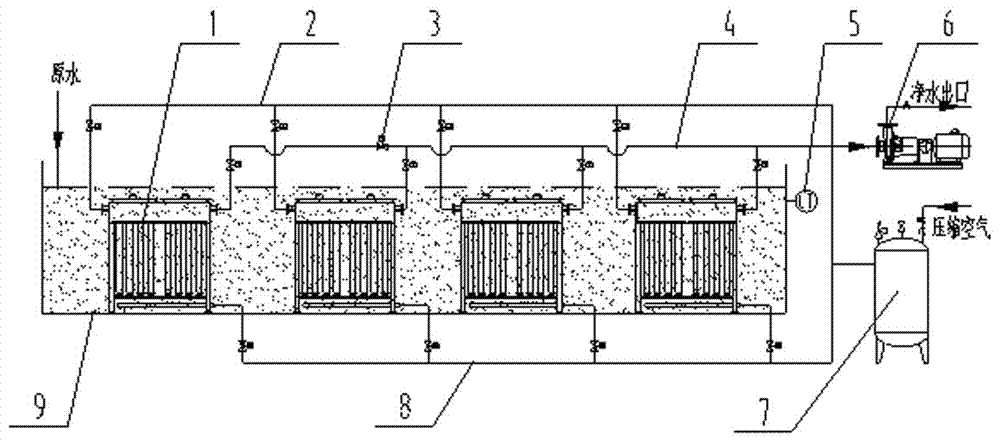

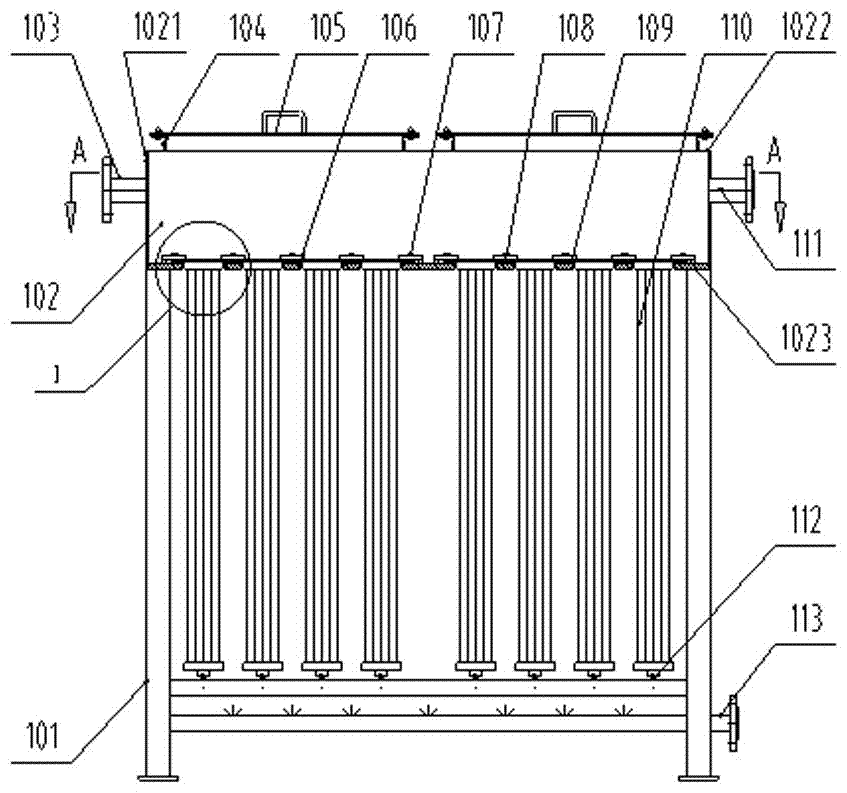

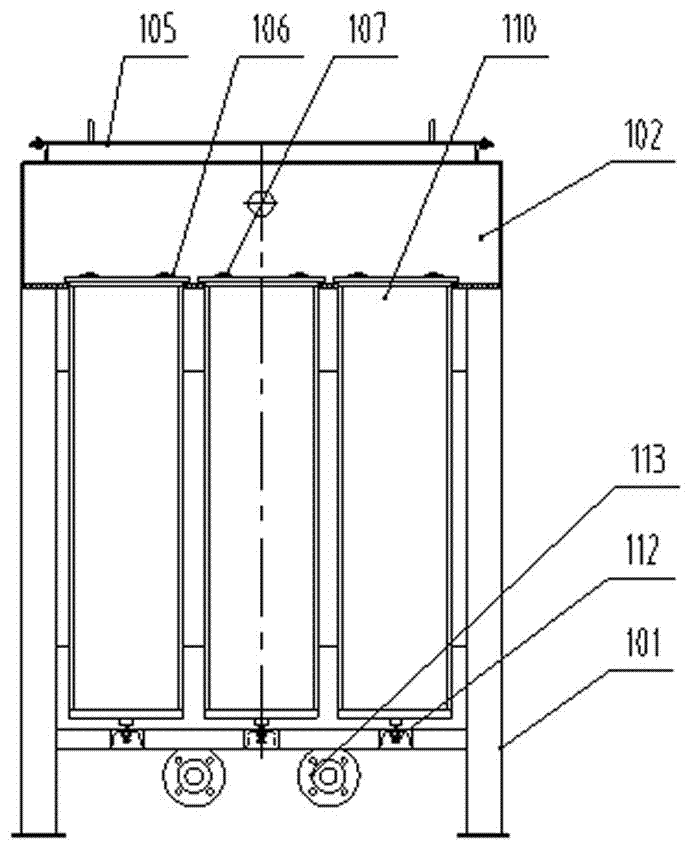

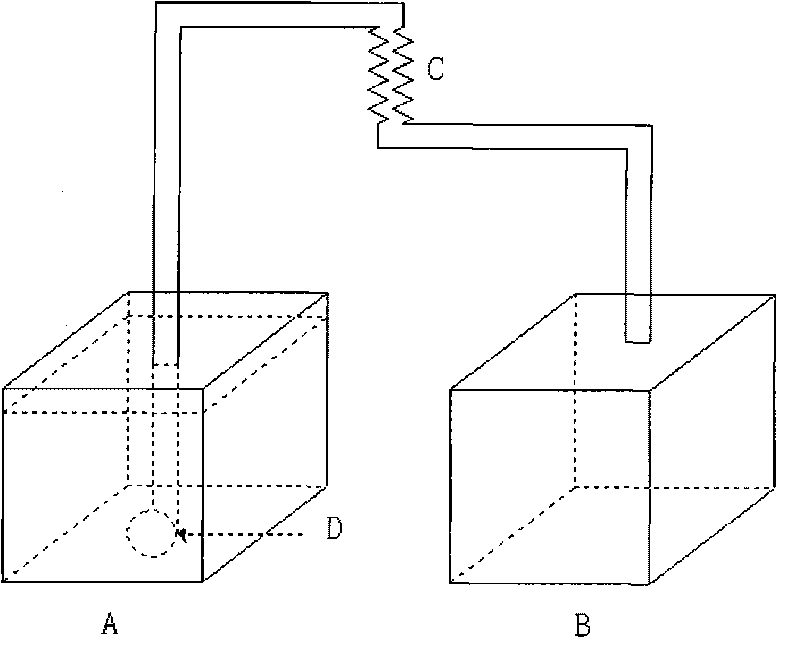

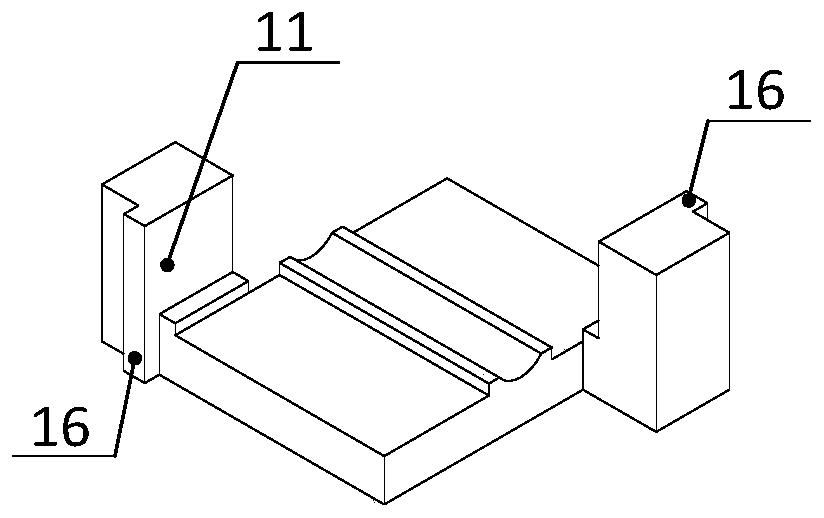

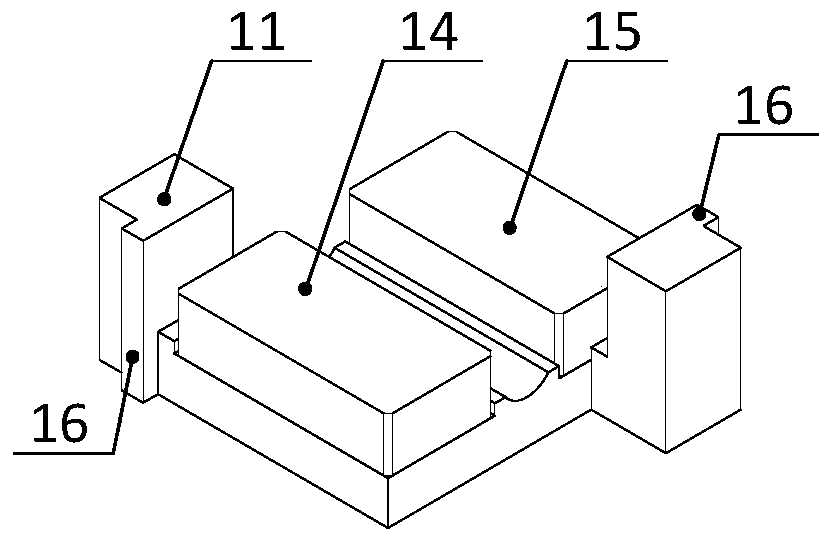

Flooded modular structure flat plate ceramic membrane filtration system

PendingCN106984197ANovel structureSimple manufacturing processSemi-permeable membranesSpecific water treatment objectivesLevel sensorEngineering

The invention discloses a flooded modular structure flat plate ceramic membrane filtration system. The system comprises a plurality of flat plate ceramic membrane filtration devices. The flat plate ceramic membrane filtration devices are used as filter units and are arranged in a line or multiple lines to form a large filter system. Each one of the filter units comprises an upper clean water outlet, a reverse cleaning gas inlet and a bottom aeration pipe. The clean water outlet, the reverse cleaning gas inlet and the aeration pipe of each one of the filter units are respectively connected to a corresponding clean water main pipe, a corresponding reverse cleaning main pipe and an aeration main pipe through corresponding branch pipes and electric valves on the branch pipes. The clean water main pipe is connected to a water pump. The reverse cleaning main pipe and the aeration main pipe are connected to a gas storage tank. The whole filter unit is immersed into a raw water tank, and one side of the upper part of the raw water tank is provided with a liquid level sensor. All the electric valves are connected to an electronic control device. The system has a novel structure, is easy to install and use, has small filtering resistance, has matching flexibility, has good regeneration effect and is not easily damaged.

