Patents

Literature

999results about How to "Reduce scan time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Touch-typable devices based on ambiguous codes and methods to design such devices

InactiveUS6885317B1Reduce manufacturing costFacilitate transfer of skillInput/output for user-computer interactionElectronic switchingPagerAmbiguity

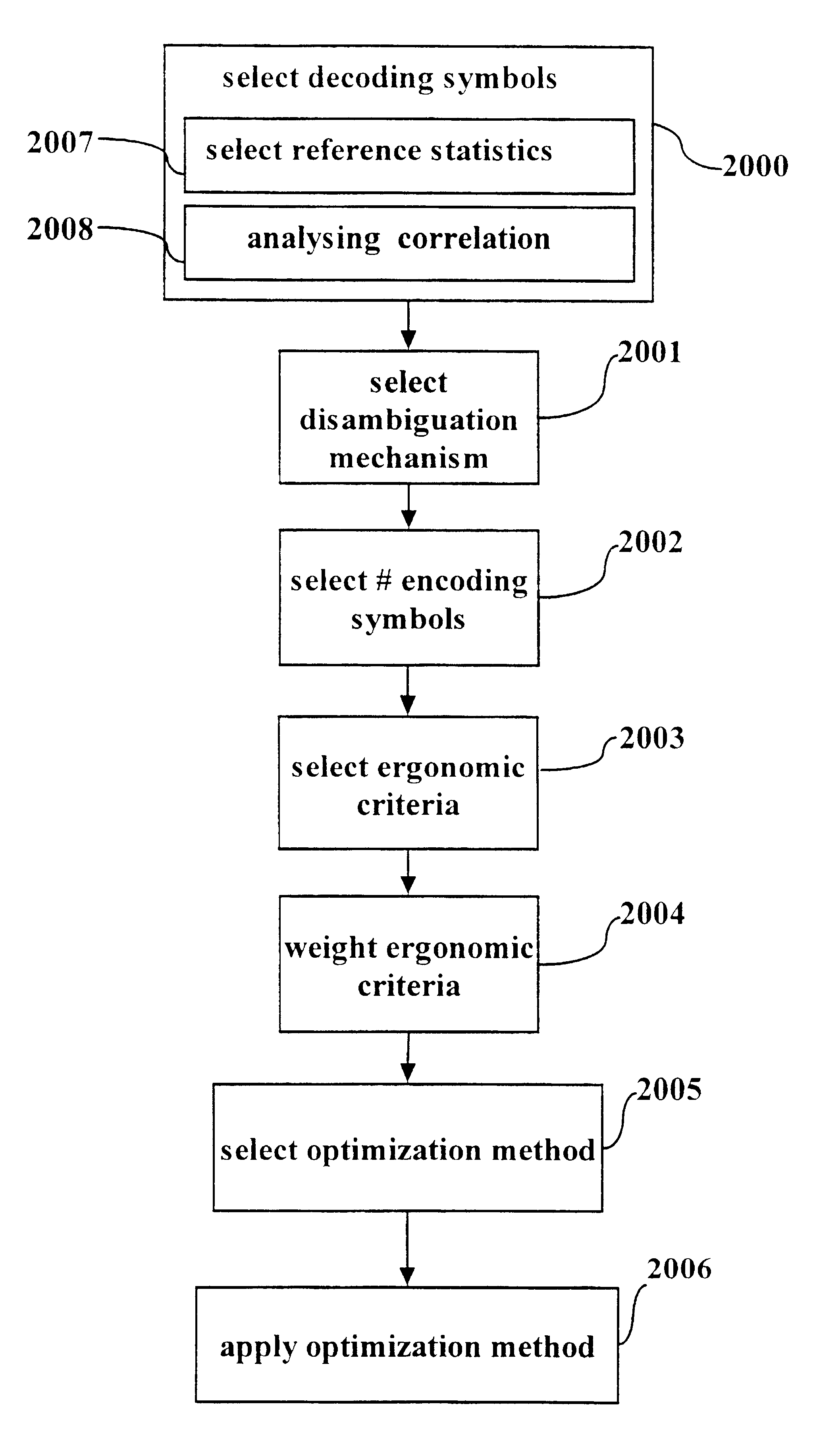

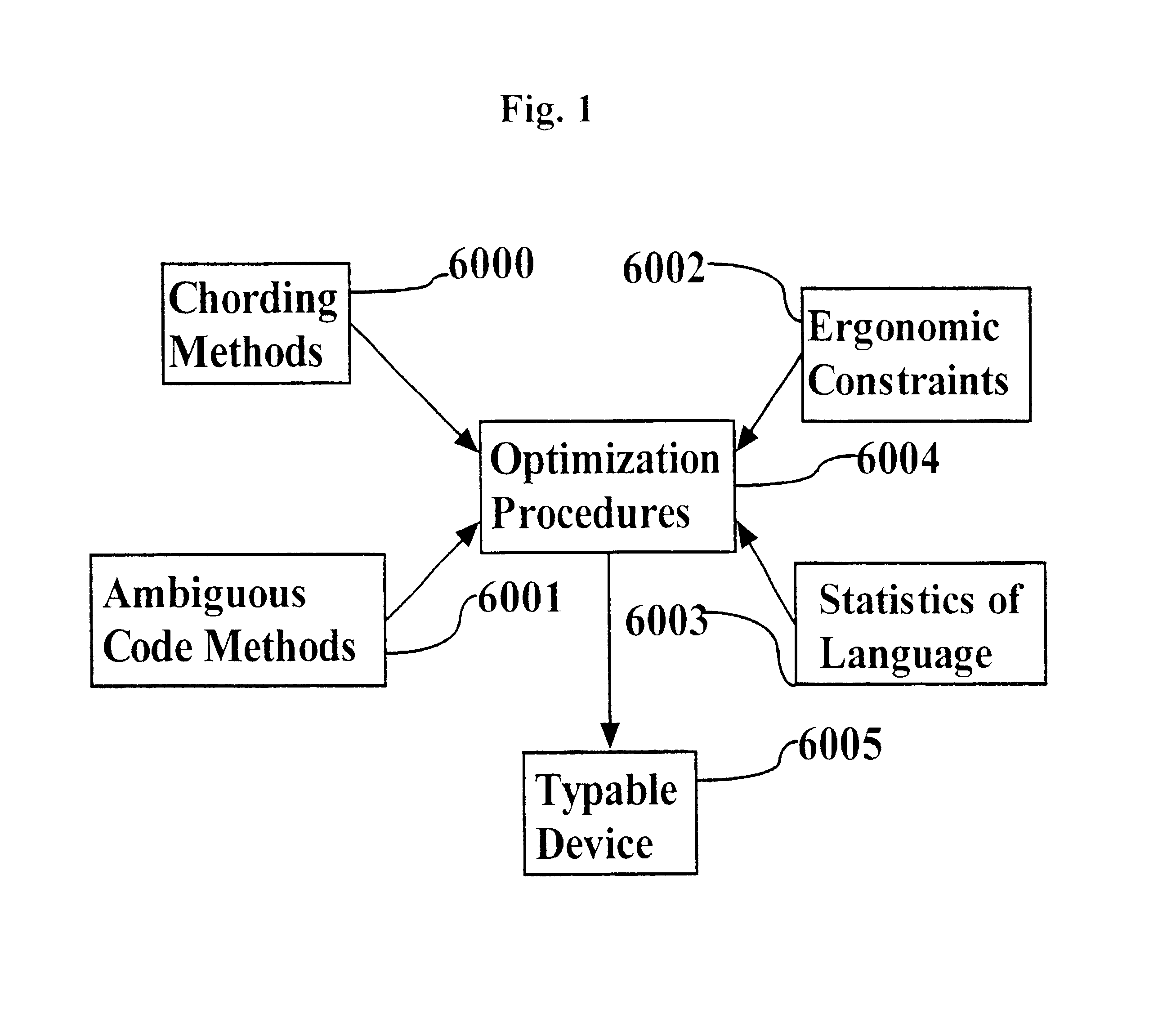

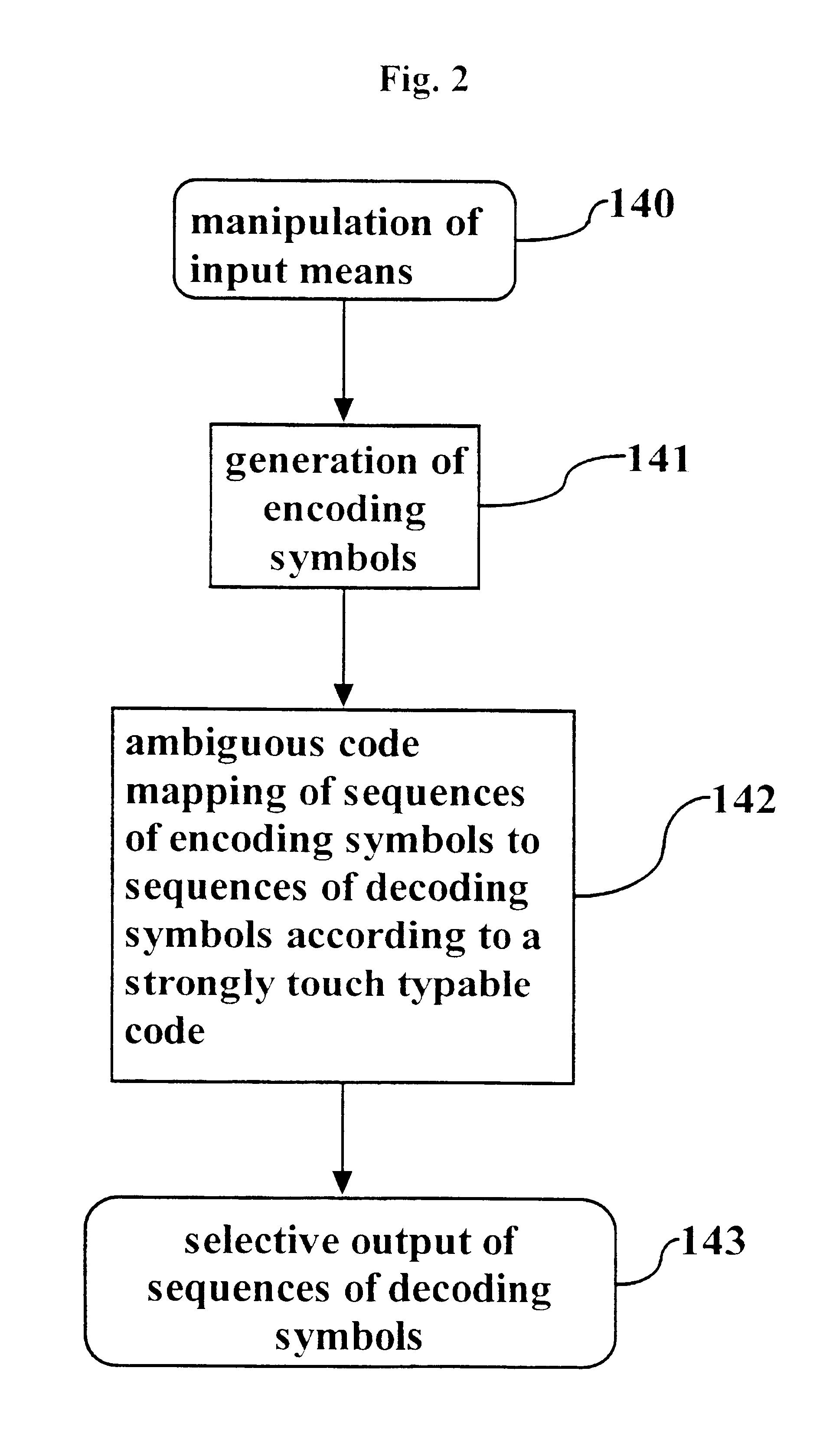

The design of typable devices, in particular, touch-typable devices embodying ambiguous codes, presents numerous ergonomic problems. Solutions for these problems are herein disclosed. This invention teaches methods for the selection of ambiguous codes from the classes of strongly-touch-typable ambiguous codes and substantially optimal ambiguous codes for touch-typable devices such as computers, telephones, pagers, personal digital assistants, smart cards, television set-top devices and other information appliances, given design constraints such as the size, shape, and computational capacity of the device, the typical uses of the device, and conventional constraints such as respect of alphabetic ordering or Qwerty ordering.

Owner:EATONI ERGONOMICS INC

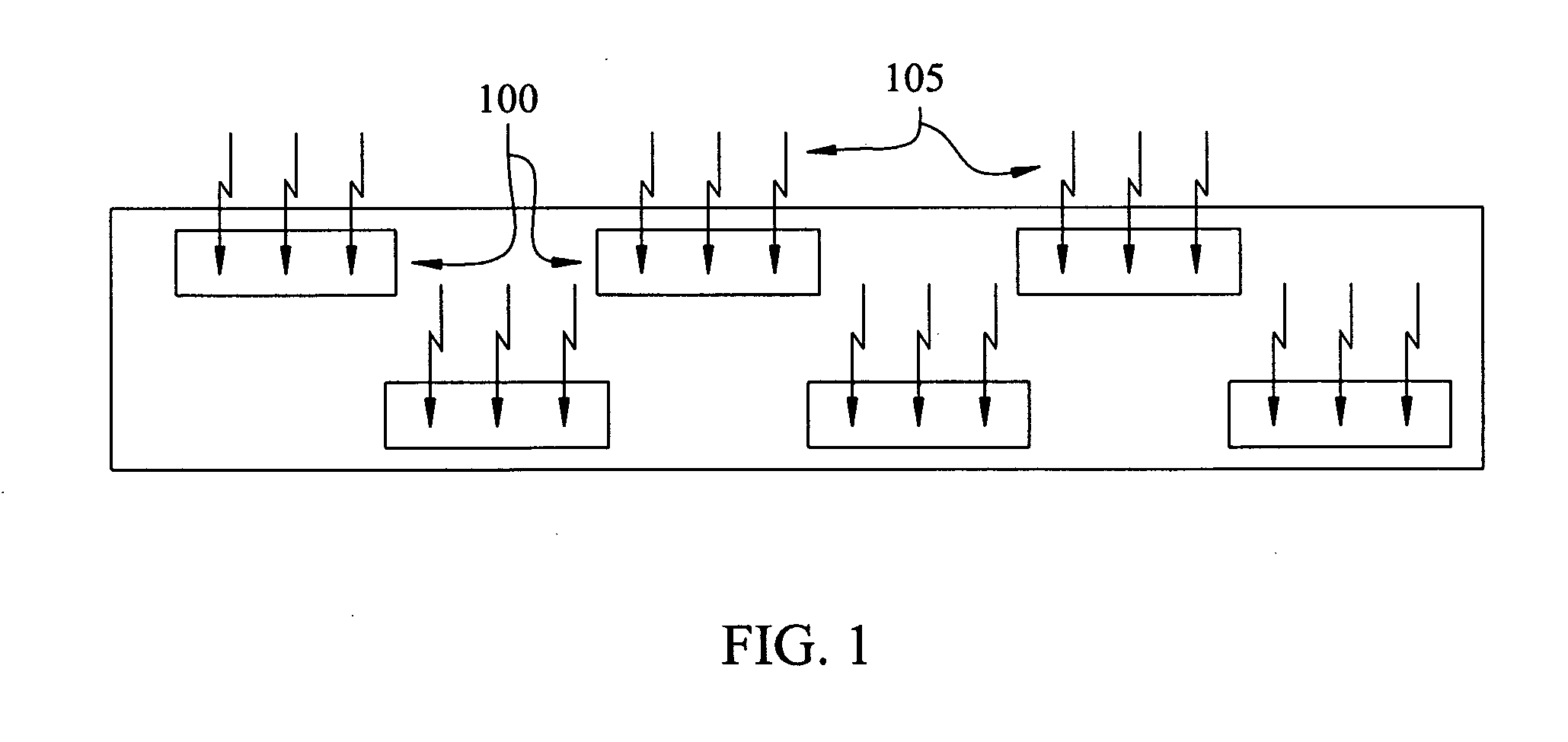

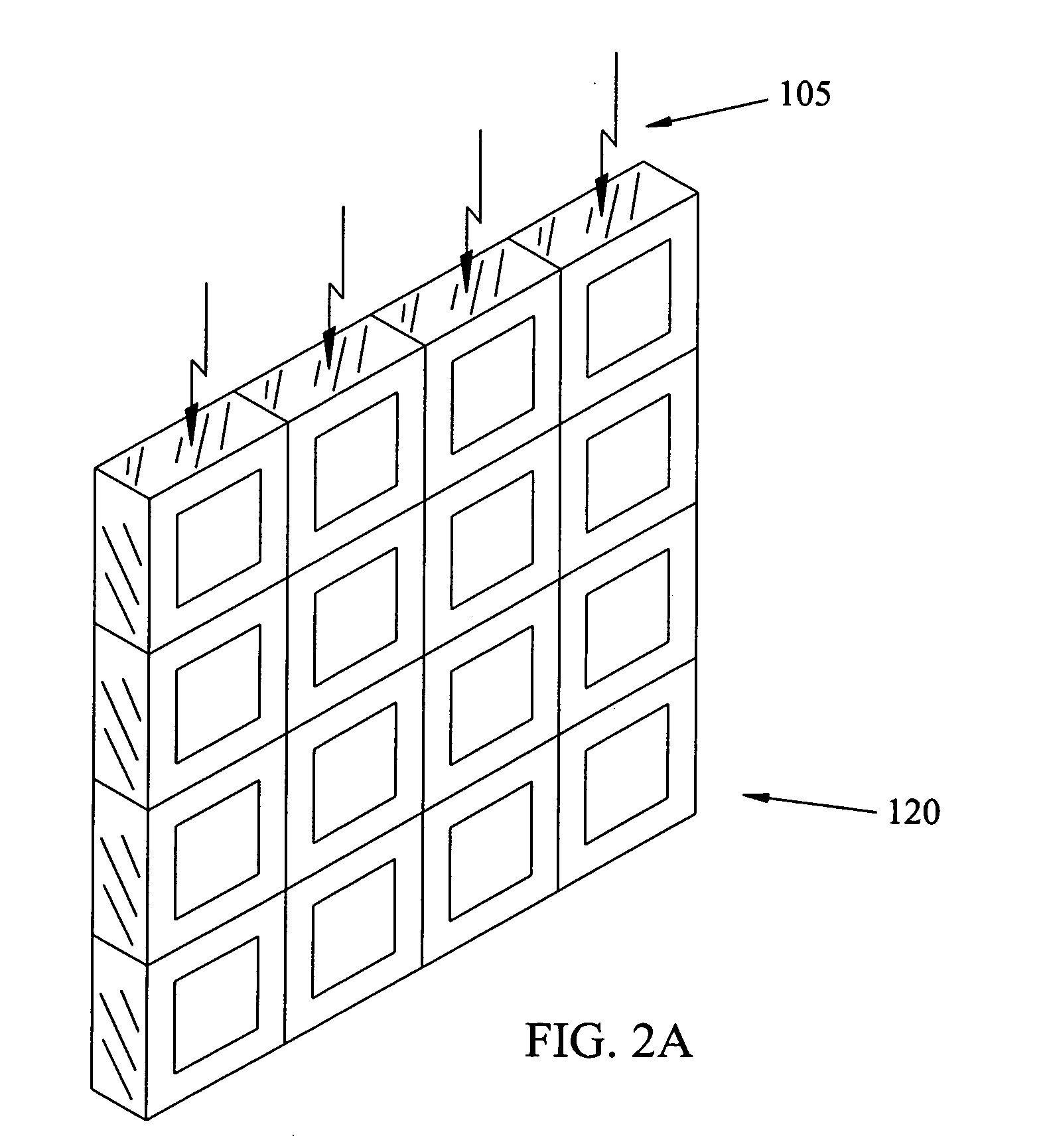

Slit and slot scan, SAR, and compton devices and systems for radiation imaging

ActiveUS20100270462A1Reduce productionReduce maintenance costsElectric discharge tubesElectroluminescent light sourcesHigh energyGas detector

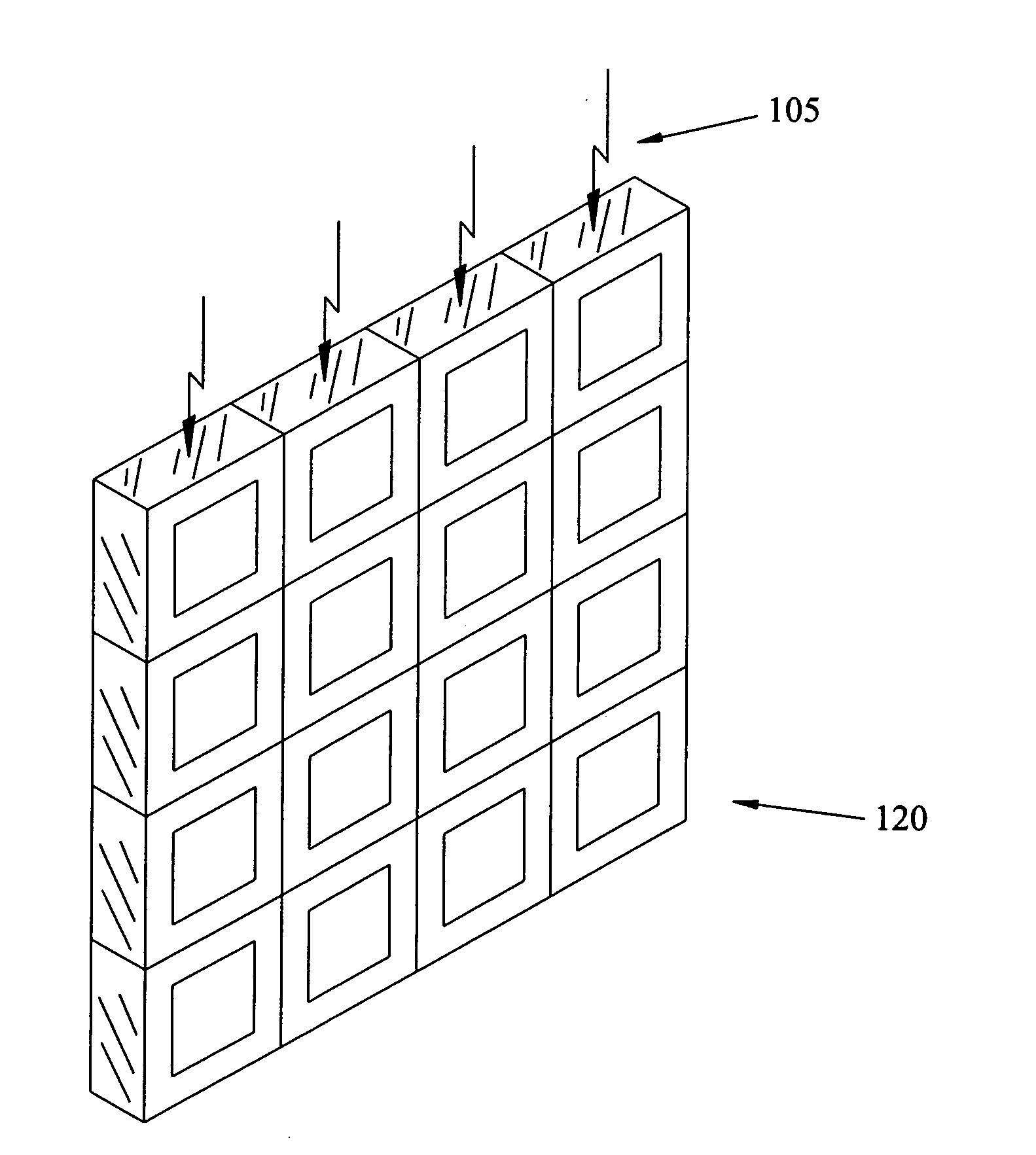

The invention provides methods and apparatus for detecting radiation including x-ray photon (including gamma ray photon) and particle radiation for radiographic imaging (including conventional CT and radiation therapy portal and CT), nuclear medicine, material composition analysis, container inspection, mine detection, remediation, high energy physics, and astronomy. This invention provides novel face-on, edge-on, edge-on sub-aperture resolution (SAR), and face-on SAR scintillator detectors, designs and systems for enhanced slit and slot scan radiographic imaging suitable for medical, industrial, Homeland Security, and scientific applications. Some of these detector designs are readily extended for use as area detectors, including cross-coupled arrays, gas detectors, and Compton gamma cameras. Energy integration, photon counting, and limited energy resolution readout capabilities are described. Continuous slit and slot designs as well as sub-slit and sub-slot geometries are described, permitting the use of modular detectors.

Owner:MINNESOTA IMAGING & ENG

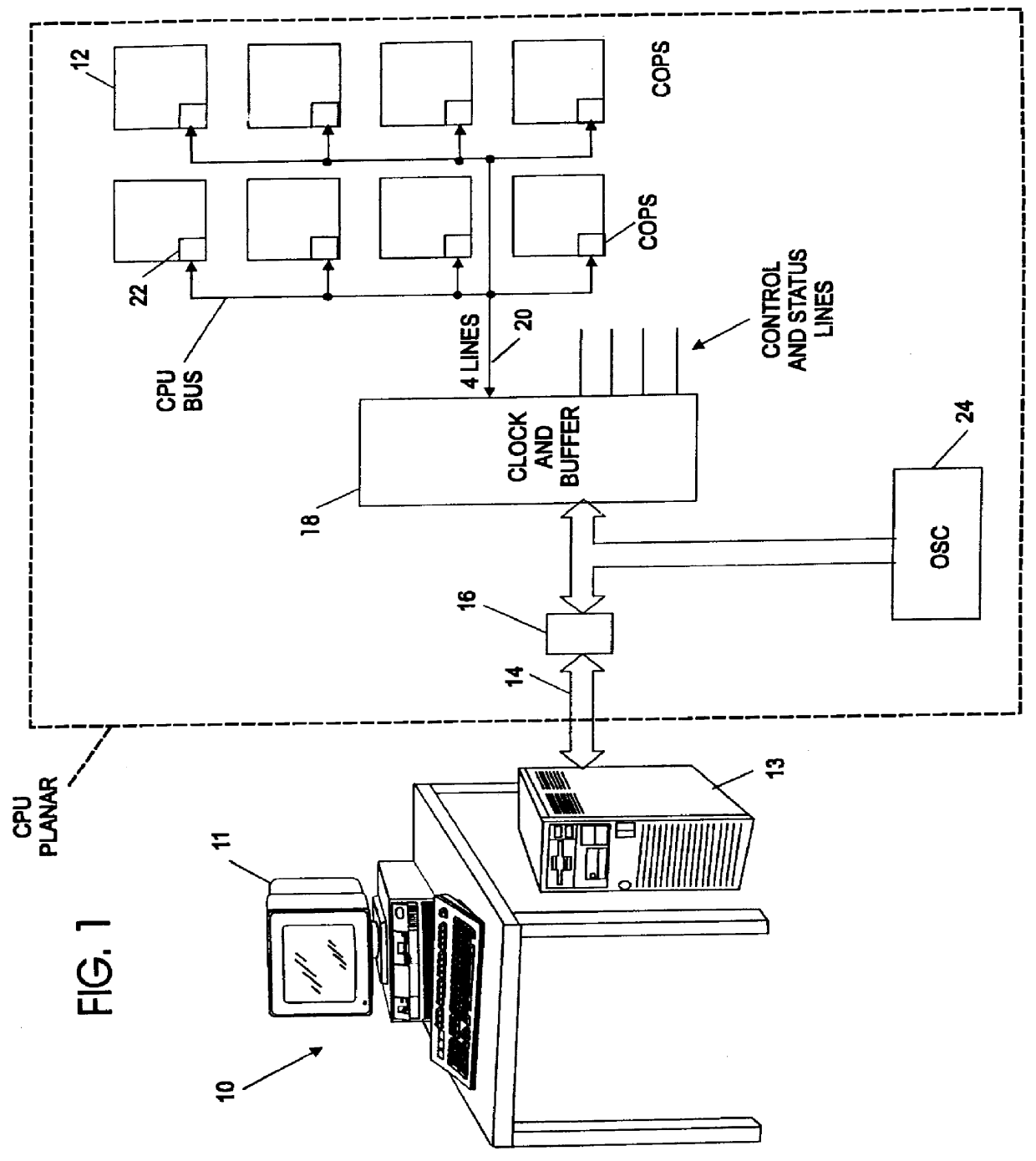

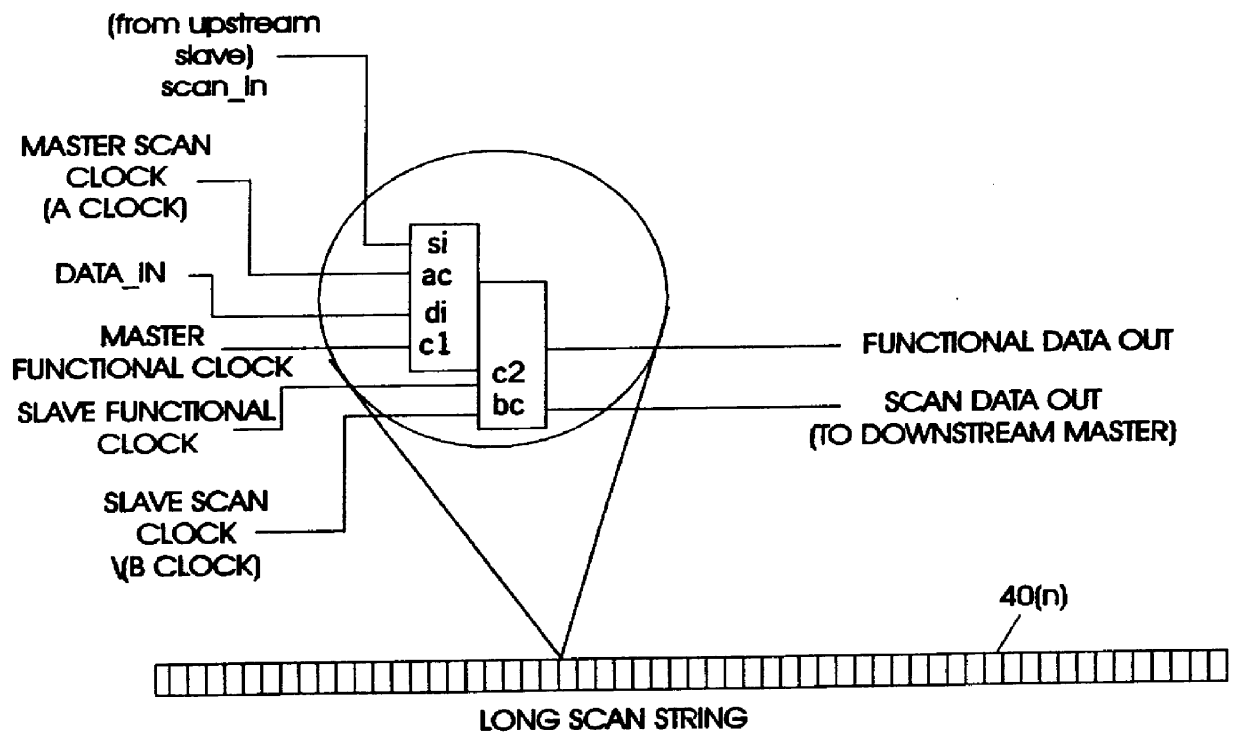

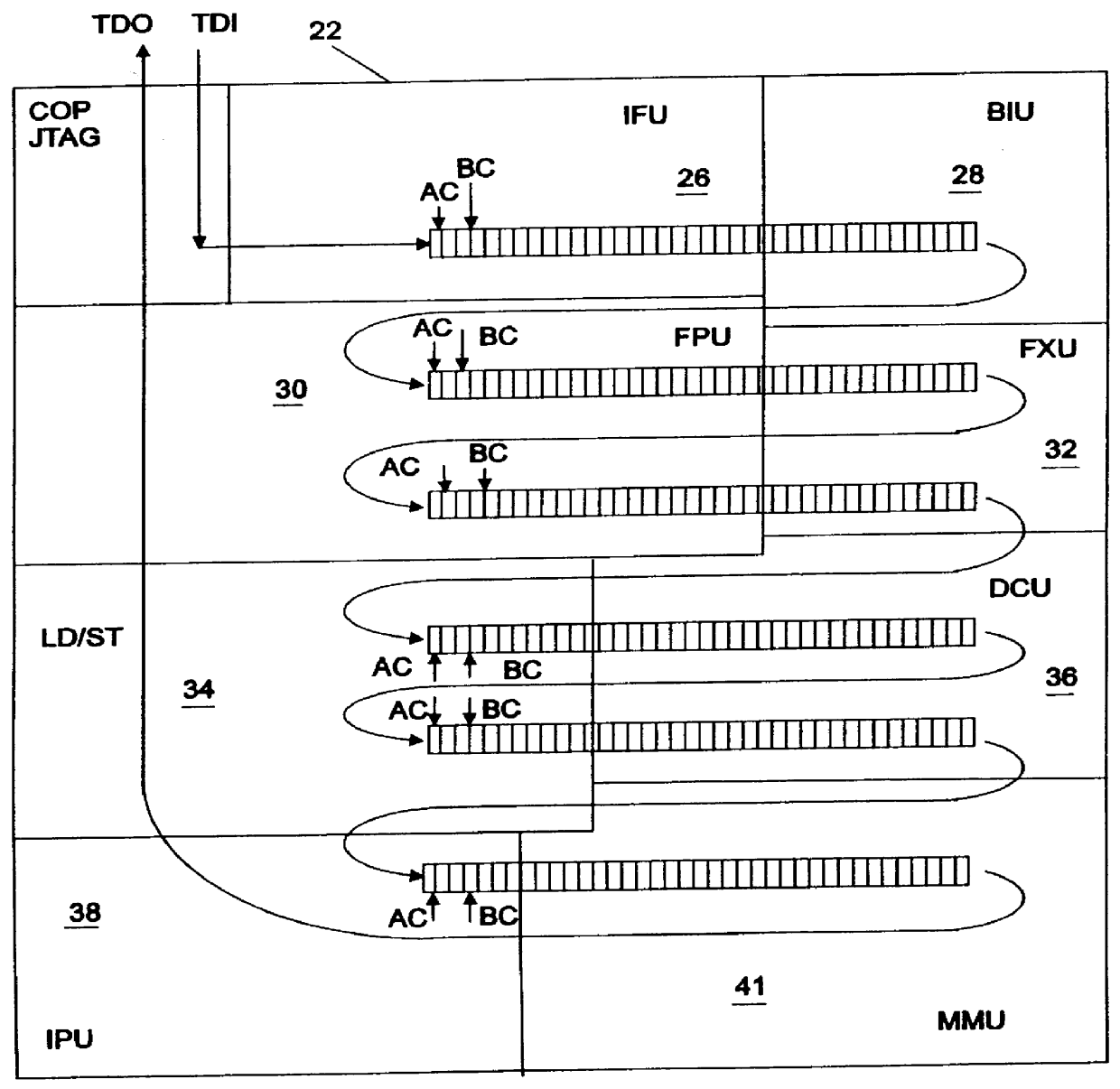

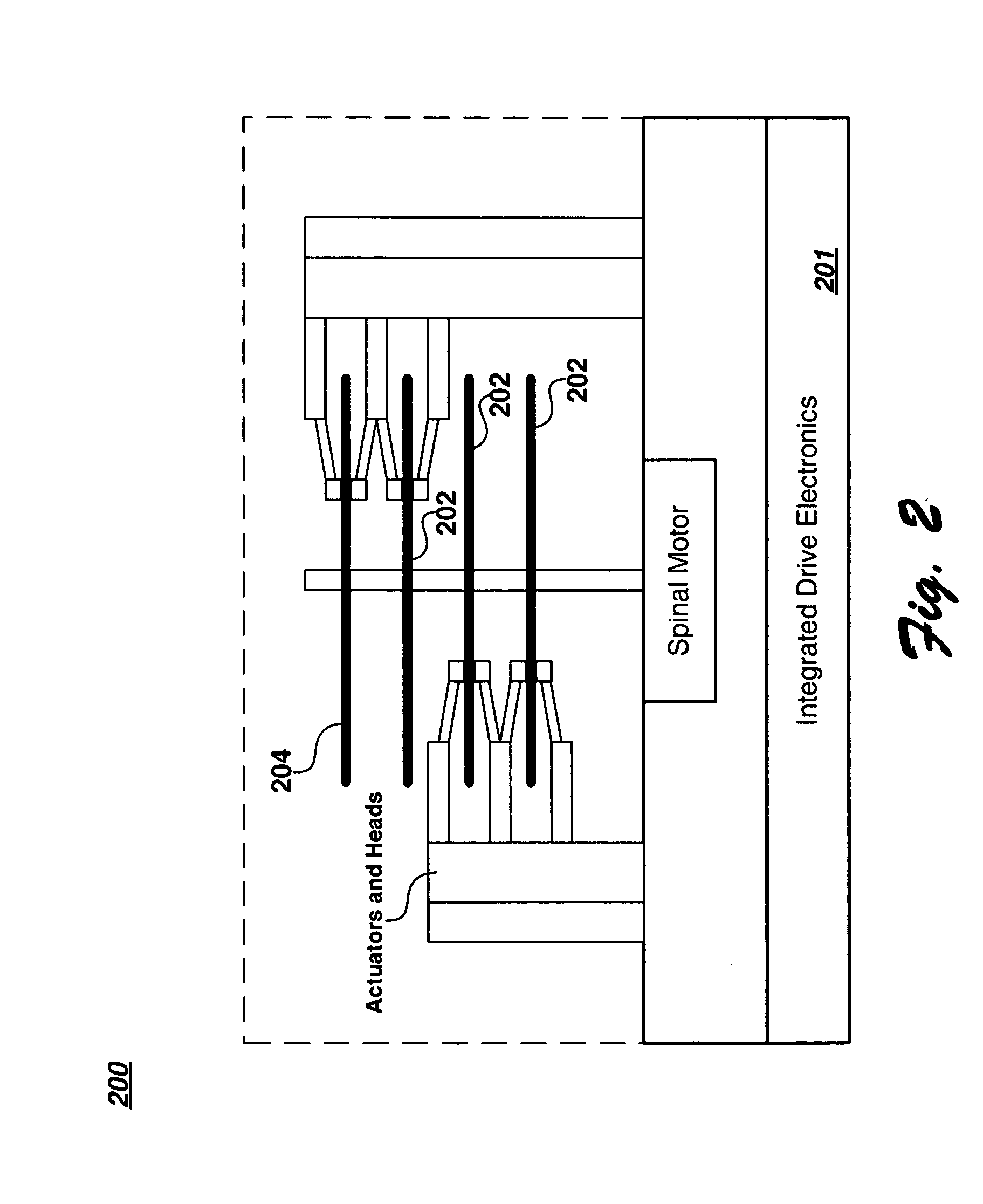

Apparatus and methods for testing a microprocessor chip using dedicated scan strings

InactiveUS6028983AReduce memory requirementsReduce scan timeElectronic circuit testingError detection/correctionTest inputJoint Test Action Group

A test apparatus and method for design verification of at least one microprocessor chip includes a compatible Joint Task Action Group (JTAG) terminal for access to a plurality of computer functional units contained in the chip. A test input terminal included in the JTAG terminal receives a scan string, the string being coupled to each computer functional unit through a first multiplexer. The scan input string is separated by the JTAG terminal under program control into a series of dedicated scan strings, each dedicated scan string being supplied to a selected functional unit through the first multiplexer. Each functional unit includes start and stop scan clocks for testing the functional under program control using the dedicated scan train for the functional unit. A test output terminal included in the JTAG terminal is coupled to each functional unit through a second multiplexer. The test results of the dedicated scan string under control of the scan clock are supplied to the output terminal through the second multiplexer. The compatible JTAG terminal includes further elements for controlling the scan clocks to select a targeted functional unit for testing purposes while the scan strings for non-targeted functional units remain in an inactive state.

