Milling cutter eccentricity rapidly measured non-contact type laser measuring method

A laser measurement, non-contact technology, applied in the direction of measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of process system stiffness changes, bandwidth limitations, difficult to operate, etc., to achieve reasonable processing parameters, The effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

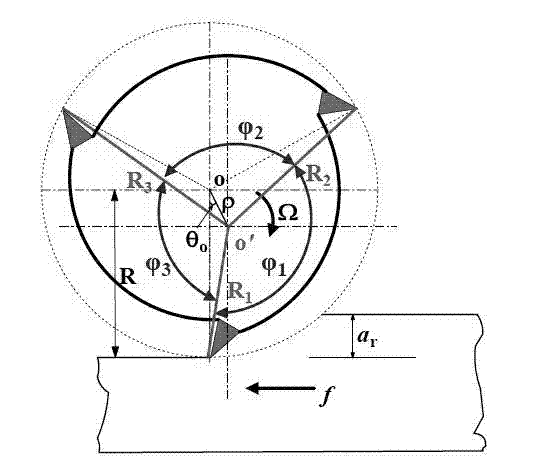

Embodiment Construction

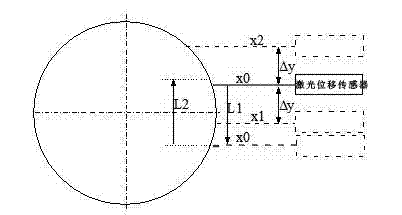

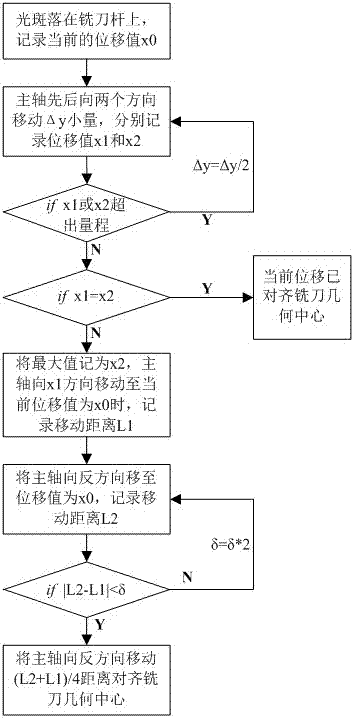

[0032]The acceptance scheme of the present invention will be further described in detail below in conjunction with the accompanying drawings and examples: This example chooses a carbide three-tooth flat-bottomed end mill as a machining tool with a uniform pitch, and the tool is clamped on a Mikron ucp800 five-axis machine tool On the above, the geometric parameters of the tool are: the measured diameter is 7.99 mm (the nominal value is 8 mm); the helix angle is 30 degrees; the total length is 65 mm; the cantilever length is 35 mm. According to the method of the present invention, carry out the eccentricity test under the situation of milling cutter rotation, its steps are:

[0033] 1. A laser displacement sensor is installed on the machine tool, and the displacement sensor is connected to the collector and the industrial computer. The technical parameters of the laser displacement sensor measurement system used are: a laser spot with a diameter of 30 microns, a sampling frequen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com