Owner:HUNAN UNIV OF SCI & TECH

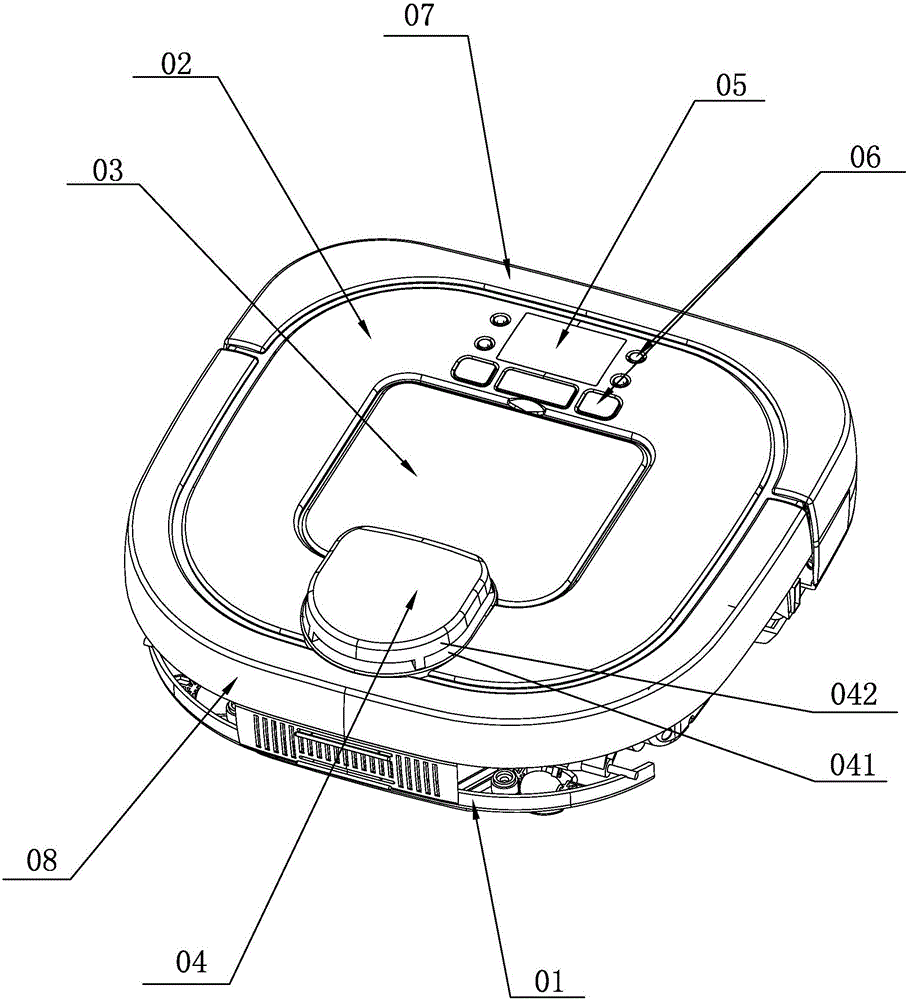

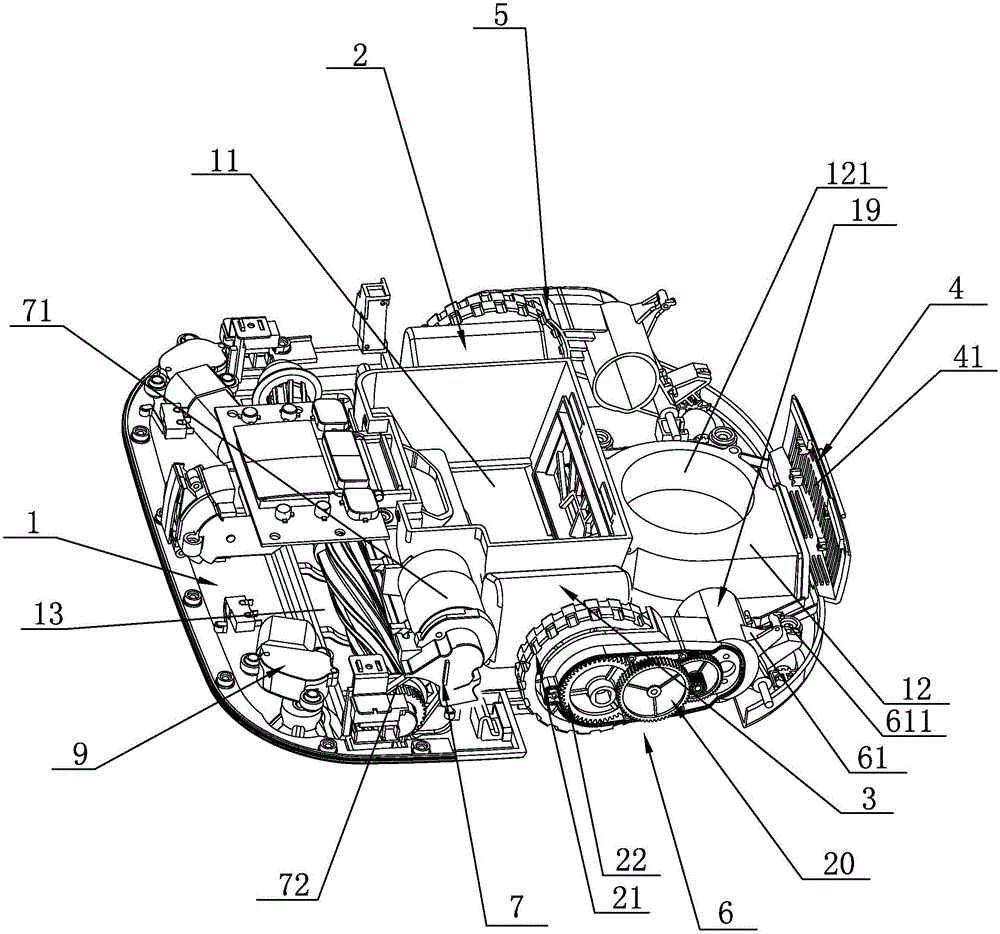

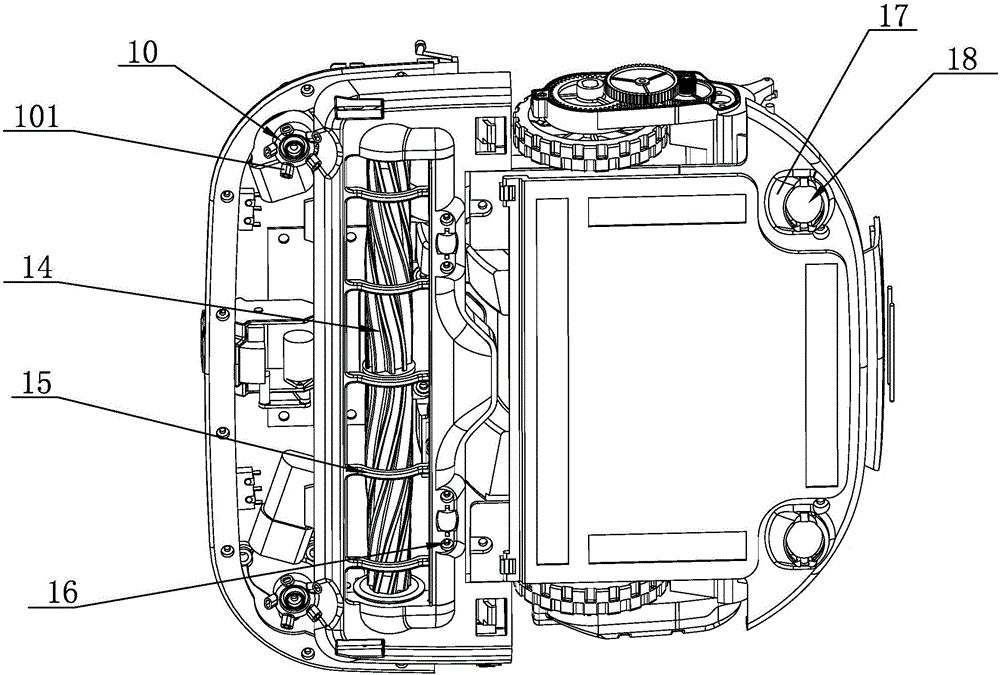

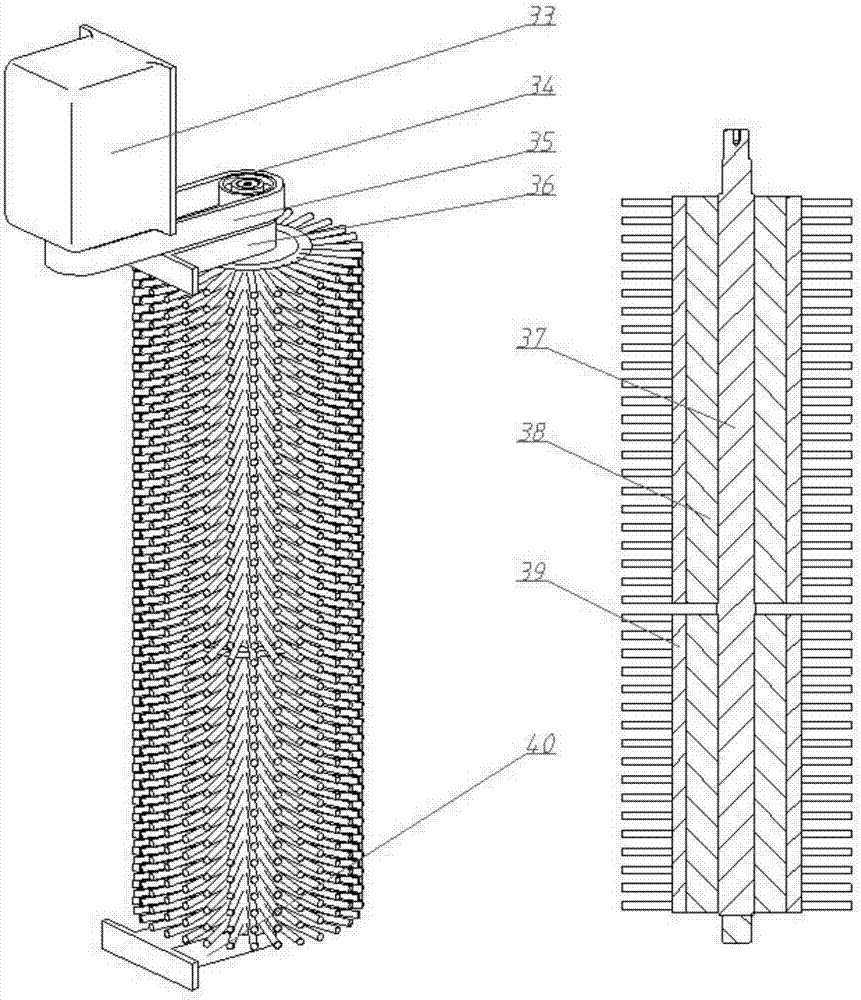

Multifunctional intelligent sweeping robot

The invention discloses a multifunctional intelligent sweeping robot. The multifunctional intelligent sweeping robot includes a base and an upper cover; the base includes a base body; a dust storage cavity is formed in an upper end surface of the base body; a first chargeable battery is fixedly stuck on an outer surface of the left end of the dust storage cavity; a second chargeable battery is fixedly stuck on an outer surface of the right end of the dust storage cavity; a first driving device and a second driving device are arranged on the centers of the left end and the right end of the base body respectively; an article storage cavity is formed in the back of the dust storage cavity formed in the base body; a rolling brush device is arranged in the article storage cavity; a rolling brush driving device is arranged on the right end of the rolling brush device; the rolling brush driving device drives the rolling brush device to roll; a support is integrally arranged on the front end of the second driving device; a camera installation groove is formed in the support; and a camera is arranged in the camera installation groove. The multifunctional intelligent sweeping robot is reasonable in structural design, is simple in structure, is low in manufacture cost, is large in charge capacity, is long in working time, is easy to use, and is various in function.

Owner:ZHEJIANG HANNAO DIGITAL TECH +1

Water-based drag reducer and application thereof

