Silk-unfolding, gluing and laminating device system based on no-woven cloth production

A laminating device and non-weft fabric technology, which is applied in the field of spinning, gluing, and laminating device systems, can solve problems such as difficulty in increasing the gluing speed, inability to guarantee the film, and affecting product quality, so that it is not easy to wrinkle and break, and the technology The structure of the scheme is simple, the effect of quick disassembly and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

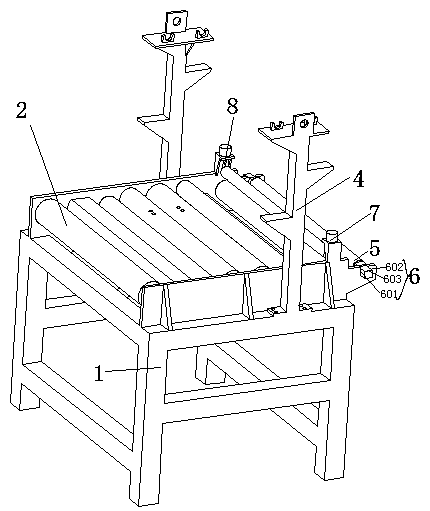

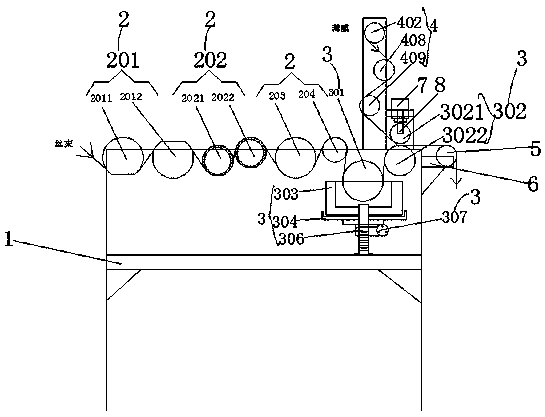

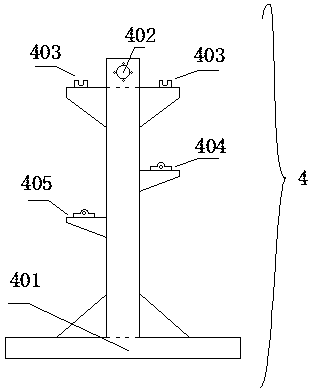

[0037] Embodiment 1: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 Now, a kind of yarn-spreading, gluing, and coating device system based on non-weft fabric production provided by the present invention is described, including a frame 1, a spinning unit 2 fixed on the frame 1 for spreading the tow into a thin sheet, and The gluing unit 3, the spreading unit 2 includes several spreading rollers arranged in sequence, and the spreading rollers are composed of a straight surface spreading roller 201, an electrostatic spreading roller 202, a large cylindrical spreading roller 203 and a small cylindrical spreading roller. Roller 204 is made up of, and described curved straight surface spreading roller 201 is made up of first curved straight surface spreading roller 2011 and second curved straight surface spreading roller 2012; Composed of wire roller 2021 and second electrostatic wire spreading roller 2022; the gluing unit 3 ...

Embodiment 2

[0038] Example 2: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 , as an improvement of the present invention, the curved and straight surface spreading roller 201 is a cylindrical base body 2015, the peripheral wall of the base body 2015 has a flat surface 2013, and the peripheral wall of the base body 2015 is formed by a flat flat surface 2013 connected end to end along its axial direction and the arc surface 2014; the flat surface 2013 is a plane parallel to the axis of the base 2015; the arc surface 2014 is a part of a cylindrical surface coaxial with the base 2015.

Embodiment 3

[0039] Embodiment 3: see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 8 , as an improvement of the present invention, the straight surface 2013 of the first curved straight spreading roller 2011 is installed facing downward, and the straight surface 2013 of the second curved straight spreading roller 2012 is installed facing upward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com