Owner:GOOGLE LLC

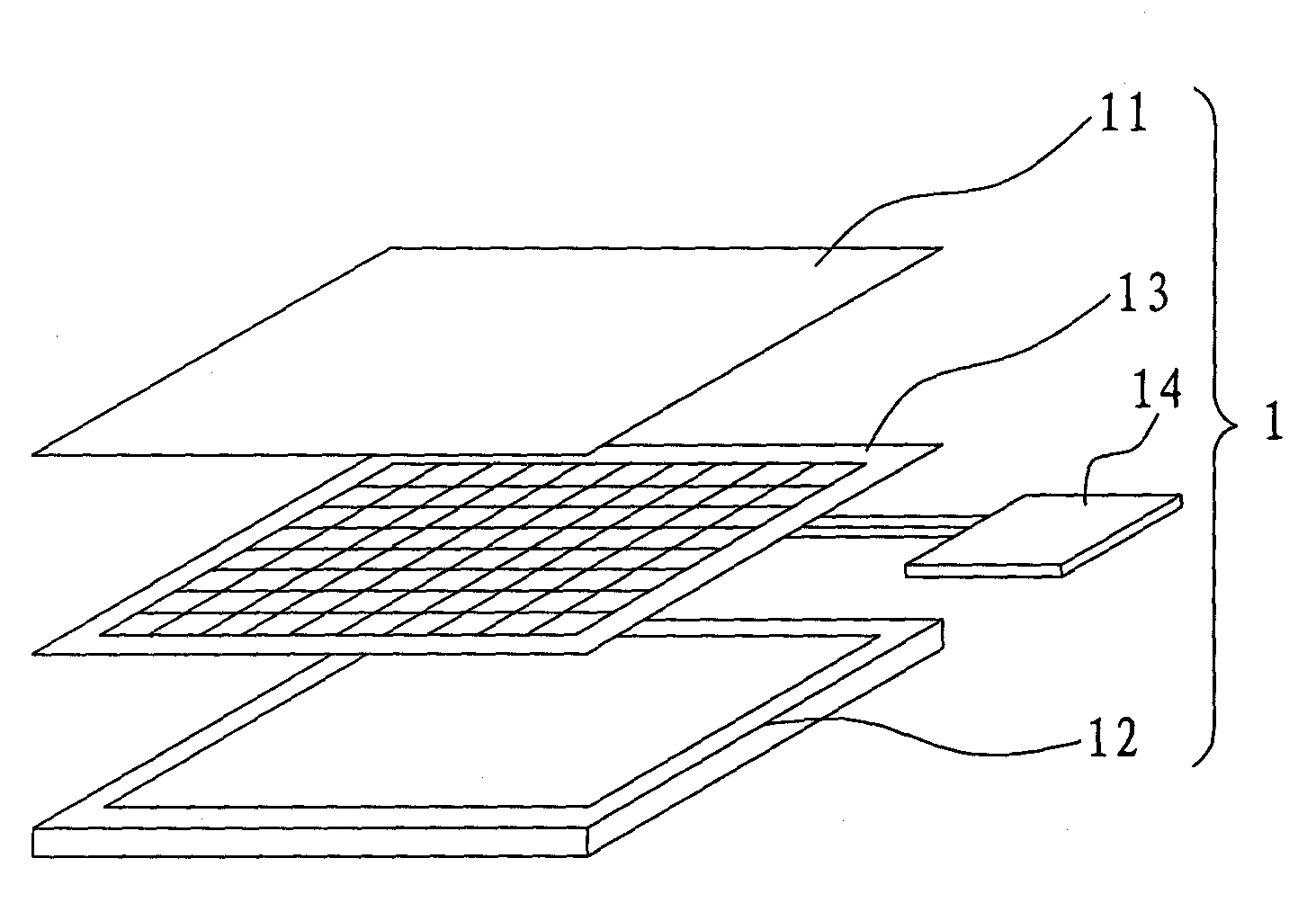

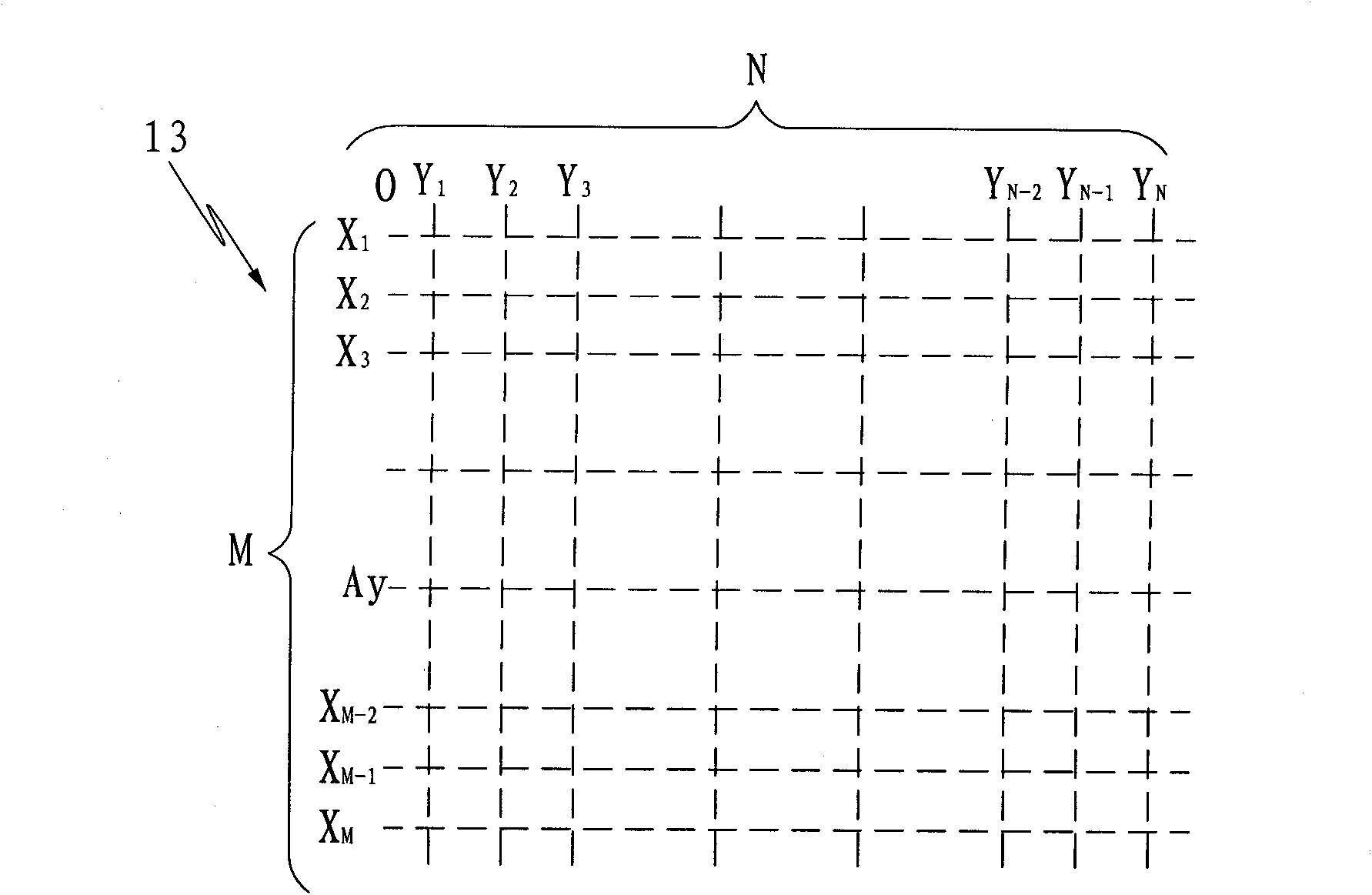

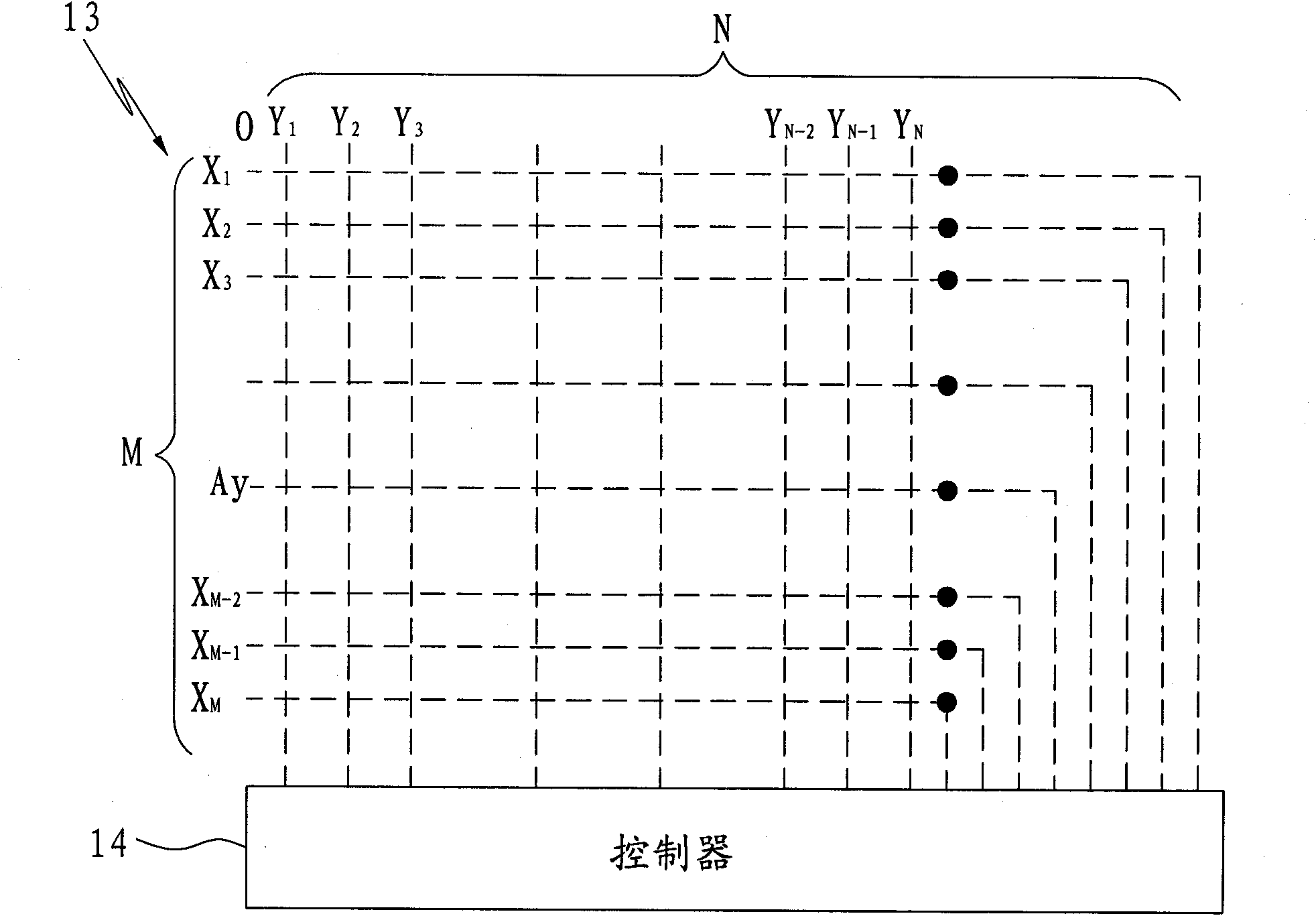

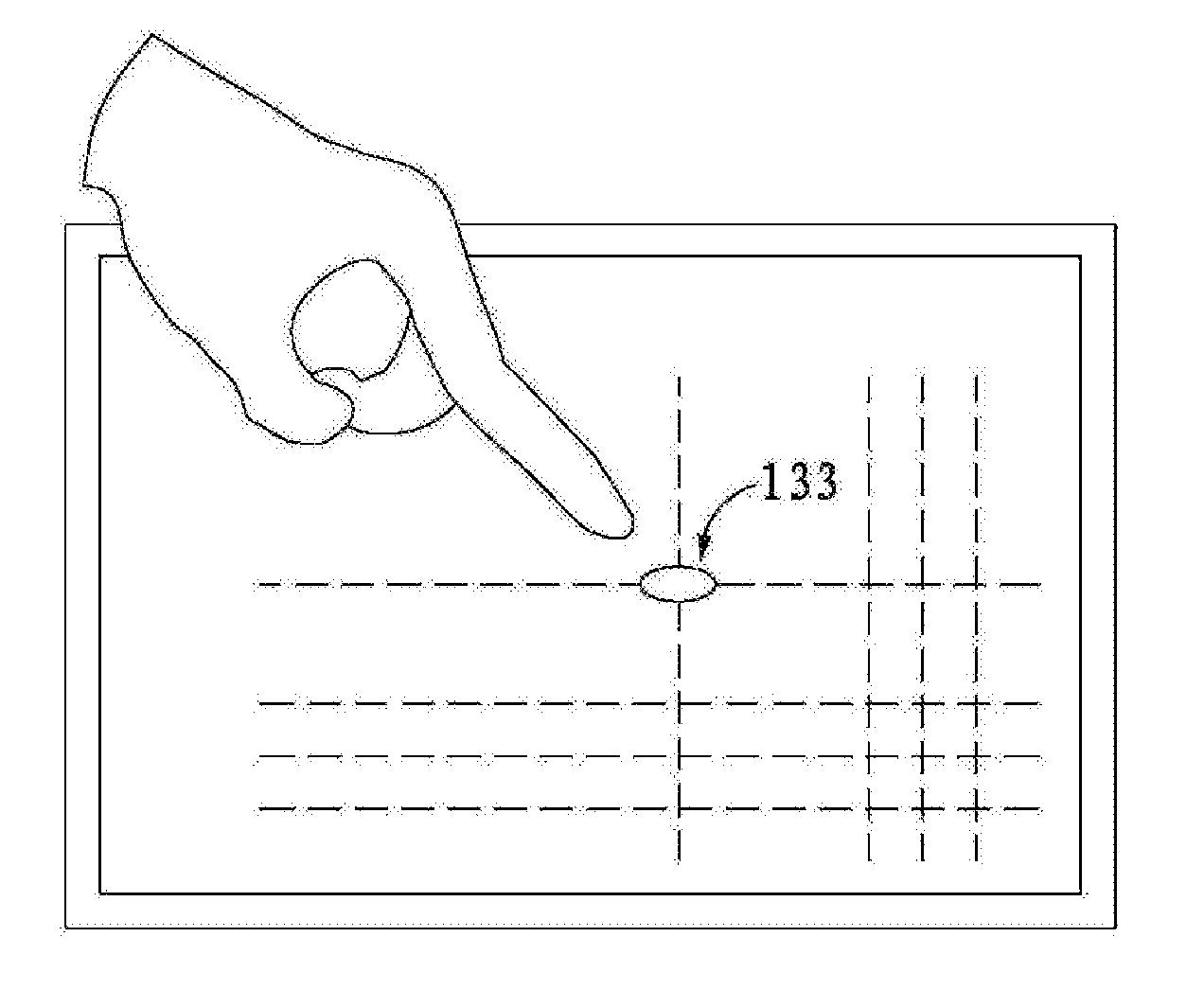

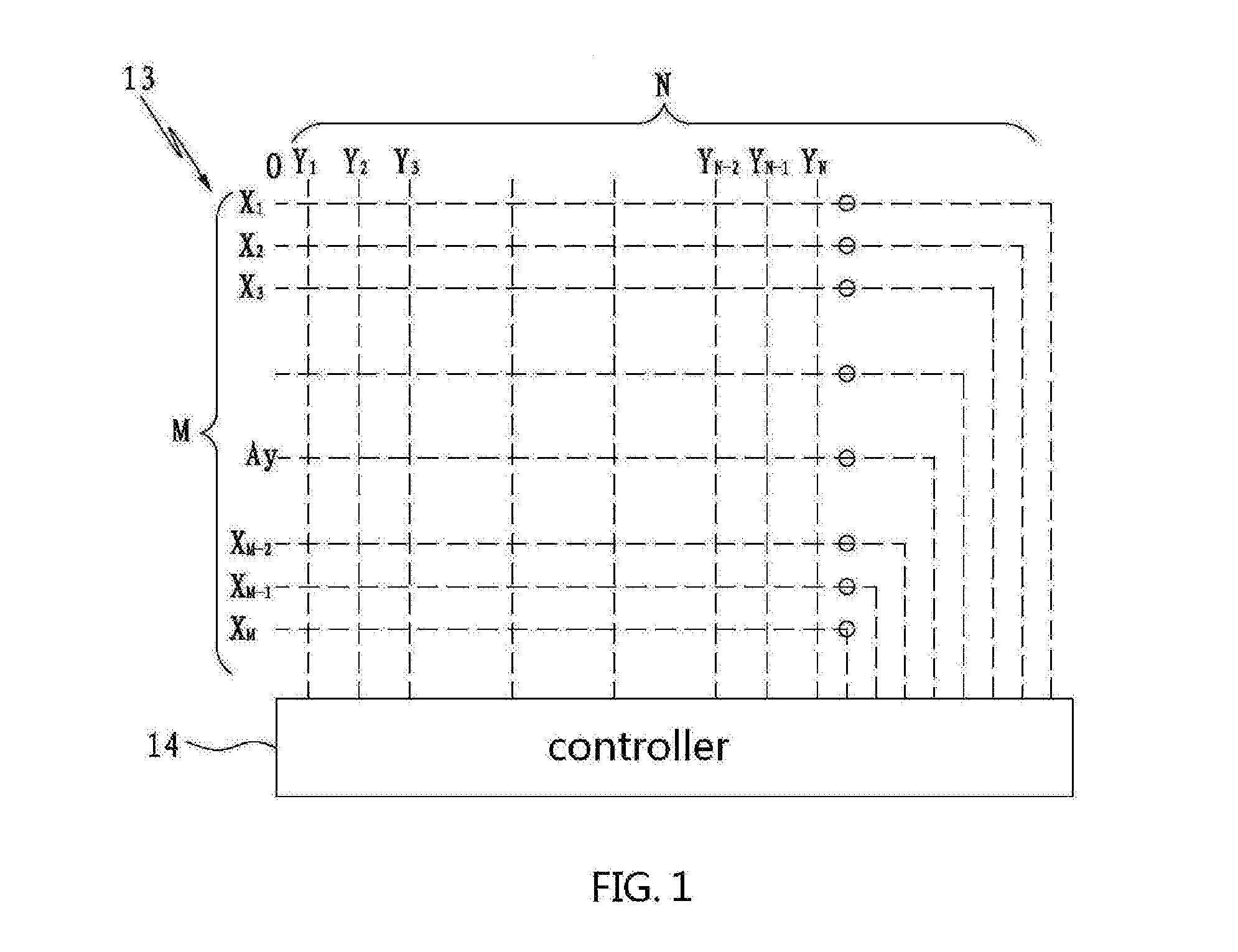

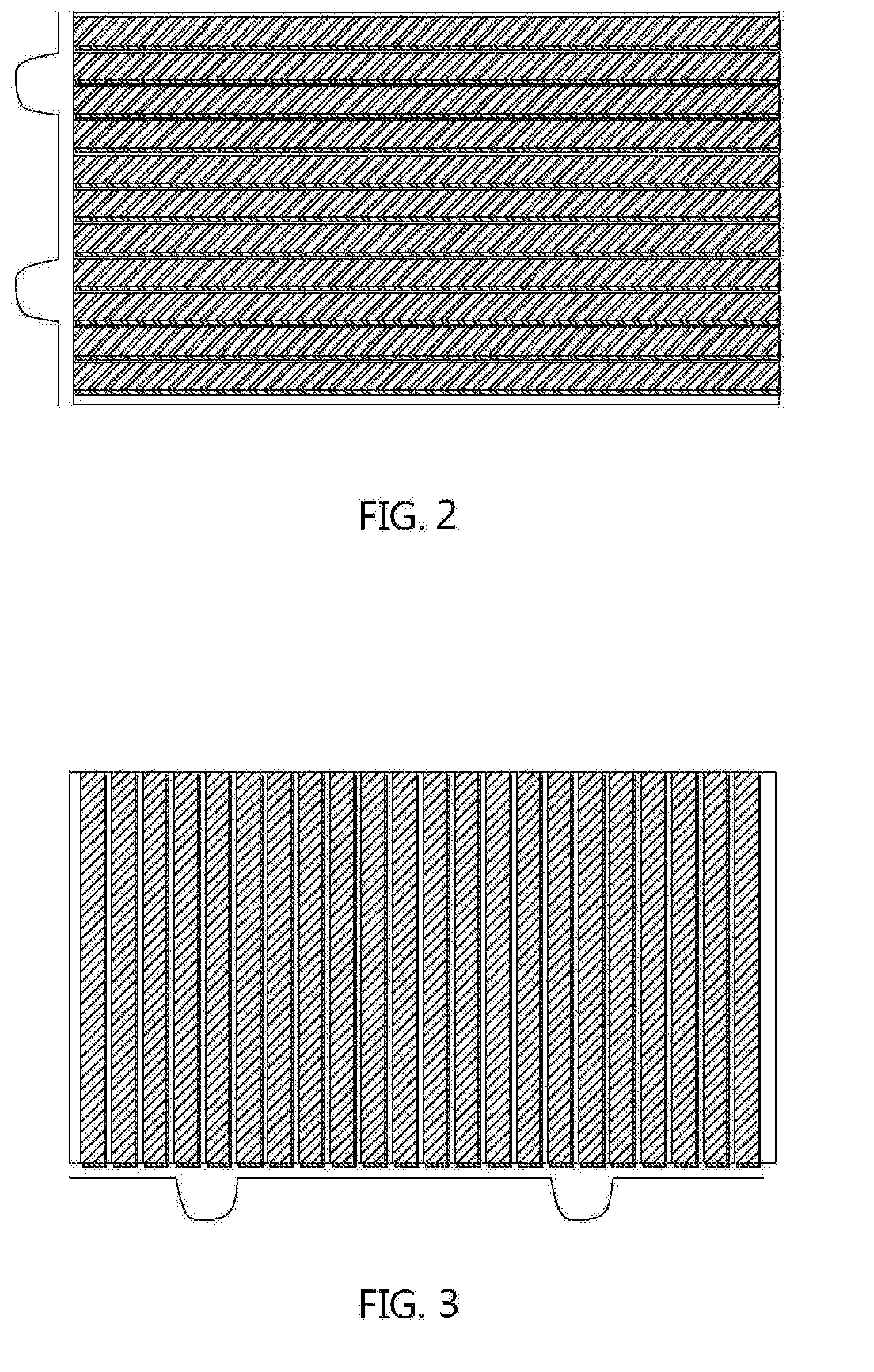

Scanning method for projected capacitive touch panels

ActiveCN101840293AReduce scan areaReduce scan timeInput/output processes for data processingTouch panelPhysics

The invention relates to a scanning method for projected capacitive touch panels, which includes the following steps that: (a) the self capacitance reference values of each first electrode and each second electrode and the mutual capacitance reference value of each intersection are set; (b) a controller scans the self capacitances of all the electrodes to obtain the current self capacitance value of each electrode, which is compared with the self capacitance reference value corresponding to the electrode to determine that the first and the second electrodes with the changed self capacitance values are touched; and (c) the controller scans the mutual capacitance of each intersection between the first and the second electrodes determined to be touched in the step b to obtain the current mutual capacitance value of each intersection, which is compared with the mutual capacitance reference value corresponding to the intersection to determine that the area where the intersection with the changed mutual capacitance value is positioned is an actually touched area. The method effectively combines self capacitance scanning with mutual capacitance scanning, the scanning frequency is high, the precision is high, and the method is particularly suitable for the multi-spot scanning of medium-sized and large-sized touch panels.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

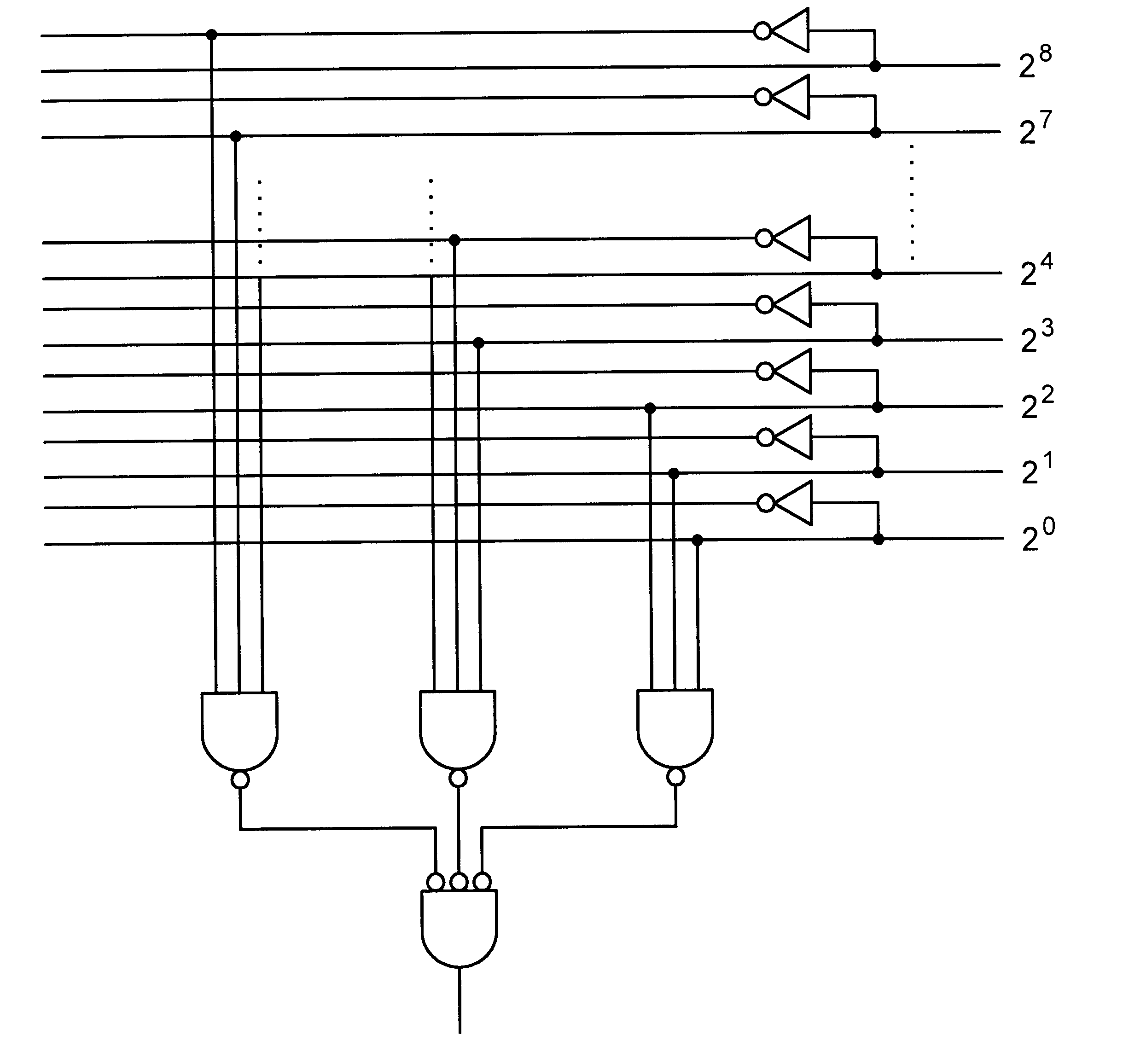

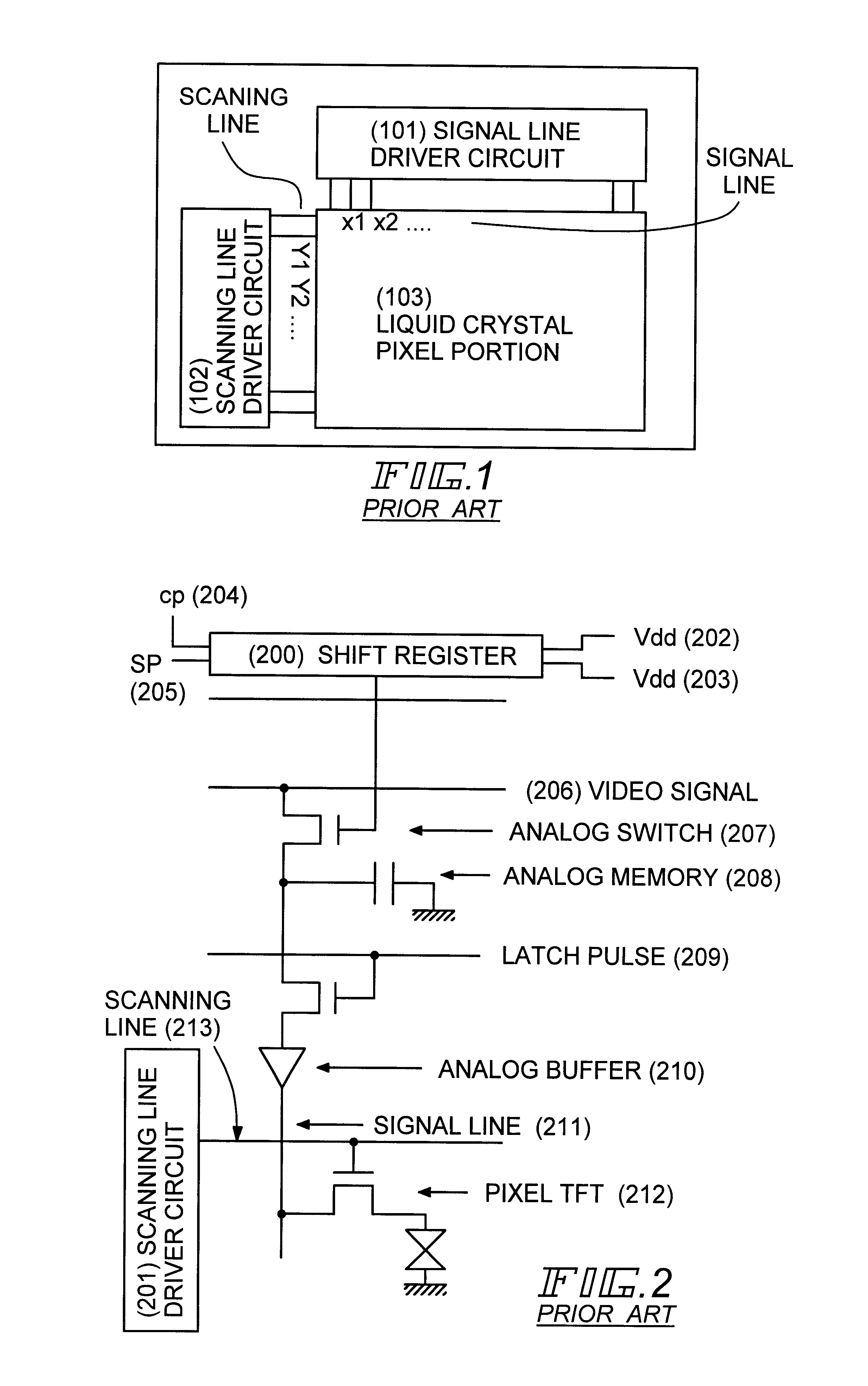

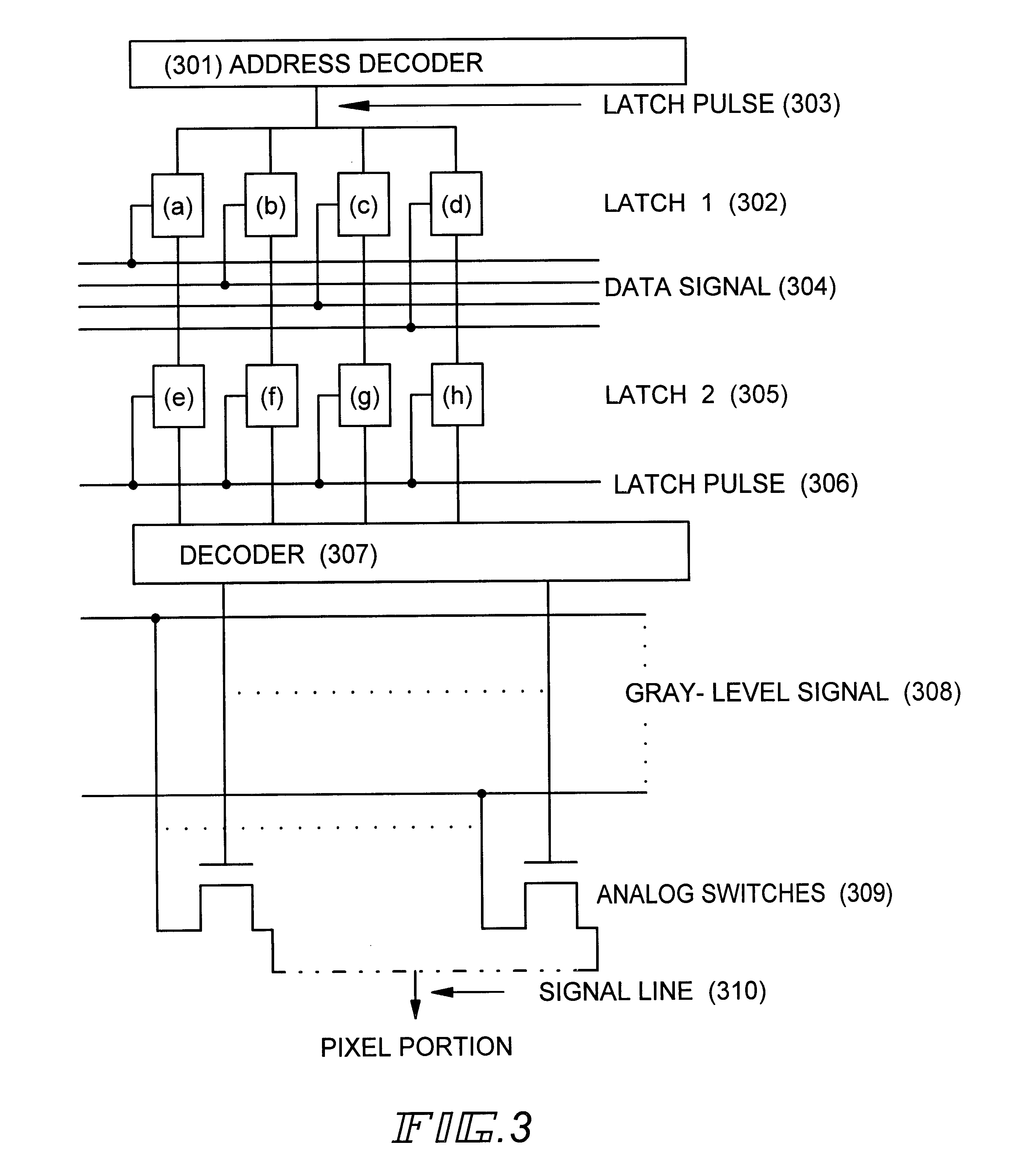

Drive circuit for display device

InactiveUS6344843B1Reduce scan timeRun at high speedCathode-ray tube indicatorsInput/output processes for data processingAddress decoderGray level

A driver circuit for use in an active matrix display having switching devices at pixels. The driver circuit uses no shift registers. Random access to signal lines or scanning lines can be obtained. The display quality is improved. The production yield is improved. Also, lower electric power consumption and higher-speed operation can be accomplished. Data about gray levels assumes the form of digital values and is supplied to the driver circuit. The signal lines or scanning lines are selected by an address decoder circuit.