InactiveCN101746875AAccurate flow resistance characteristic dataImprove energy efficiencyWater/sewage treatment by substance additionWater/sewage treatment using germicide/oligodynamic-processWater basedValidation methods

The invention discloses a water-based drag reducer and application thereof. The water-based drag reducer comprises the following components in parts per million by weight: 30-200ppm of non-ionic surface active agent fatty alcohol-polyoxyethylene ether, 5-40ppm of defoaming agents or 5-40ppm of organopolysiloxane defoaming agents and 5-30ppm of dodecyl dimethyl ammonium bromide bactericides, wherein the 5-40ppm of defoaming agents or the 5-40ppm of organopolysiloxane defoaming agents are emulsified by using special emulsifiers and taking methyl polysiloxane and nanometer-grade silicon dioxide as main bodies. A method of mechanical kneading with multi-layer fine gauze filtering is adopted for mixed preparation so that the non-ionic surface active agent is dissolved in water in a foamy way; the adding temperature of the drag reducer is 5 DEG C-70 DEG C; when the drag reducer is used in a horizontal pipeline, the energy consumption of a water pump motor is reduced more than 20 percent at the same flow rate; and the increase rate of the water circulating flow rate of the horizontal pipeline using the drag reducer is 10-20 percent. The water-based drag reducer not only changes boundary conditions of the fluid interior and fluid and a pipe wall, but also changes the physical, chemical and mechanical properties of the fluid interior and boundary materials, thereby greatly reducing the resistance of a delivery pipeline and achieving the purpose of electricity saving of the water pump motor; and in addition, the water-based drag reducer and a validation method are scientific, reasonable and practical and open a new way for reducing the energy consumption of a circulating water system.

