Laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method

A micro-beam plasma and 3D printing technology, applied in the direction of additive processing, can solve the problems of unfavorable industrial promotion and application of laser 3D printing equipment, troublesome maintenance and operation, and high price of lasers, so as to solve the contradiction between technical efficiency and accuracy, and improve the molding process. Efficiency, the effect of reducing scan time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

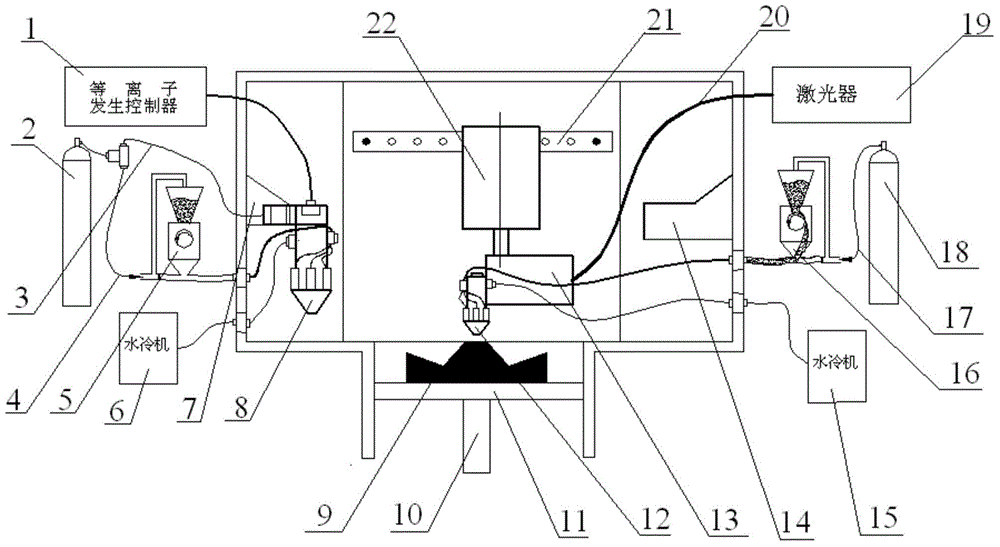

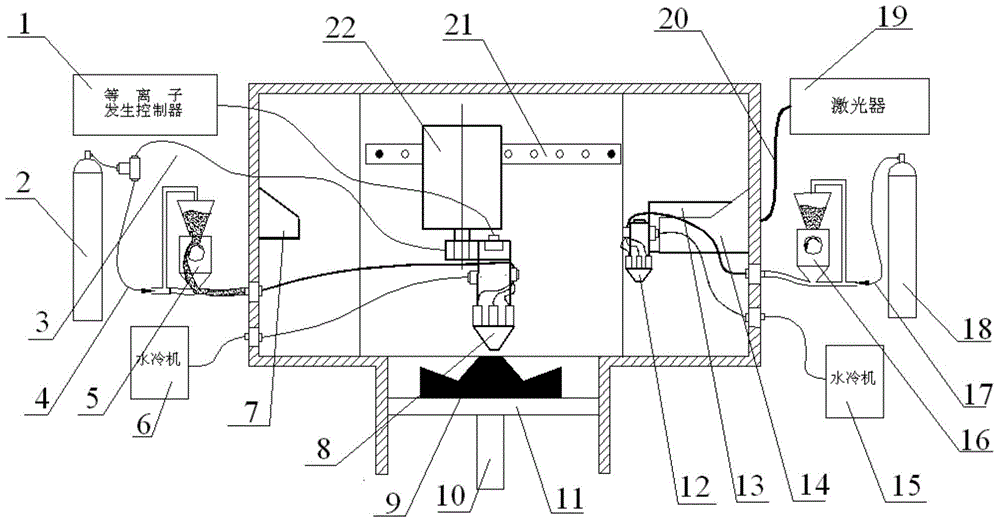

[0030] Such as figure 1 , 2 shown. The present invention is a laser and micro-beam plasma composite 3D printing equipment, including a central control system, a sealed molding chamber, a molding cylinder, a laser molding device, and a plasma processing device; the molding cylinder, laser molding device, and plasma processing device are controlled by the central control system control, characterized by:

[0031] Described laser forming device comprises laser forming nozzle 12, and described plasma processing device comprises plasma gun 8; The right side inner wall of described sealed molding chamber is provided with the laser nozzle holder 14 that is used to place laser forming nozzle 12, and the laser nozzle bracket 14 of described sealed molding chamber The left inner wall is provided with a plasma gun bracket 7 for placing a plasma gun 8;

[0032] In the sealed molding chamber and above the molding cylinder, there is a co-working CNC spindle drive guide rail 21 and a co-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com