Owner:SEMICON ENERGY LAB CO LTD

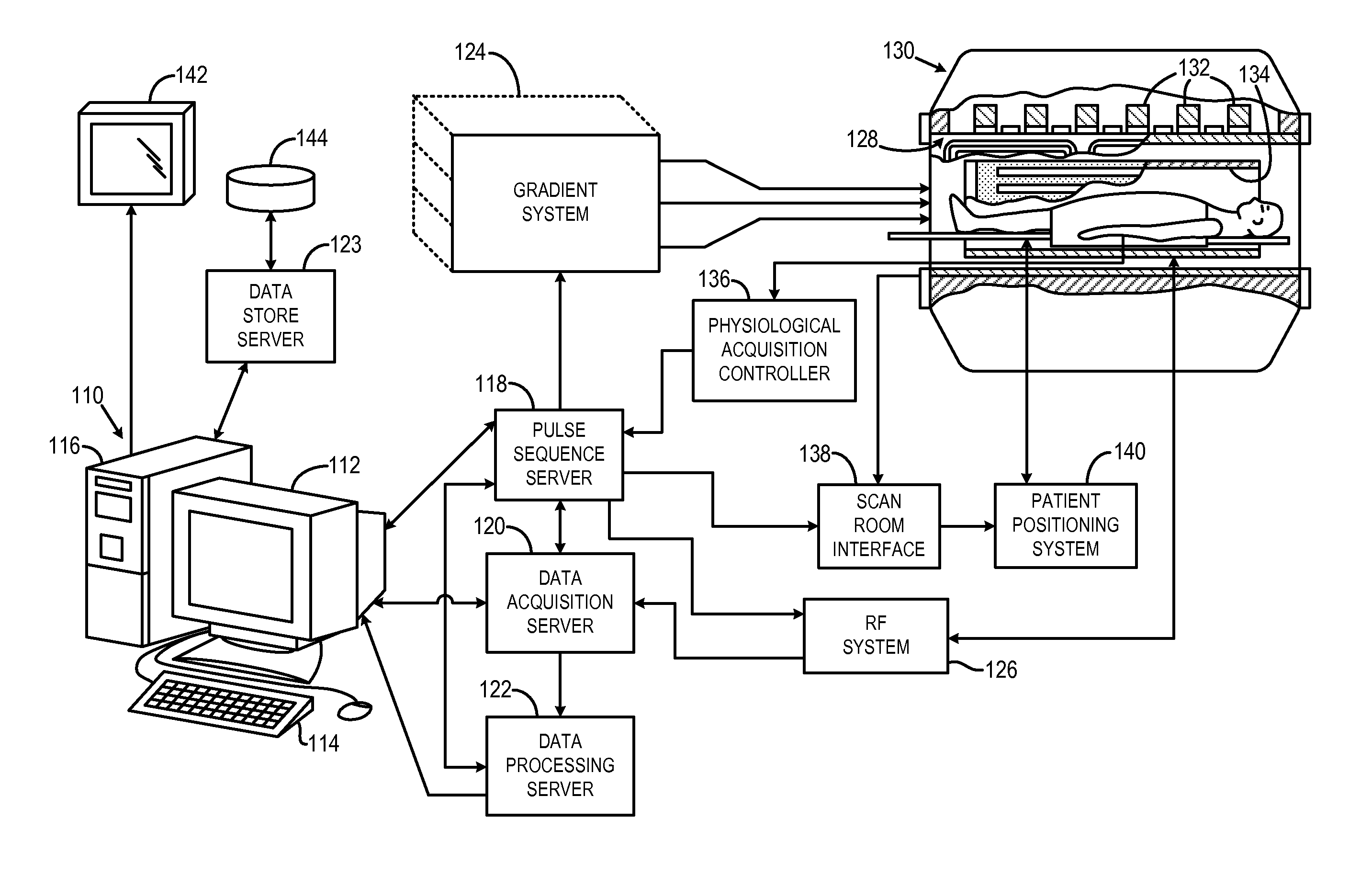

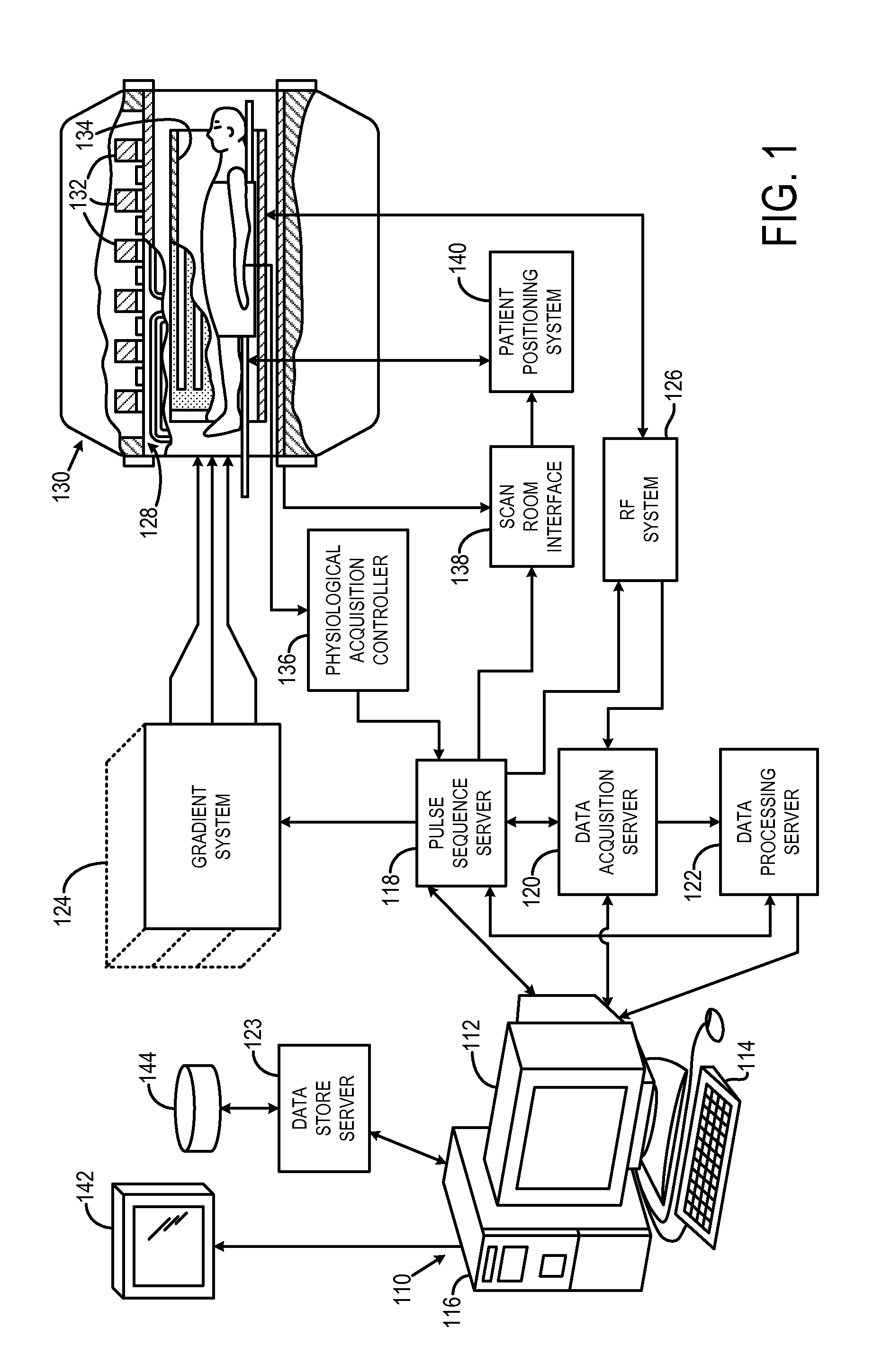

Method for simultaneous multi-slice magnetic resonance imaging

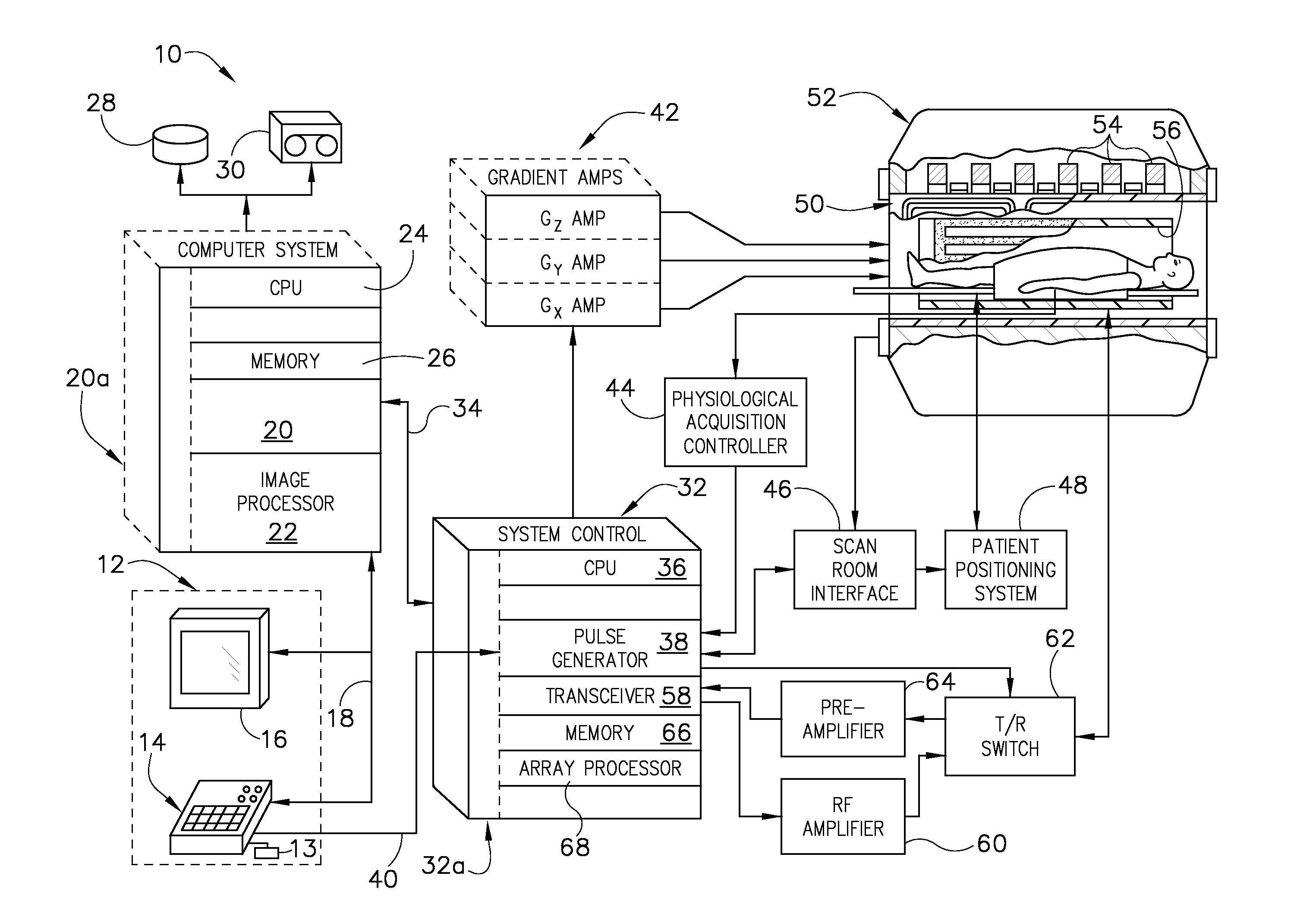

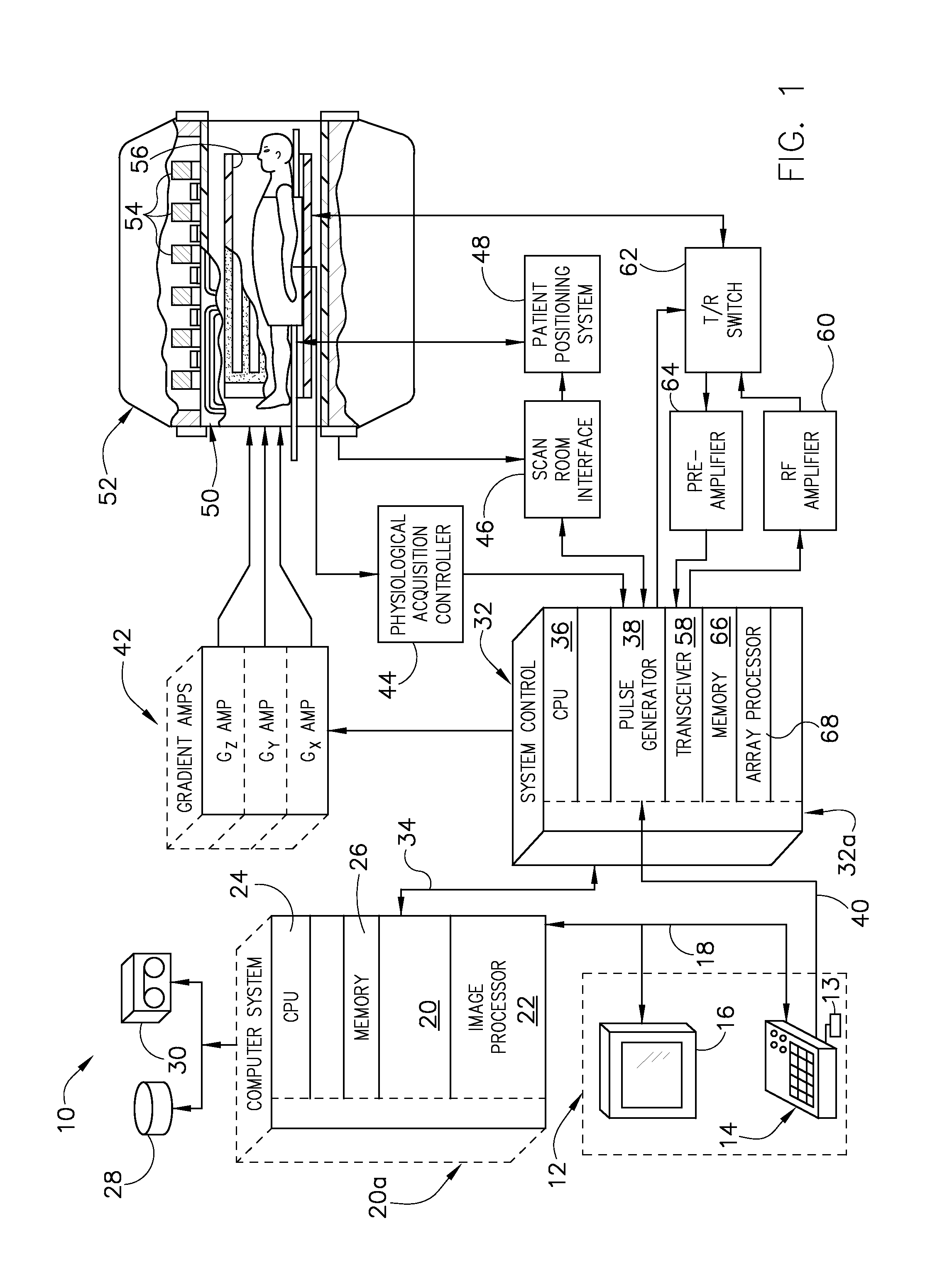

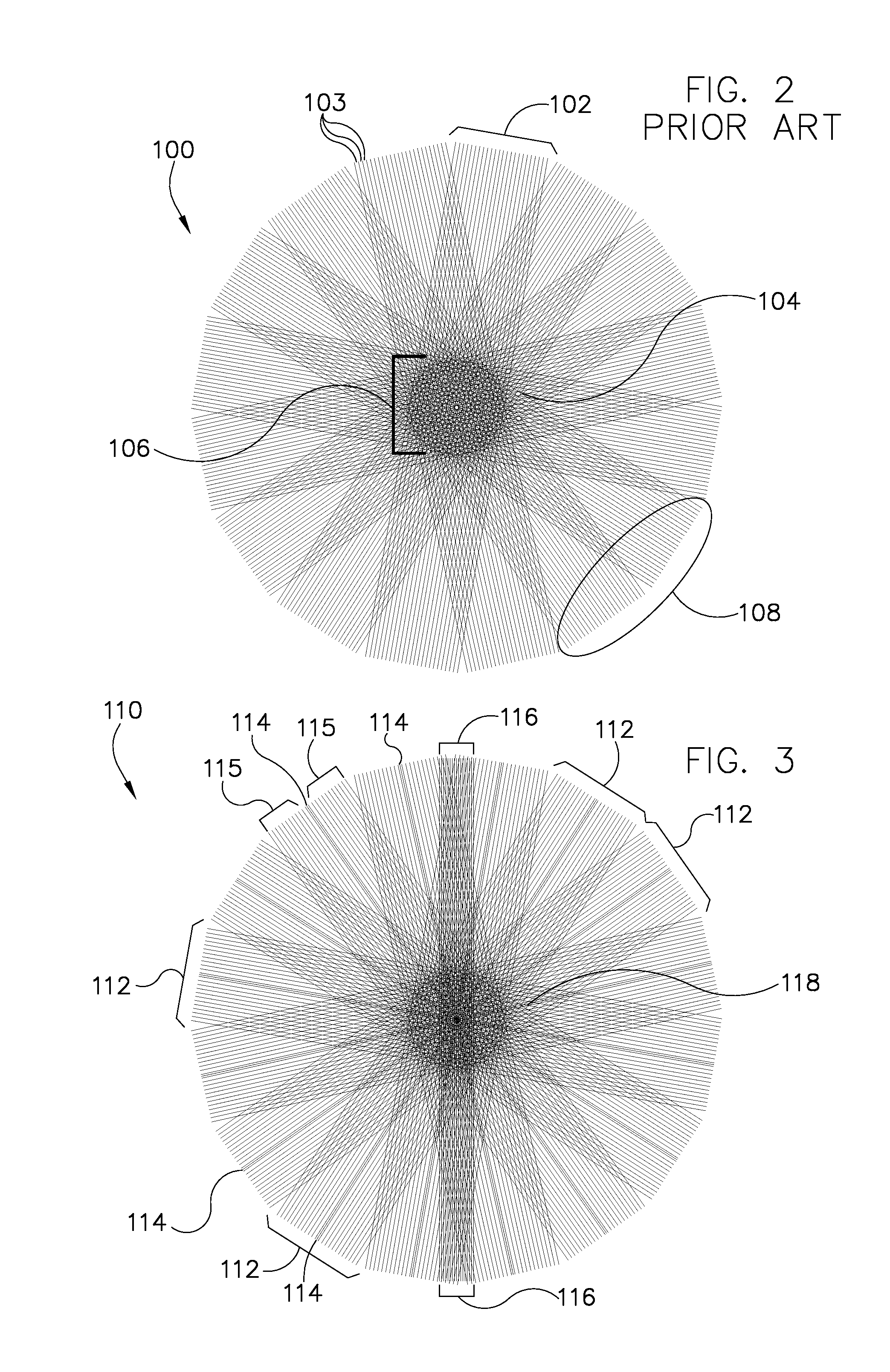

ActiveUS20110254548A1Reliable separationLarge possible separationMeasurements using NMR imaging systemsElectric/magnetic detectionMagnetic gradientMulti slice

A method for multi-slice magnetic resonance imaging, in which image data is acquired simultaneously from multiple slice locations using a radio frequency coil array, is provided. By way of example, a modified EPI pulse sequence is provided, and includes a series of magnetic gradient field “blips” that are applied along a slice-encoding direction contemporaneously with phase-encoding blips common to EPI sequences. The slice-encoding blips are designed such that phase accruals along the phase-encoding direction are substantially mitigated, while providing that signal information for each sequentially adjacent slice location is cumulatively shifted by a percentage of the imaging FOV. This percentage FOV shift in the image domain provides for more reliable separation of the aliased signal information using parallel image reconstruction methods such as SENSE. In addition, the mitigation of phase accruals in the phase-encoding direction provides for the substantial suppression of pixel tilt and blurring in the reconstructed images.

Owner:THE GENERAL HOSPITAL CORP

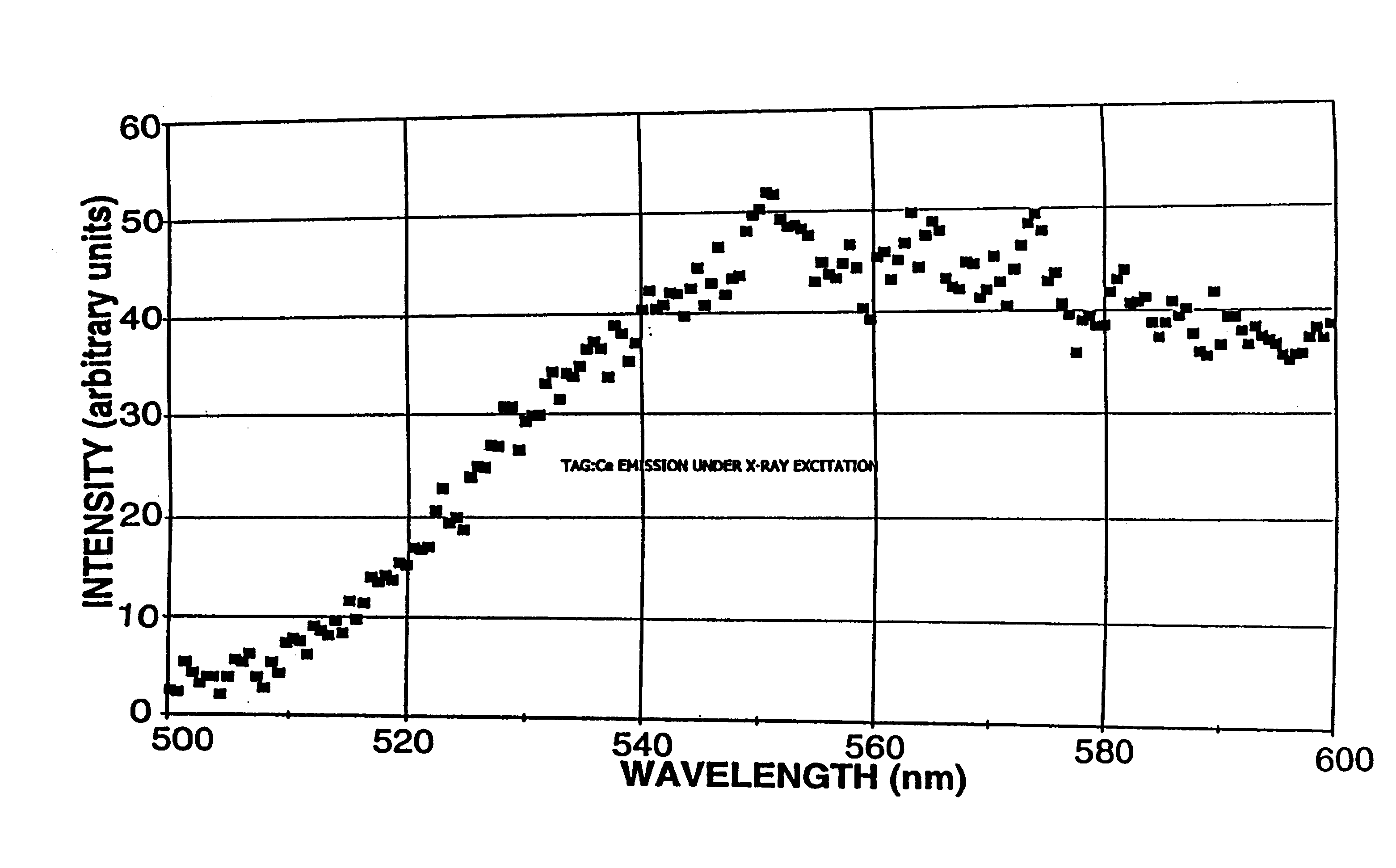

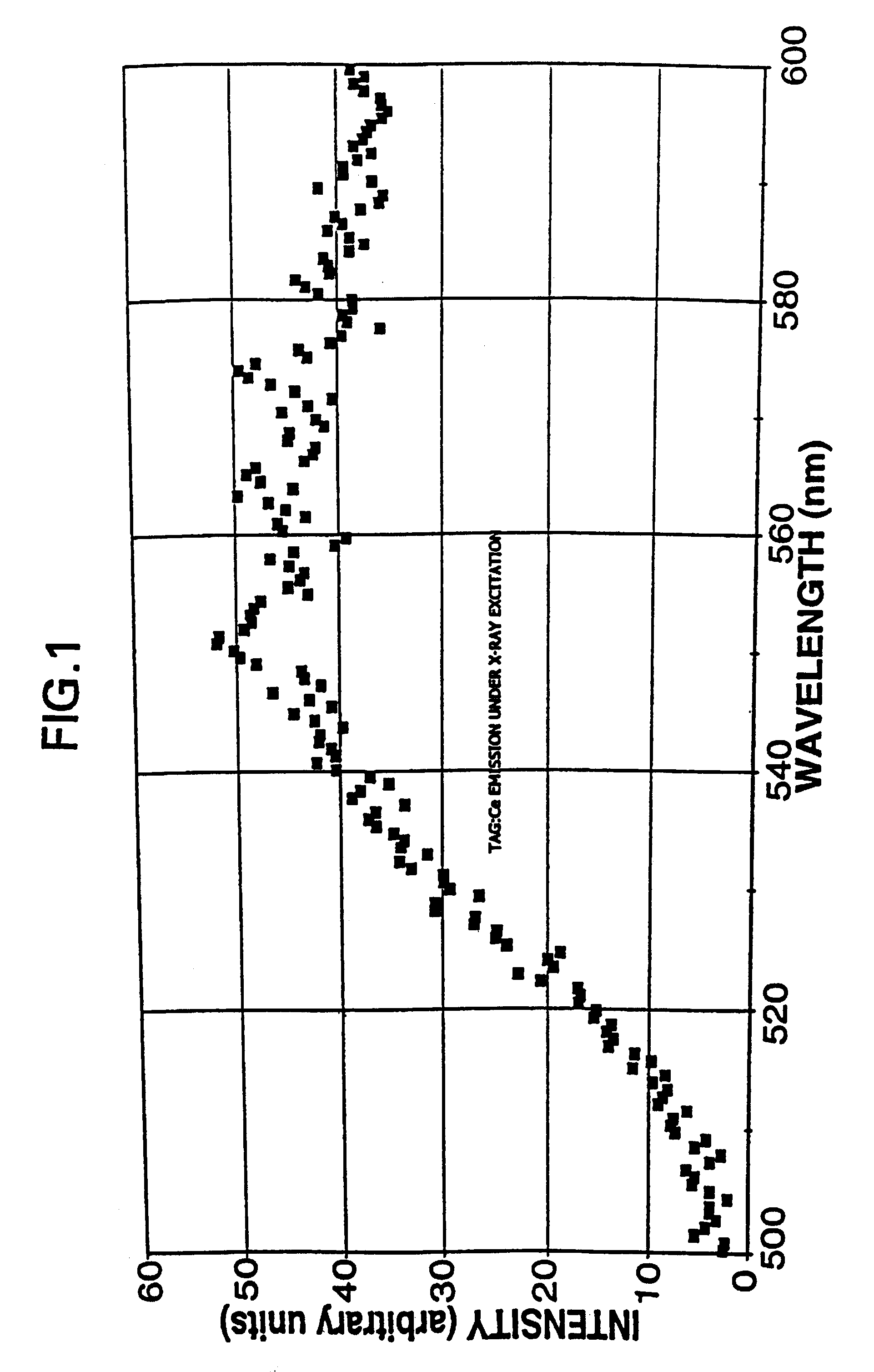

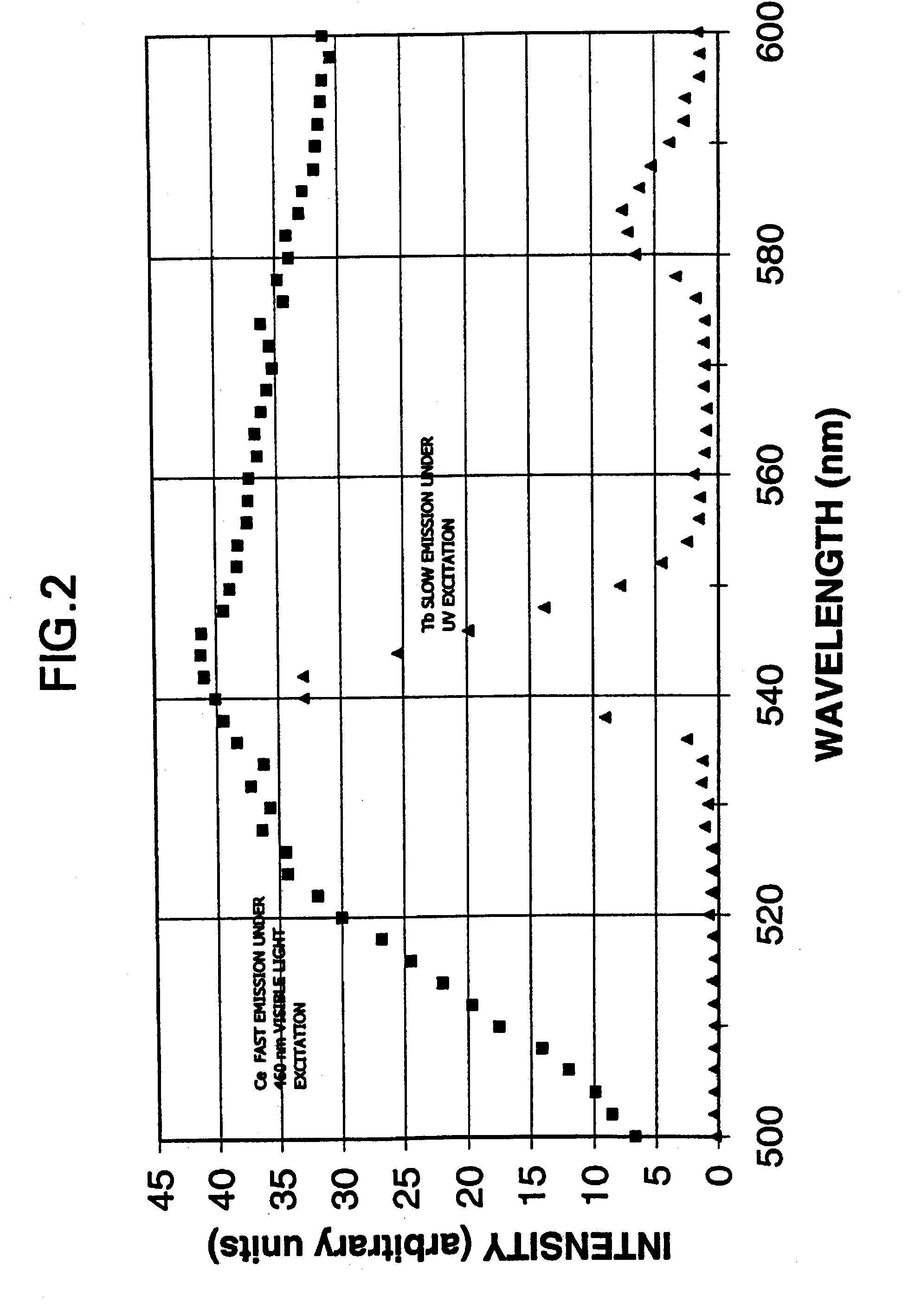

Terbium- or lutetium - containing garnet phosphors and scintillators for detection of high-energy radiation

InactiveUS6630077B2Improve light outputShort decay timePolycrystalline material growthMaterial analysis using wave/particle radiationLutetiumHigh energy

Owner:GENERAL ELECTRIC CO

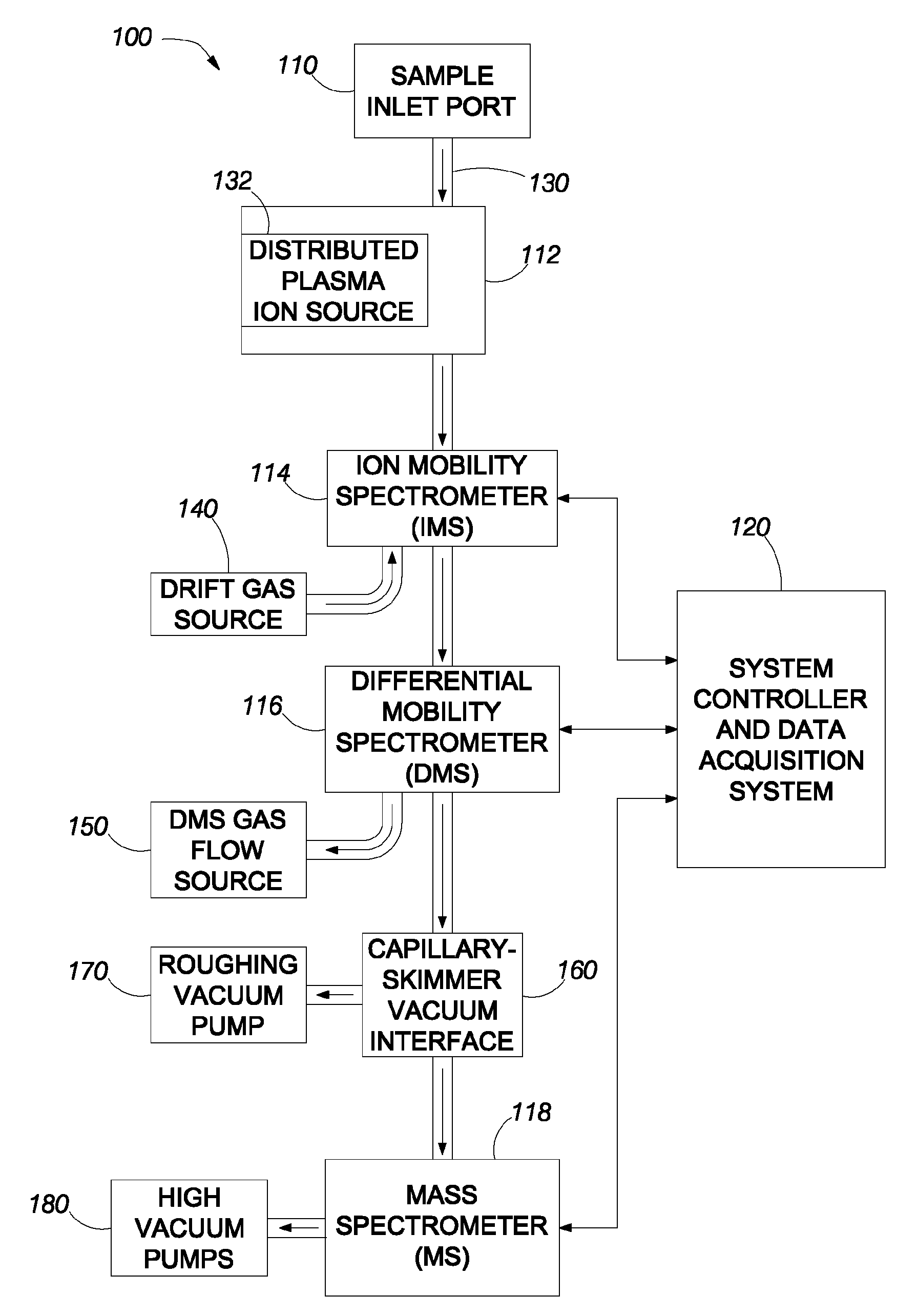

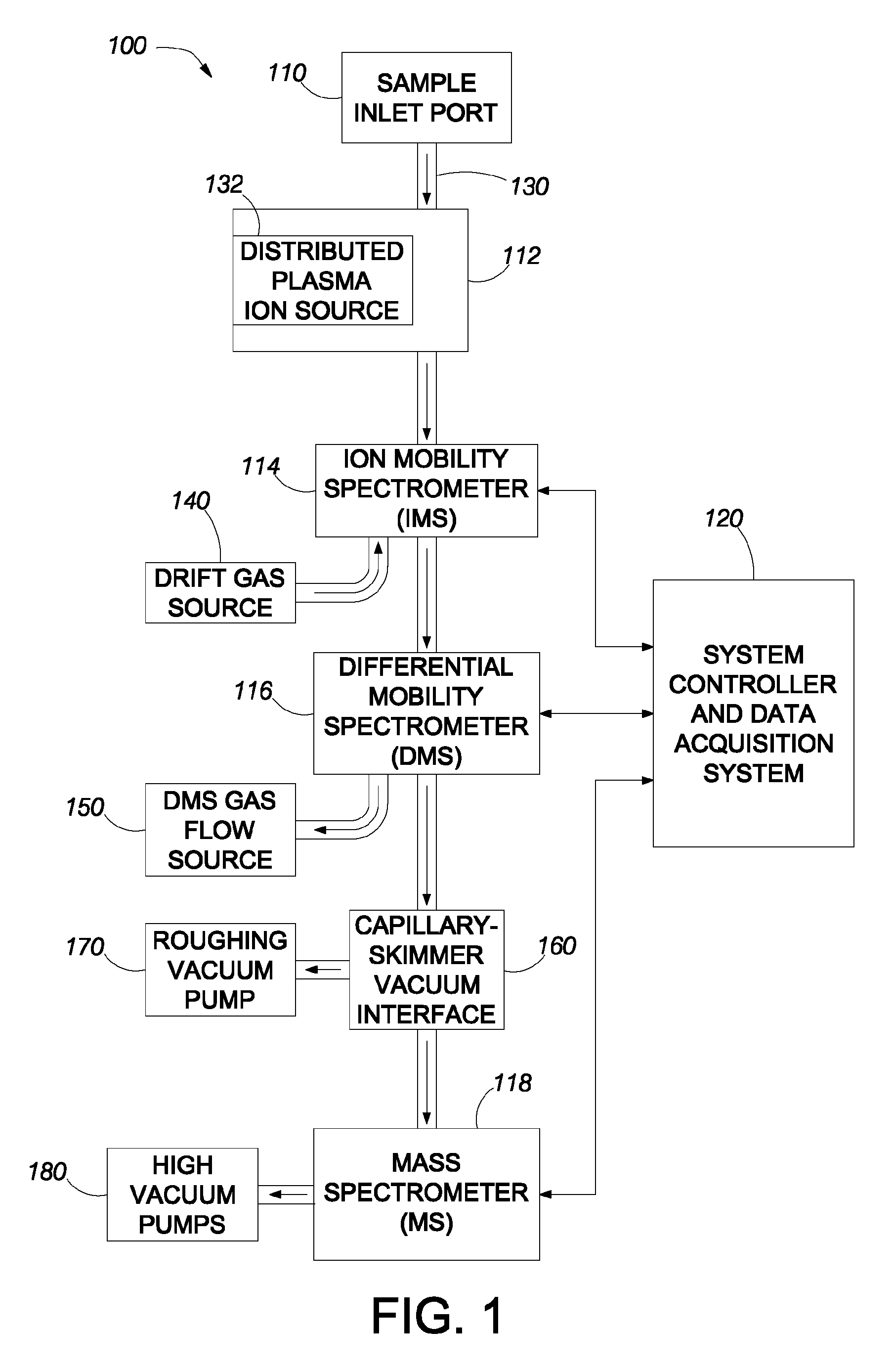

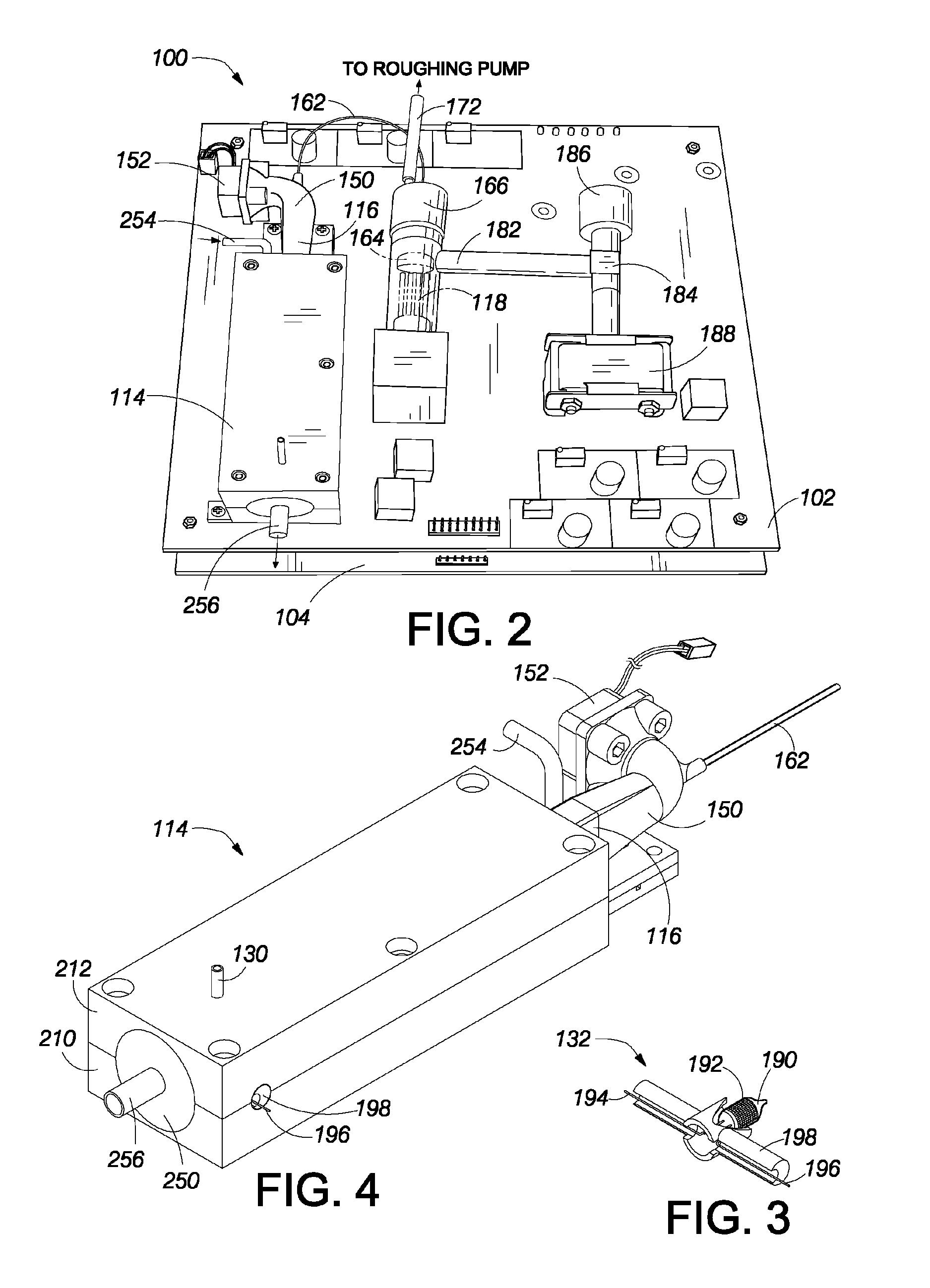

Real-time trace detection by high field and low field ion mobility and mass spectrometry

ActiveUS8173959B1Low costLow powerMaterial analysis by electric/magnetic meansIsotope separationIonizationMass spectrum analysis

A trace detection system includes at least two stages coupled to operate in series. An ion mobility spectrometer (IMS) stage has a sampling inlet to receive a sample to be analyzed. An ion source ionizes the sample. The IMS applies an electrical field to the ionized sample to move the ionized sample toward an IMS outlet. A differential mobility spectrometer (DMS) stage coupled in series with the IMS stage receives the ionized sample from the IMS stage. Preferably, the system includes a mass spectrometer (MS) stage coupled in series with the DMS stage to receive the ionized sample from the DMS stage via a vacuum interface. A roughing vacuum pump evacuates a first stage of the MS stage to a first pressure below atmospheric pressure. A high vacuum pump evacuates a second stage of the MS stage to a second pressure below the first pressure.