Owner:任西平

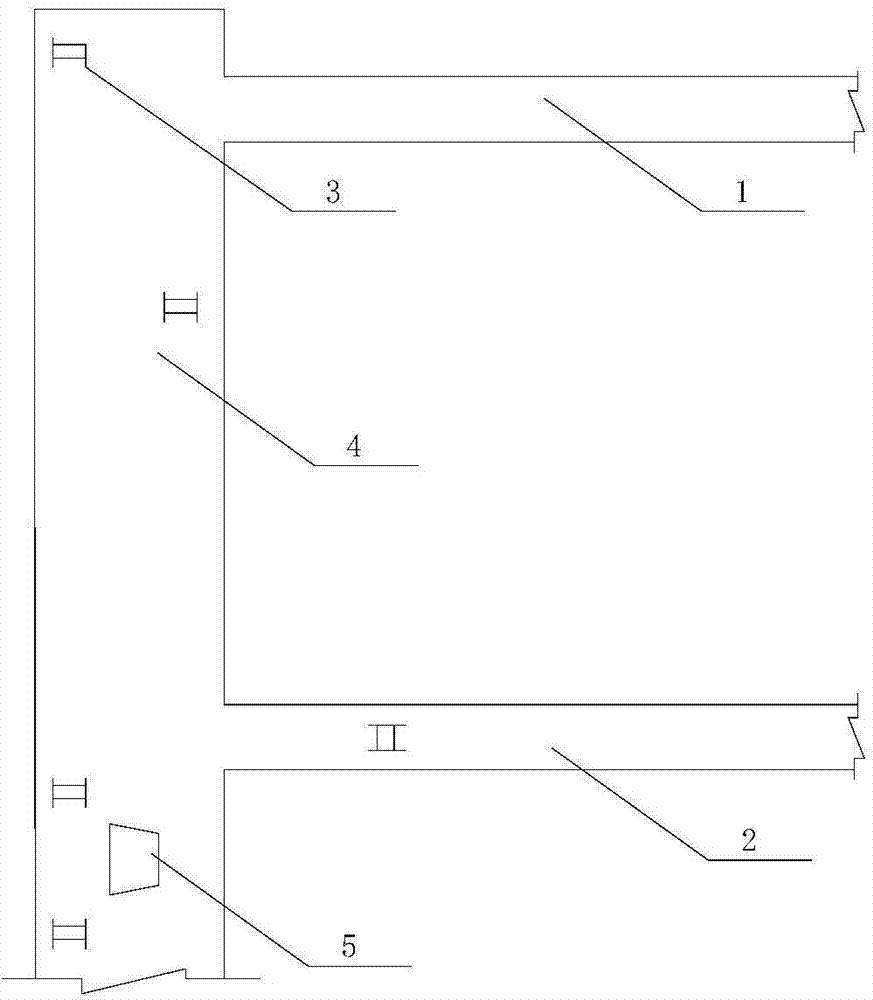

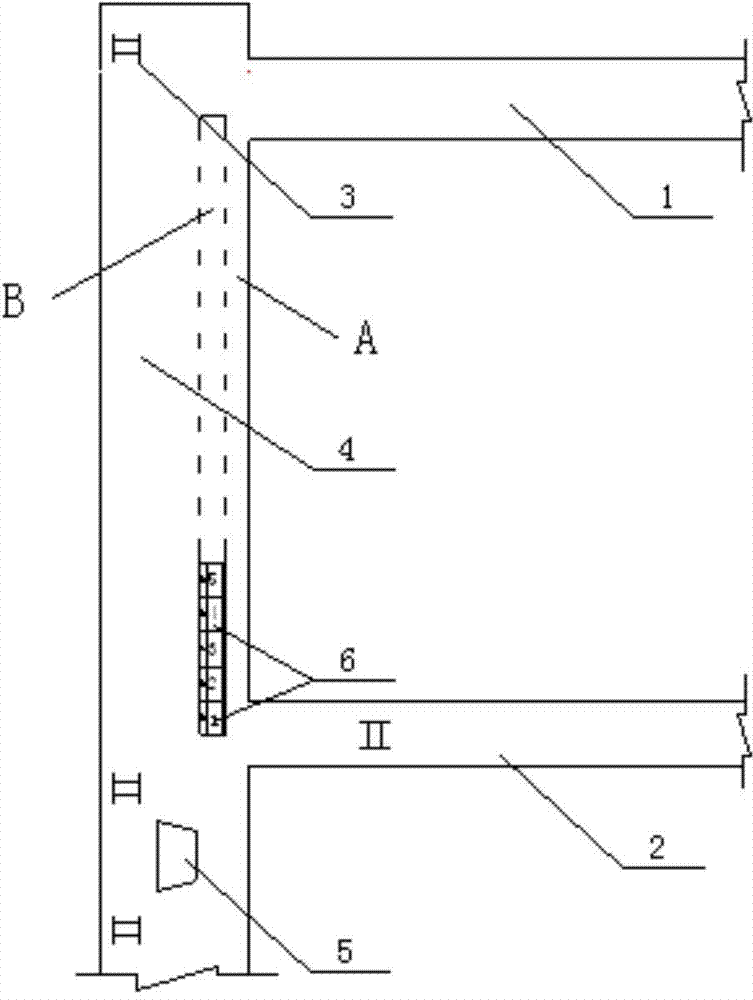

Installation method of comprehensive mechanized filling, coal mining and open-off cutting equipment

The invention discloses an installation method of comprehensive mechanized filling, coal mining and open-off cutting equipment. The installation method comprises the main steps: carrying out open-off cutting and open-off cutting shoring, laying a rail on the coal wall side, and transporting and installing a scraper conveyer; then, laying a rail in a goaf region, and transporting and installing a support; then making two gaps in a headpiece, and transporting and installing a coal mining machine; then transporting and installing a reversed loader by using a winch in a return air tunnel; finally laying a rail in the goaf region side after advance of the face by 3m, and installing a rear top beam of the support, a tamping mechanism and a porous bottom-dump conveyer. The installation method disclosed by the invention aims at solving the technical problem that the installation space of rear equipment is not enough after filling and coal mining front equipment is mounted, and a brand new method is provided for rapid installation of the comprehensive mechanized filling, coal mining and open-off cutting equipment. The installation method is simple, simple and convenient to operate and wide in practicability.

