Turn-over device

The technology of a flipping device and a flipper is applied in the directions of measuring device, transportation and packaging, material analysis using radiation, etc. It can solve the problems of long working cycle, affecting the speed of the conveyor line and production rhythm, complex structure, etc. The effect of shortening the working cycle, stable and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

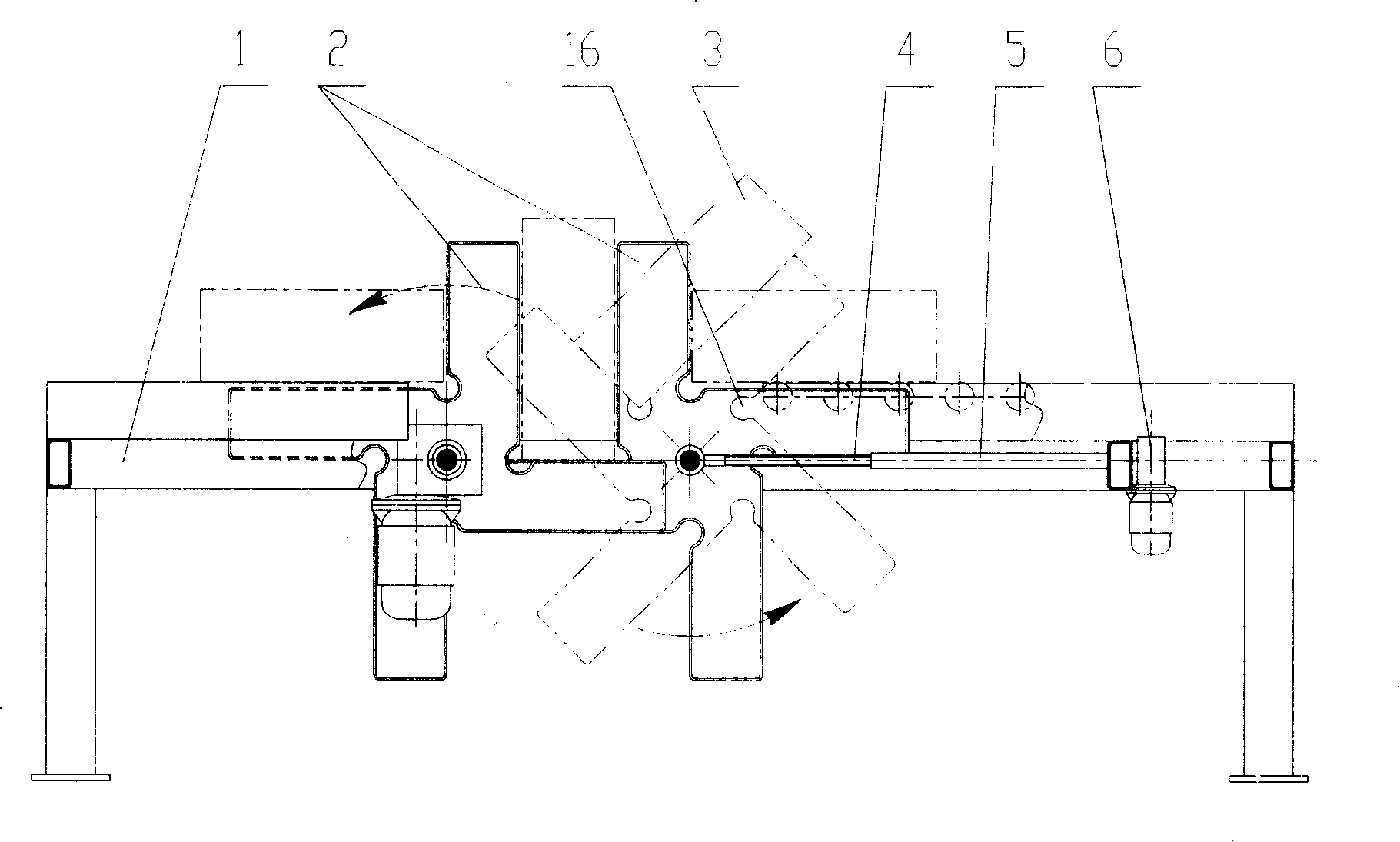