Owner:LEIDOS SECURITY DETECTION & AUTOMATION INC

Method for Scanning Projective Capacitive Touch Panel, Storage Medium and Apparatus for Scanning Projective Capacitive Touch Panel

InactiveUS20110175835A1Reduce scan timeIncrease scan frequencyInput/output processes for data processingEngineeringTouchscreen

The present invention relates to a method for scanning a projective capacitive touch panel including: A. scanning each first-axis electrode arranged along a first-axis and each second-axis electrode arranged along a second-axis, then obtaining the first-axis electrode and the second-axis electrode whose self capacitance changes; B. detecting the mutual capacitance at each intersection between the first-axis electrode and the second-axis electrode whose self capacitance changes to determine whether the mutual capacitance changes, then the area where the mutual capacitance changes being taken as a touched area. The present invention also relates to a storage medium storing instructions of implementing above method and an apparatus that implements the above method.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

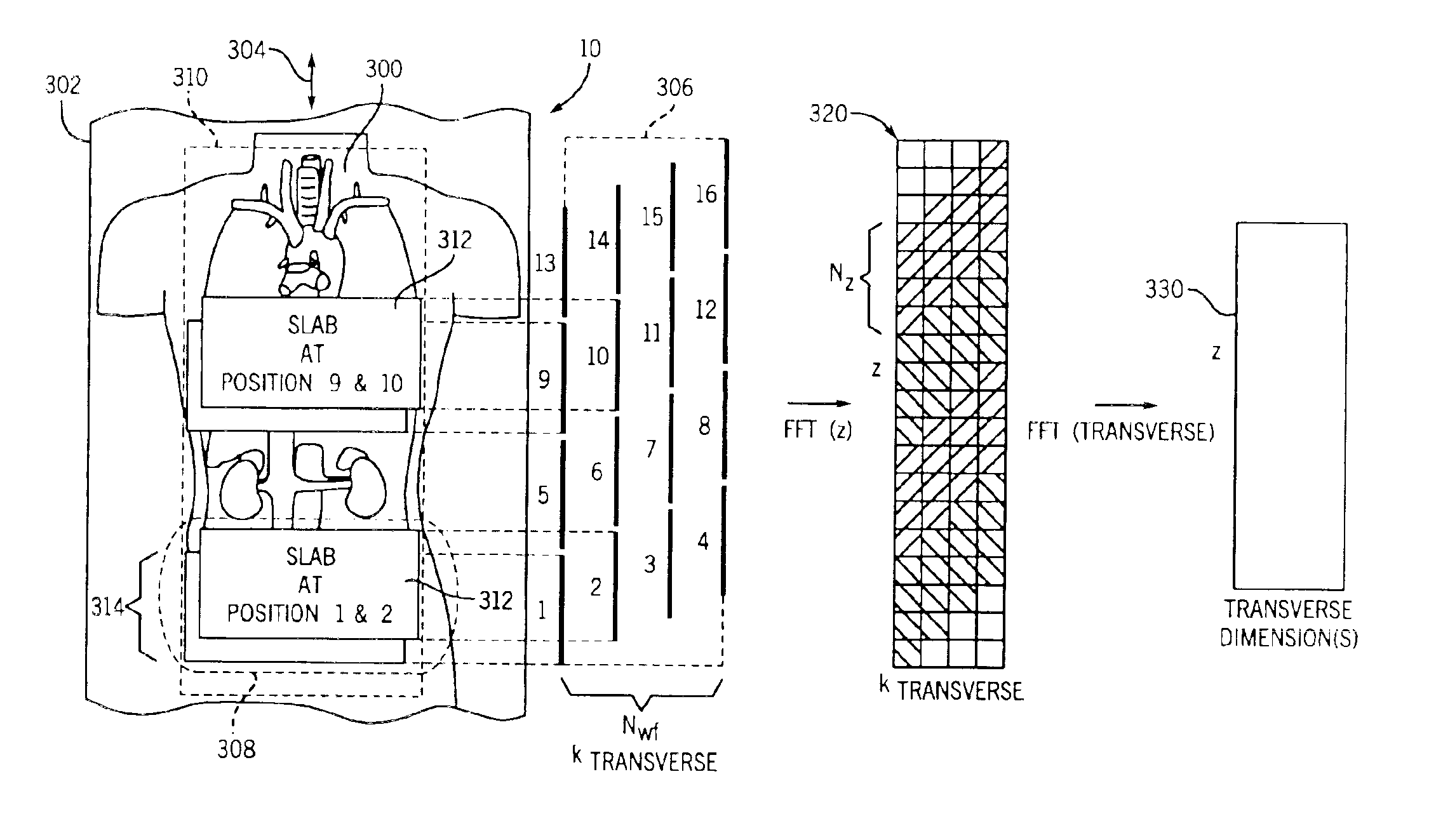

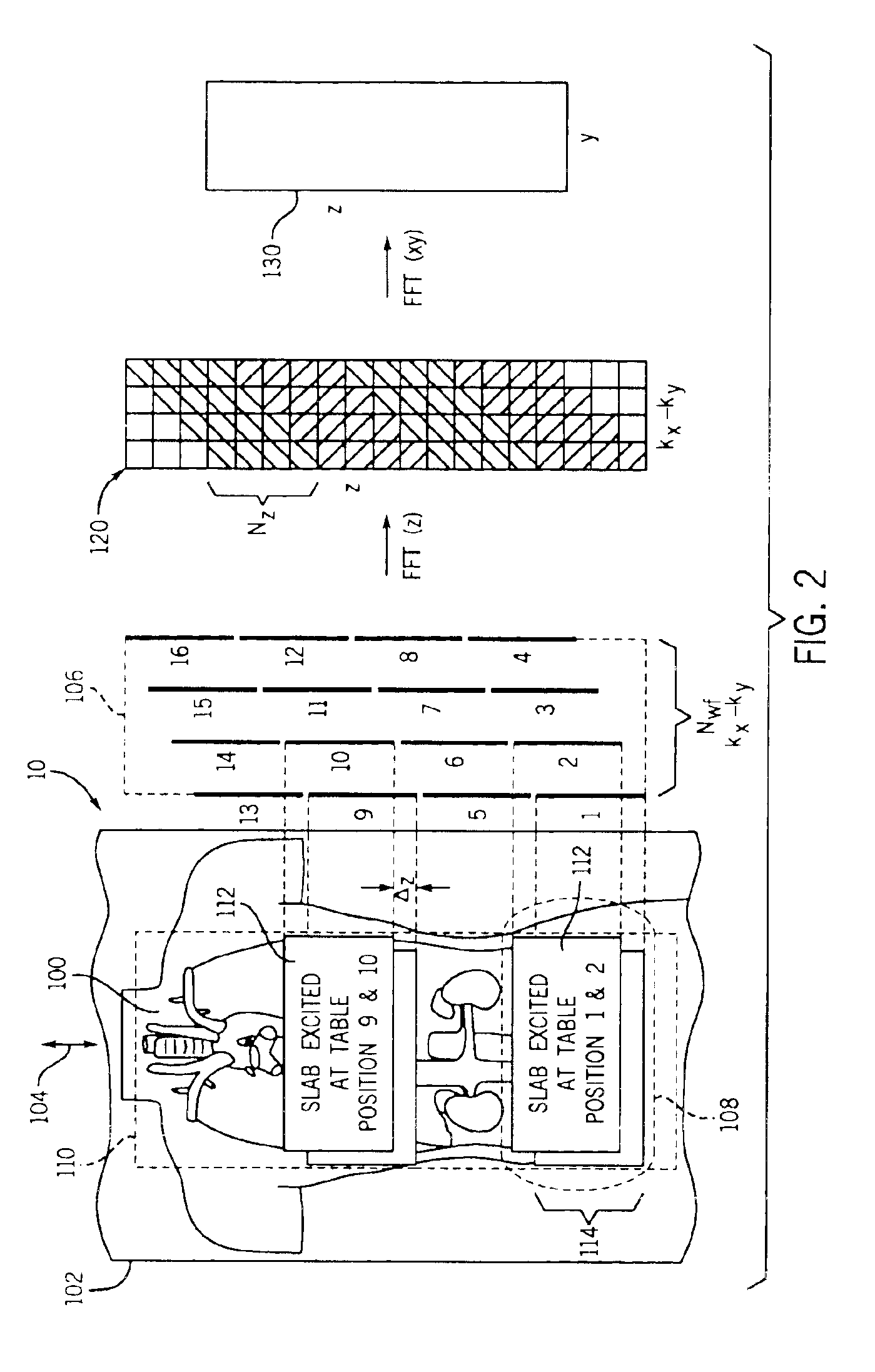

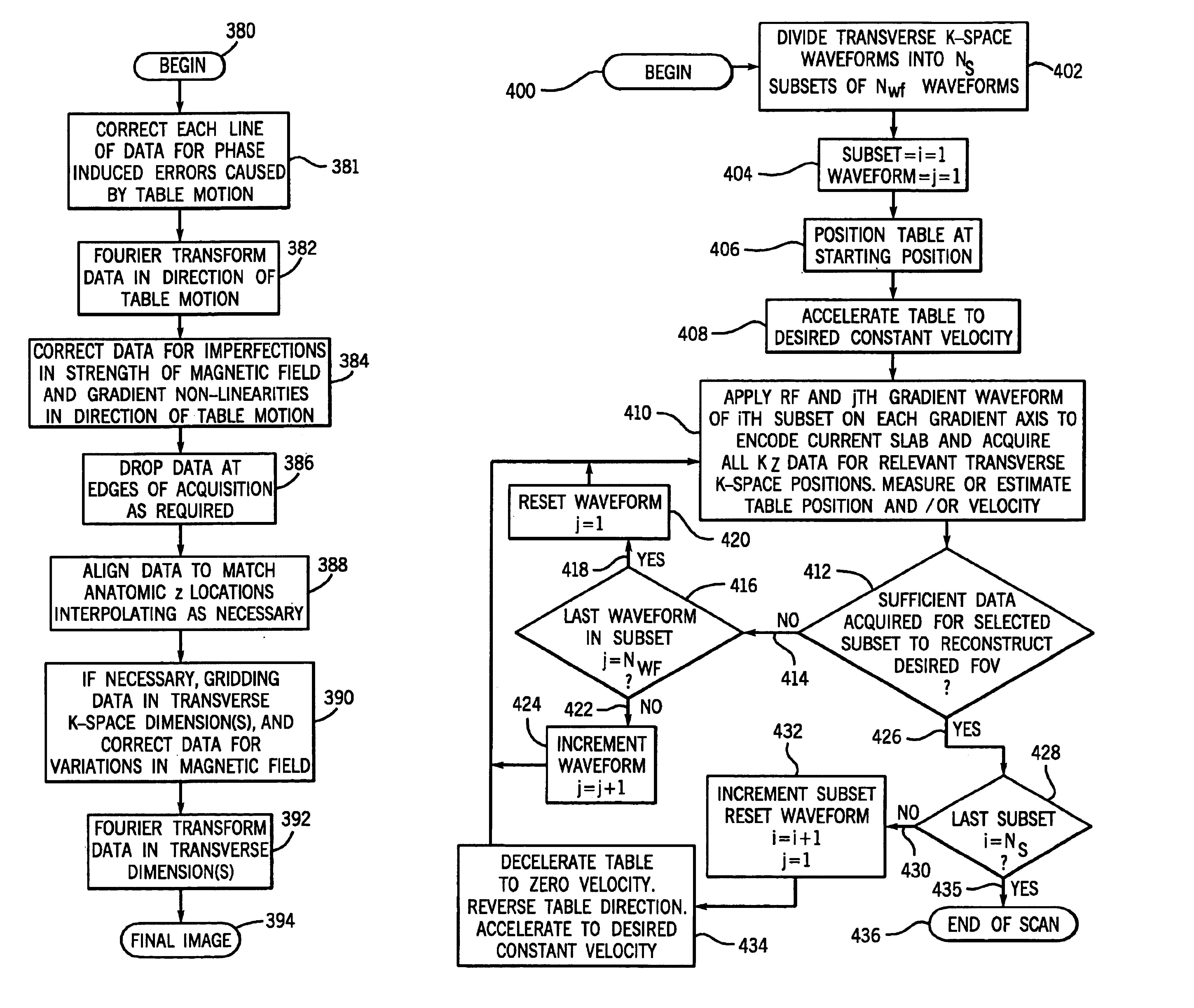

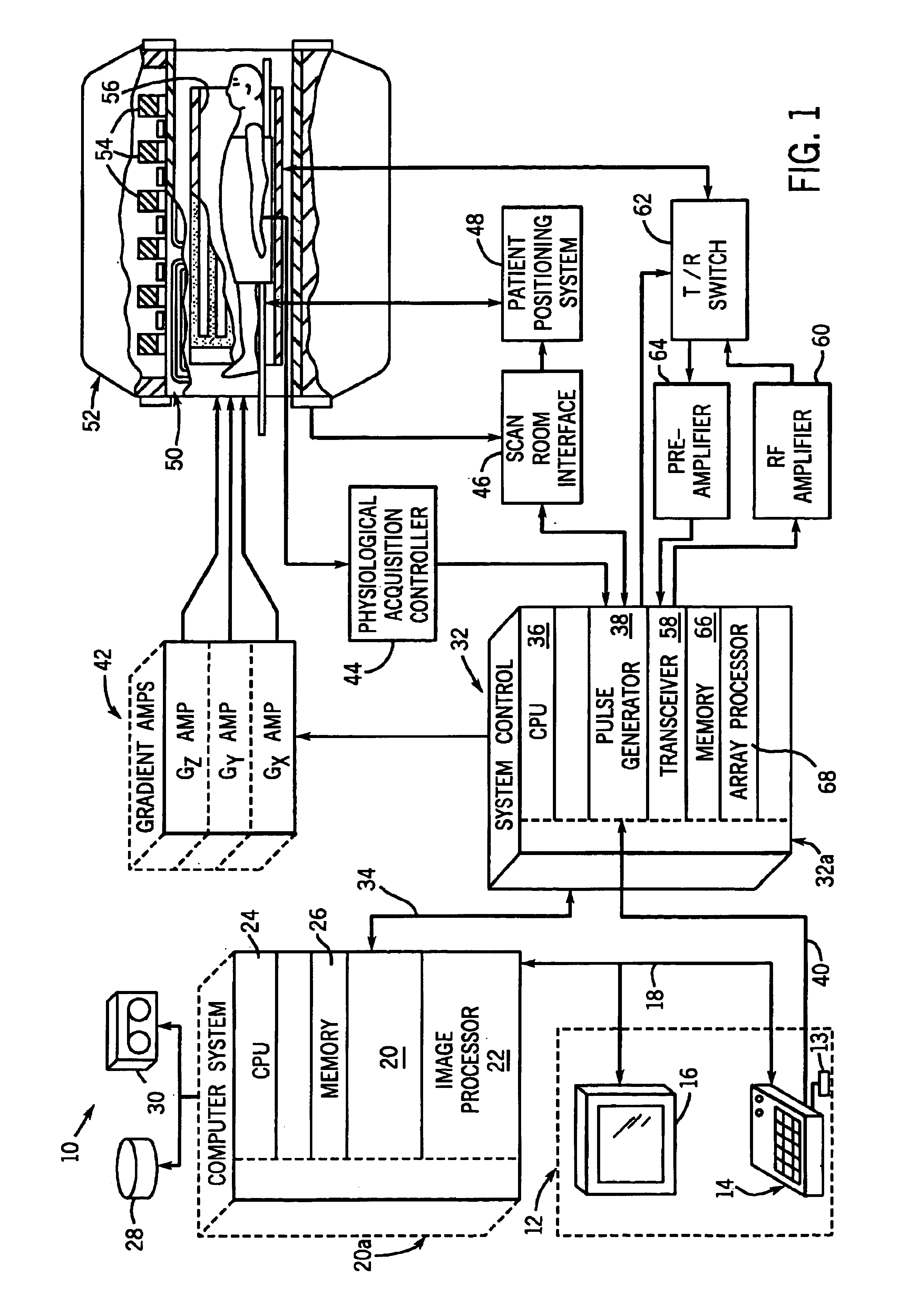

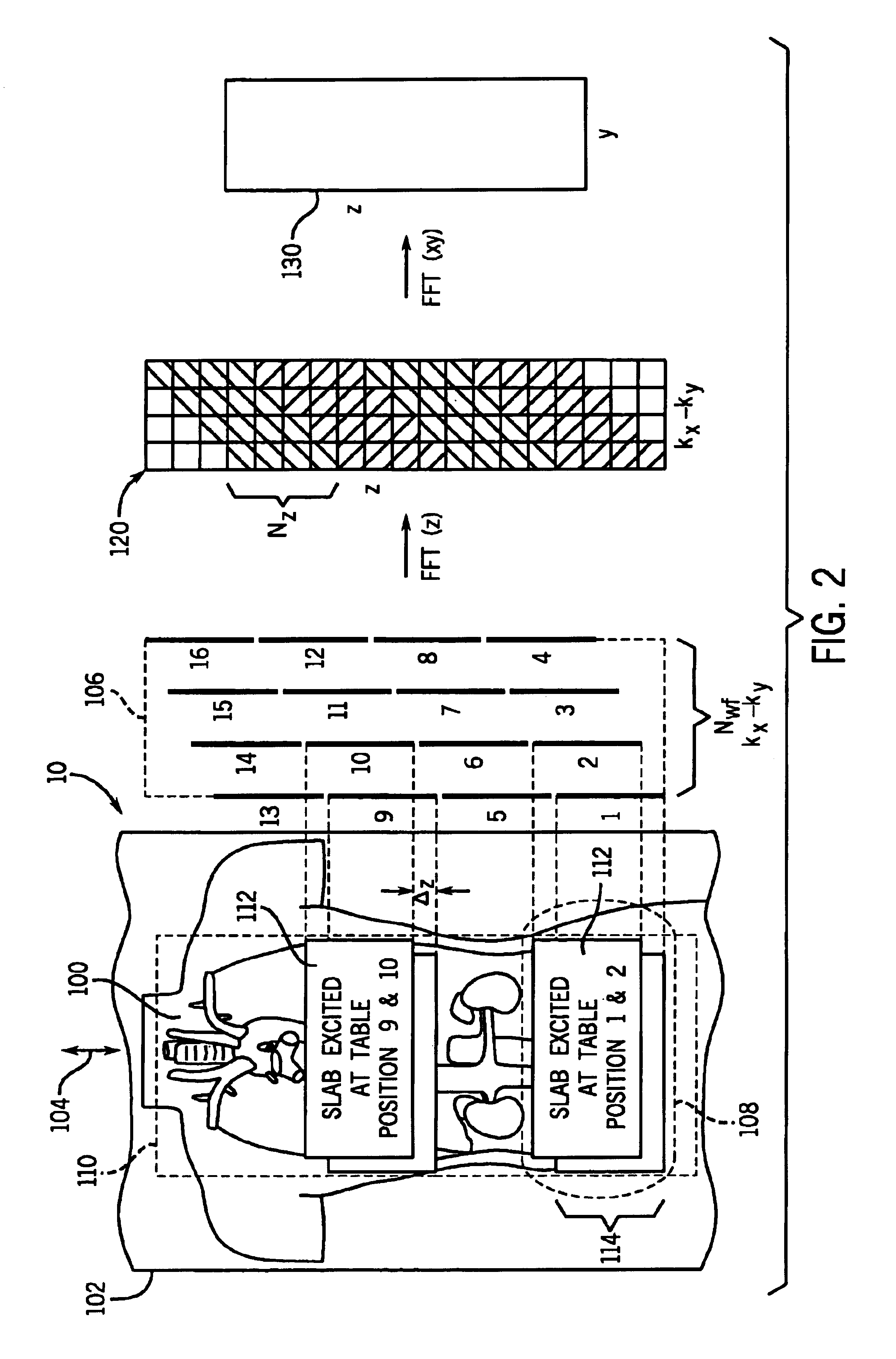

Moving table MRI with frequency-encoding in the z-direction

InactiveUS6897655B2Expand coverageShorten the timeDiagnostic recording/measuringSensorsLarge fovAcquisition time

A system and method are disclosed using continuous table motion while acquiring data to reconstruct MR images across a large FOV without significant slab-boundary artifacts that reduces acquisition time. At each table position, full z-encoding data are acquired for a subset of the transverse k-space data. The table is moved through a number of positions over the desired FOV and MR data are acquired over the plurality of table positions. Since full z-data are acquired for each slab, the data can be Fourier transformed in z, interpolated, sorted, and aligned to match anatomic z locations. The fully sampled and aligned data is then Fourier transformed in remaining dimension(s) to reconstruct the final image that is free of slab-boundary artifacts.

Owner:GENERAL ELECTRIC CO +1

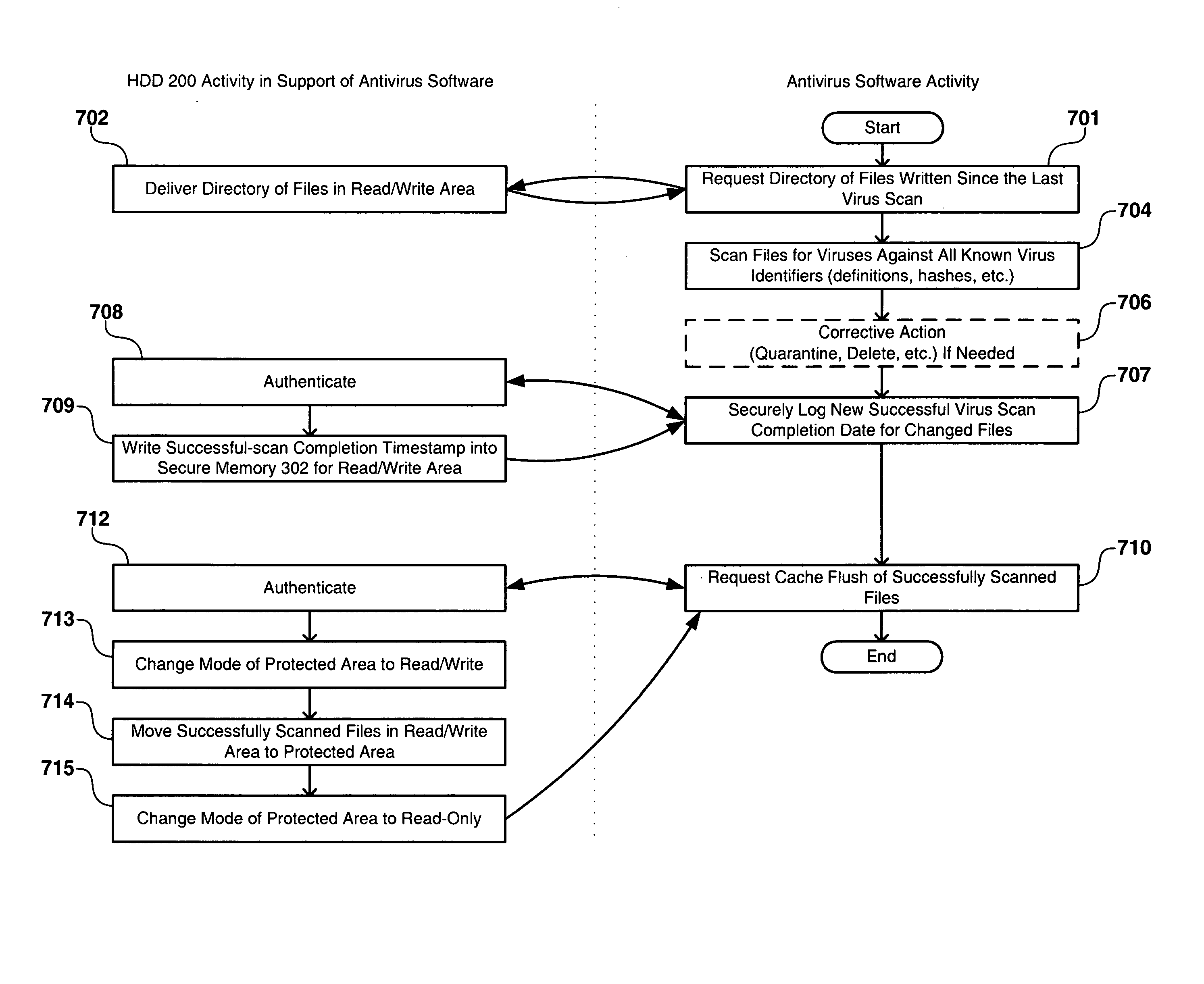

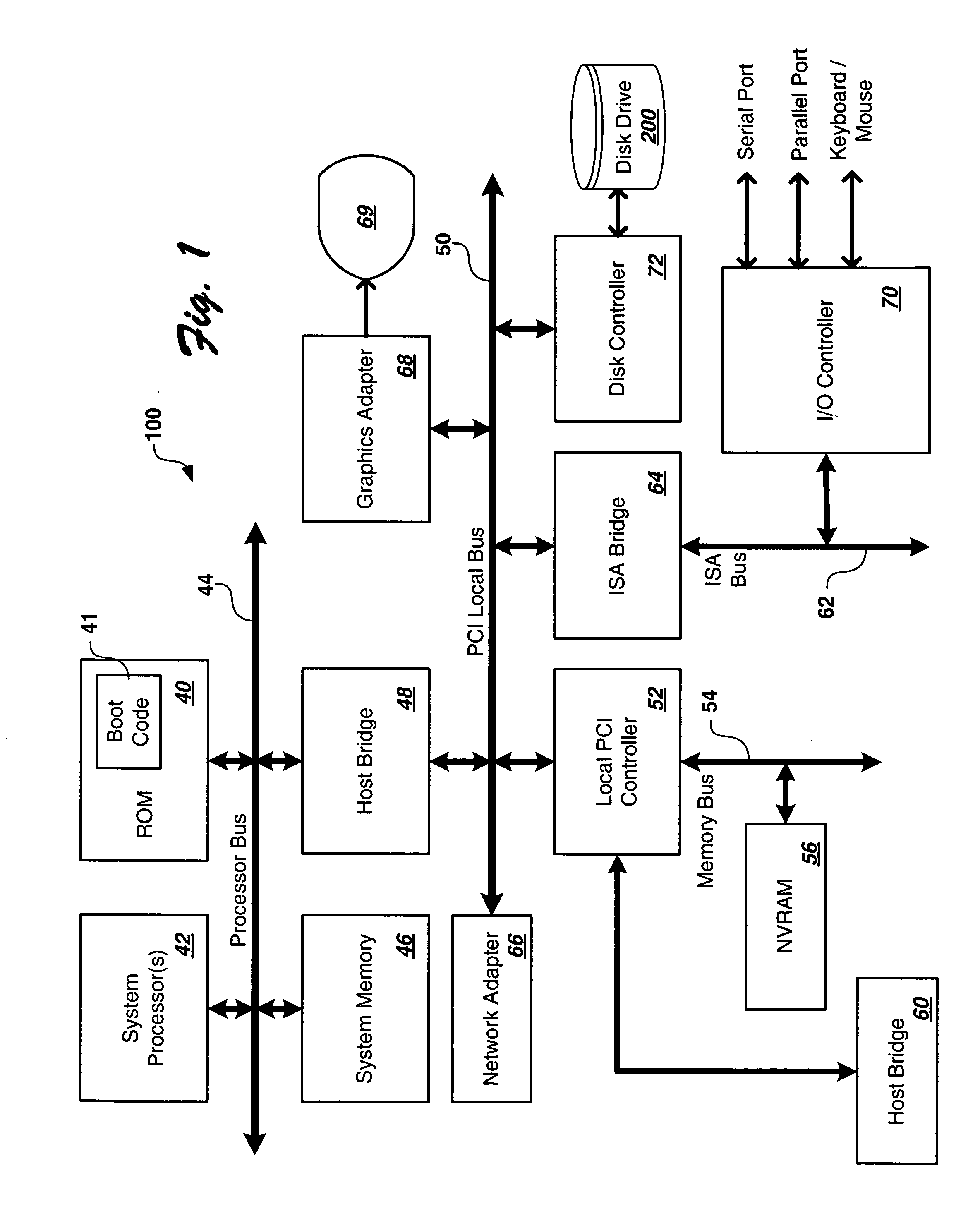

Storage conversion for anti-virus speed-up

ActiveUS20060021041A1Reduce scan timeEfficient and secureMemory loss protectionError detection/correctionAnti virusVirus

A computer system includes a security subsystem which is able to trustfully track which files or storage areas of a storage device have been altered since a last virus scan. The trusted information can then be used to accelerate scans for undesirable code or data such as viruses and invalid or corrupt registry entries. In the case of viruses, files or storage areas which have been altered are scanned against a super-set of virus definitions. Unaltered files or storage areas are scanned against a subset of virus definitions.

Owner:LENOVO PC INT

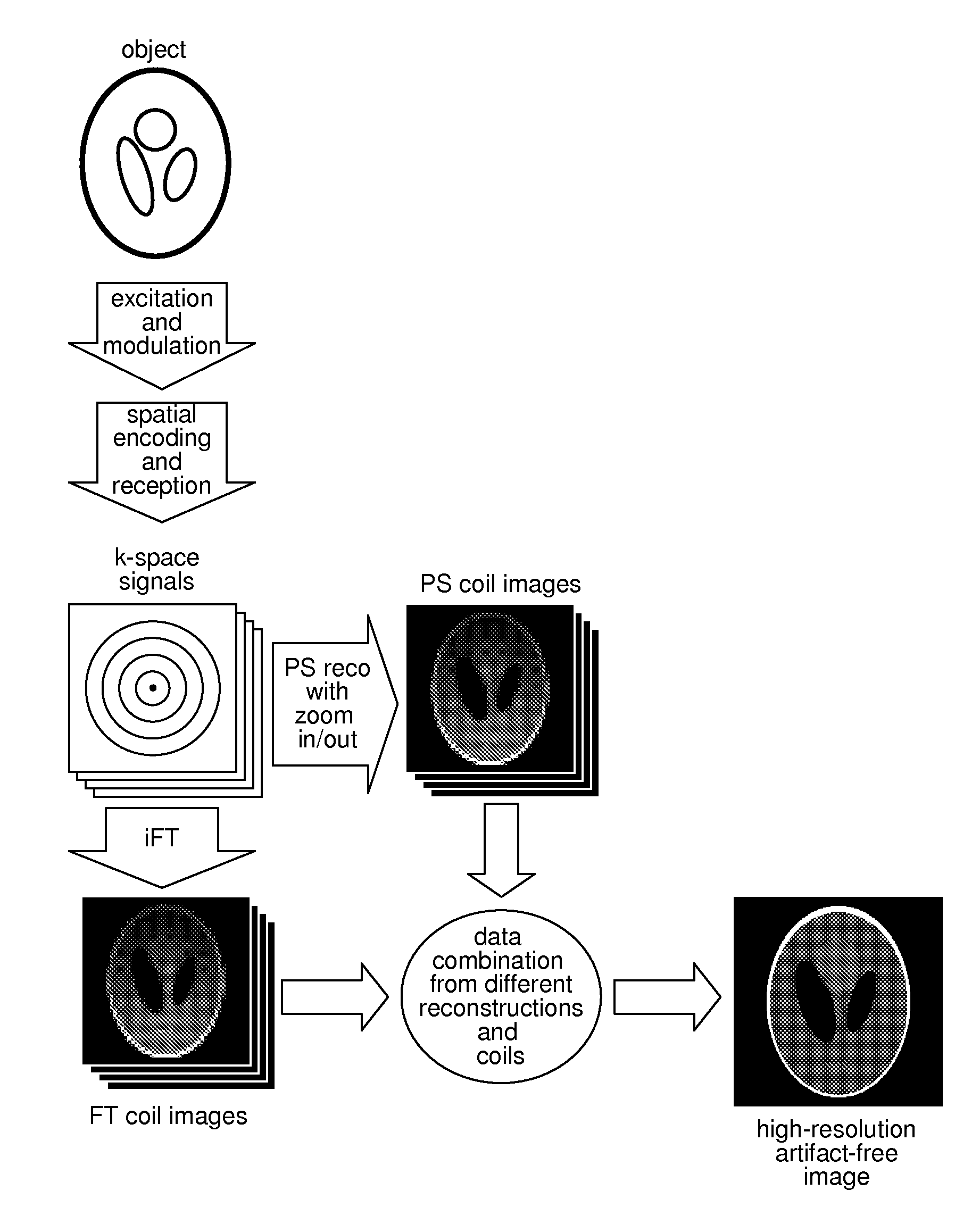

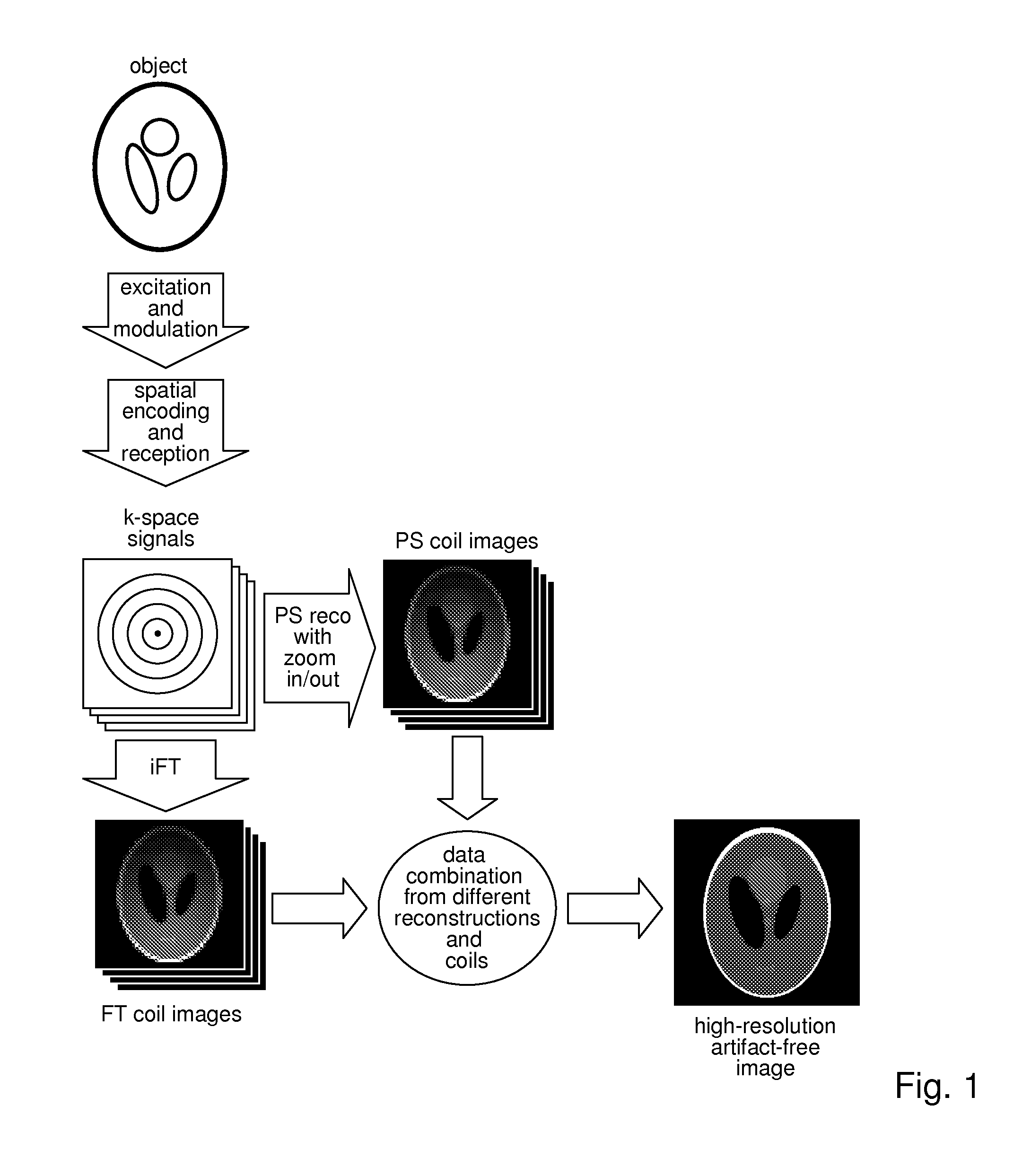

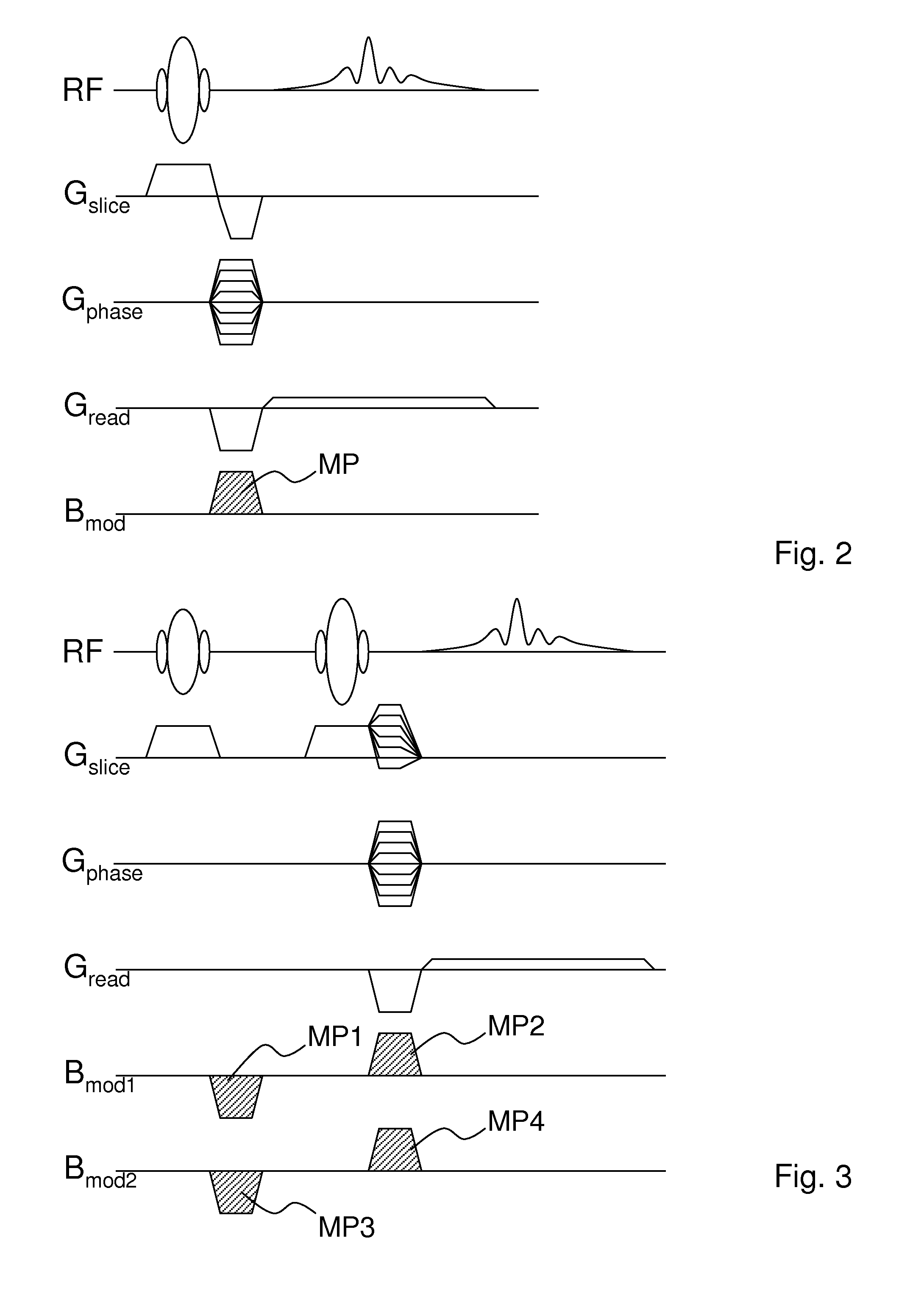

Method for data acquisition acceleration in magnetic resonance imaging (MRI) using receiver coil arrays and non-linear phase distributions

InactiveUS20110148410A1Specifically designedIncrease freedomElectric/magnetic detectionMeasurements using NMRTransverse magnetizationData acquisition

A method for accelerating data acquisition in MRI with N-dimensional spatial encoding has a first method step in which a transverse magnetization within an imaged object volume is prepared having a non-linear phase distribution. Primary spatial encoding is thereby effected through application of switched magnetic fields. Two or more RF receivers are used to simultaneously record MR signals originating from the imaged object volume, wherein, for each RF receiver, an N-dimensional data matrix is recorded which is undersampled by a factor Ri per selected k-space direction. Data points belonging to a k-space matrix which were not recoded by a selected acquisition schema are reconstructed using a parallel imaging method, wherein reference information concerning receiver coil sensitivities is extracted from a phase-scrambled reconstruction of the undersampled data matrix. The method generates a high-resolution image free of artifacts in a time-efficient manner by improving data sampling efficiency and thereby reducing overall data acquisition time.