Owner:JIANGSU ZHENGXING MINING TECH DEV CO LTD

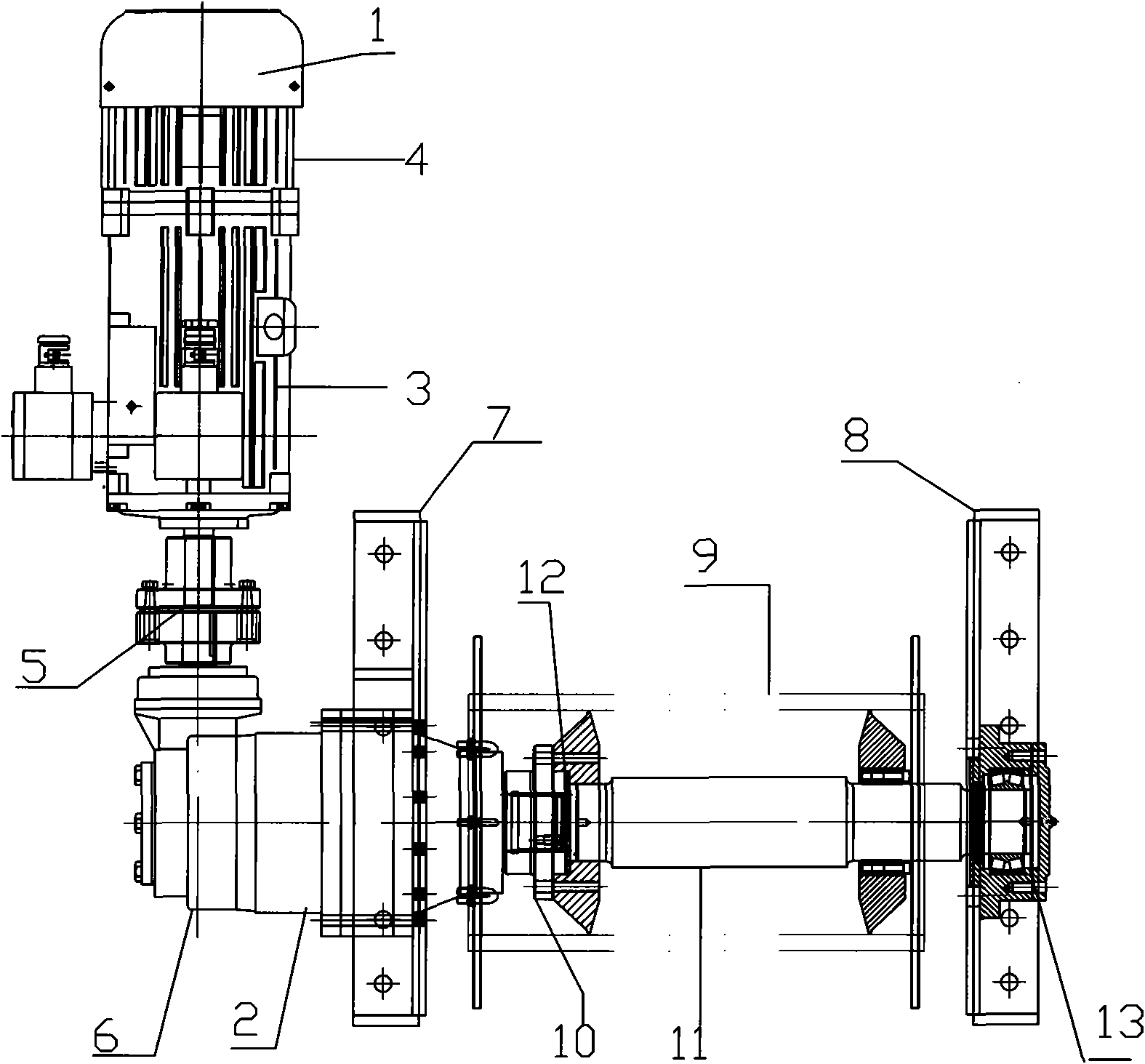

Electromagnetic braking tensioning winch

InactiveCN101780928APrecise tension controlQuick response abilityWinding mechanismsCouplingReduction drive

The invention discloses an electromagnetic braking tensioning winch comprising an electromagnetic braking motor and a winch, wherein the electromagnetic braking motor comprises a motor and an electromagnetic brake, and the electromagnetic brake is coaxially arranged at the tail of the motor; the winch is connected with a motor shaft by a coupling; the winch comprises a speed reducer, a support seat, a roller support and a rope twisting roller, wherein the speed reducer is arranged on the support seat; the speed reducer is connected with the rope twisting roller; and the roller support is arranged at the other end of the rope twisting roller. The invention has the advantages of no hydraulic pressure, single electric control on tensioning, faster response capability and more accurate, quicker and stable tension control.

