EOD (Explosive Ordnance Disposal) robot control system, EOD robot control method and EOD robot using EOD robot control method

It is a technology for EOD robots and control systems. It is applied in the direction of program control manipulators, manipulators, and manufacturing tools. It can solve the problems of unbalanced layout, inability to adapt to complex terrain, and inability to complete tasks. It achieves a moderate wireless radio frequency transmission distance and is easy to automate. Control and reduce the effect of workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

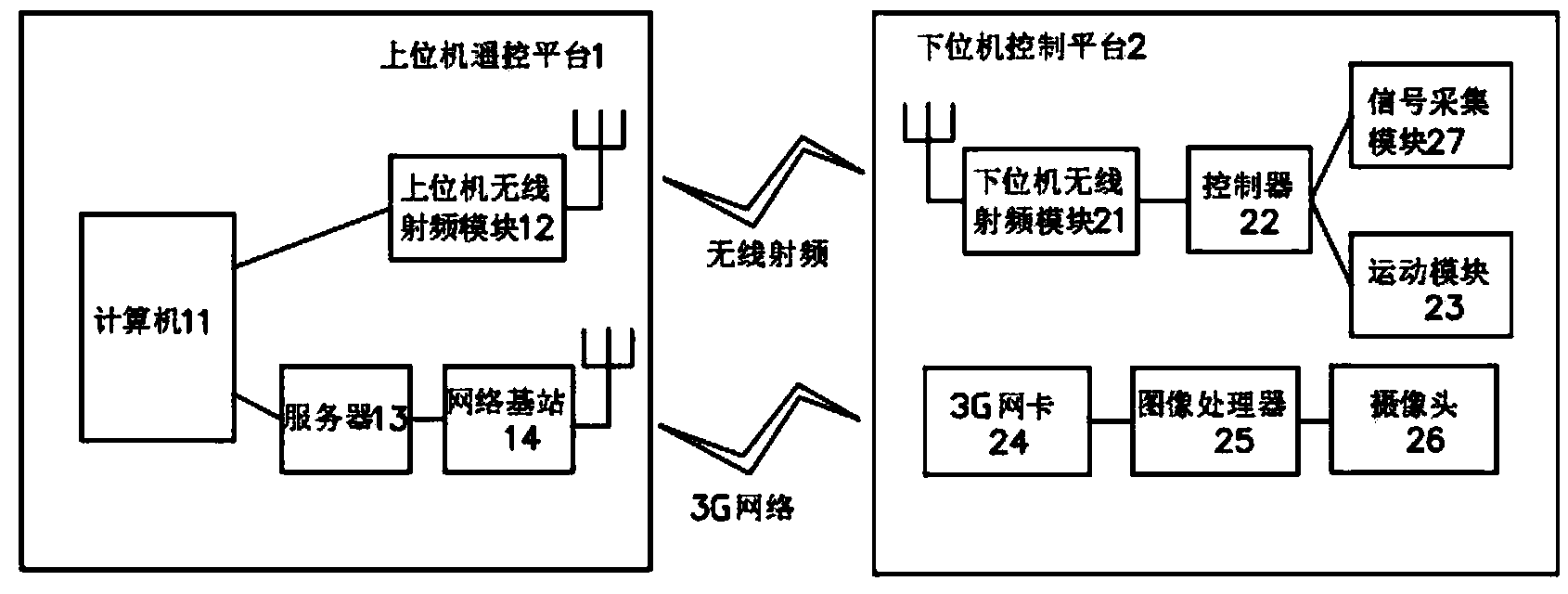

[0053] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

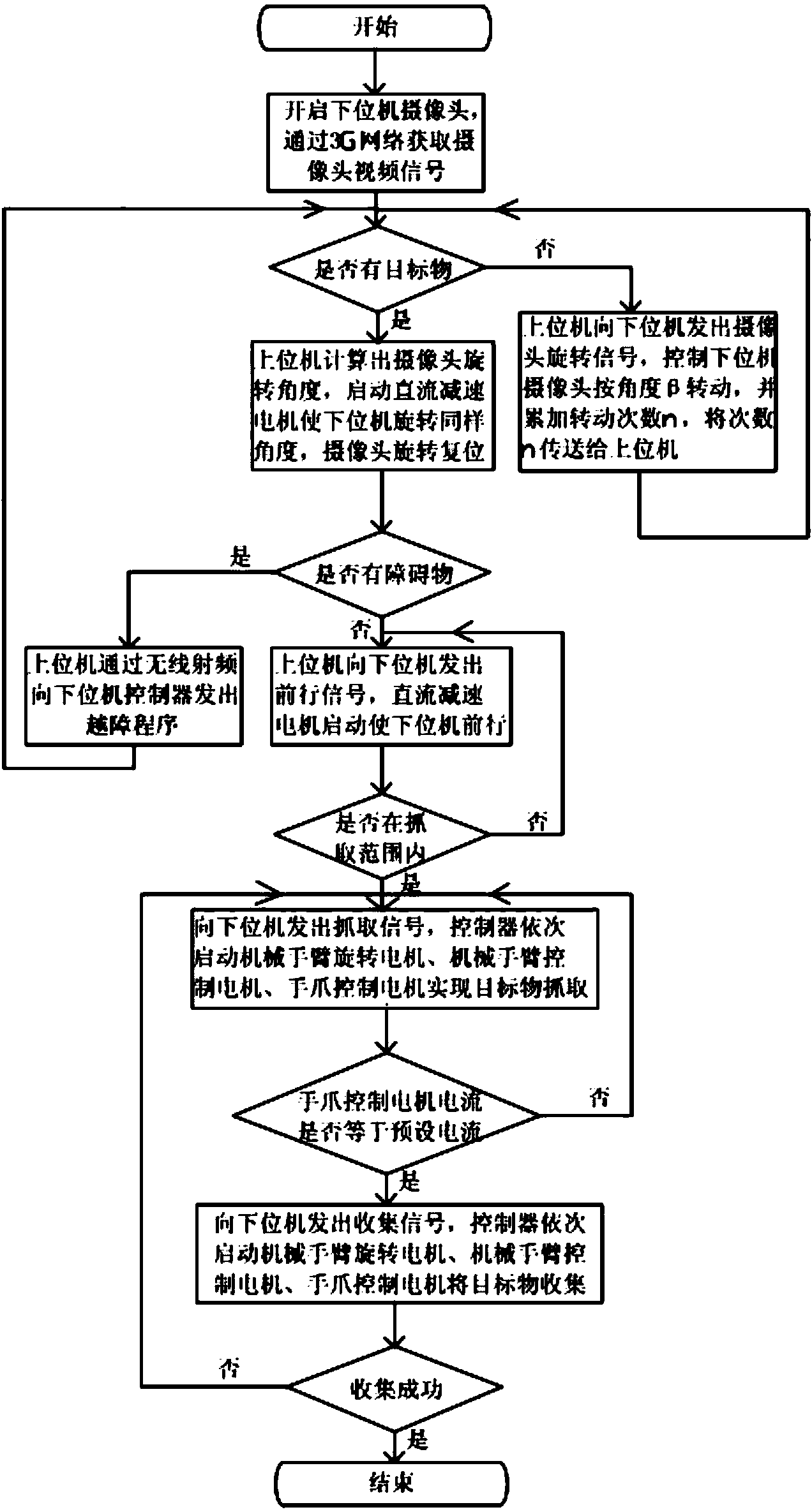

[0054] Such as figure 1 as shown, figure 1 It is a schematic diagram of the overall flow of the control method of the EOD robot of the present invention, a control method of the EOD robot, and the specific steps are:

[0055] A1. Turn on the camera of the lower computer, obtain the video signal of the camera through the 3G network, and enter step A2; start the modules of the upper computer and the lower computer, and the lower computer performs two-way transmission, one route is used to collect video signals from the camera, and the other is routed to the controller to control each motor drive. The upper computer analyzes the video and issues control instructions.

[0056] A2. Judging whether there is a target in the route: when no target is found, go to step A3; when a target is found, go to step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com