[0021] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

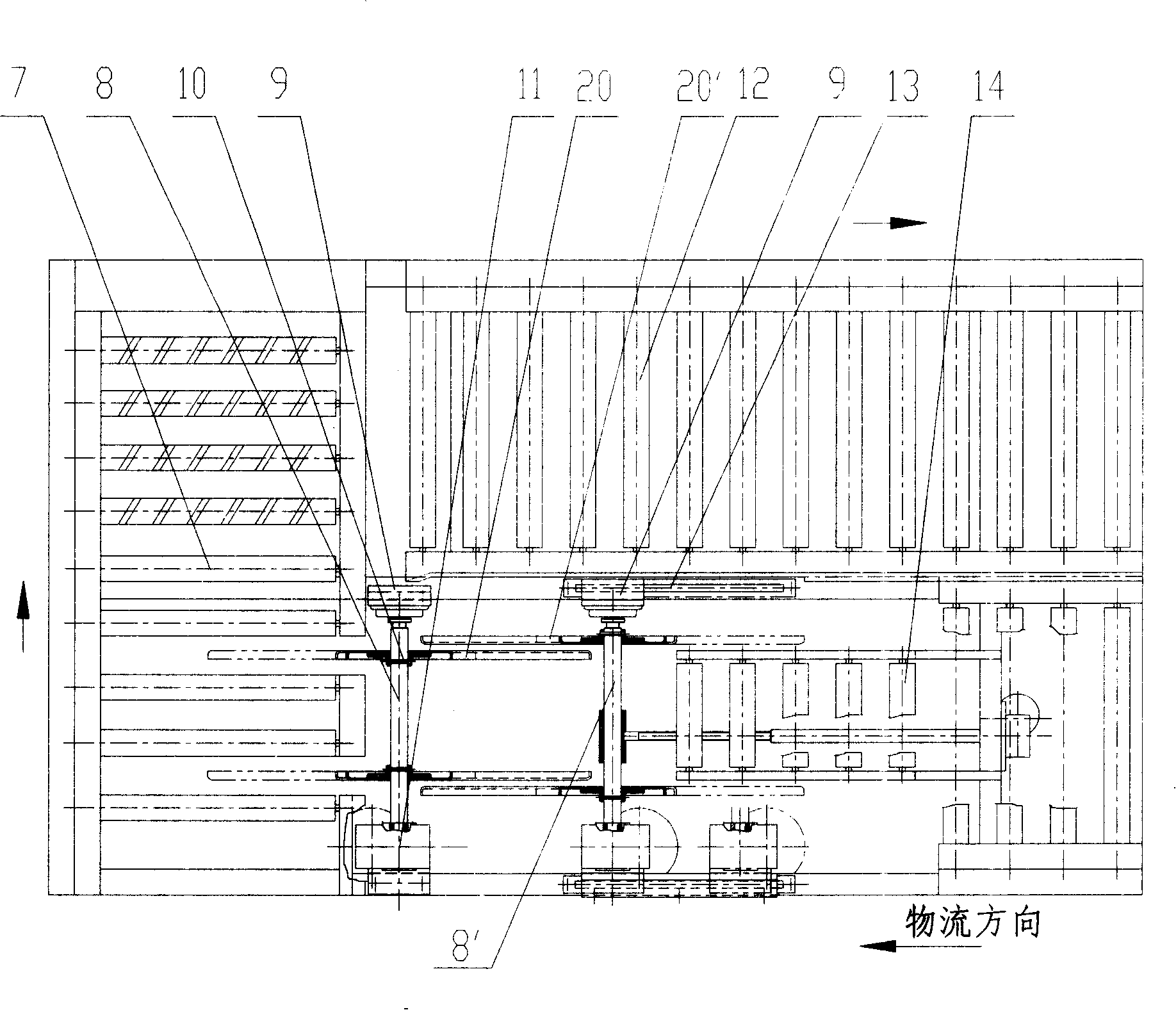

[0022] Such as figure 1 As shown, a conveyor line structure under electron beam irradiation includes a frame 1 , a forward conveyor roller set 14 , a turning conveyor roller set 7 and a reverse conveyor roller set 12 sequentially installed on the frame 1 . The overturning device of the present invention is installed on the frame 1 between the forward conveying roller group 14 and the turning conveying roller group 7 .