Owner:杨丽焕

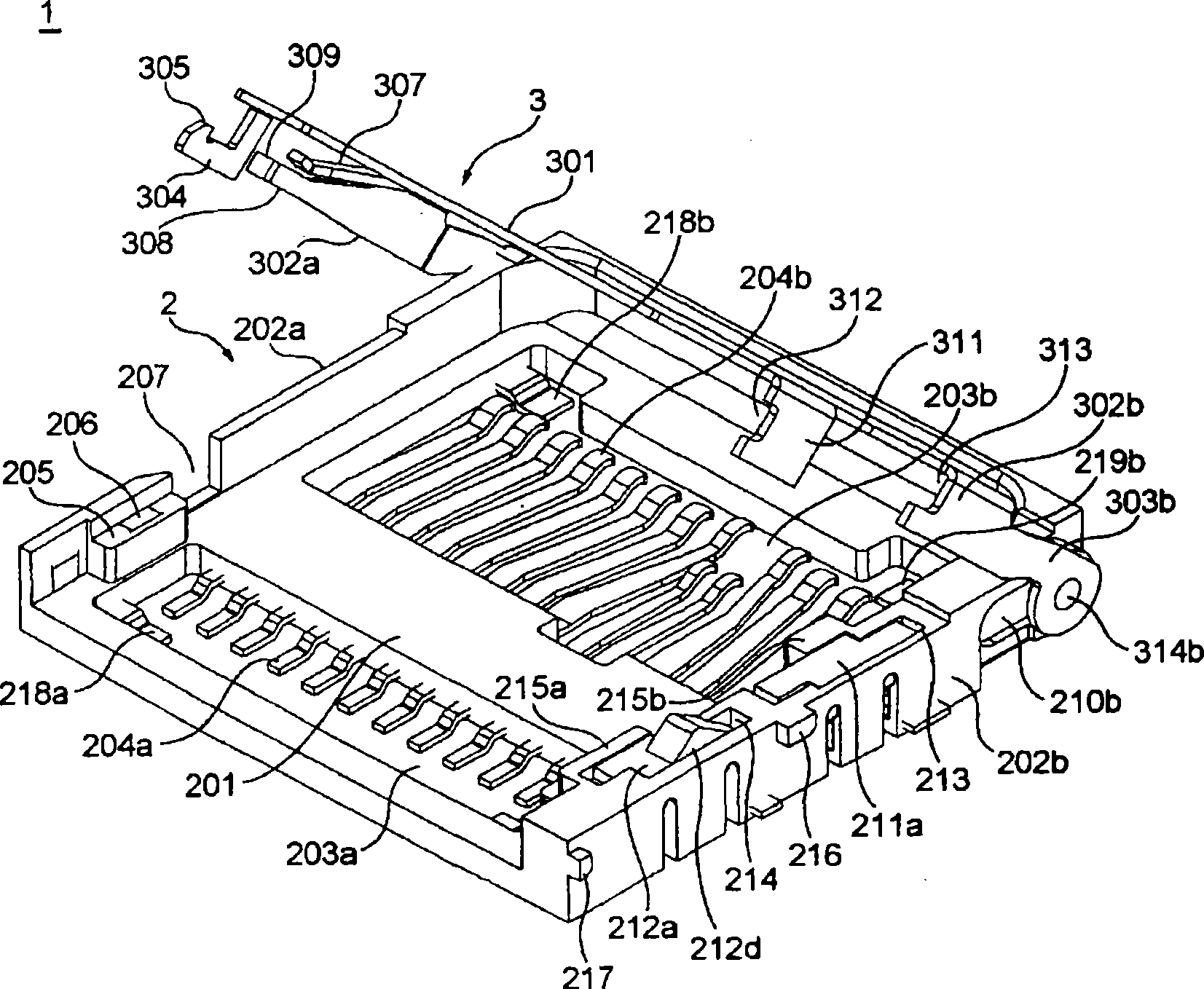

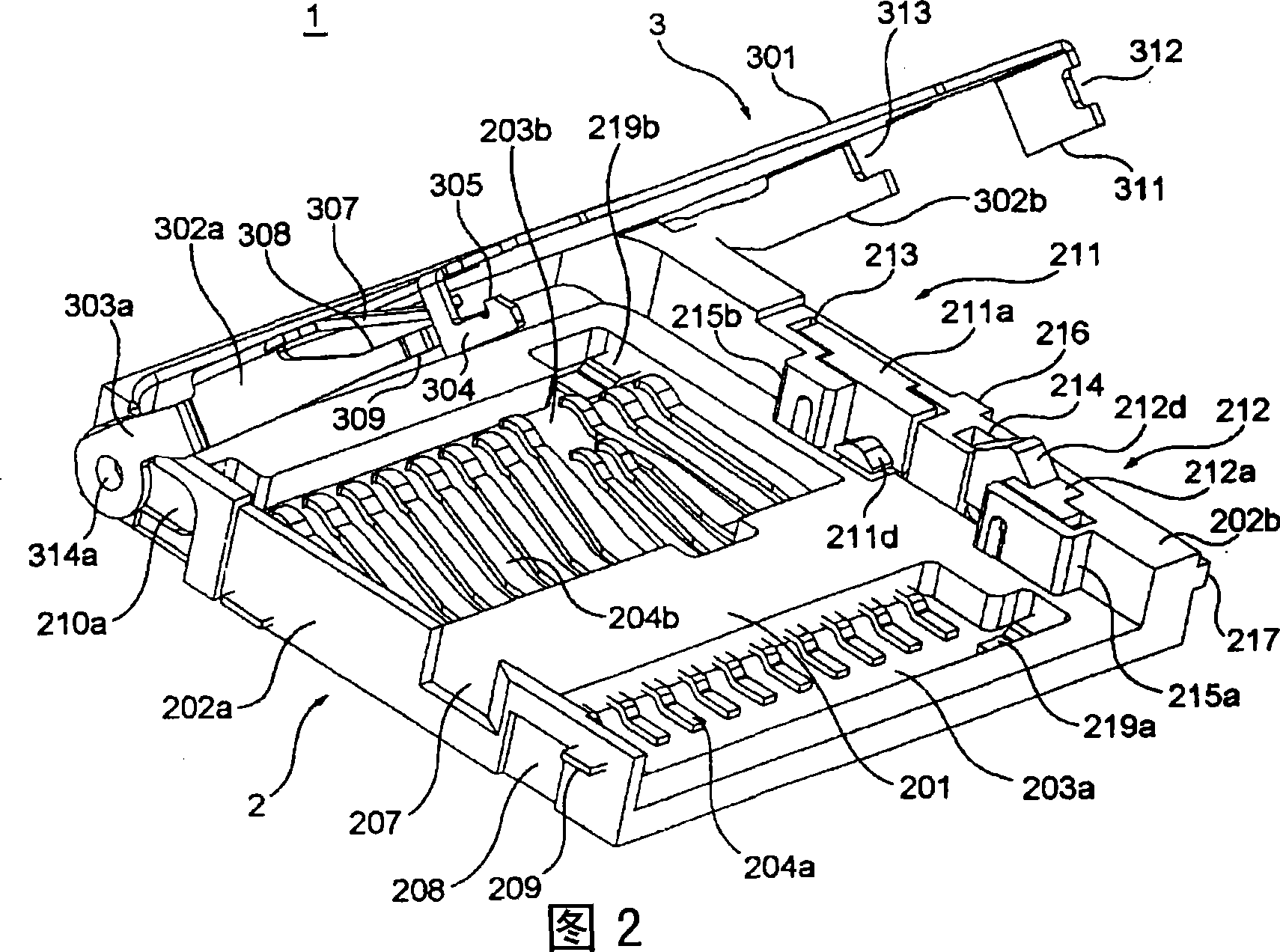

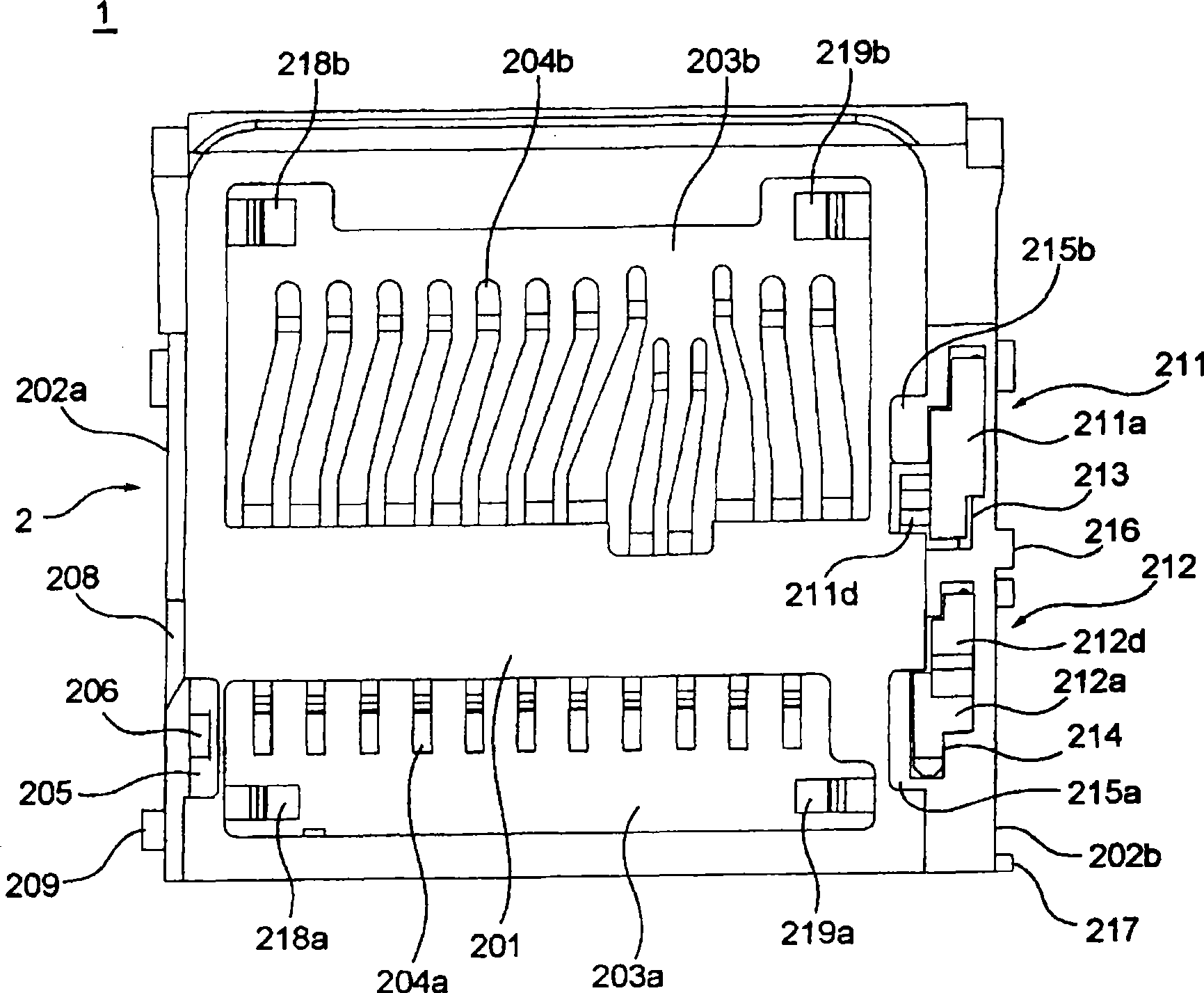

Card connector

InactiveCN101399408AReasonable installationIncorrect coupling preventionCo-operative working arrangementsEngineering

Owner:ALPS ALPINE CO LTD

Air exhaust integration workstation device

InactiveCN101357416ASimple structureEasy to installWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFrame work

The invention relates to an air exhaust integrated worktable device. An air exhaust worktable is arranged on a frame work and is divided into a plurality of air exhaust chambers in an end-to-end arrangement; all the air exhaust chambers are connected with a main aspiration channel; bearing roll balls are arranged at the two sides of the top end face of the air exhaust worktable and a material rest is arranged on a frame work arranged between the bearing roll balls; frame works under the material rest are respectively provided with a hopper which is positioned in each air exhaust chamber. The bottom end of the frame work is provided with an adjusting bolt and at least one side of the frame work is provided with a longitudinal linear lead rail, under which a toothed bar that is matched with the linear lead is arranged; a drive portal frame is connected on the longitudinal linear lead rail in a sliding way and an output gear wheel of the drive portal frame is engaged with the toothed bar; a link stopper is arranged at the lower end face of the drive portal frame and connected with a mechanical control valve arranged on the frame work; the mechanical control valve is connected with a cylinder by a connecting pipe and a piston rod of the cylinder is articulated with a detachable door body of the air exhaust chamber. The device has the advantages of simple structure, convenient installation, simple and convenient maintenance, simple operation, etc.