Owner:UNIVERSITATSKLINIKUM FREIBURG

Noise Reduction Apparatus, Systems, and Methods

InactiveUS20090136104A1Improve signal-to-noise ratioReduce noiseCharacter and pattern recognitionMeasurements using NMR imaging systemsFrequency spectrumNoise reduction

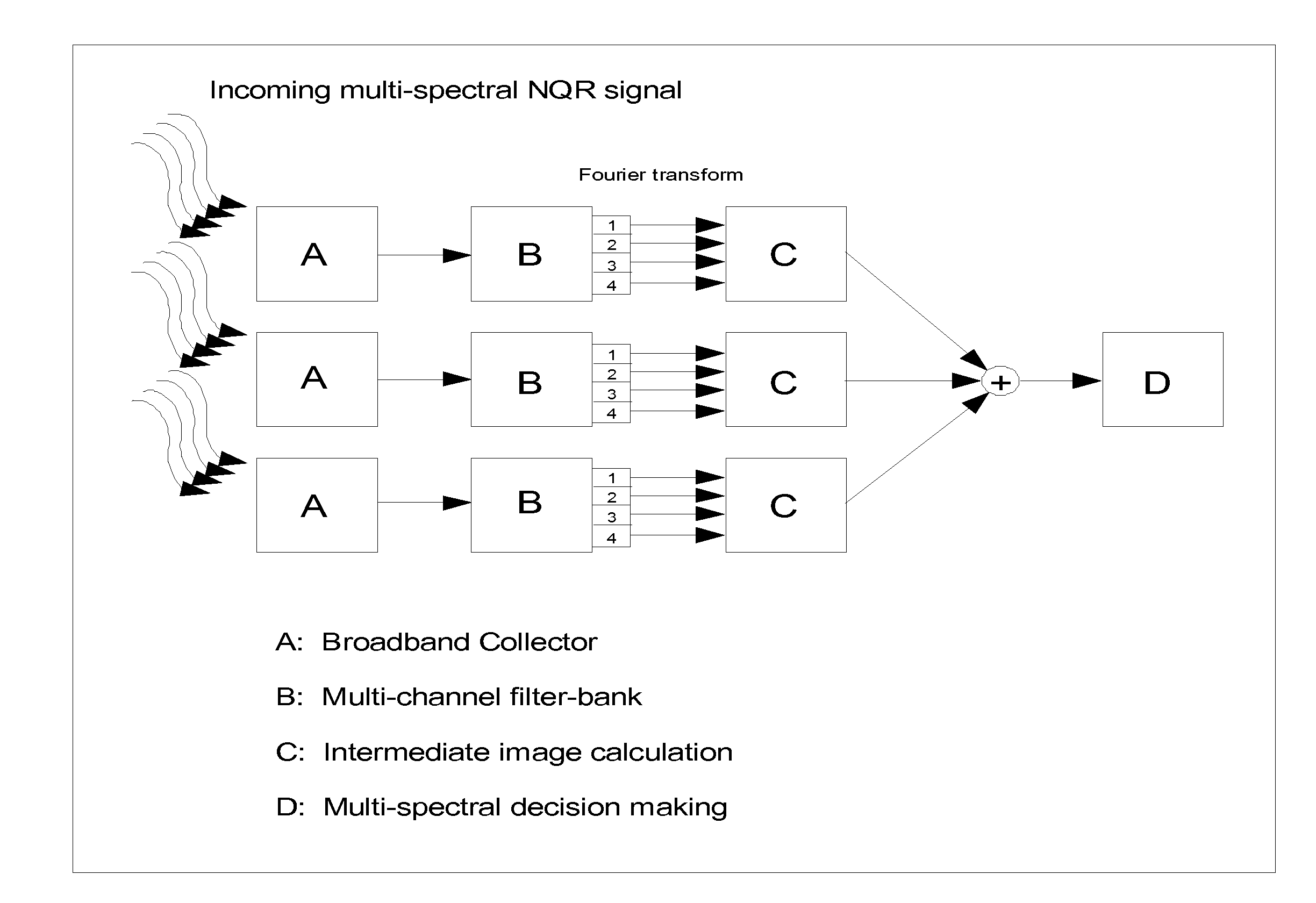

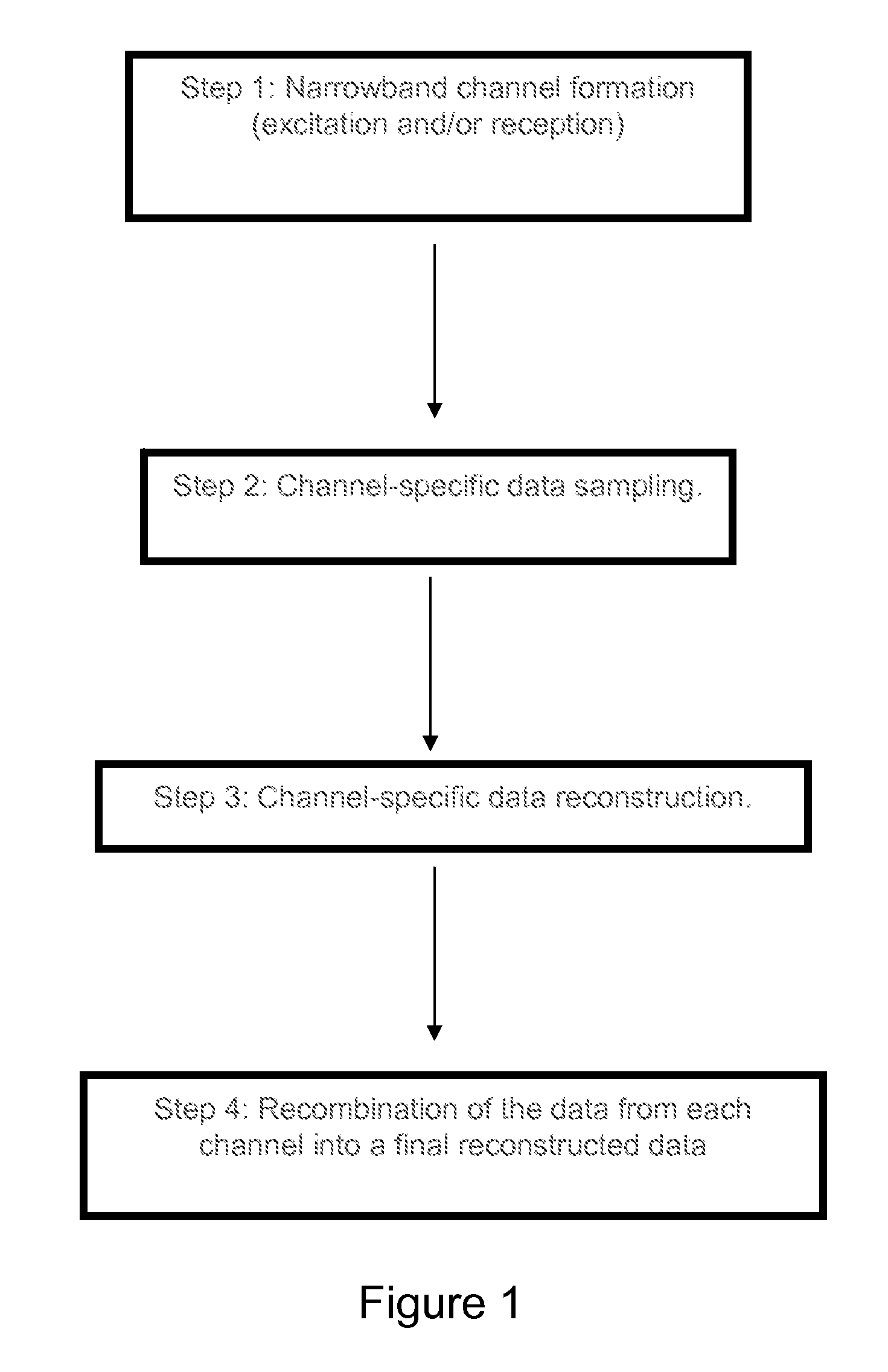

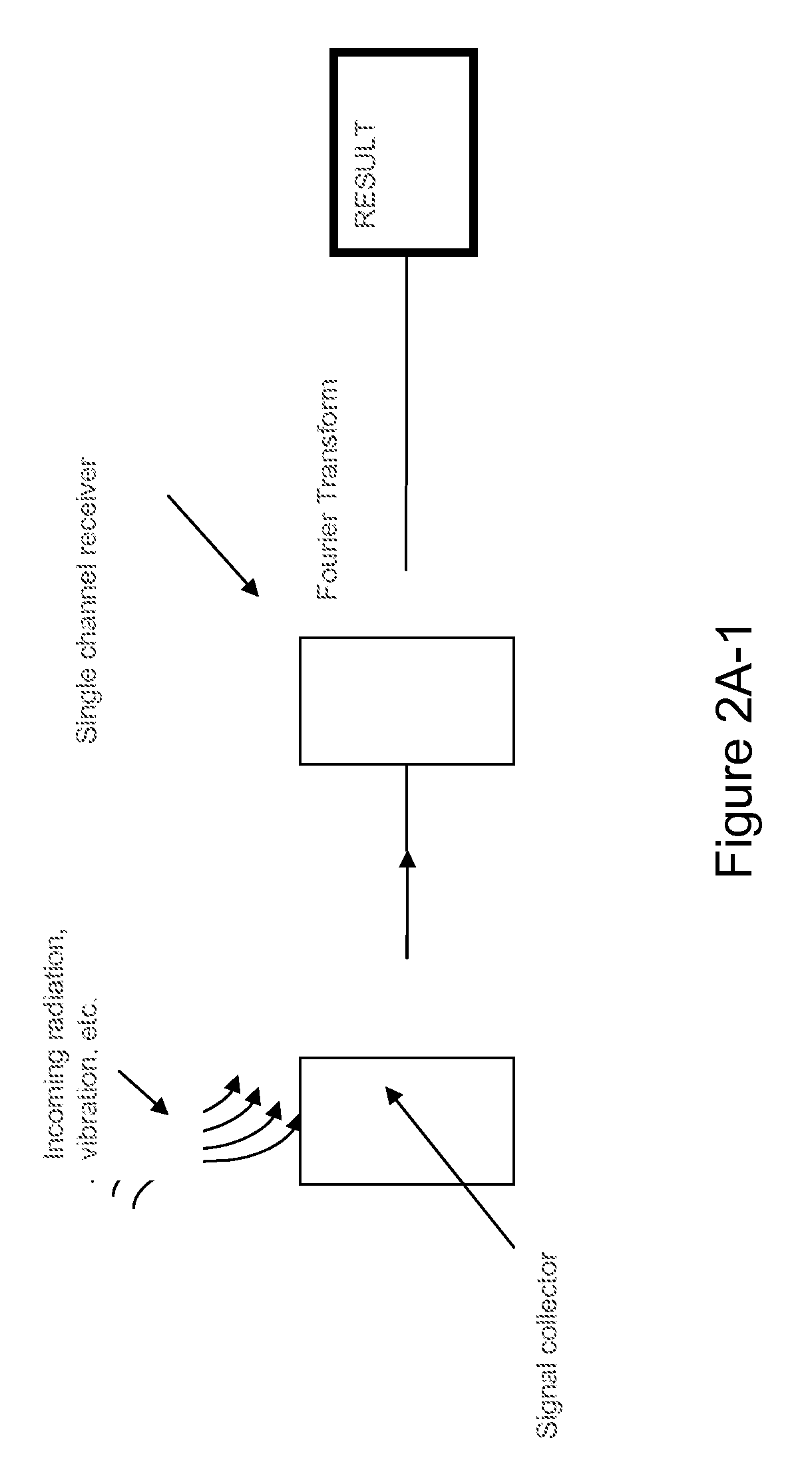

This document describes a general system for noise reduction, as well as a specific system for Magnetic Resonance Imaging (MRI) and Nuclear Quadrupole Resonance (NQR). The general system, which is called Calculated Readout by Spectral Parallelism (CRISP), involves reconstruction and recombination of frequency-limited broadband data using separate narrowband data channels to create images or signal profiles. A multi-channel CRISP system can perform this separation using (1) frequency tuned hardware, (2) a frequency filter-bank (or equivalent), or (3) a combination of implementations (1) and (2). This system significantly reduces what we call cross-frequency noise, thereby increasing signal-to-noise-ratio (SNR). A multi-channel CRISP system applicable to MRI and NQR are described.

Owner:ARJAE SPECTRAL ENTERPRISES

Apparatus and method for producing color filters by discharging material

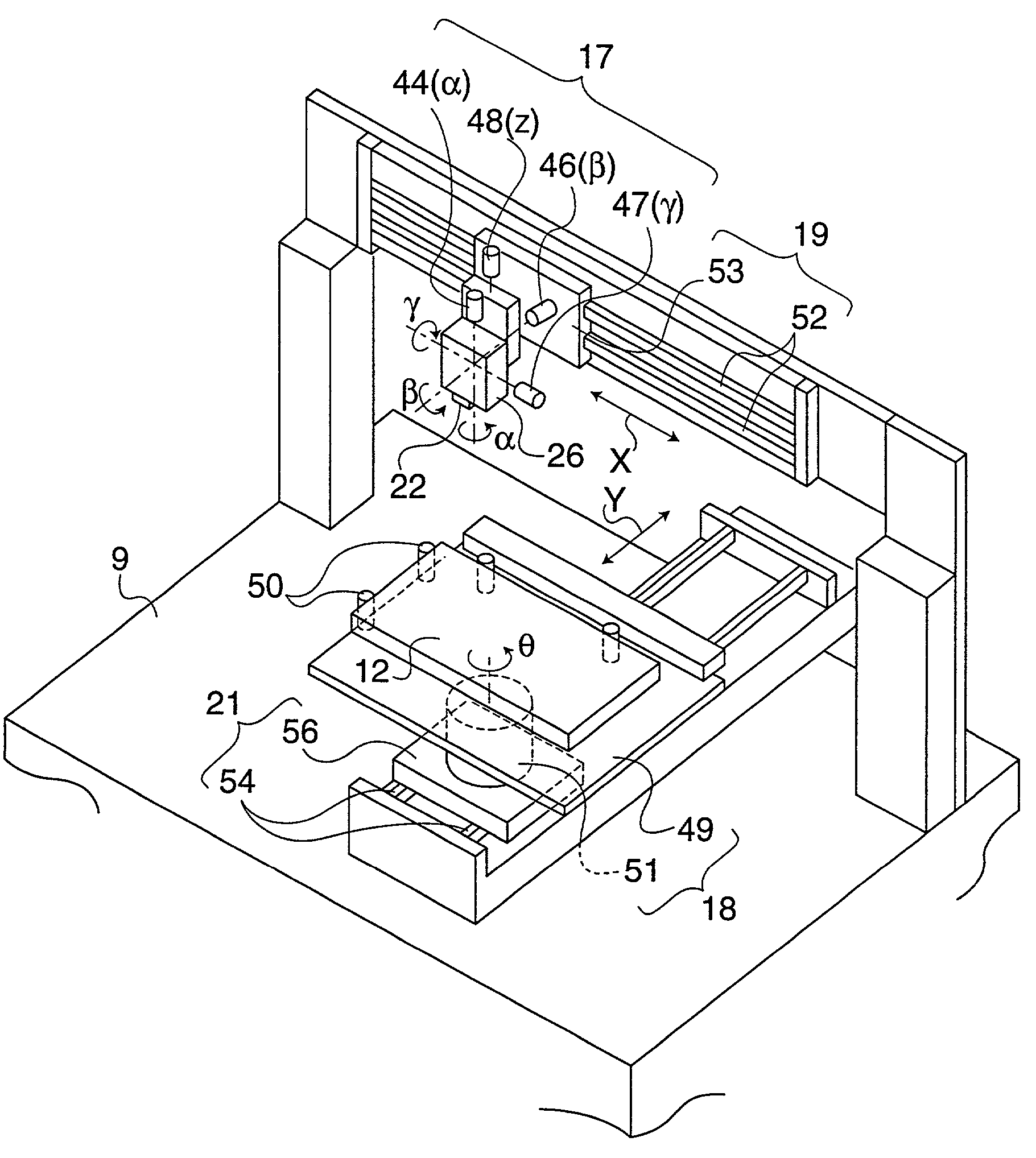

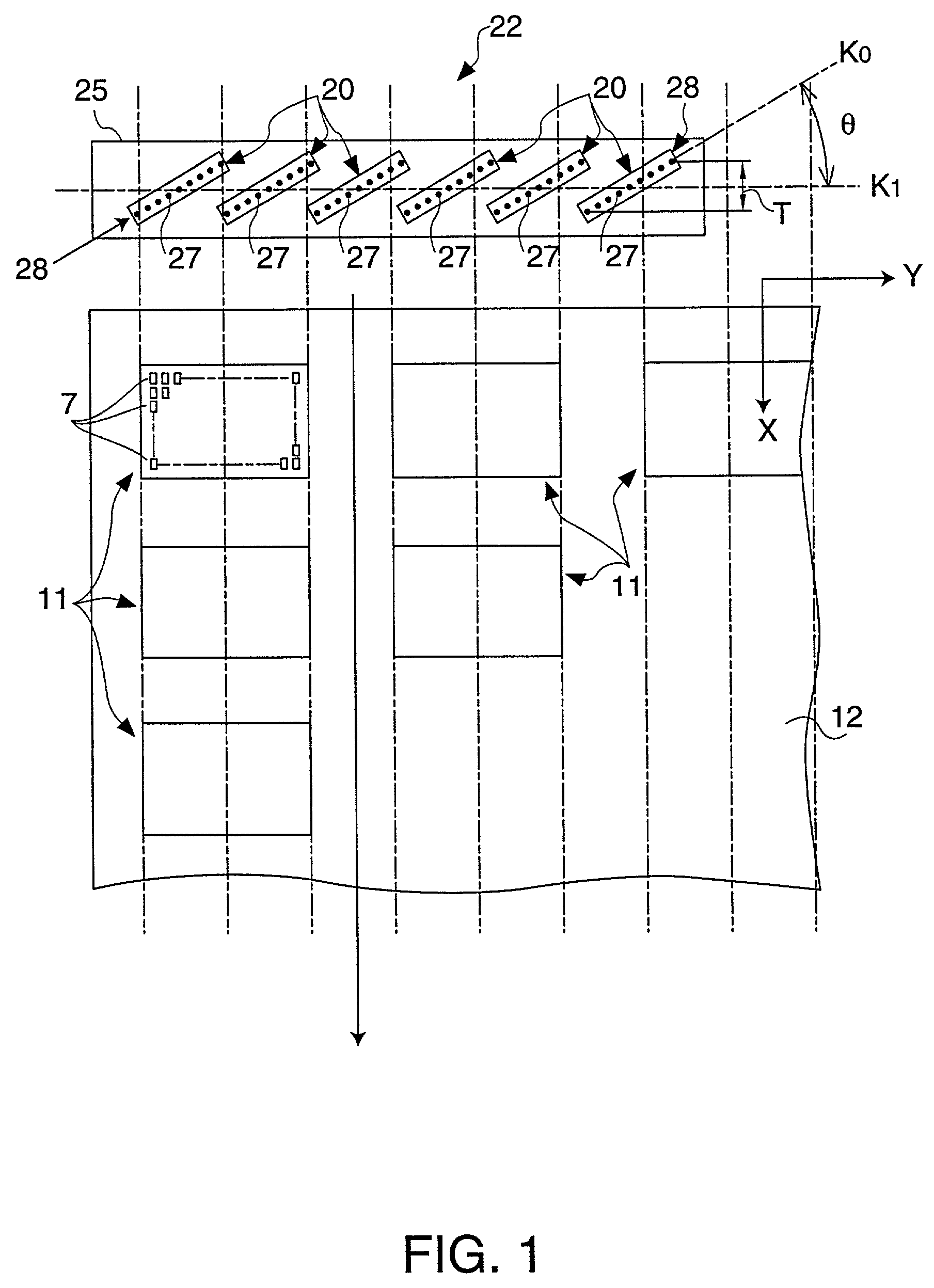

InactiveUS7182815B2Increase scan timeReduce scan timeLiquid surface applicatorsInking apparatusIn planeSpray nozzle

The present invention provides a system which shortens the scanning time with an ink jet head for forming a pattern of filter elements of a color filter, picture element pixels of an electroluminescence (EL) device, or the like. An apparatus for producing a color filter can include a plurality of filter elements arranged on a substrate. The apparatus can further include a plurality of heads each having a nozzle row having a plurality of nozzles arranged, an ink supply device for supplying a filter element material to the heads, a carriage supporting the heads arranged thereon, a main scanning driving device for moving the carriage by main scanning in the X direction, and a sub-scanning driving device for moving the carriage by sub-scanning in the Y direction. The carriage supports the plurality of heads each of which is inclined at an in-plane inclination angle θ.

Owner:KATEEVA

Method for simultaneous multi-slice magnetic resonance imaging

ActiveUS8405395B2Reliable separationLarge possible separationMagnetic measurementsElectric/magnetic detectionMagnetic gradientMulti slice

Owner:THE GENERAL HOSPITAL CORP

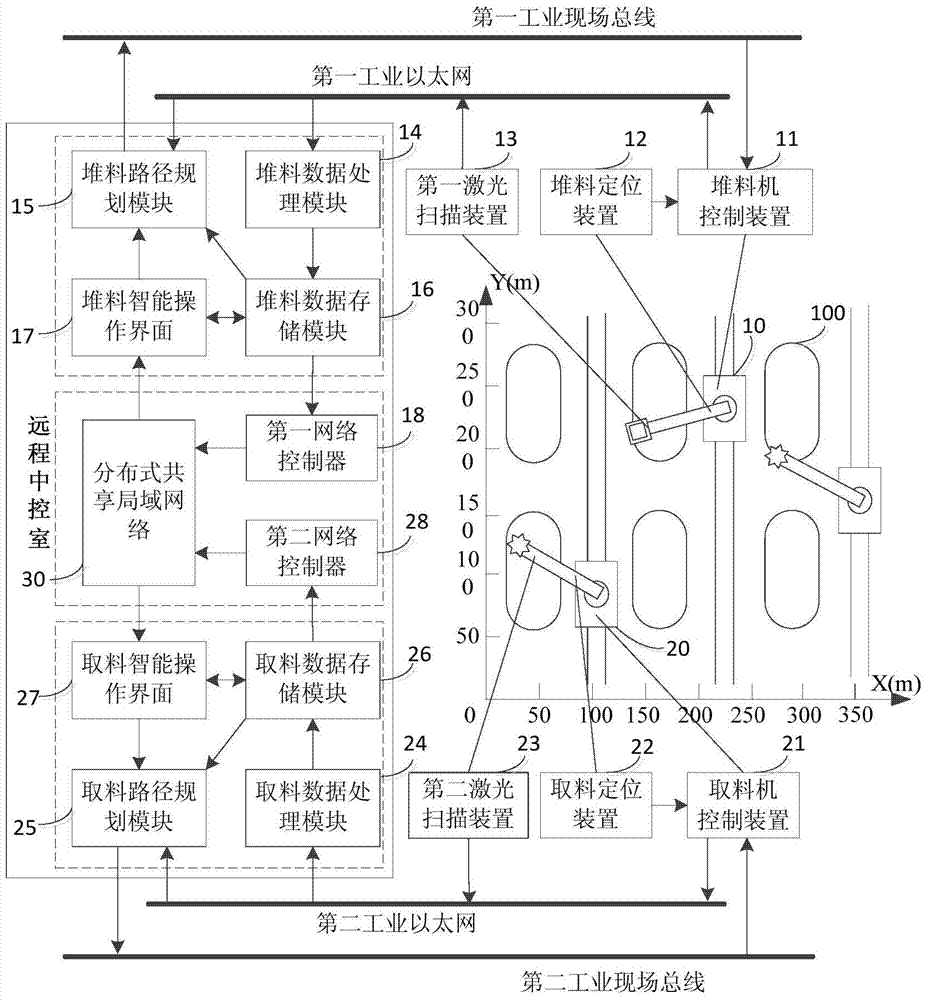

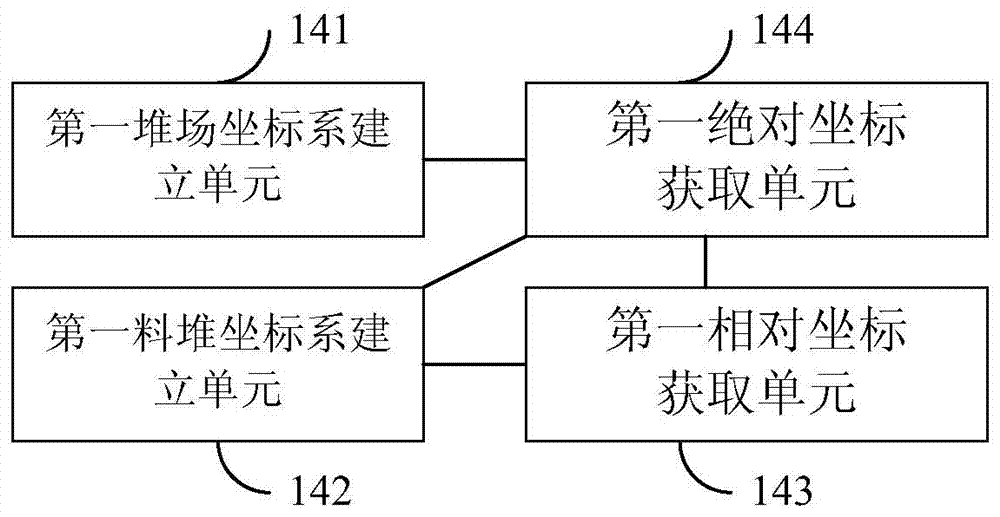

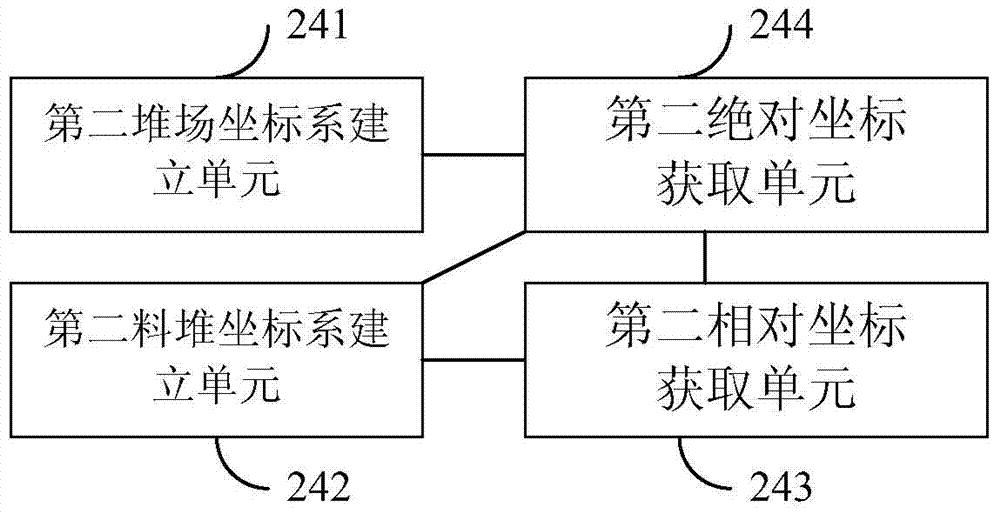

Automatic stacking/reclaiming system for bulk cargo storage yard

InactiveCN104724506ASimplify hardware configurationEasy to installLoading/unloadingBulk cargoControl signal

The invention provides an automatic stacking / reclaiming system for a bulk cargo storage yard. The automatic stacking / reclaiming system comprises a stacker distributed in the storage yard and provided with a stacking cantilever, a reclaimer distributed in the storage yard and provided with a reclaiming cantilever, a first laser scanning device installed on the stacking cantilever and used for acquiring scanning data of the storage yard, a second laser scanning device installed on the reclaiming cantilever and used for acquiring the scanning data of the storage yard, a stacking positioning device and a reclaiming positioning device for acquiring GNSS positioning information, a stacker control device, a reclaimer control device, a remote stacking processing device and a remote reclaiming processing device. The stacker control device and the reclaimer control device acquire and output the GNSS positioning information, receive a stacking control signal and a reclaiming control signal, and control the stacker and the reclaimer to execute corresponding stacking / reclaiming actions according to the control signals. The remote stacking processing device and the remote reclaiming processing device receive a stacking instruction and a reclaiming instruction input by a peripheral user, acquire coordinate information of the corresponding storage yard according to the instructions, the scanning data and the GNSS positioning information, and generate stacking / reclaiming path information to serve as the stacking / reclaiming control signals to be output to the stacker control device and the reclaimer control device. The automatic stacking / reclaiming system is based on GNSS positioning, and is high in accuracy and low in cost, data can be shared, and automatic operation of the bulk cargo storage yard is achieved.

Owner:CCCC THIRD HARBOR CONSULTANTS

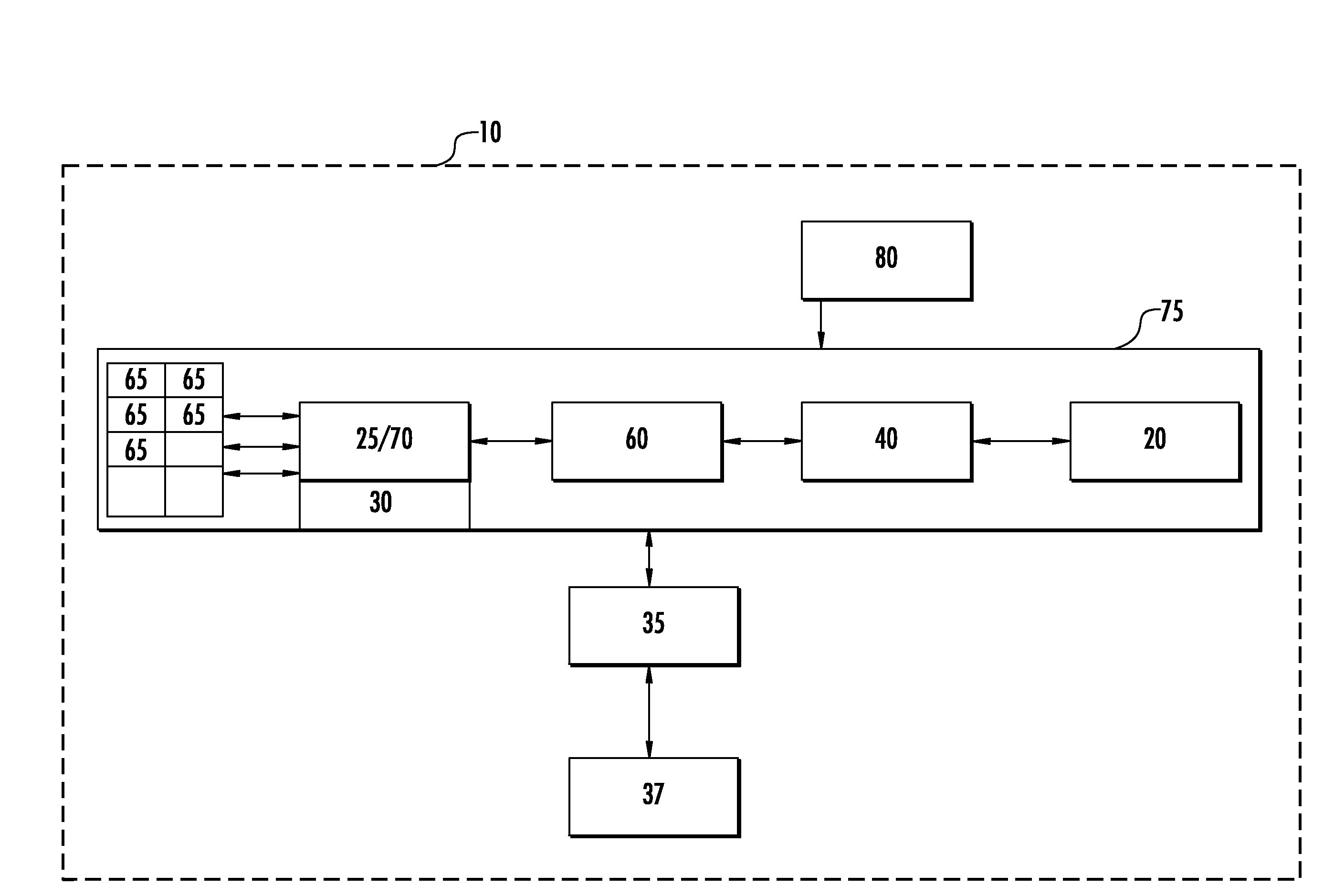

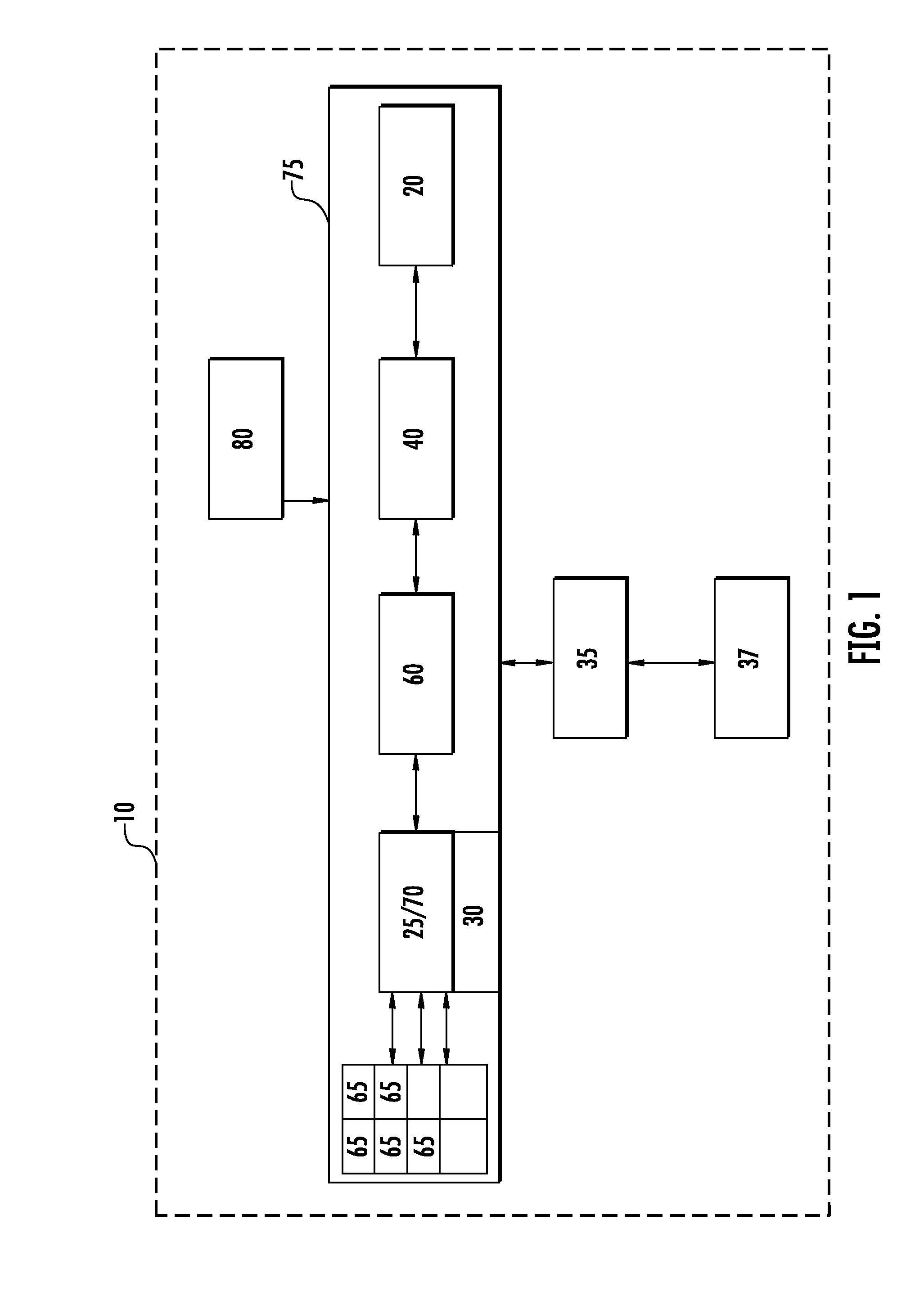

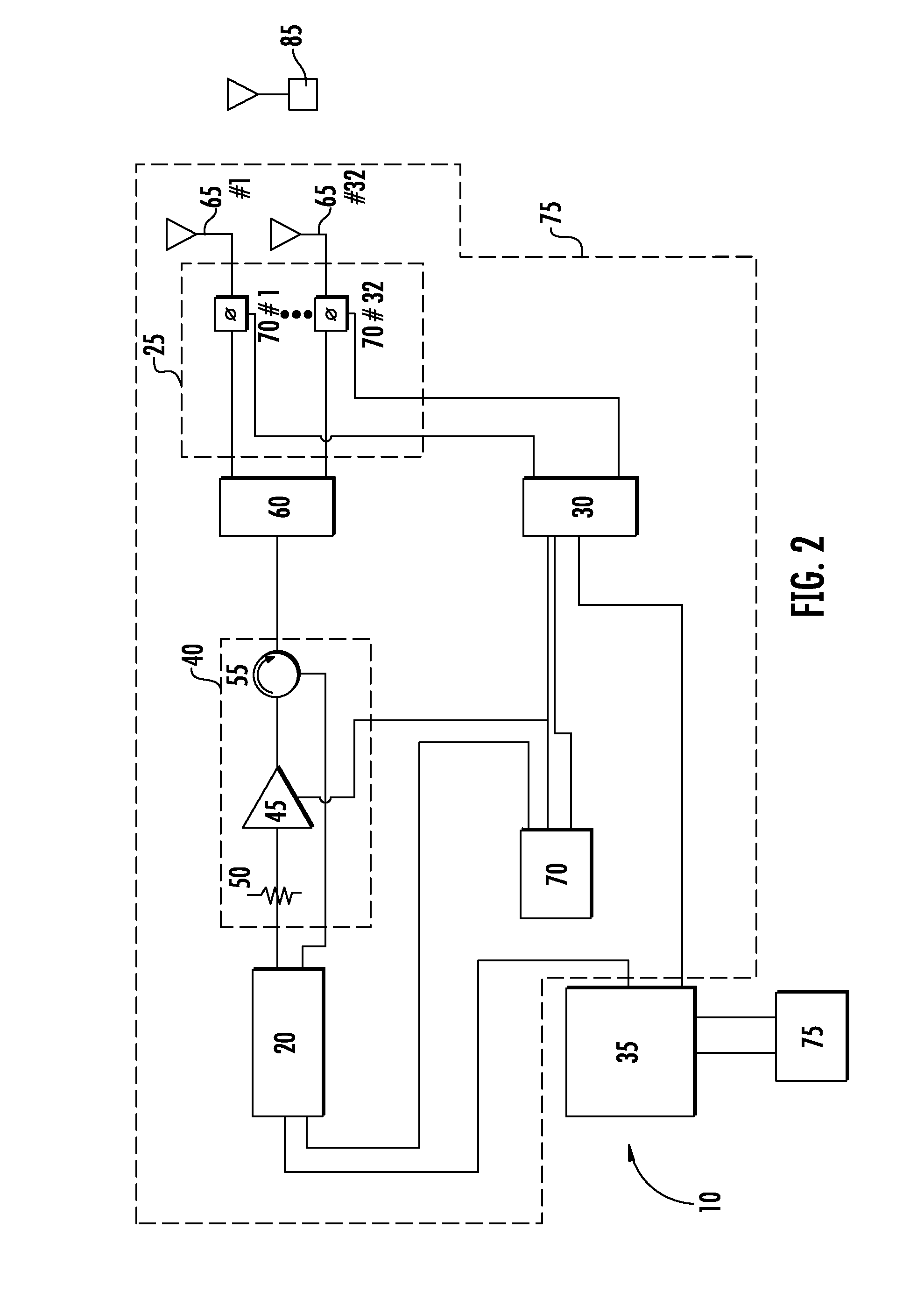

Steerable phase array antenna RFID tag locater and tracking system and methods

ActiveUS20100207738A1Improve production efficiencyEasy to installSensing detailsAntenna supports/mountingsLight beamBeam steering

A system for and method of tracking and locating RFID tags, including where at least one steerable phase array antenna may locate the tags associated with items in three dimensions in real time, through the use of a beam steering unit and controller therewith to control the direction of a beam launched by the at least one steerable phase array antenna.

