Patents

Literature

80results about How to "Overcome size limitations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

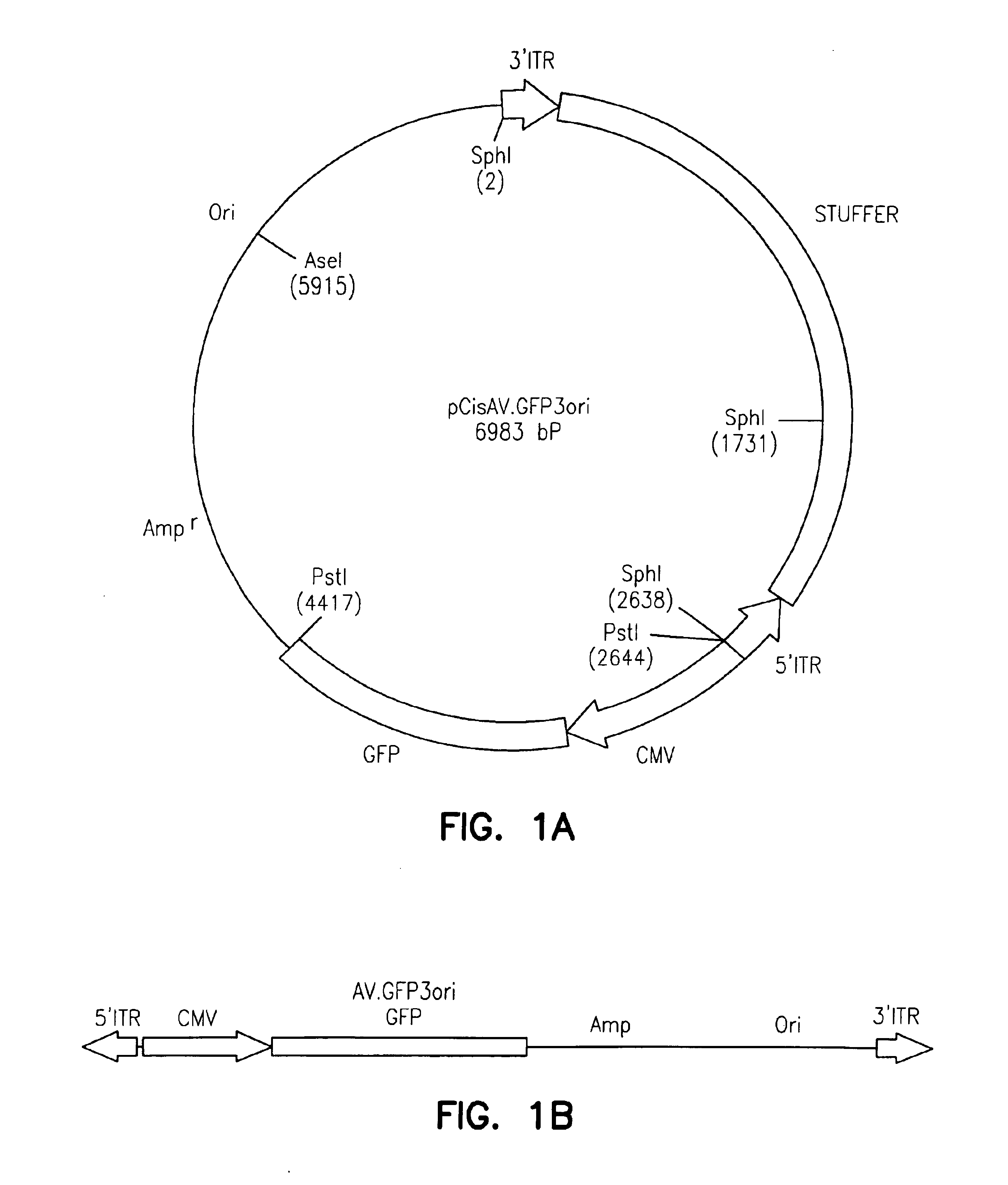

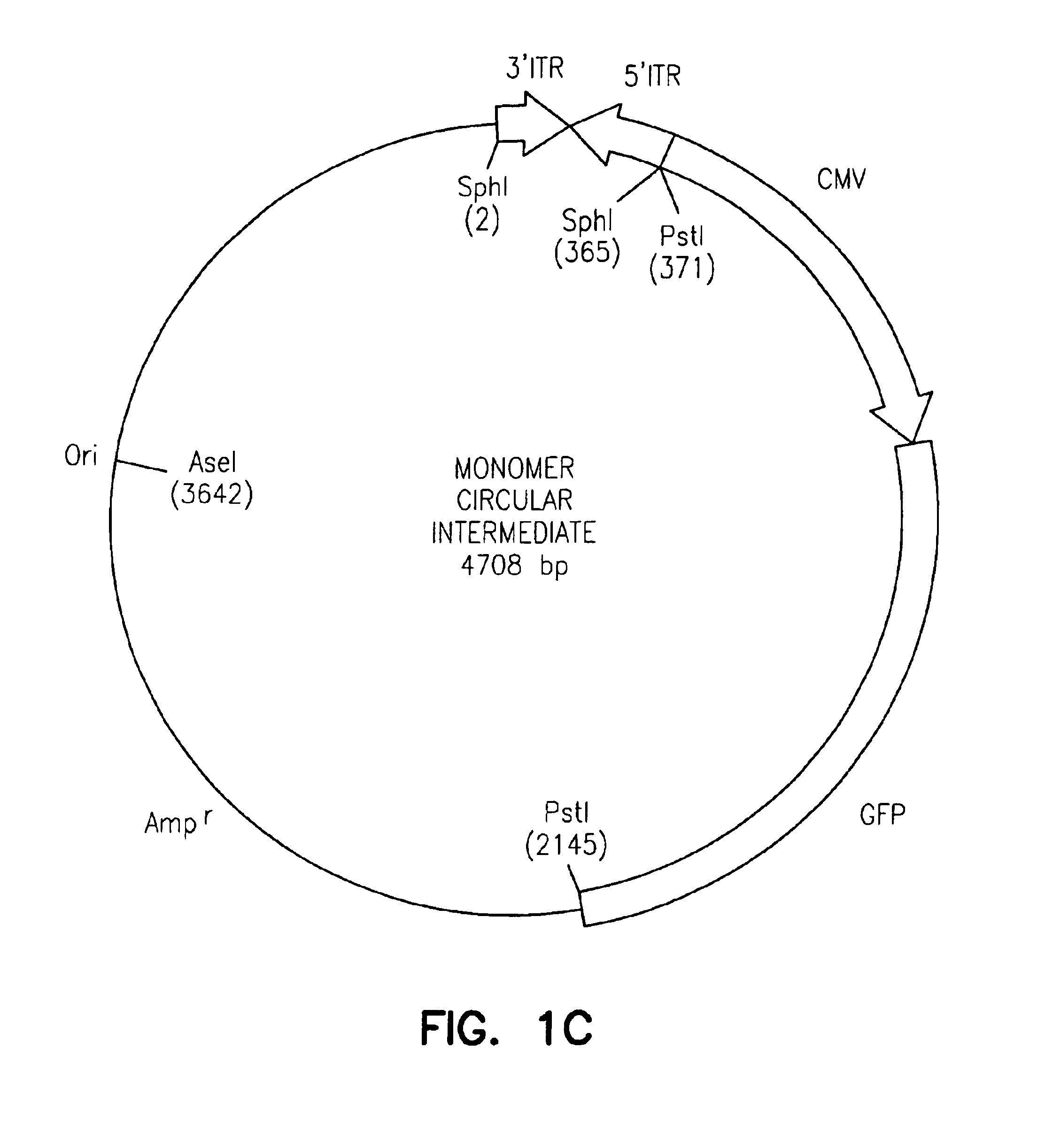