Owner:WUXI HUALIAN SCI & TECH GROUP

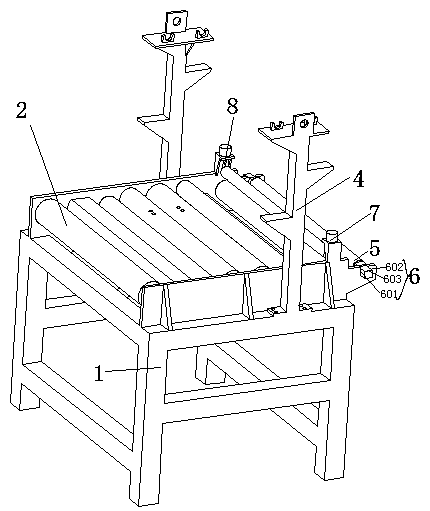

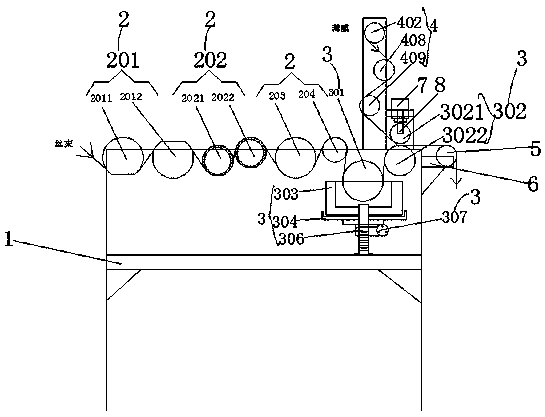

Silk-unfolding, gluing and laminating device system based on no-woven cloth production

ActiveCN108855759AGuaranteed stable workOvercoming the problem of not being able to disassembleLiquid surface applicatorsCoatingsMechanical engineeringEngineering

The invention discloses a silk-unfolding, gluing and laminating device system based on no-woven cloth production. The silk-unfolding, gluing and laminating device system comprises a machine frame, silk-unfolding units fixed to the machine frame for unfolding silk flocks into sheets and a gluing unit. The silk-unfolding units comprise a plurality of silk-unfolding rollers arranged in sequence, andthe silk-unfolding rollers are composed of curved straight surface silk-unfolding rollers, electrostatic silk-unfolding rollers, a large cylindrical silk-unfolding roller and a small cylindrical silk-unfolding roller. The gluing unit comprises a glue dipping roller, a glue pressing roller pair of which pressure and ground clearance of the axes are adjustable, a glue tank, trays, a scaleplate and lifting structures for controlling the height of the glue tank. The glue dipping roller is disposed directly above the glue tank, and the trays are fixed to both ends of a glue tank body. The scaleplate is disposed on the lifting structures, and the lifting structures are lifting devices with hand-cranking arms and are fixed to the machine frame. According to the overall technical scheme, the silk-unfolding, gluing and laminating device system is simple and compact in structure, ingenious and reasonable in connection between the components, easy to install and adjust, low in cost, and conduciveto the market promotion and the use of middle and small-sized enterprises.

Owner:JIANGSU SHENTAI SCI & TECH DEV

High-frequency direct-acting force motor based on mixed air gap

PendingCN110994932AThe same two-way output forceEvenly distributedOperating means/releasing devices for valvesMagnetic circuitControl theoryMechanical engineering

The invention discloses a high-frequency direct-acting force motor based on a mixed air gap. The high-frequency direct-acting force motor comprises an armature component, a yoke component, a reset spring component, a front end cover and a shell, and the armature component comprises a first armature, a second armature and a push rod; and 90-degree bosses opposite in direction protrude out of diagonal lines of the long sides of the armature respectively, a connecting bridge circuit is arranged between two arms of a yoke frame of the yoke component in a striding mode, a control coil is installedin the middle of the connecting bridge circuit, and the opposite sides of the ends of the two arms of the yoke frame protrude out to form four symmetrical axial pole shoes. The control coil is completely symmetrical and equal along the path from the yoke frame to the four axial pole shoes; the armature component is arranged in a three-dimensional space formed by four axial pole shoes, four secondradial pole shoes and a connecting bridge circuit of the yoke frame; the yoke frame and bosses of the first armature and the second armature respectively form a first working air gap, a third workingair gap, a second working air gap and a fourth working air gap in the axial direction; and the armature part and the four radial pole shoes of the yoke part are in one-to-one correspondence to form radial air gaps.