Owner:RF CONTROLS

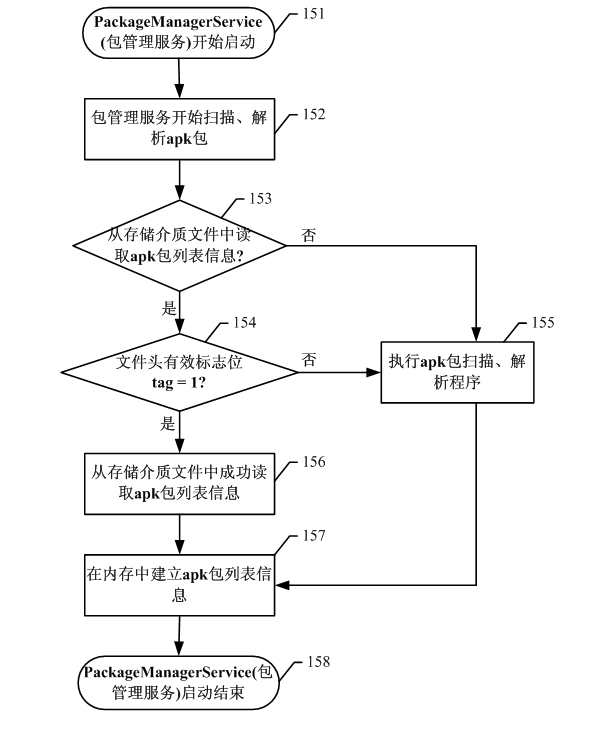

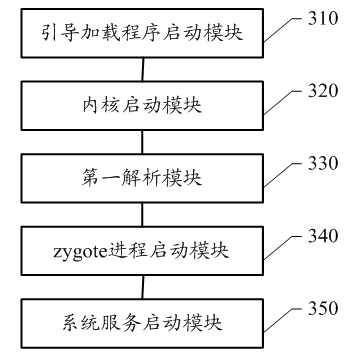

Method and device for accelerating starting Android system

ActiveCN102012832AReduce scan timeReduce startup timeProgram loading/initiatingOperating systemOperational system

The invention relates to the field of an operating system, disclosing a method and a device for accelerating starting an Android system. The method saves list information of all the apk packets of the Android system a file of a device storing medium, so that the list information in the file can be directly read while restarting the system; the method of establishing the information list of the apk packets in the internal memory to replace gradually scanning and analyzing the apk packet saves the time for scanning and analyzing the apk packets, thereby quickly starting the Android system.

Owner:TCL CORPORATION

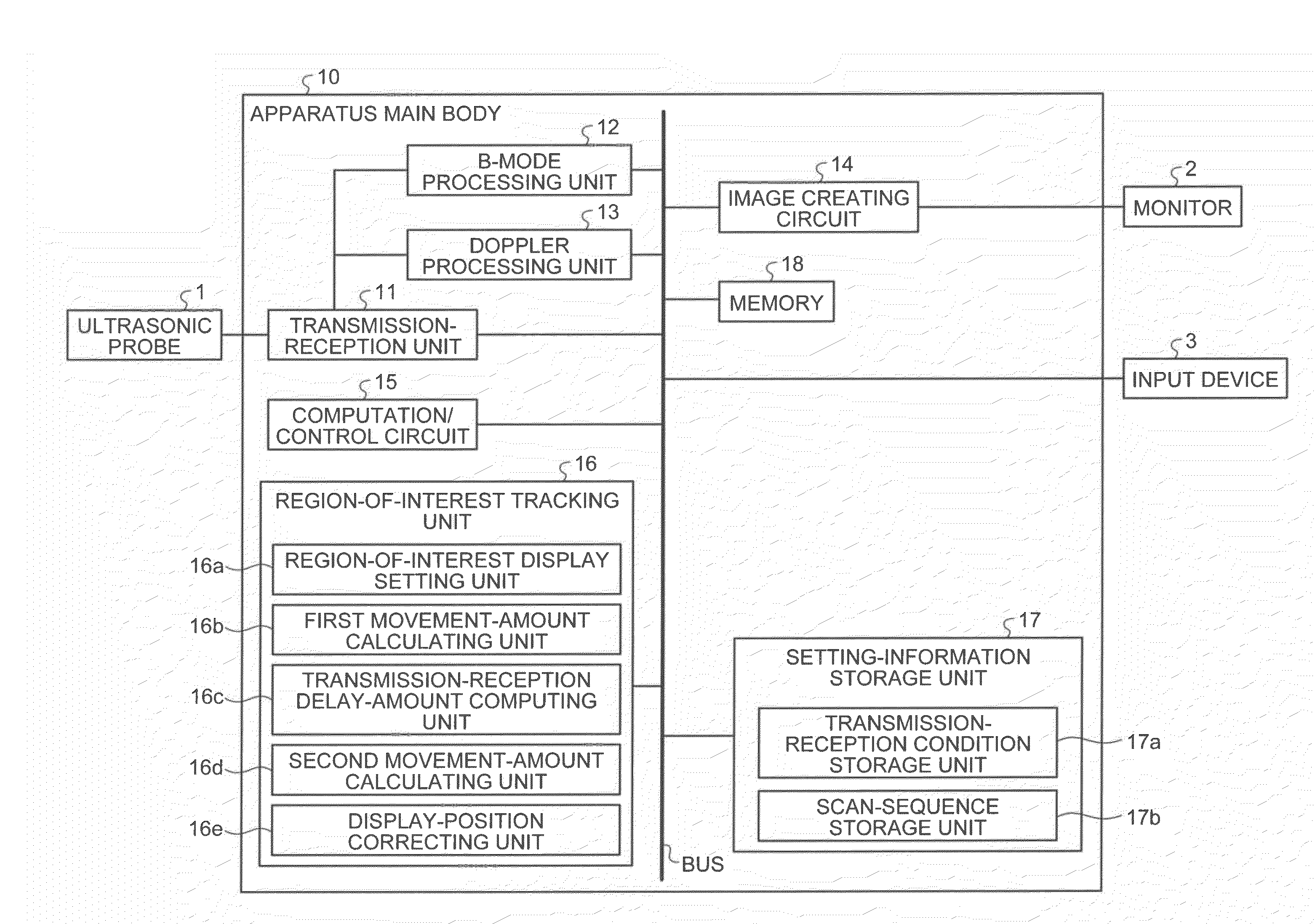

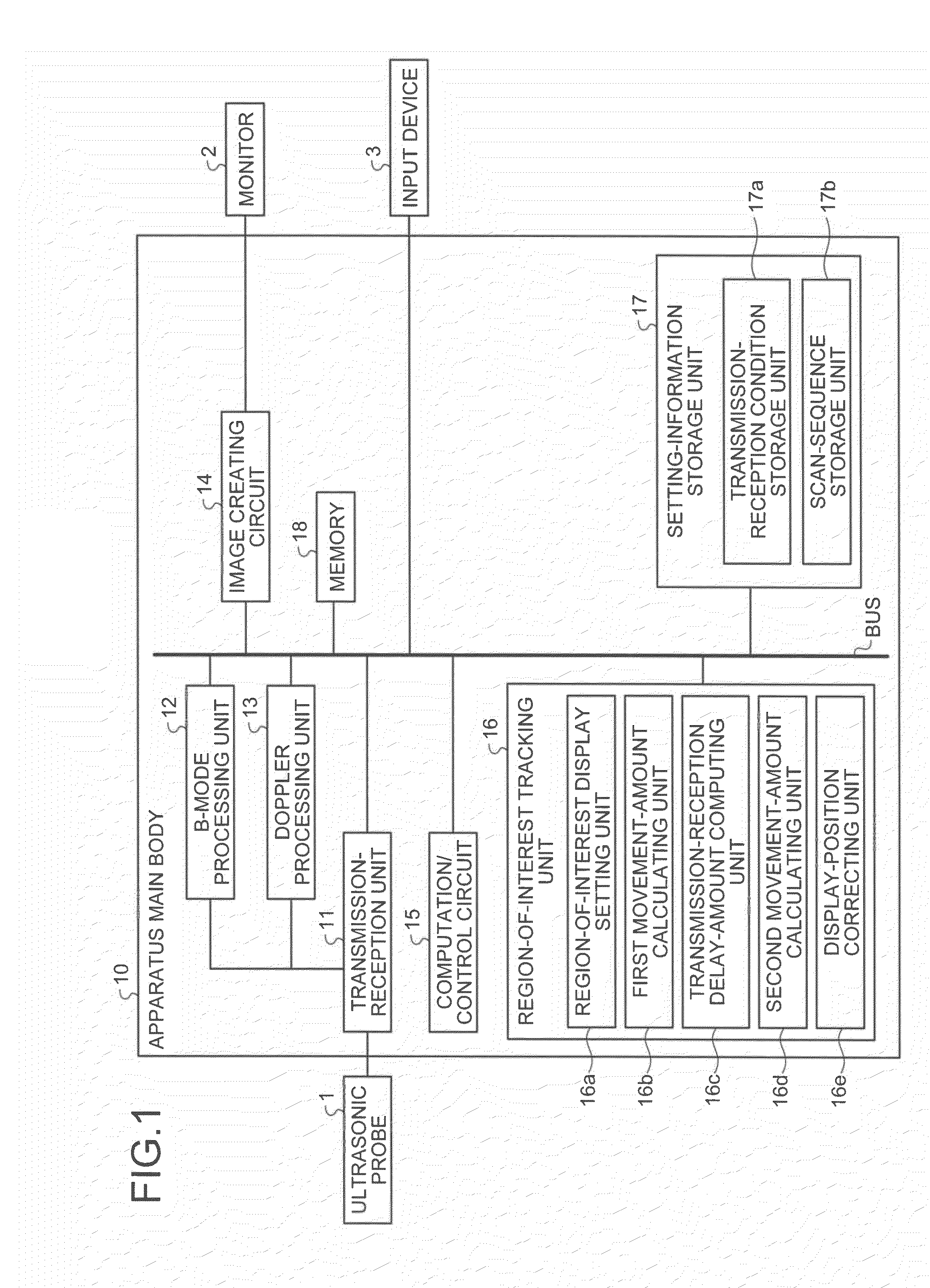

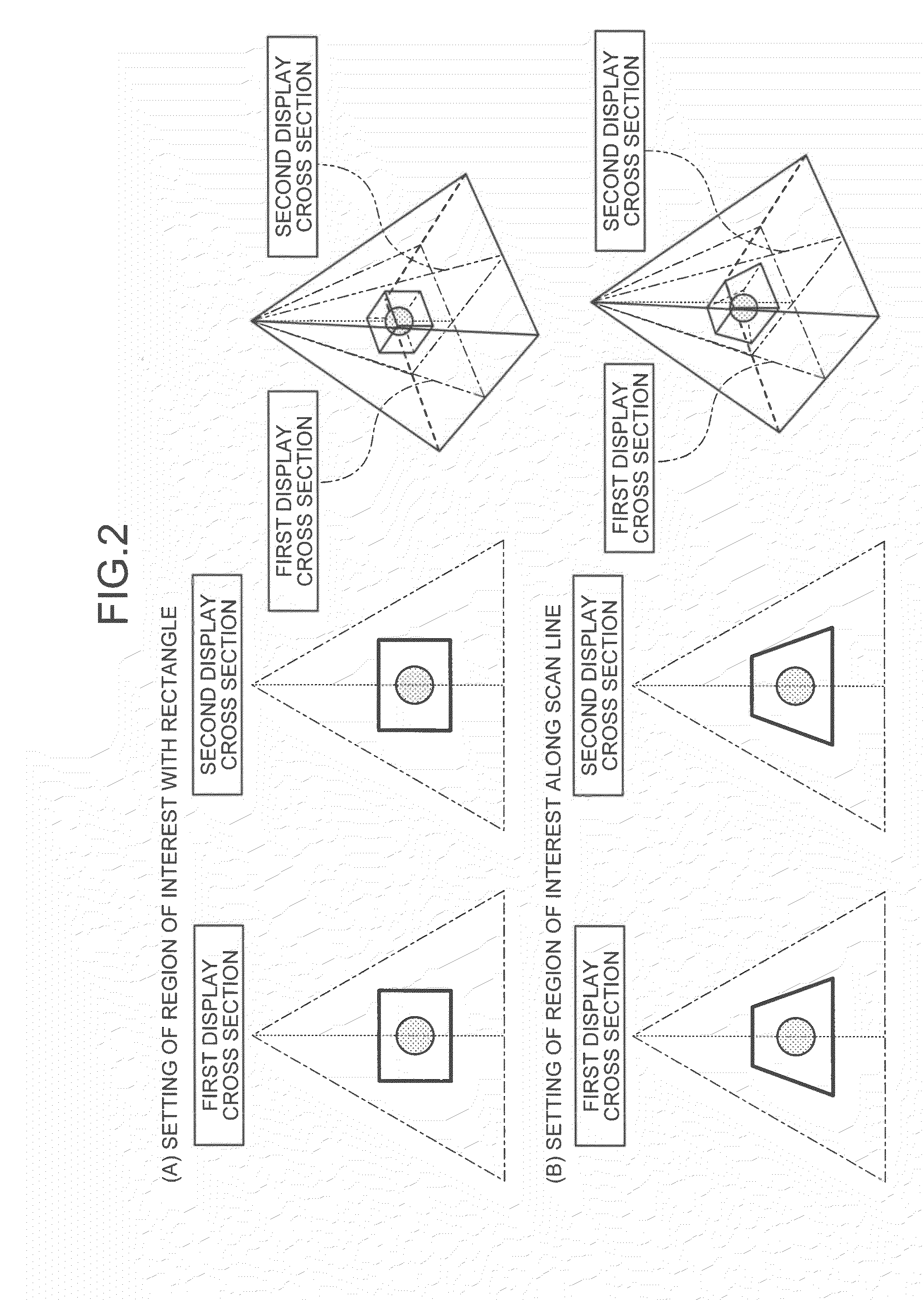

Ultrasonic diagnostic apparatus and computer program product

ActiveUS20100069756A1Reduce scan timeImage quality of a created ultrasound image is lowerOrgan movement/changes detectionCharacter and pattern recognitionSonificationUltrasonic beam

A region-of-interest setting unit sets a region of interest to be included in an ultrasound image. A first movement-amount calculating unit sequentially calculates a movement amount of the set region of interest between reception data along the time sequence as a first movement amount. A transmitting-receiving delay-amount computing unit computes a delay amount for sequentially shifting a scan region of an ultrasonic beam based on the sequentially calculated first movement amount. A computation / control circuit performs control so as to generate a high voltage pulse based on the computed delay amount. A second movement-amount calculating unit sequentially calculates a movement amount of the region of interest between image data along the time sequence as a second movement amount. A display-position correcting unit performs a correction such that the region of interest included in the image data is to be displayed at the same display position, based on the second movement amount.

Owner:TOSHIBA MEDICAL SYST CORP

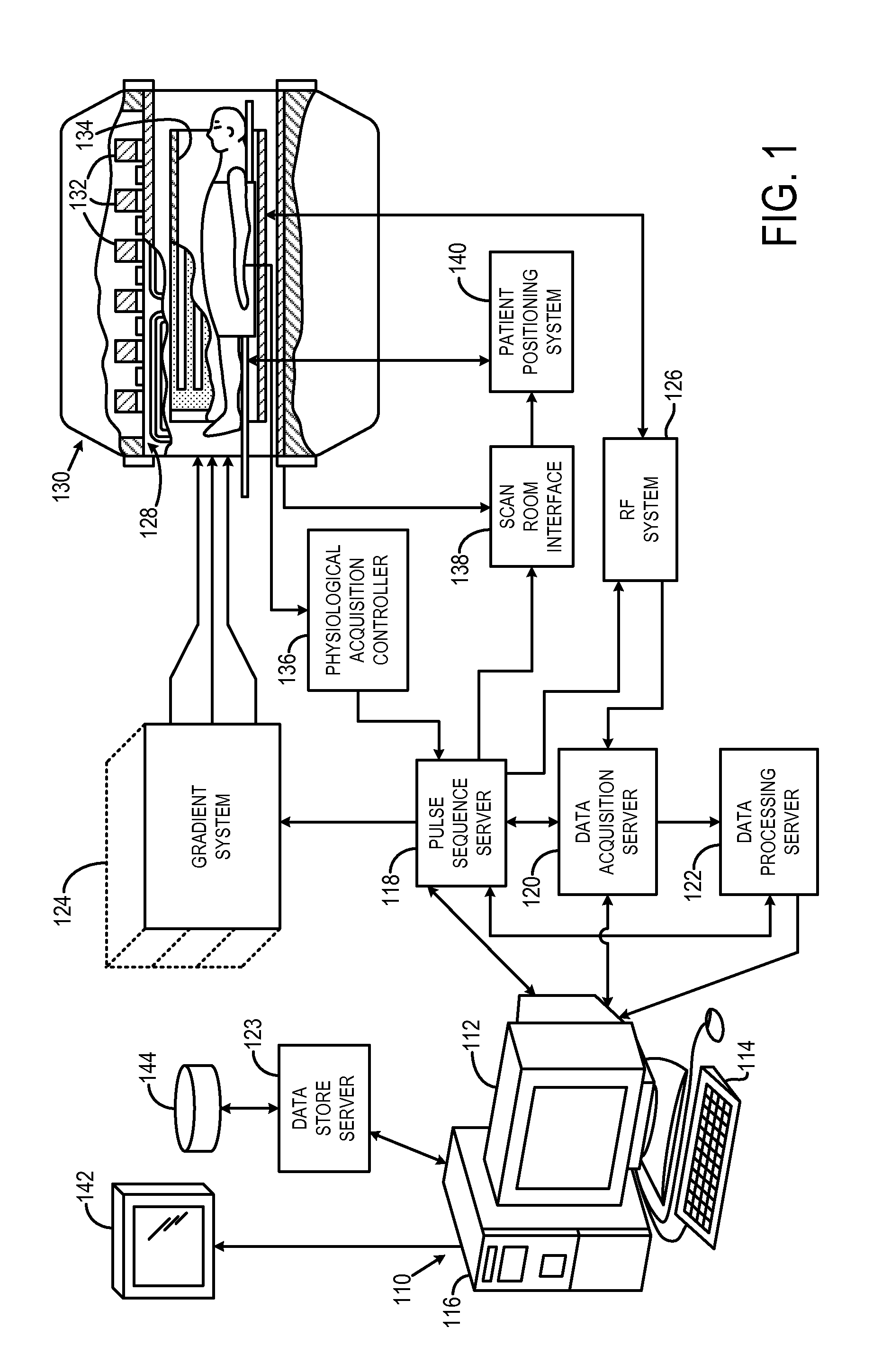

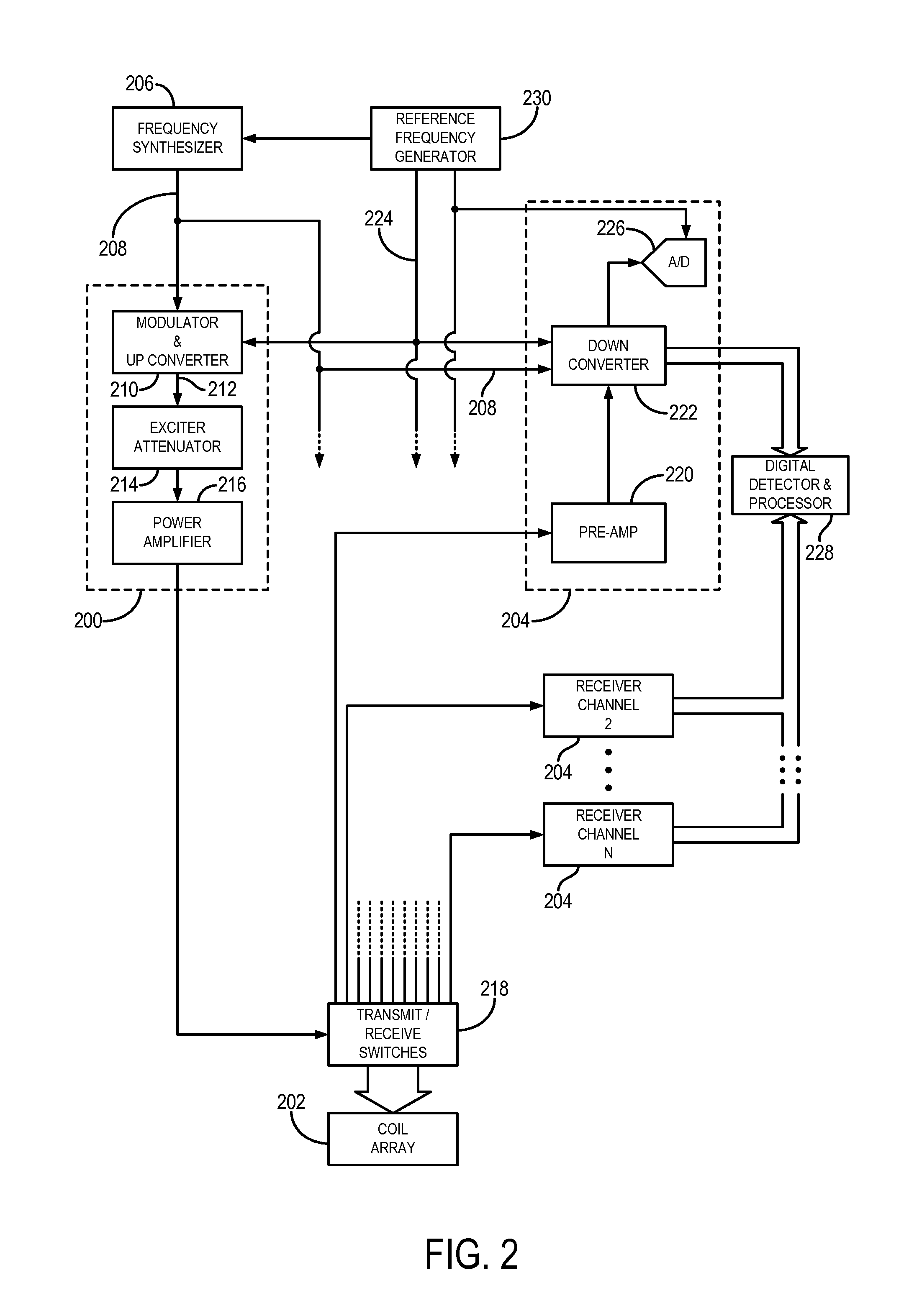

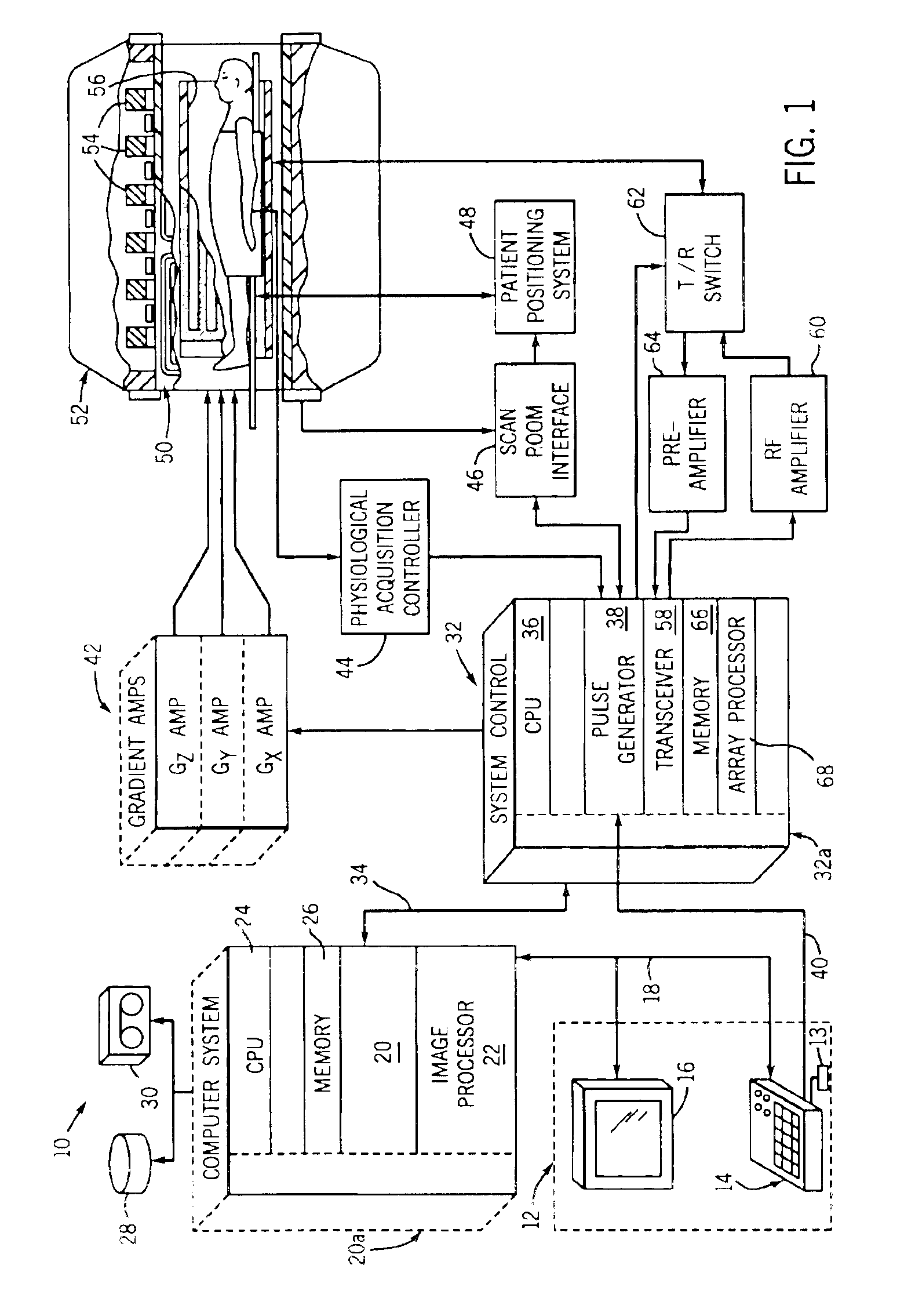

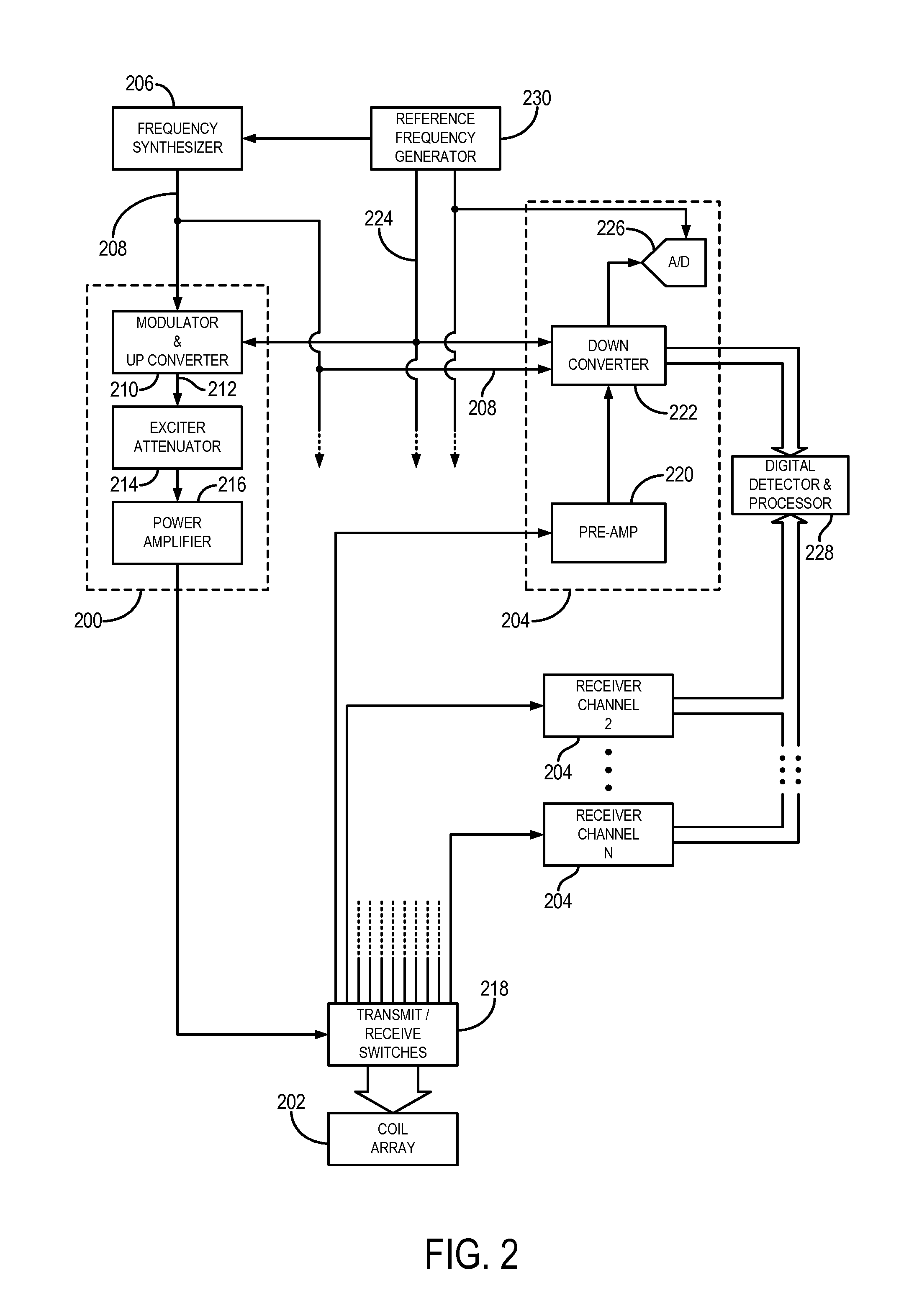

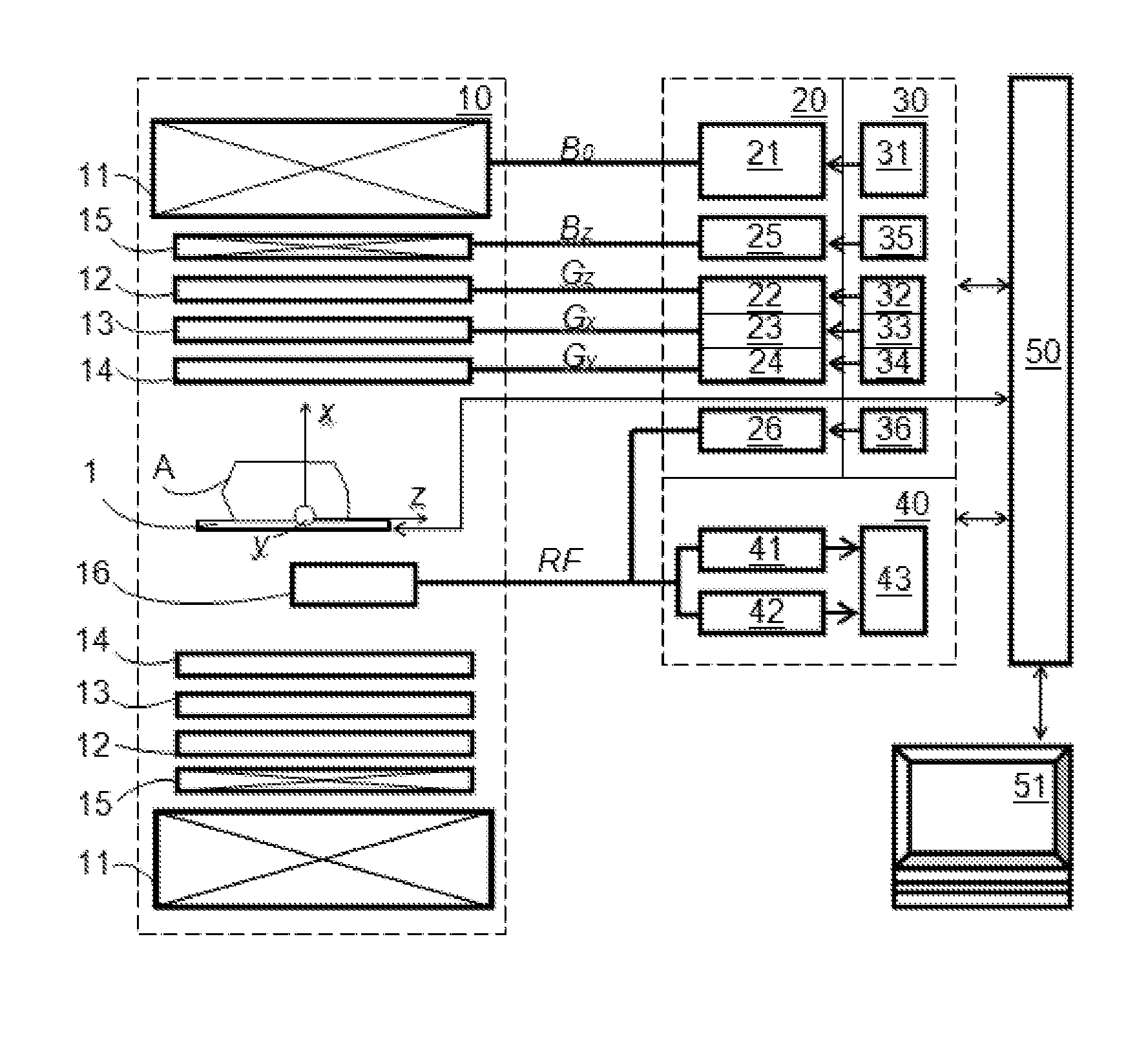

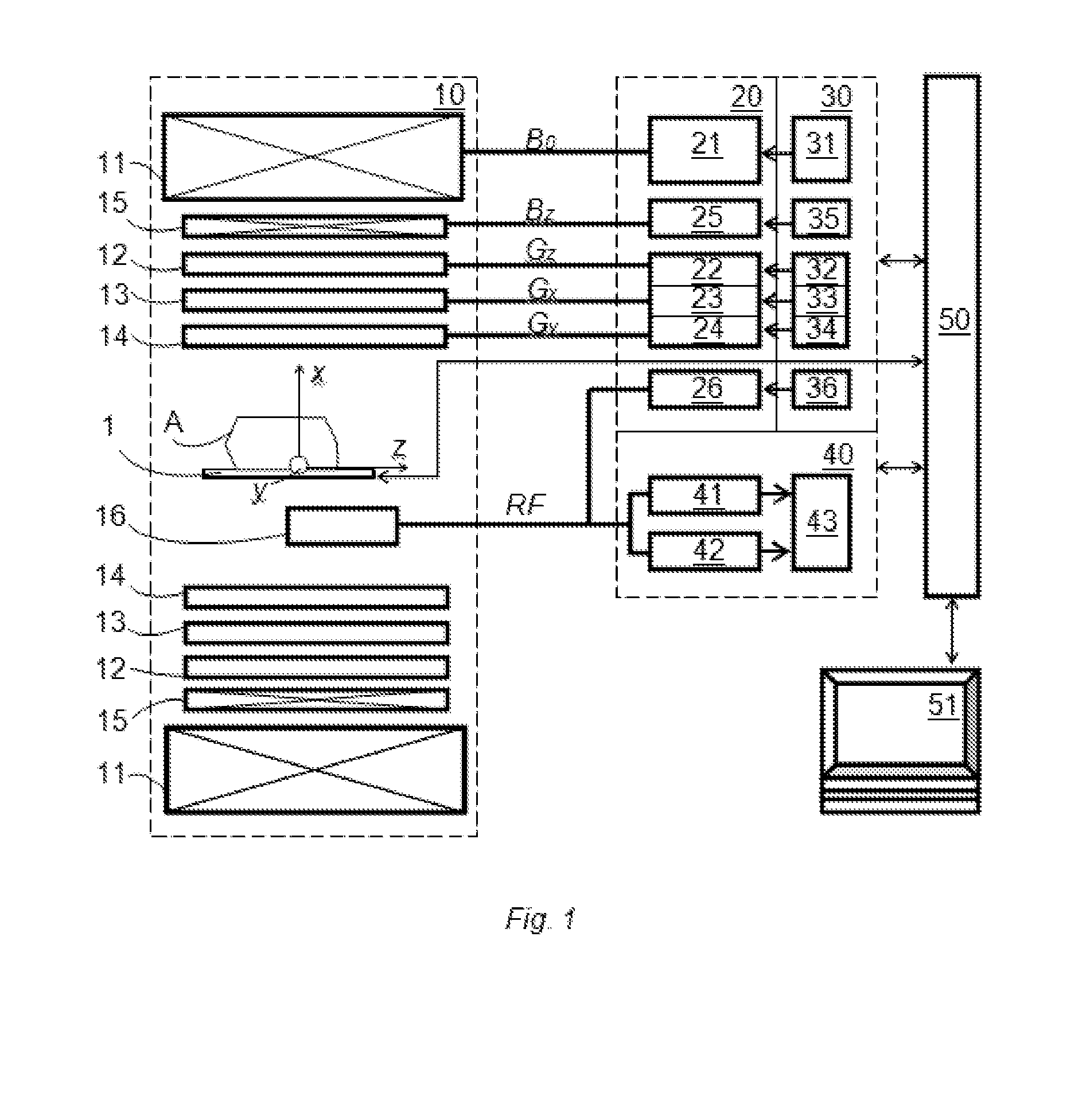

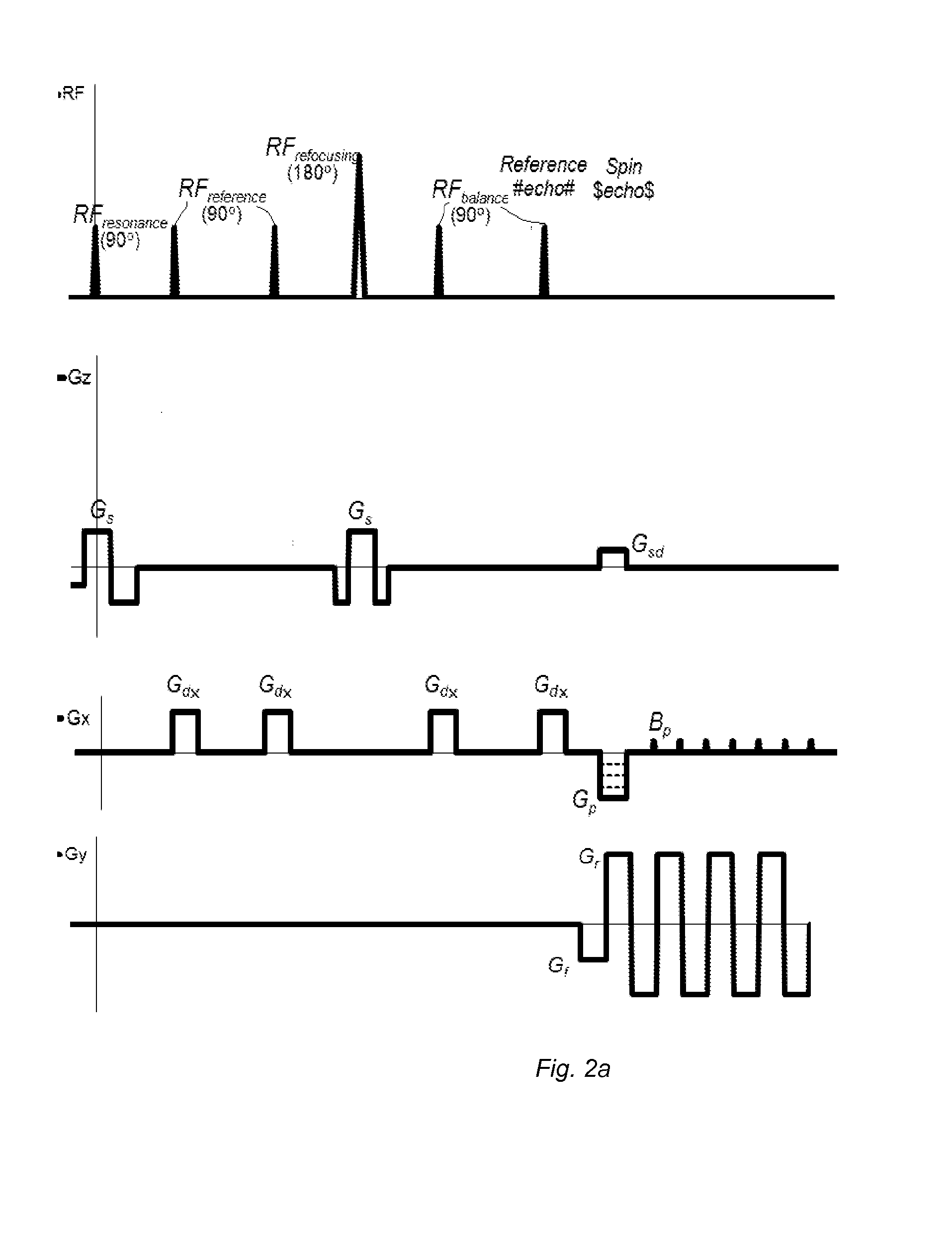

Method and apparatus for magnetic resonance imaging

ActiveUS20140266195A1Reduce sensitivityReduce scan timeMagnetic measurementsElectric/magnetic detectionPhase shiftedResonance

The method and system for correcting motion-induced phase errors in Magnetic Resonance Imaging (MRI) use a phase shift of the non-phase encoded reference echo-signal accumulated during the diffusion-weighting in order to characterize bulk motion and tissue deformation and to compensate their effect for correcting the diffusion / perfusion-weighted image. The sequences unbalanced with respect to the first motion derivative are used for distinguishing the perfusion component. The MRI apparatus provides additional excitation resonance-frequency ranges for forming the reference echo signals.