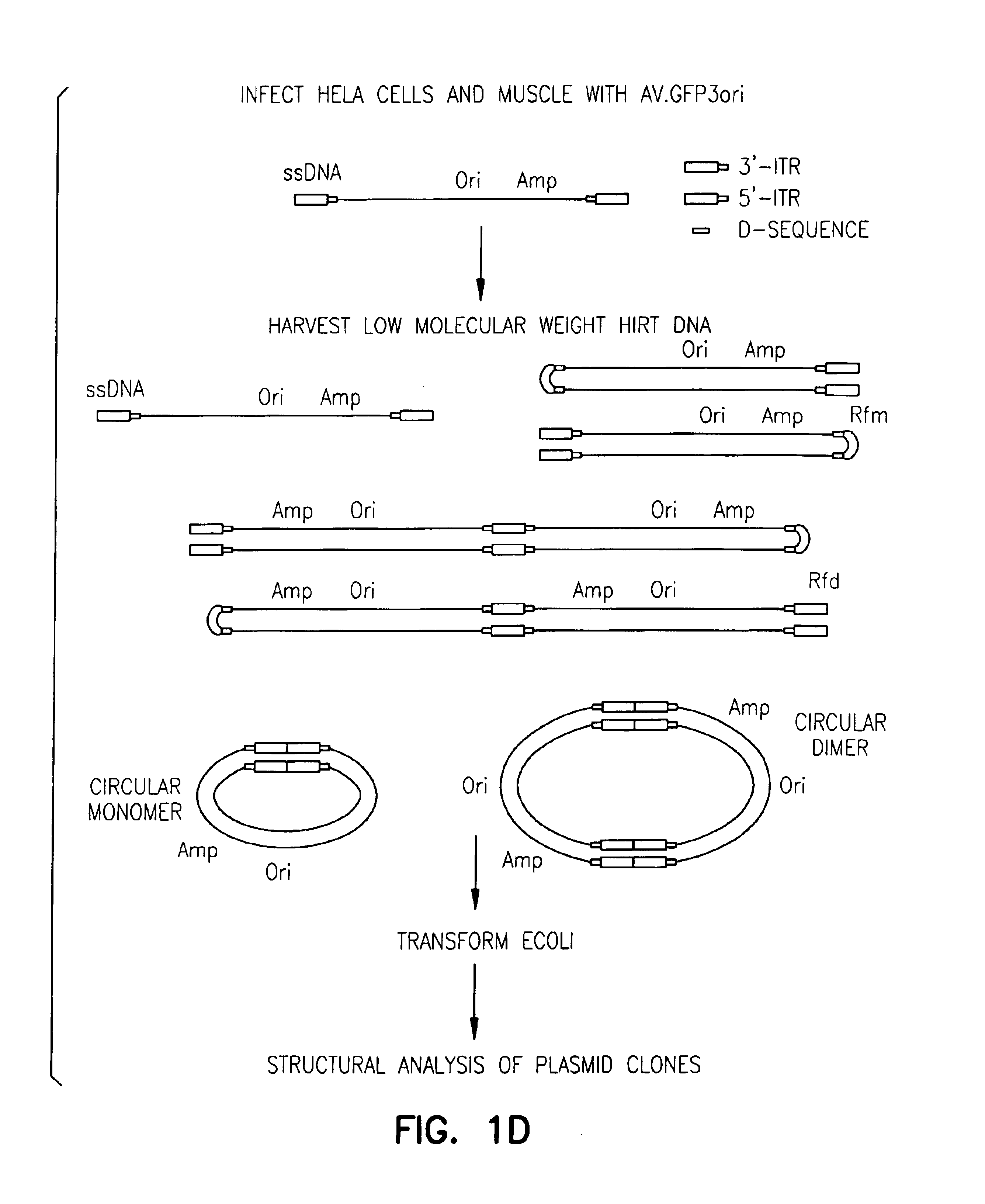