Owner:ZHEJIANG UNIV OF TECH

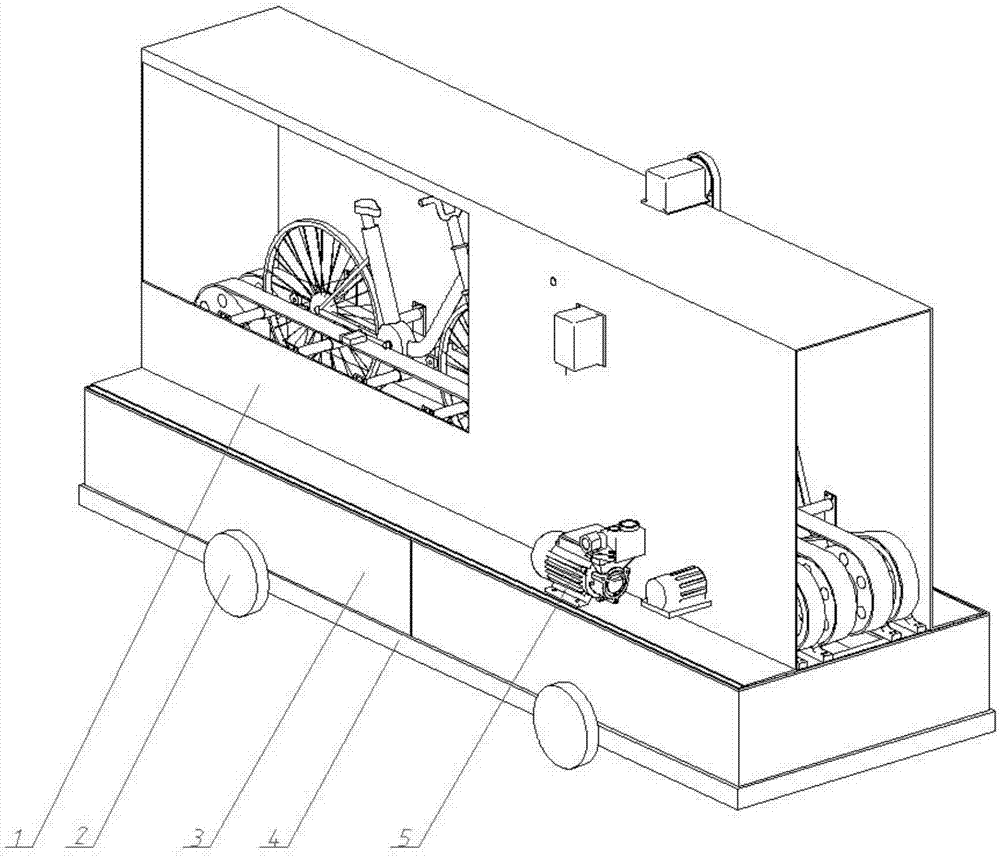

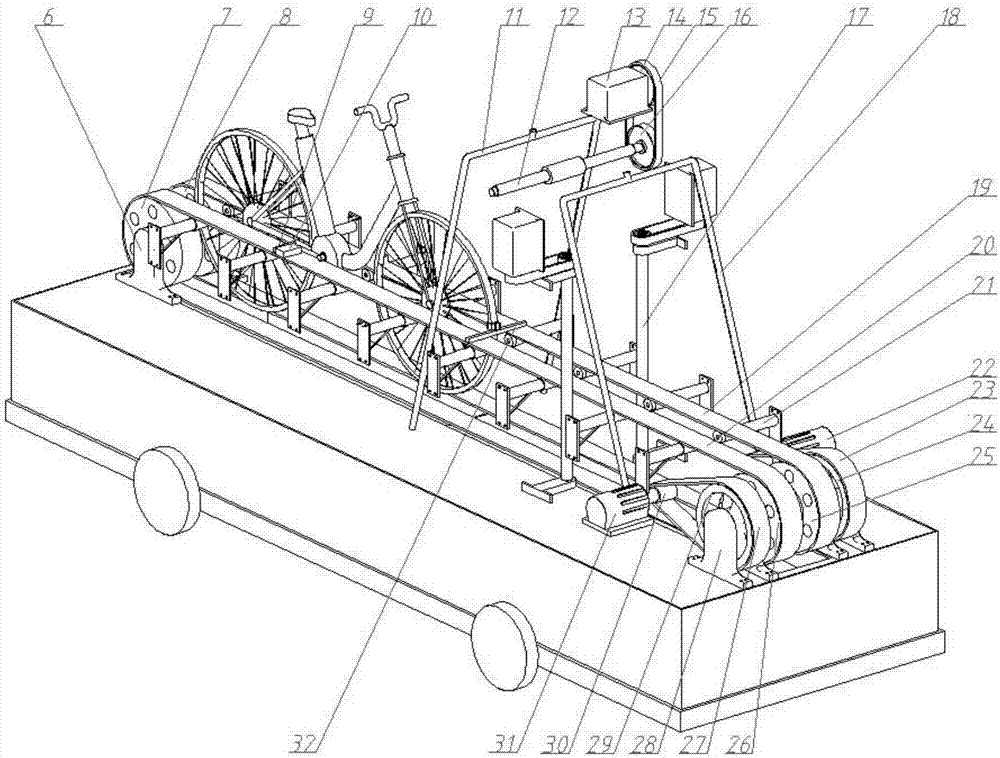

Automatic cleaning device of public bicycles on city road

PendingCN106915335AAchieve fixationPrevent rotationCleaning apparatus for vehicle exteriorsEngineeringElectrical and Electronics engineering

The invention discloses an automatic cleaning device of public bicycles on a city road. According to the automatic cleaning device of the public bicycles on the city road, the problems that in the prior art, bicycles are low in operation efficiency and poor in cleaning effect are solved, and the effects that cleaning efficiency is high, water for a machine is recycled, and manual labor is relieved are achieved. According to the scheme of the automatic cleaning device of the public bicycles on the city road, the automatic cleaning device of the public bicycles on the city road comprises a base and a side hairbrush; a spray mechanism is arranged on the base, one side of the spray mechanism is provided with a bicycle scrubbing mechanism which comprises a support, and the bicycle is arranged on one side of the support; and the top of the support is provided with a horizontally or obliquely arranged top hair brush which can rotate to clean the upper half portion of a bicycle body of the bicycle, and the side hairbrush is vertically arranged or obliquely arranged and can rotate to clean the lower half portion of the bicycle body of the bicycle.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

Ore pulp conveying electric valve device monitoring system and monitoring method thereof

ActiveCN102052499AAccurately calculate usage timeReal-time monitoring of usage timeOperating means/releasing devices for valvesDisplay contrastMonitoring system

The invention relates to an ore pulp conveying electric valve device monitoring system which comprises an electric valve use information acquisition system and an electric valve use information analyzing and reading system, wherein the electric valve use information acquisition system is used for collecting use time data of a plurality of electric valves on an ore pulp conveying pipeline; and the electric valve use information analyzing and reading system is used for storing the use time data of the plurality of electric valves collected by the electric valve use information acquisition system, comparing the time data with rated use time of each electric valve, and displaying contrast results and / or the use time data of the plurality of electric valves in a readable mode. According to the invention, the use time of the electric valves for conveying ore pulp in the pipeline can be calculated accurately, and the information such as the replacing time, ordering time, production time of the electric valves can be calculated accurately according to the use time, thus providing a time reference for electric valve users and electric valve suppliers.

Owner:YUNNAN DAHONGSHAN PIPELINE

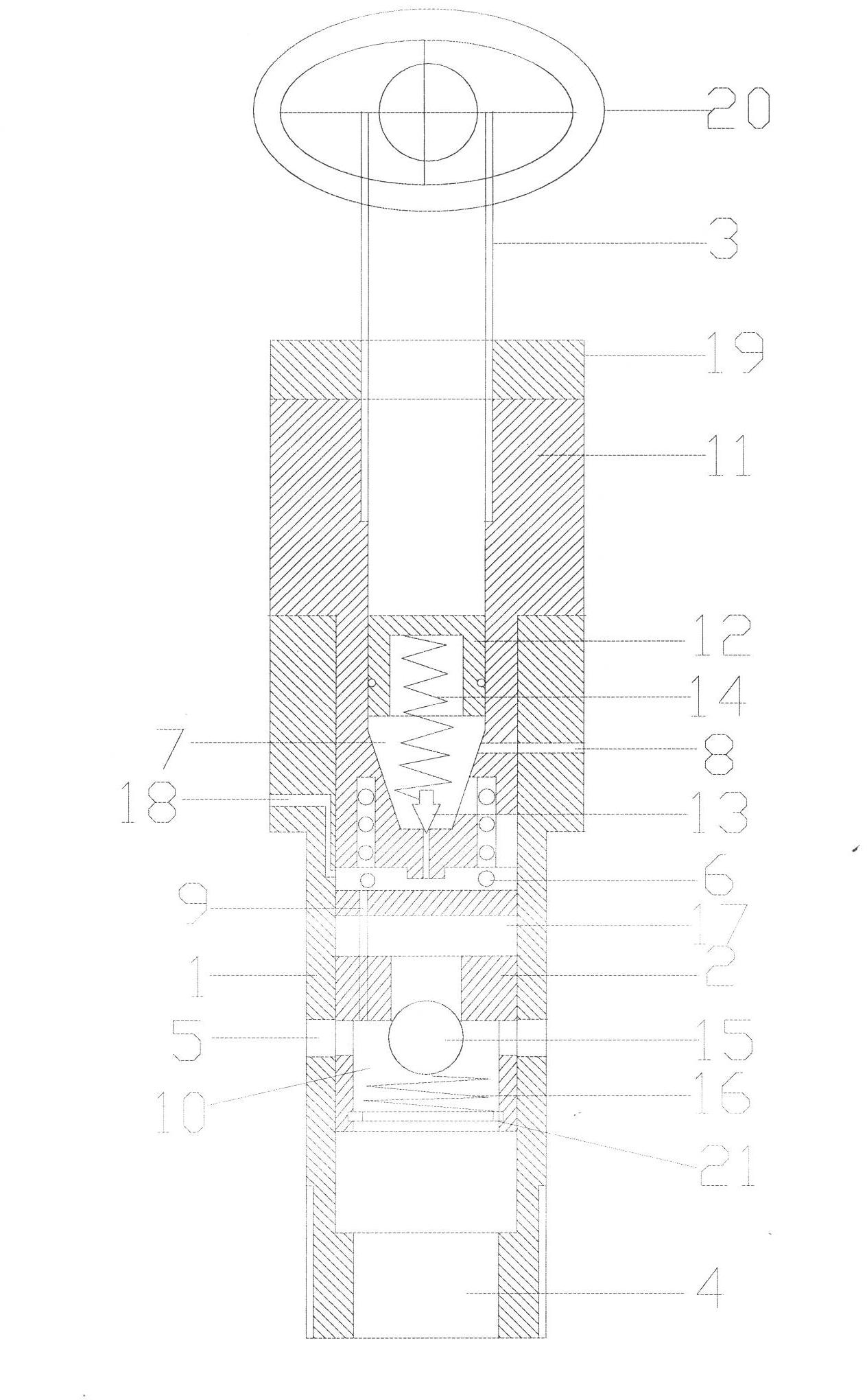

Pilot-operated one-way sequence valve

InactiveCN102563140AFlow is easy to controlPlay a connecting roleCheck valvesValve housingsPilot valveEngineering

The invention discloses a pilot-operated one-way sequence valve, which comprises a valve body (1), a main valve spool (2), a pilot valve and an adjusting rod (3). A liquid inlet (4) and a liquid outlet (5) are arranged on the valve body (1), the main valve spool (2), the pilot valve and the adjusting rod (3) are arranged in the valve body, the outer diameter of the head at the upper end of the valve body is larger than that of a portion below the head, an external thread is arranged on the portion below the head of the valve body which is vertically through, the liquid inlet (4) is arranged at an opening of the lower end of the valve body, the liquid outlet is arranged on the valve wall of the portion below the head of the valve body, a reset spring (6) is connected between the pilot valve and the main valve spool (2), a pilot valve cavity (7) is arranged in the pilot valve and communicated with the outside through a drainage channel (8), and an axial channel (9) is arranged on the main valve spool. The external shape of the valve body is equivalent to that of a hinged bolt, a hydraulic part and a pipeline can be connected by the valve body, and the hinged bolt and the pilot-operated one-way sequence valve are integrated.

Owner:林友根

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com