Owner:VAPOSUN

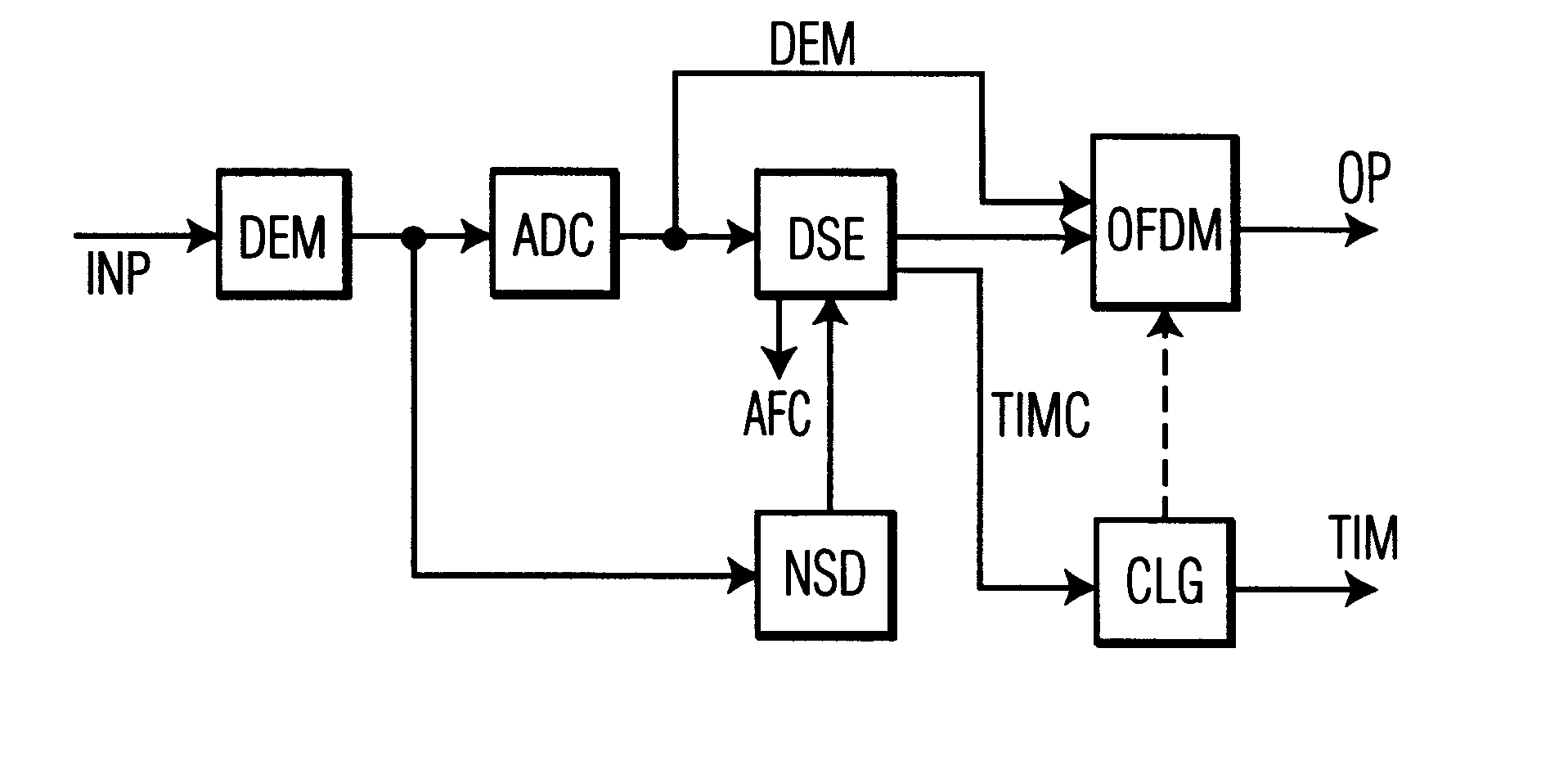

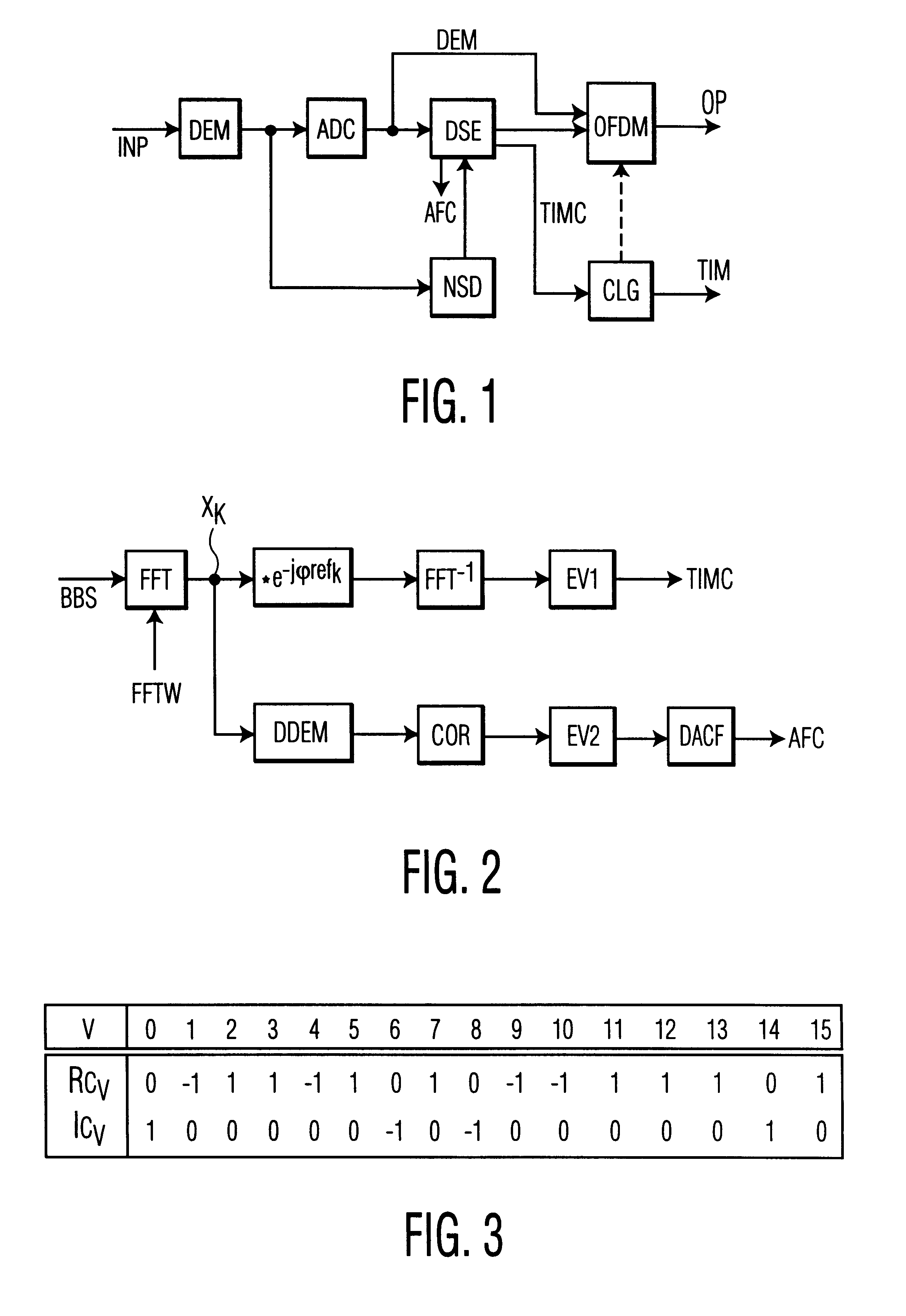

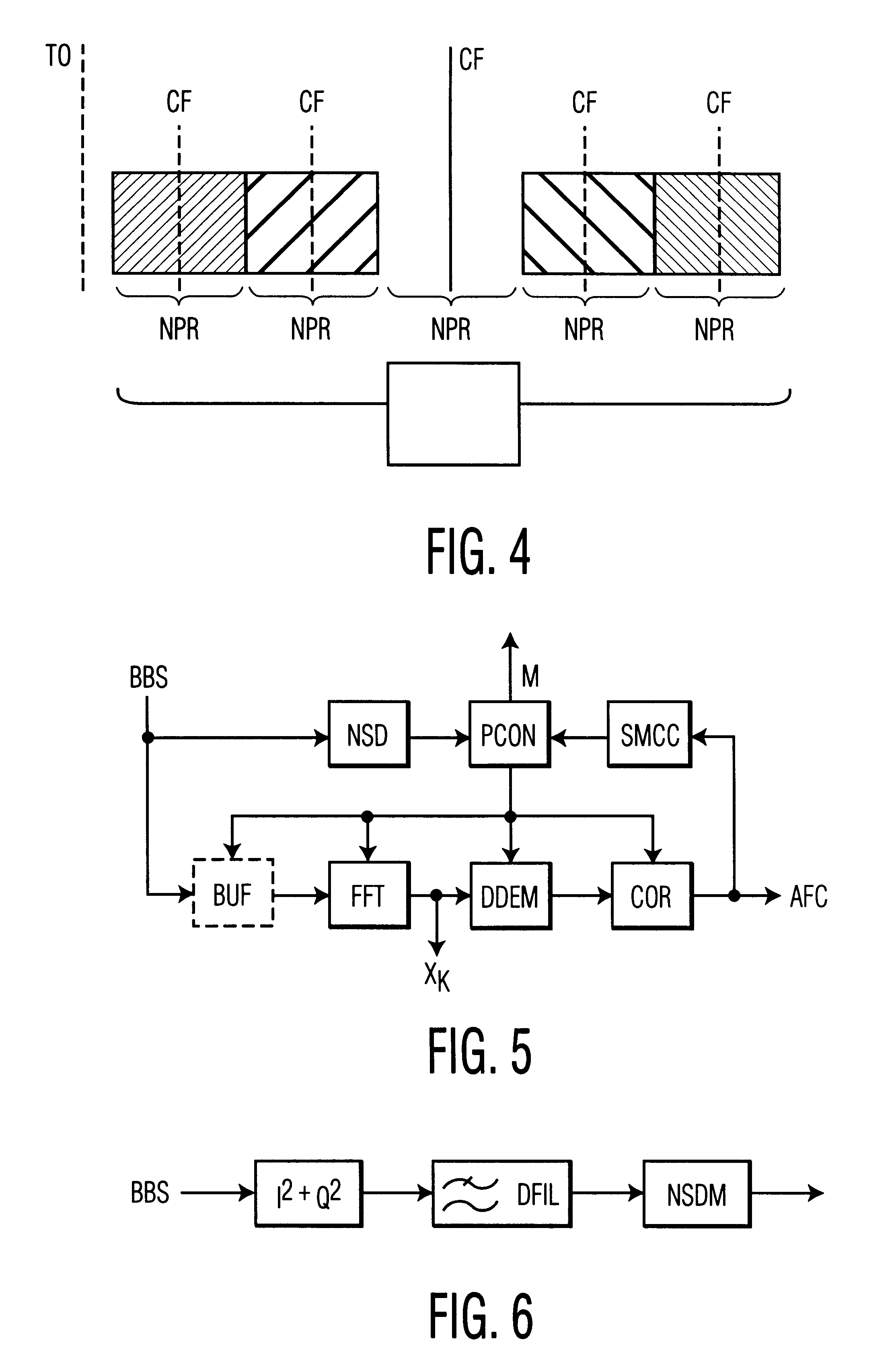

Method for reception of multicarrier signals and related apparatus

InactiveUS6208695B1Increase the number ofFurther exceptions can be avoidedBroadcast with distributionSecret communicationEngineeringMulti carrier

A problem in the reception of terrestrially transmitted digital multicarrier broadcast signals is synchronization in case a receiver is switched on or tuned to another channel. The time required by the receiver to reach a given tuning frequency with adequate accuracy and to determine that the currently received signal is not a system-compliant signal is reduced significantly if a characteristic value calculated from correlation values between a windowed and FFT transformed section of the received signal and a reference symbol stored in the receiver does not exceed a pre-defined threshold. In such case the receiver can go ahead to the next tuning frequency. If, however, the characteristic value exceeds that threshold, then a system-compliant signal is found, even with an offset. The multicarrier signal will be further decoded in the normal way. Such conformity check can also be carried out in the subsequent normal reception mode.

Owner:DEUTSCHE THOMSON-BRANDT GMBH

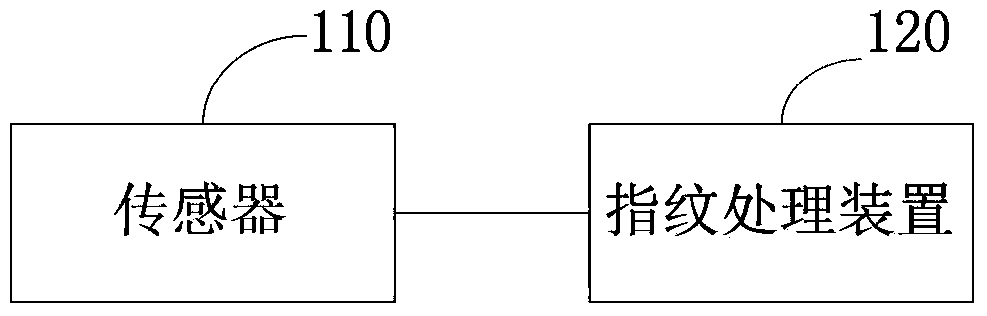

Fingerprint identification system and fingerprint processing method and device thereof

InactiveCN104281841AReduce scan timeEasy to operateDigital data authenticationPrint image acquisitionComputer visionFingerprint

The invention discloses a fingerprint identification system and a fingerprint processing method and device of the fingerprint identification system, and belongs to the technical field of fingerprint identification. The method includes the process that under a registration mode, when fingers of a user pass through a designated area in a sensor scanning area in a sliding mode, a plurality of pictures are obtained by scanning the designated area; according to the same characteristic value of the pictures, the pictures are spliced to form fingerprint images; the fingerprint images or the characteristic value of the fingerprint images is stored in a registration template. Due to the adoption of the fingerprint identification system and the fingerprint processing method and device of the fingerprint identification system, the scanning time can be shortened, operation is easy, and the fingerprint registration efficiency is improved.

Owner:SHENZHEN GOODIX TECH CO LTD

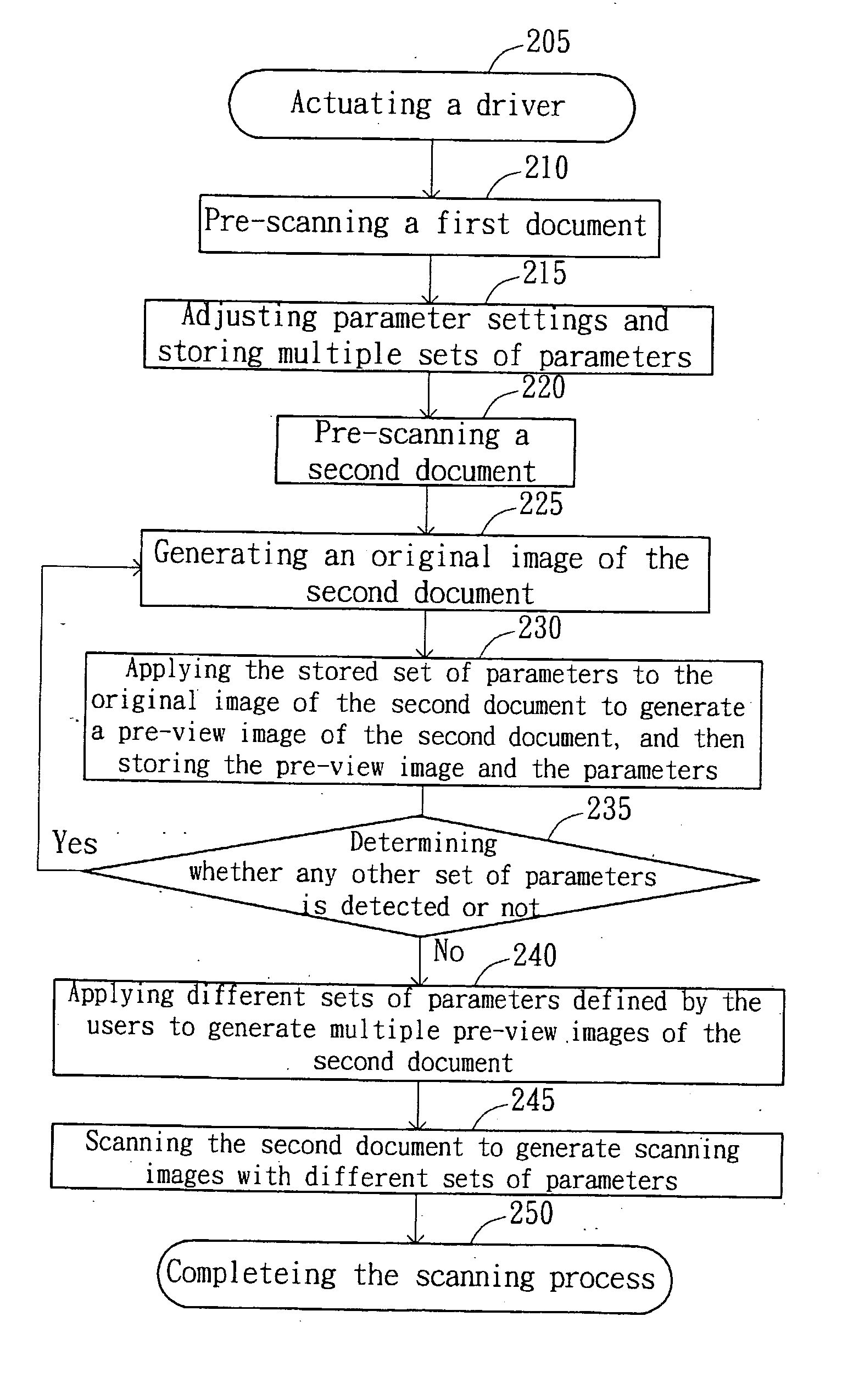

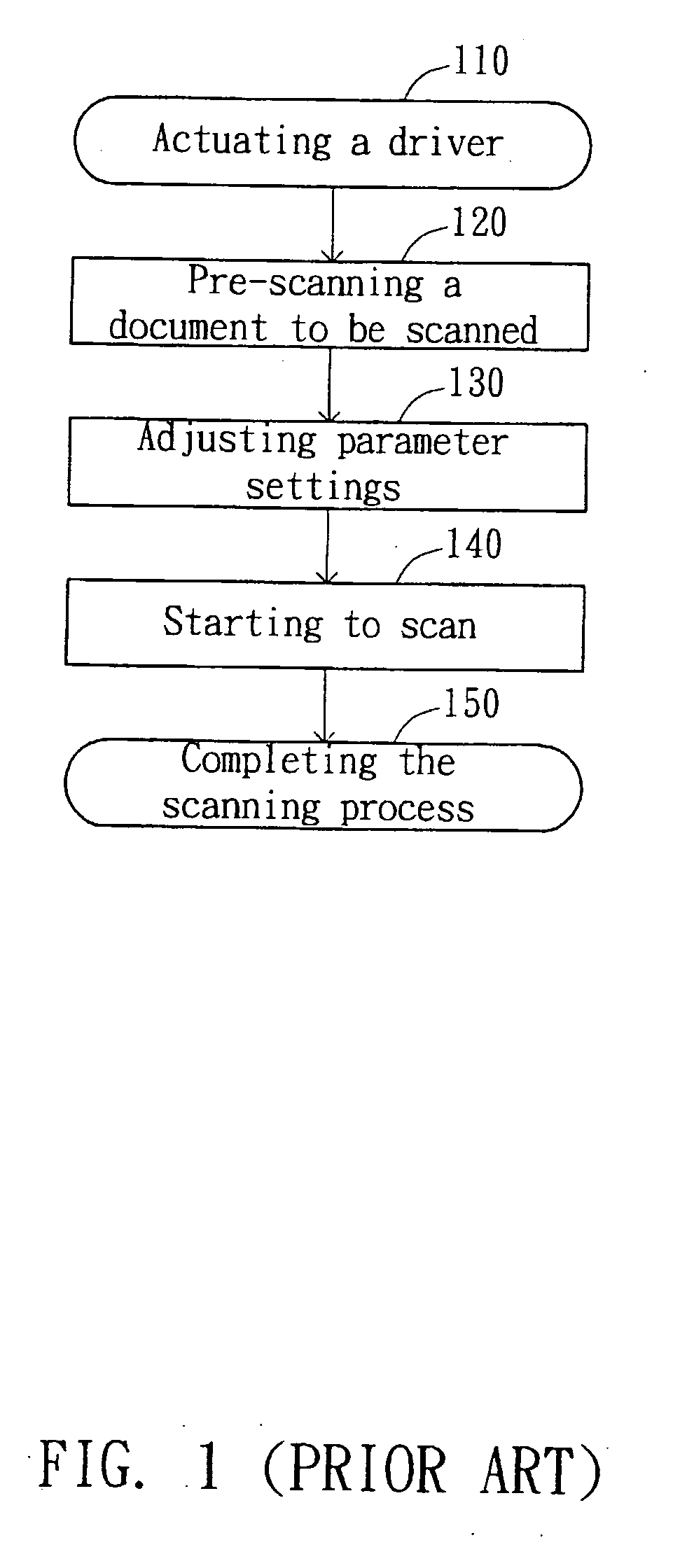

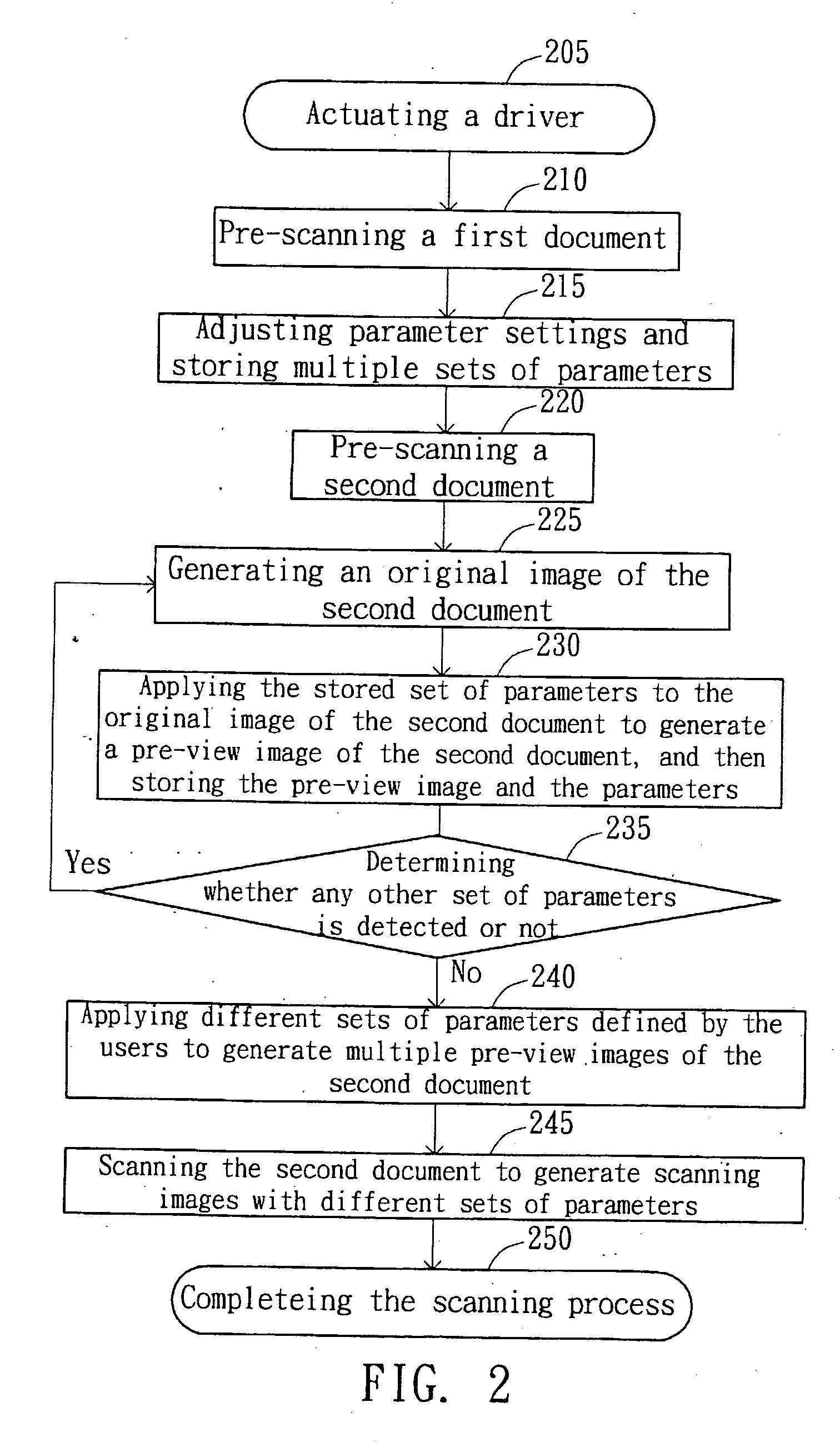

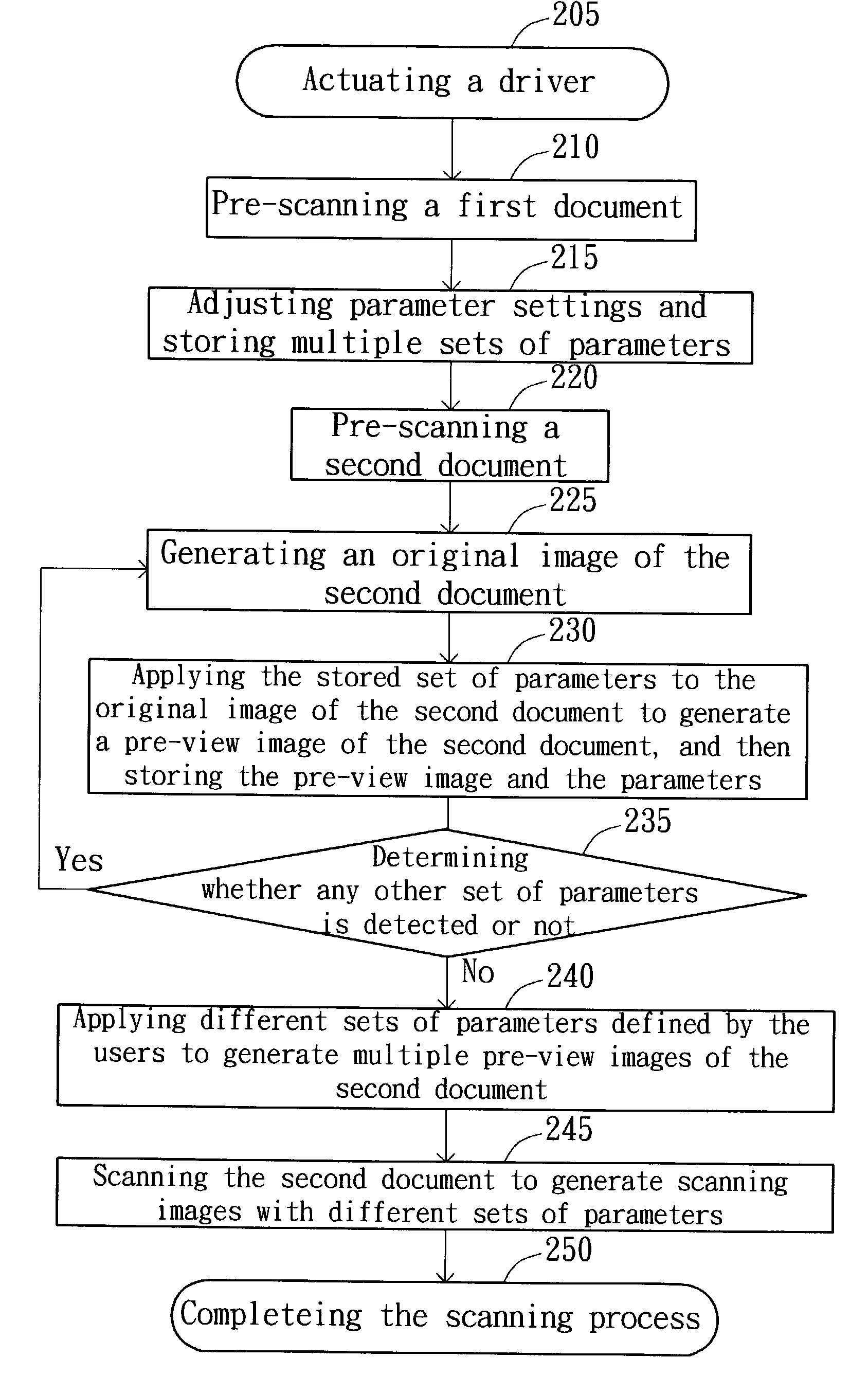

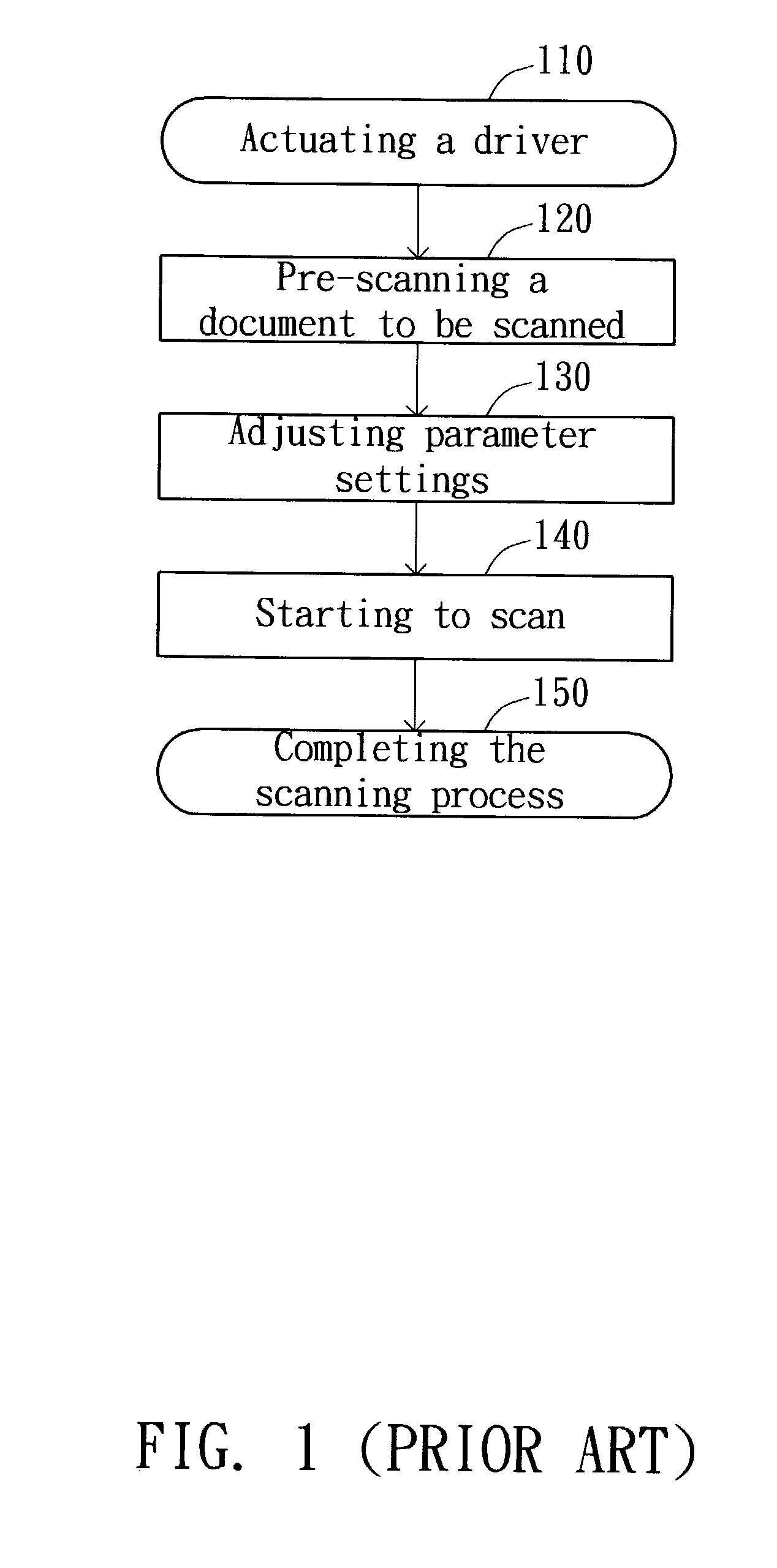

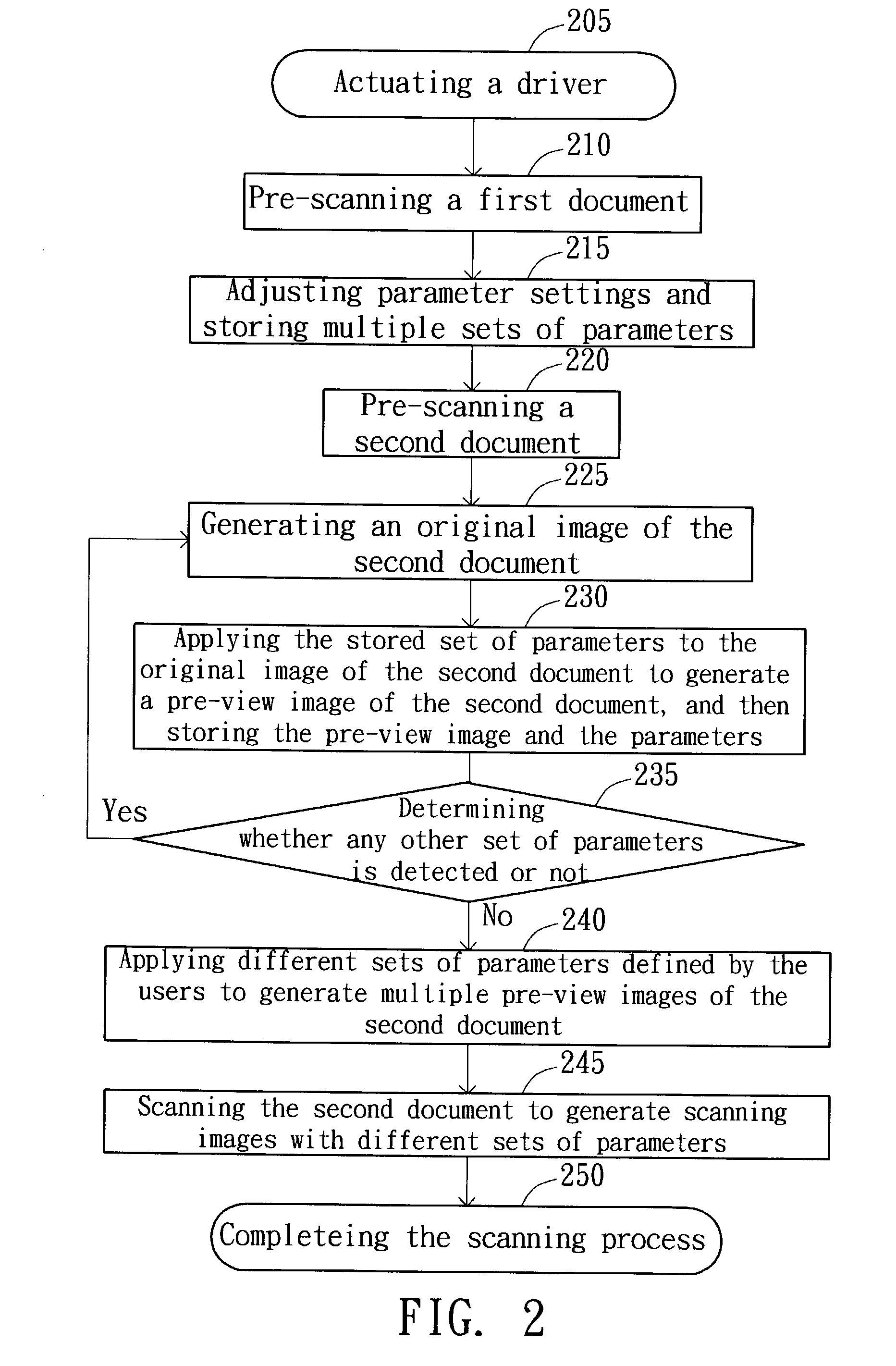

Image scanning

ActiveUS20070030540A1Reduce scan timeCharacter and pattern recognitionColour-separation/tonal-correctionPaper documentDocument preparation

Owner:AI-CORE TECH LLC

Image scanning method

ActiveUS7123387B2Reduce scan timeCharacter and pattern recognitionColour-separation/tonal-correctionBrightness perceptionLightness

Owner:INTELLECTUAL VENTURES I LLC

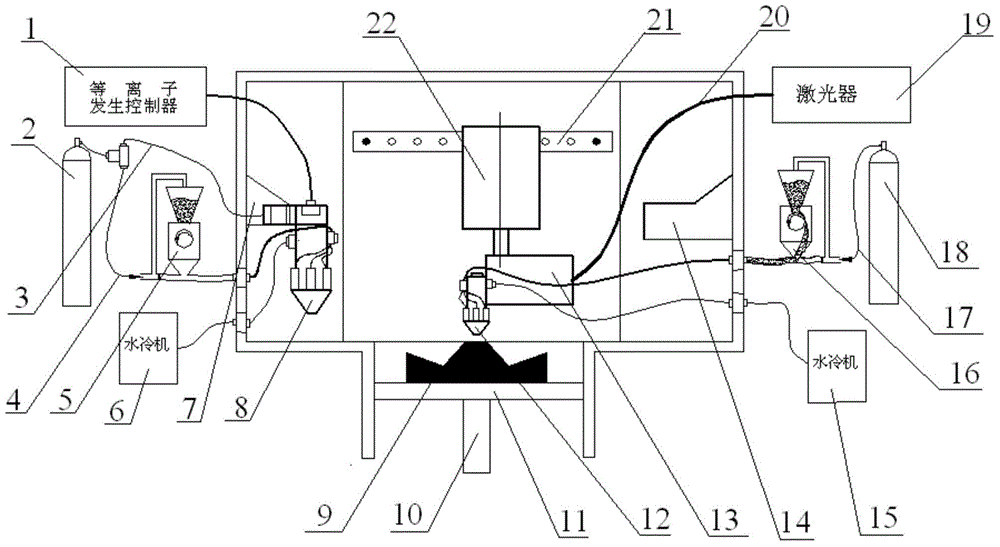

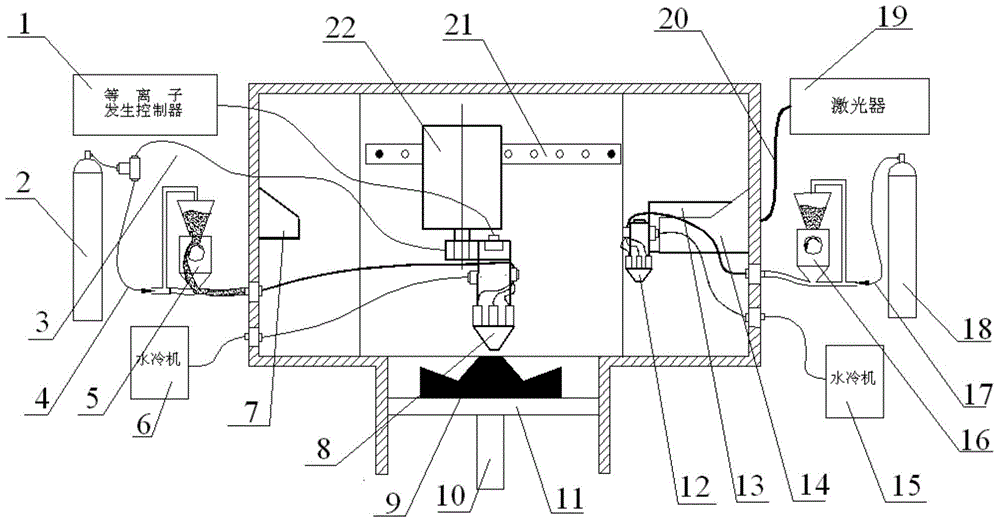

Laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method

ActiveCN104801712ASolve efficiency problemsSolve the accuracy problemAdditive manufacturing apparatusNumerical controlControl system

The invention discloses a laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method. The equipment comprises a central control system, a sealing forming chamber, a laser forming device and a plasma processing device, wherein a laser forming spray head and a plasma gun are correspondingly put on a support frame arranged at the left and right side inner walls of the sealing forming chamber, and the laser forming spray head or the plasma gun is clamped through a co-work numerical control main shaft, so that the laser forming spray head or the plasma gun moves in the Z, X and Y directions in the sealing forming chamber. The central control system controls the co-work numerical control main shaft for conveying back the laser forming spray head back to the support frame, then, the co-work numerical control main shaft clamps the plasma gun for filling the inside of the profile of a formed metal part, and the work is alternately carried out in such a way until the part manufacturing is completed, so that the scanning time is reduced to a great degree. The laser fast forming is combined with the plasma, the problem of conflict between the efficiency and the precision of a metal 3D printing technology is solved, and in addition, the plasma is adopted for replacing the laser to be used as a heat source, so that the high-efficiency and low-cost industrial level metal 3D printing equipment is obtained.