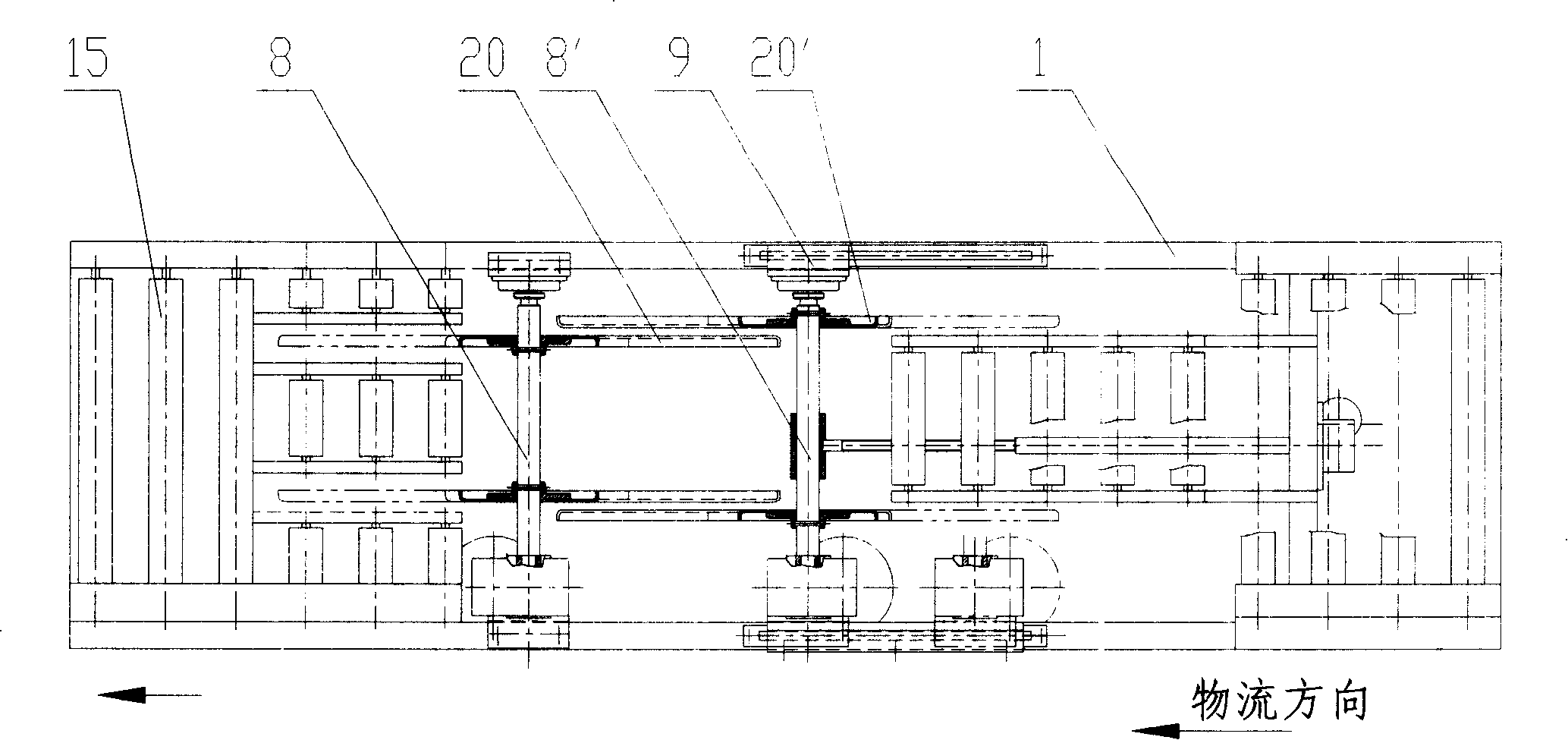

[0023] Such as figure 2 As shown, another conveying line structure under electron beam irradiation includes a frame 1 , a set of forward conveying rollers 14 and a set of straight output rollers 15 mounted on the frame 1 . The overturning device of the present invention is installed on the frame 1 between the forward conveying roller group 14 and the linear output roller group 15 .

[0024] Such as figure 1 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com