Owner:SOUTH CHINA UNIV OF TECH

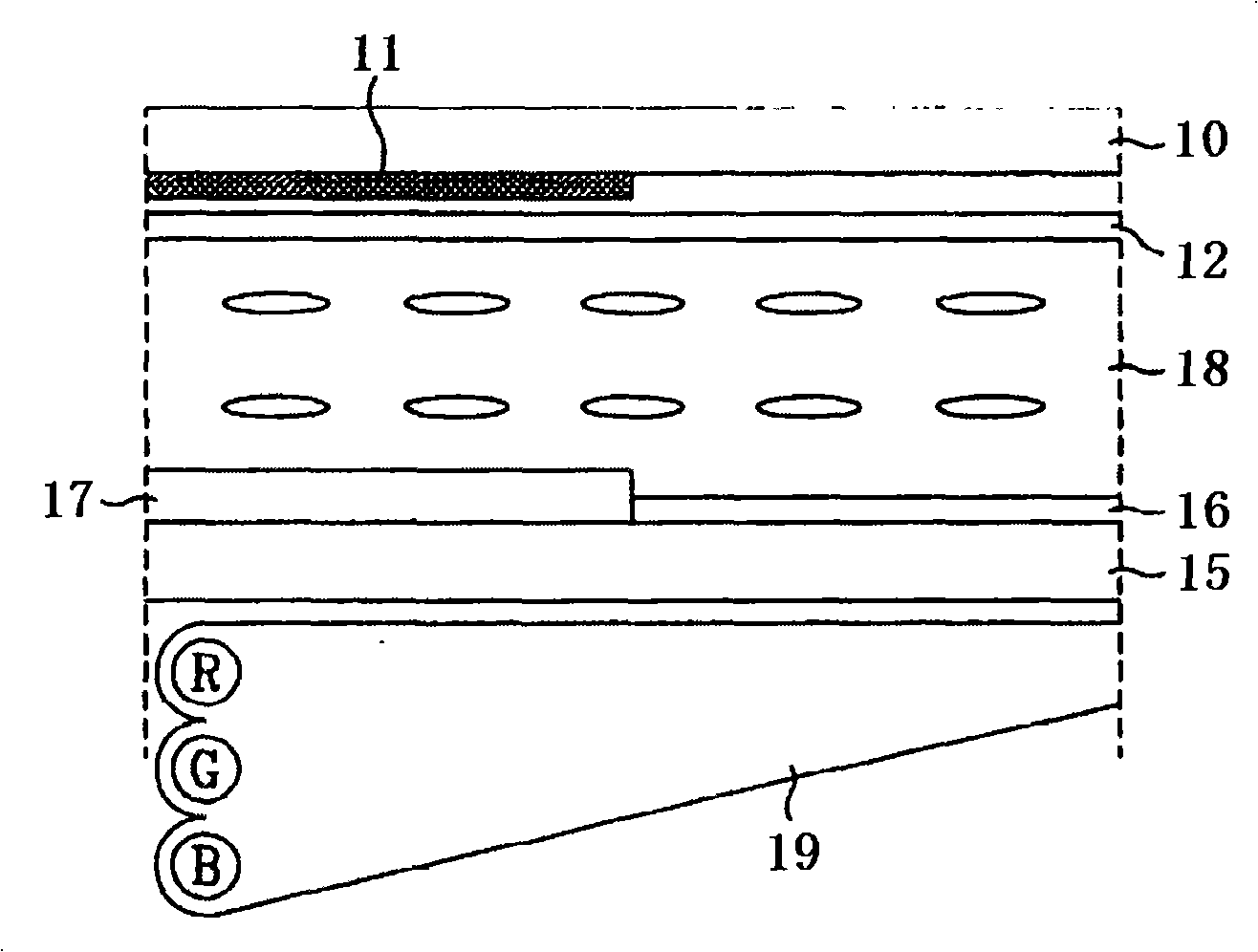

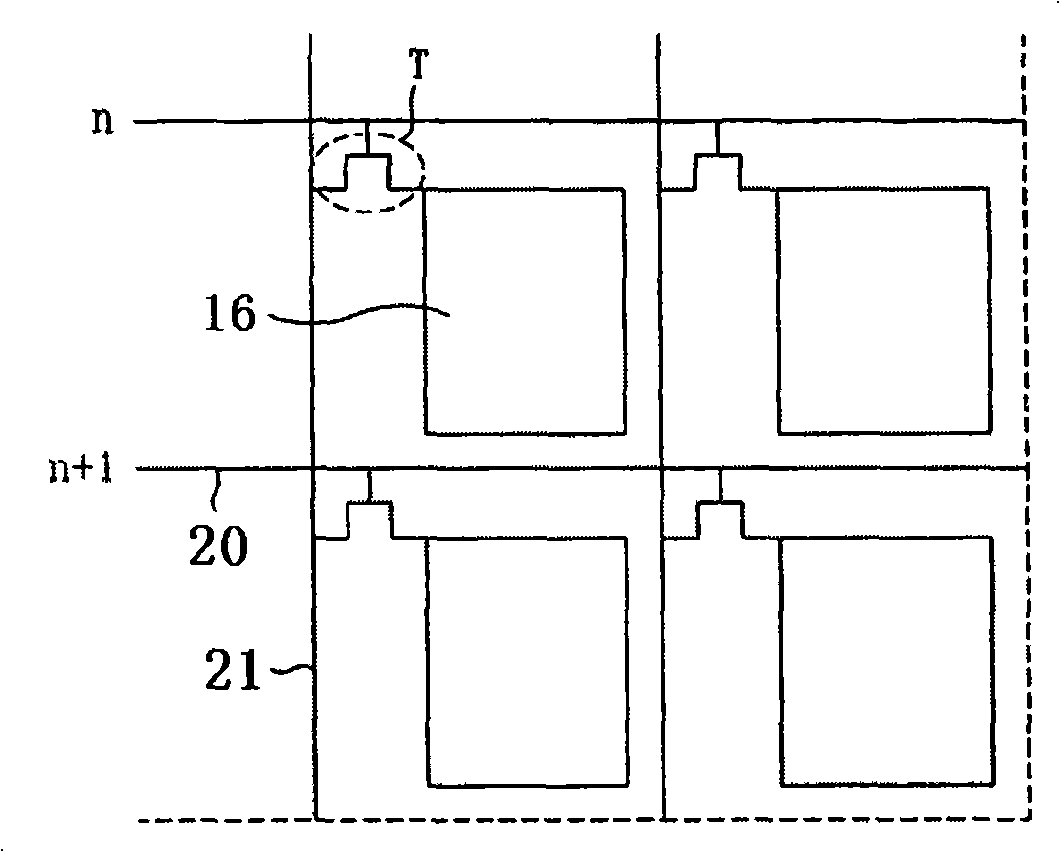

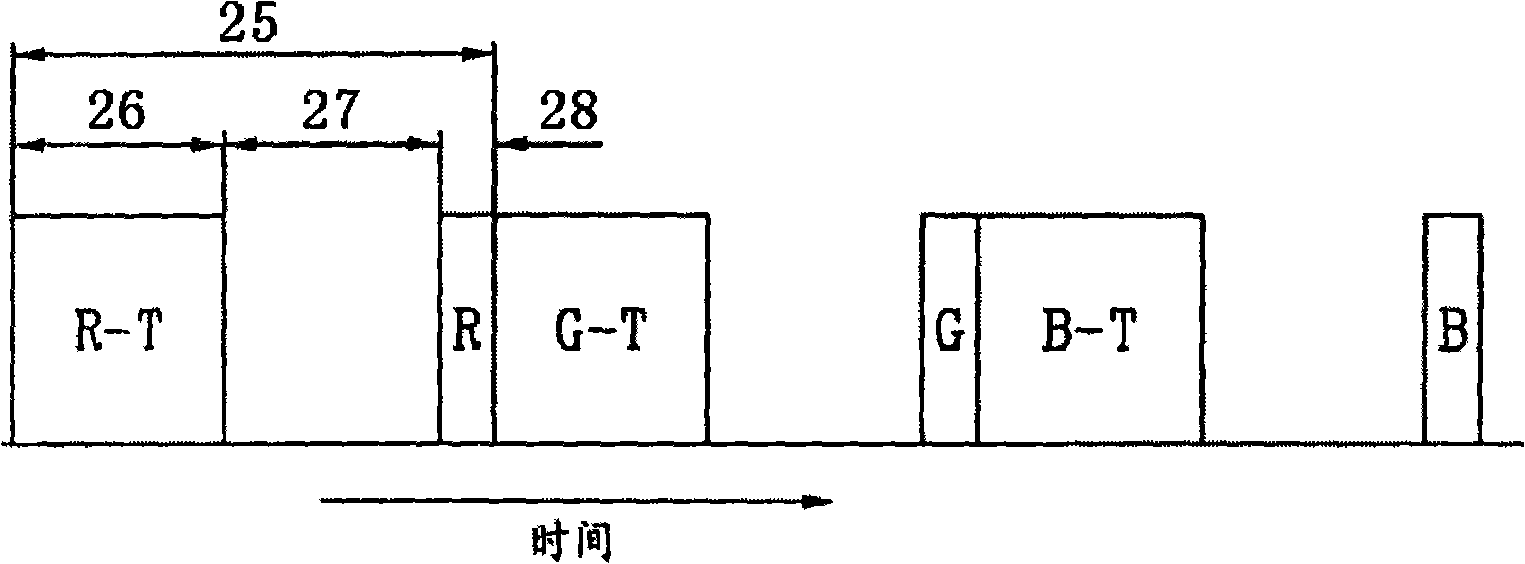

Field sequence type crystal display device and driving method thereof

InactiveCN101266371AReduce scan timeGuaranteed opening rateStatic indicating devicesNon-linear opticsScan lineEngineering

The present invention provides a field sequence liquid crystal display device and driving method thereof. The LCD device contains a liquid crystal panel, a back light source, a scan driver and a data driver, wherein the liquid crystal panel is divided into a plurality of areas, each area contains a plurality of scan lines, each area meanwhile respectively scans and controls pixel rows in every area; in each scan period, at least one pixel row of the upper and lower areas are scaned and controlled at the same time, and in the scan period, the image data are respectively transmitted to at least one pixel row of the upper and lower areas. The present invention can provide sufficient conducting time for every row transistor gate, and cut short scanning time of the entire TFT panel, which is propitious to ensure opening rate of the panel, can realize high-contrast and high brightness of the display panel, and provides furthermore wide prospect for the development of the LCD device.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

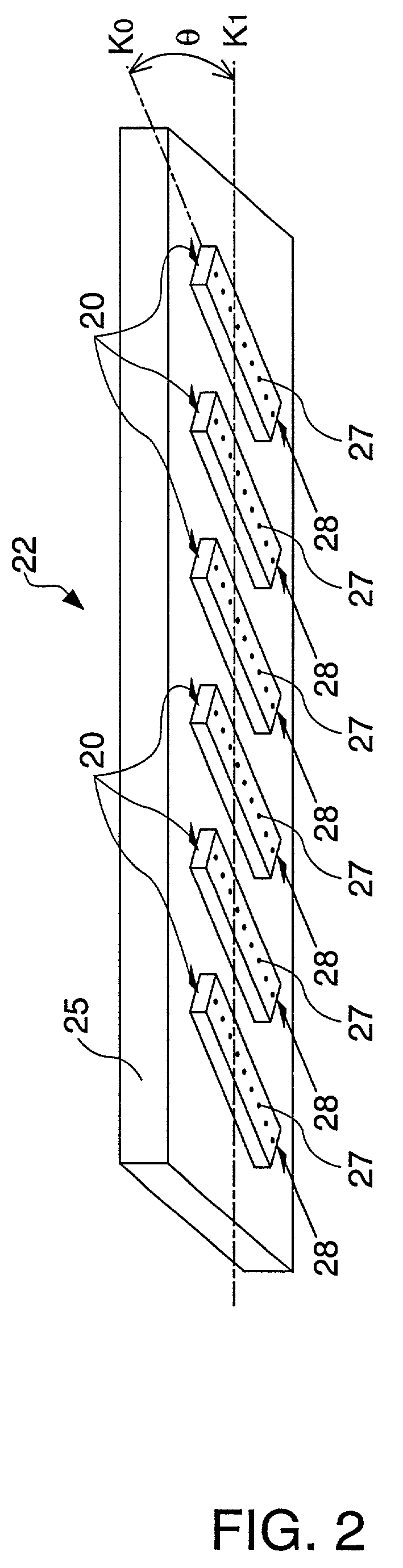

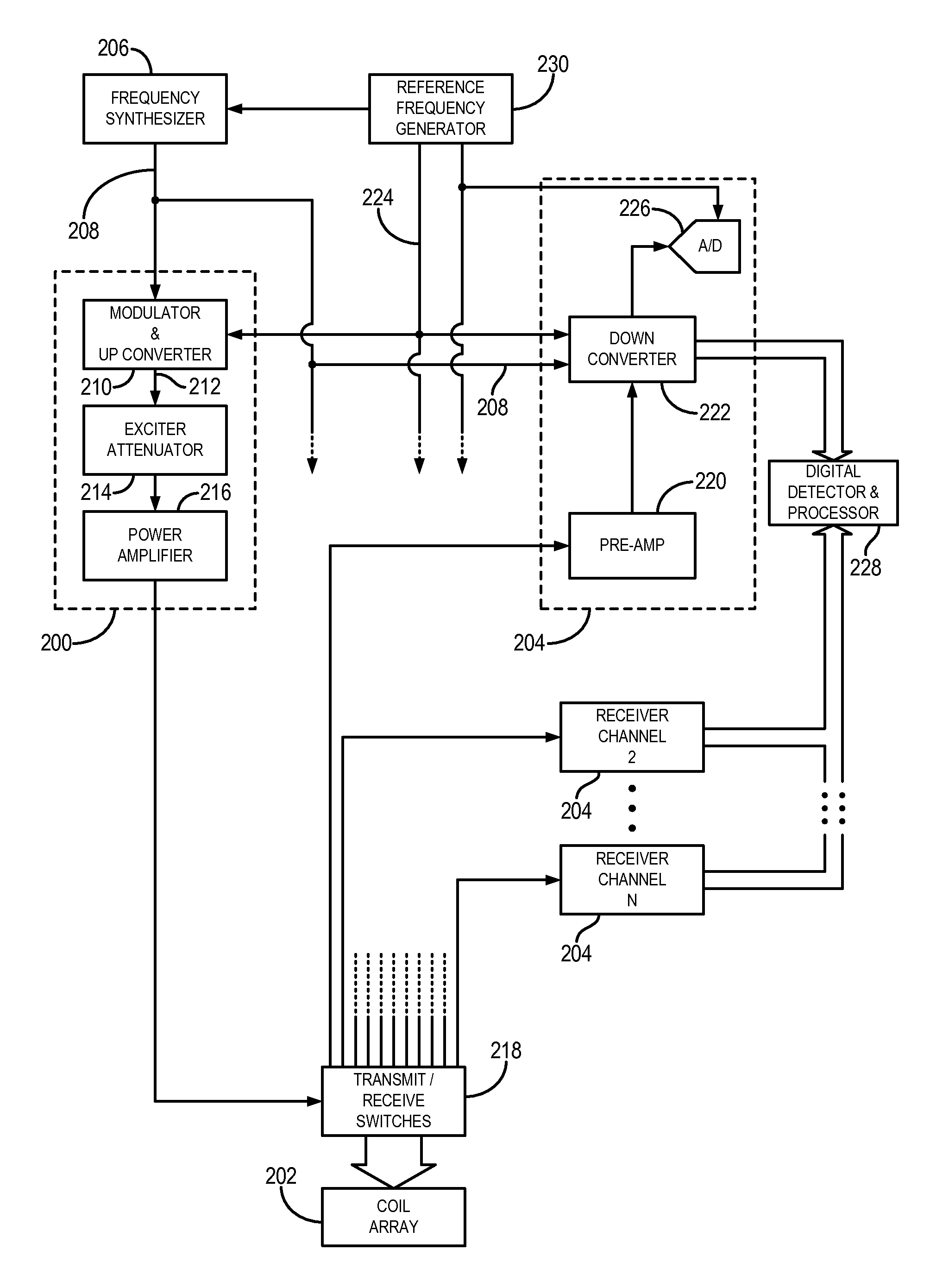

System and method for accelerated magnetic resonance parallel imaging

ActiveUS20080303521A1Data acquisition is reducedReduce scan timeMagnetic measurementsElectric/magnetic detectionData setParallel imaging

A system and method for MR imaging includes the use of a form of autocalibrated parallel imaging. By combining a segmented, rotated acquisition trajectory with autocalibration parallel imaging (API), the system and method can achieve improved motion insensitivity while maintaining the benefits of accelerated acquisition due to parallel imaging. In various embodiments, calibration values from a set of reference data or from another set of imaging data can be used in determining reconstruction weights for a given k-space data set. Thus, separate calibration data need not necessarily be acquired for each set of imaging data.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

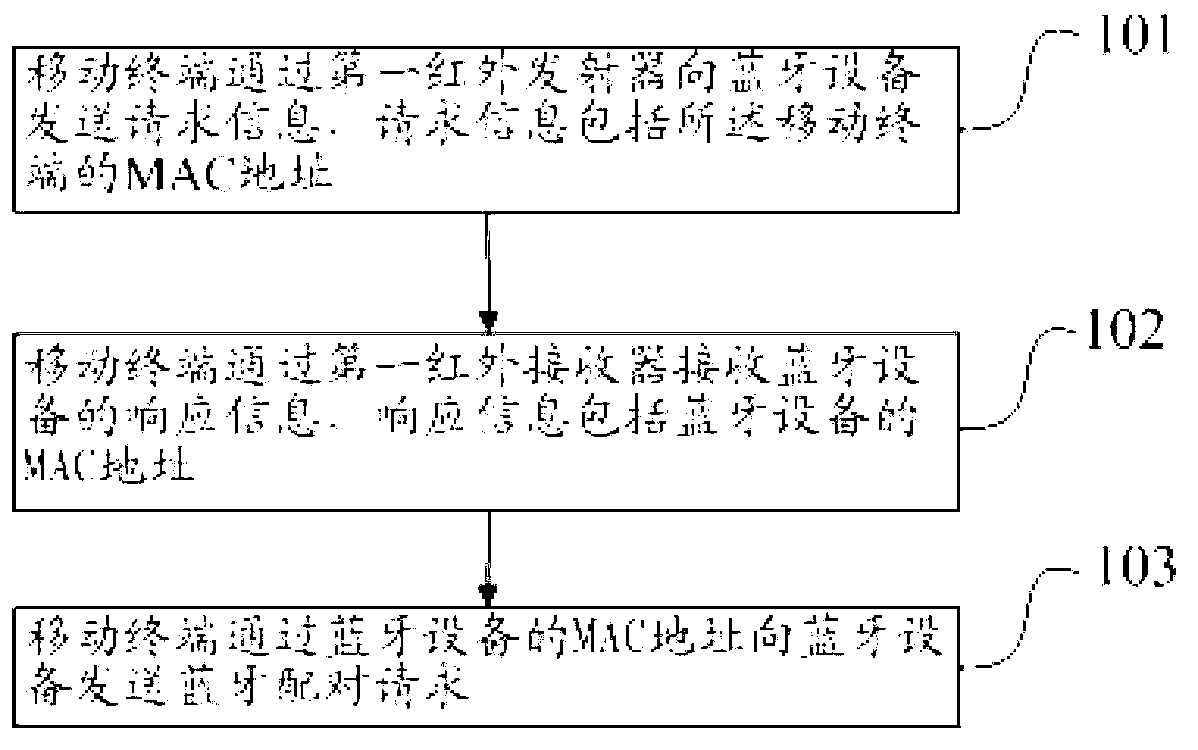

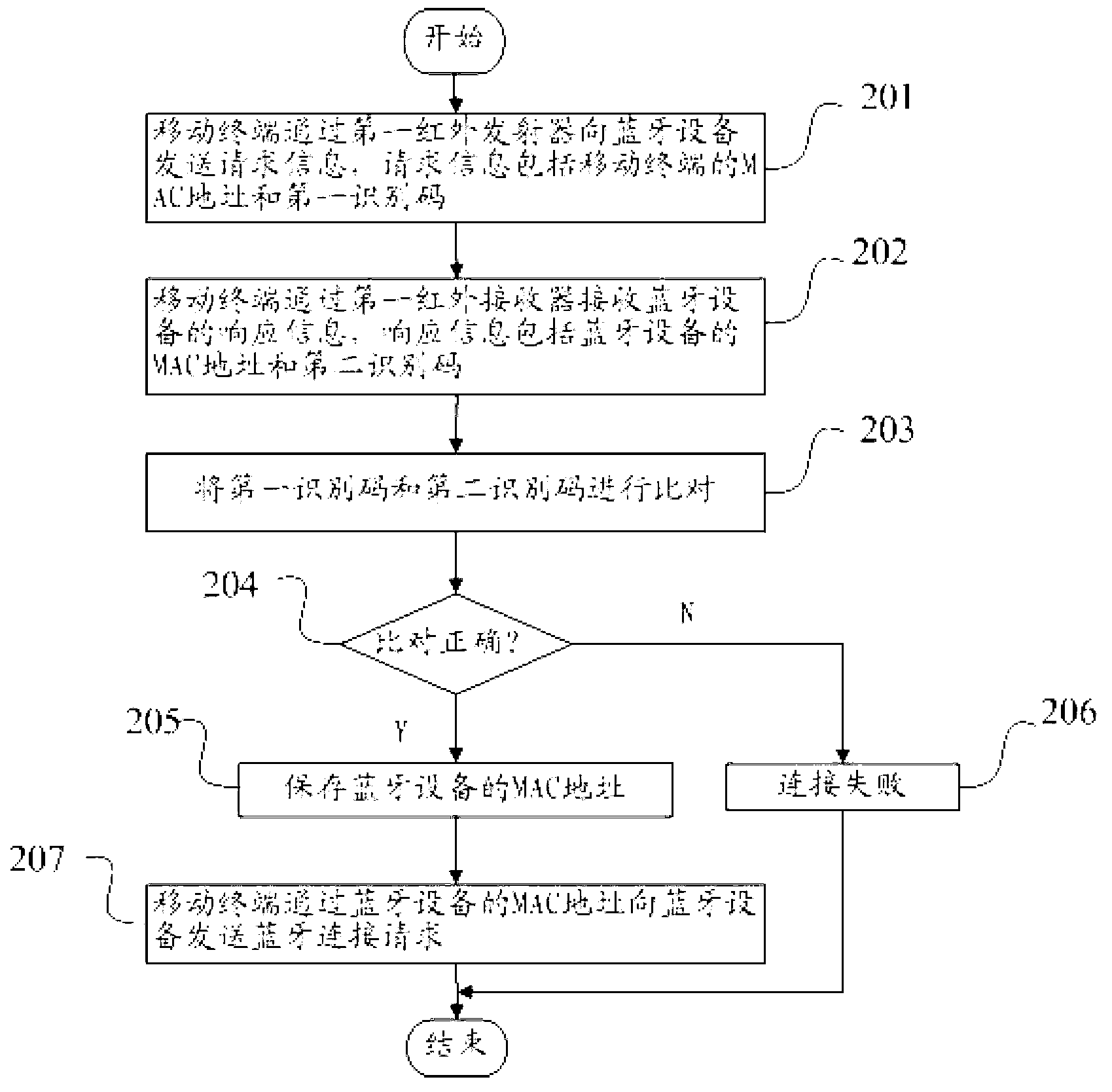

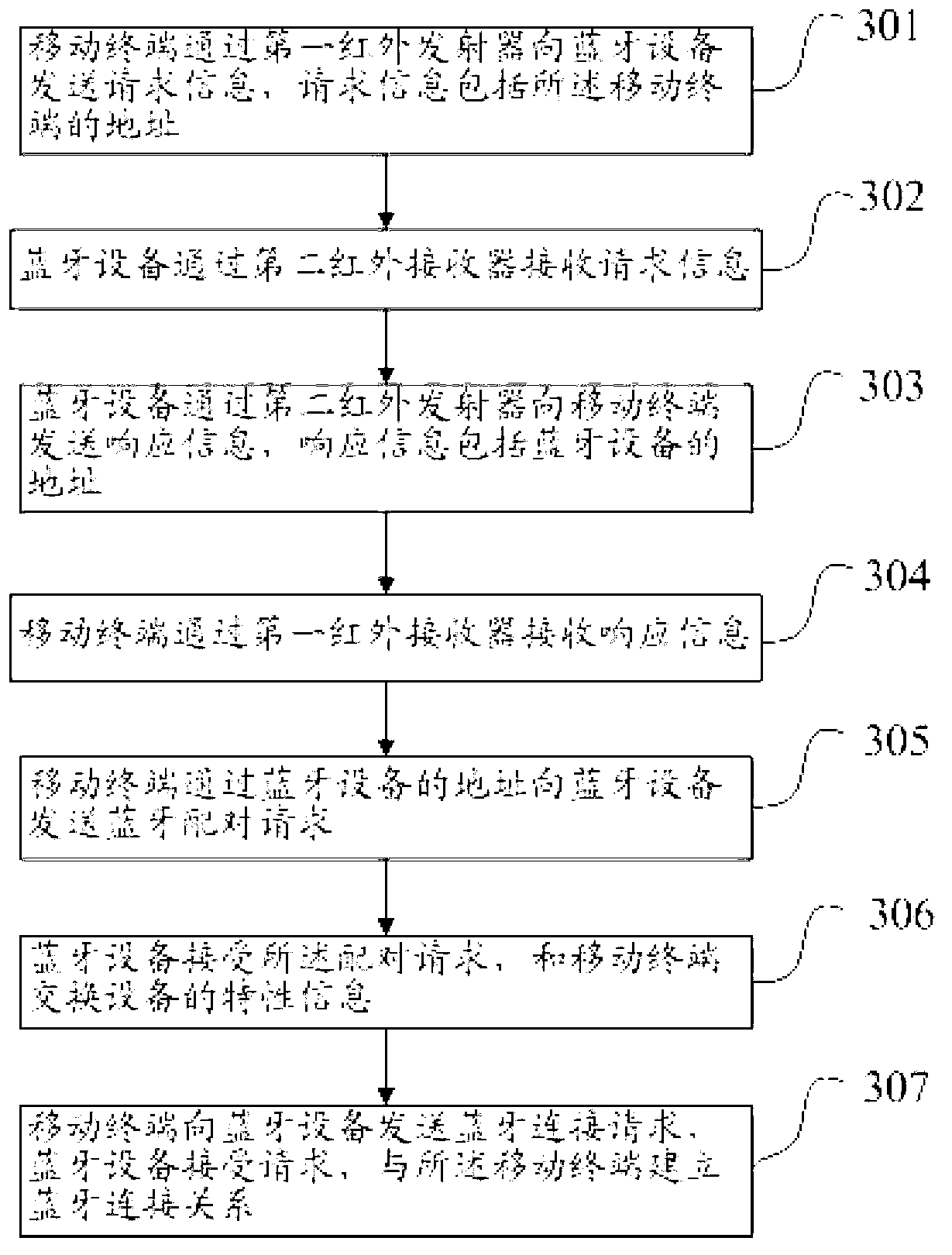

Bluetooth connecting method and mobile terminal

InactiveCN103067055AReduce scan timeImprove efficiency and accuracyNear-field systems using receiversInfrared emitterDevice name

The invention discloses a Bluetooth connecting method which comprises the steps that a mobile terminal sends requesting information to a Bluetooth device through a first infrared emitter, receives response information of the Bluetooth device through a first infrared outer receiver, and sends a connecting request to the Bluetooth device through the address of the Bluetooth device. Further disclosed is the mobile terminal. In practical implementation manner, due to the fact that the mobile terminal directly conducts exchange of measurement and control (MAC) address through the infrared emitter and the infrared receiver, the mobile terminal and the Bluetooth device are enabled to directly build Bluetooth connection according to the MAC address obtained through the exchange, scanning to devices around is not required, and therefore scanning time is saved, a condition that scanning is required to be repeated when names of the devices are the same, precision and efficiency of Bluetooth device connecting is improved, and meanwhile experience of users is improved.

Owner:SHENZHEN TINNO WIRELESS TECH

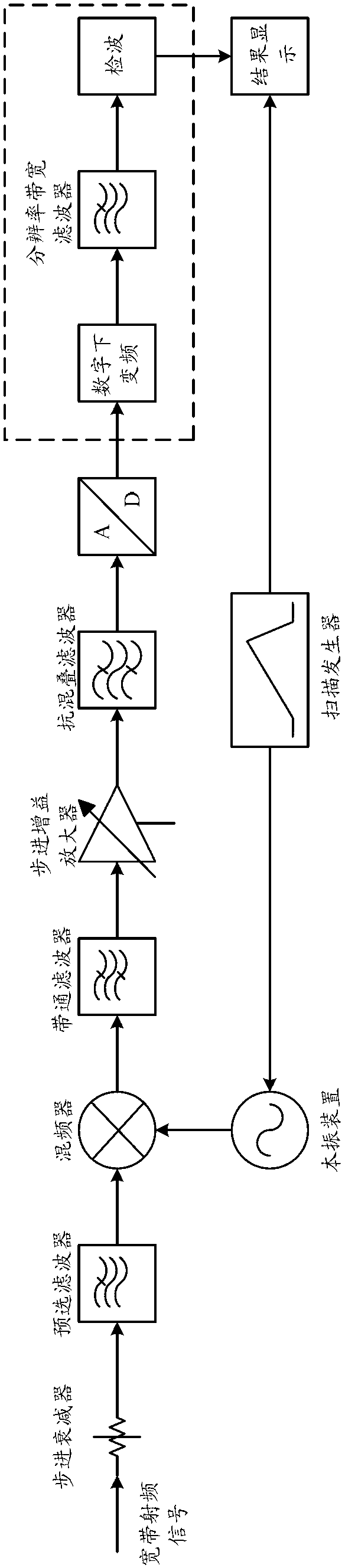

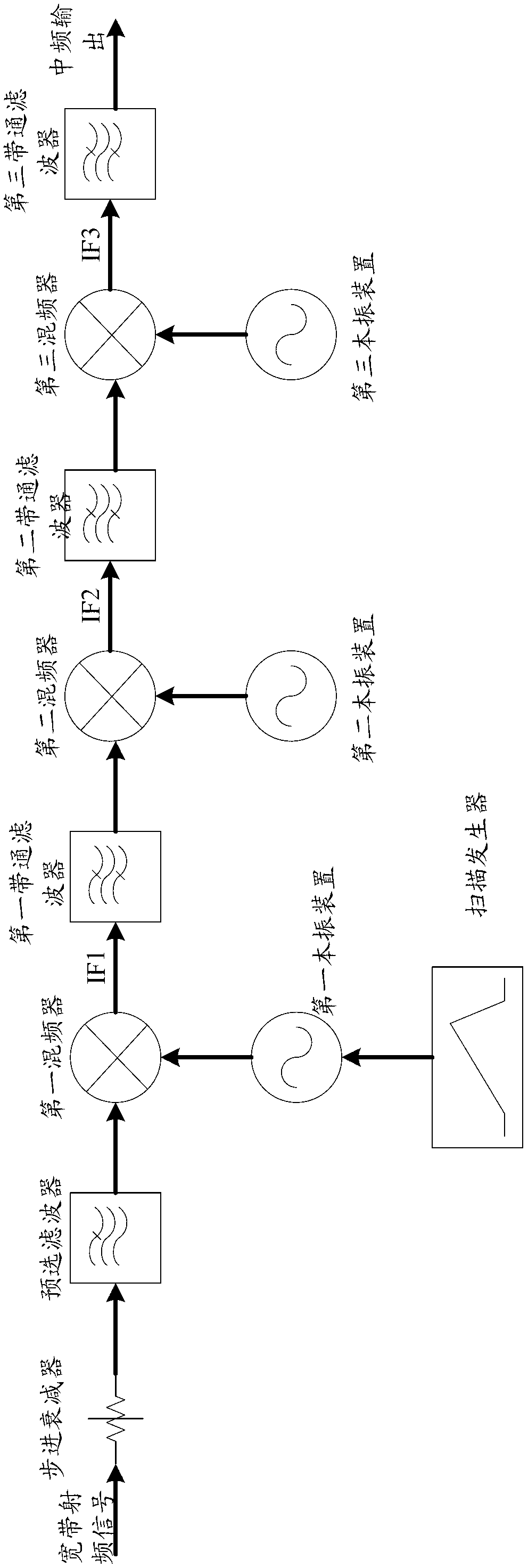

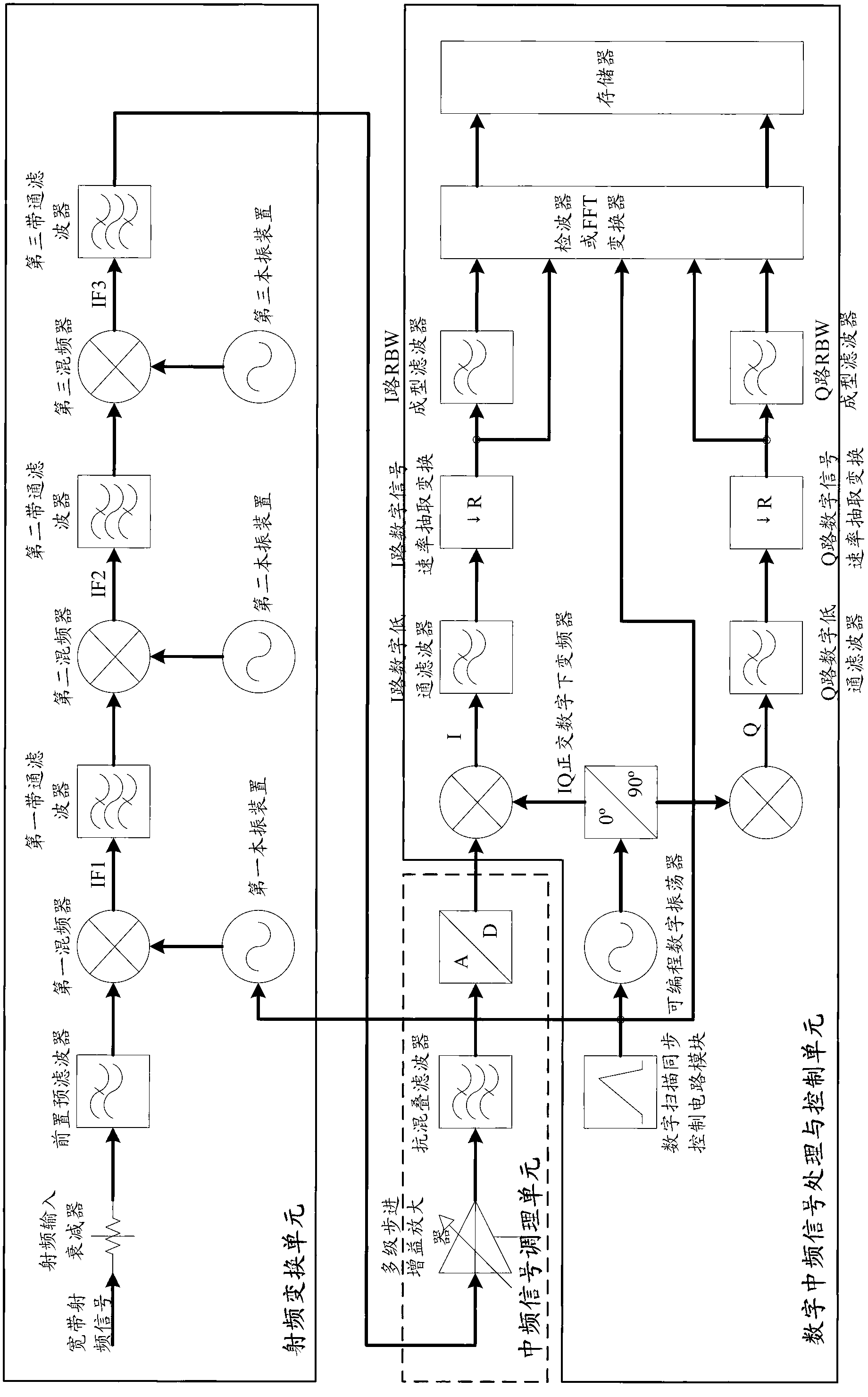

System and method for measuring radio-frequency signal high-speed sweeping frequency spectrum based on digital local oscillator

ActiveCN103067104ASimplify design difficultySimplify Design ComplexitySpectral/fourier analysisTransmission monitoringFast Fourier transformFrequency spectrum

The invention relates to a system for measuring a radio-frequency signal high-speed sweeping frequency spectrum based on a digital local oscillator. The system comprises a radio frequency conversion unit, an intermediate frequency signal conditioning unit and a digital intermediate frequency signal processing and controlling unit which are sequentially connected in series. The digital intermediate frequency signal processing and controlling unit is provided with a digital scan synchronous control circuit module and a programmable digital oscillator, wherein the digital scan synchronous control circuit module is connected with an in-phase quadrature (IQ) signal shunt processing circuit module through the programmable digital oscillator, the digital scan synchronous control circuit module is connected with a first local oscillator device, a detector, or a fast fourier transform (FFT) convertor. The invention further relates to a method which is based on the system and achieves synchronous control for the scanning in high-speed sweeping frequency spectrum measurement. Due to the fact that the system and method for measuring radio-frequency signal high-speed sweeping frequency spectrum based on the digital local oscillator are adopted, scanning time is greatly shortened, local frequency accuracy in a scanning process is improved, circuit hardware is simplified, cost is reduced, working performance is stable and reliable, and range of application is wide.

Owner:TRANSCOM INSTR

Moving table MRI with frequency-encoding in the z-direction

InactiveUS6891374B2Expand coverageShorten the timeDiagnostic recording/measuringSensorsLarge fovComplete data

A system and method are disclosed using continuous table motion while acquiring data to reconstruct MR images across a large FOV without significant slab-boundary artifacts that reduces acquisition time. At each table position, full z-encoding data are acquired for a subset of the transverse k-space data. The table is moved through a number of positions over the desired FOV and MR data are acquired over the plurality of table positions. Since full z-data are acquired for each slab, the data can be Fourier transformed in z, interpolated, sorted, and aligned to match anatomic z locations. The fully sampled and aligned data is then Fourier transformed in remaining dimension(s) to reconstruct the final image that is free of slab-boundary artifacts.

Owner:GENERAL ELECTRIC CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com