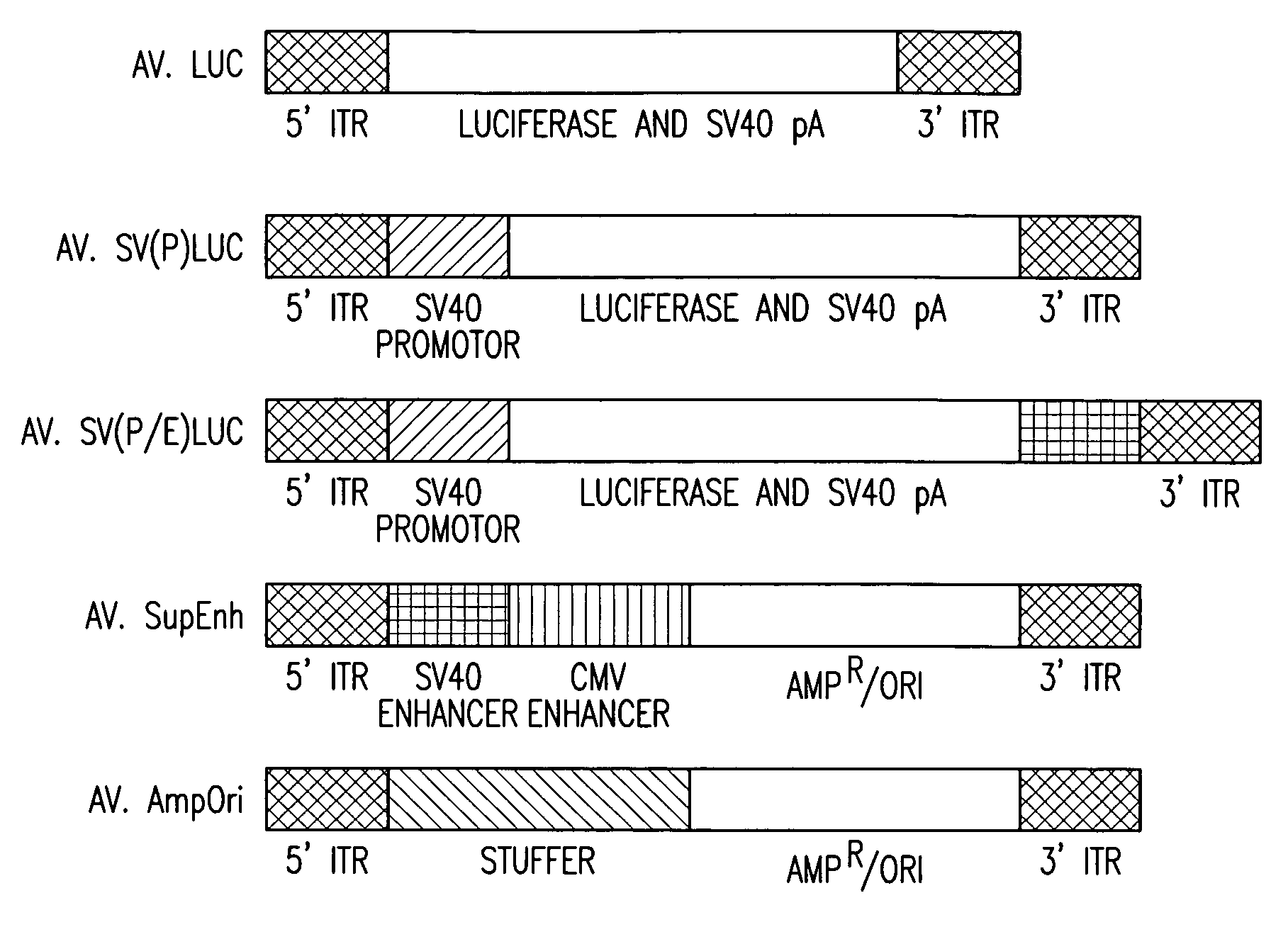

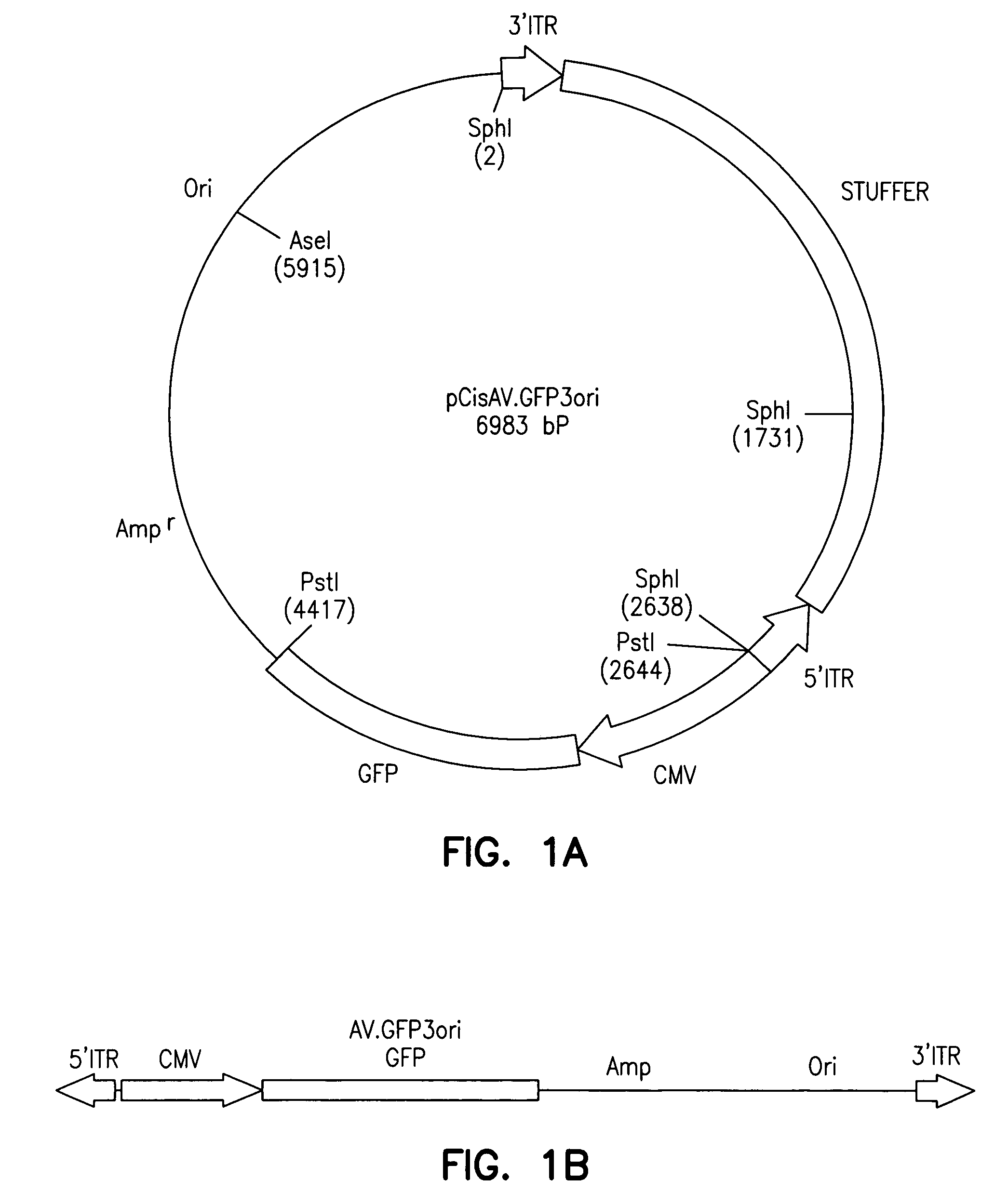

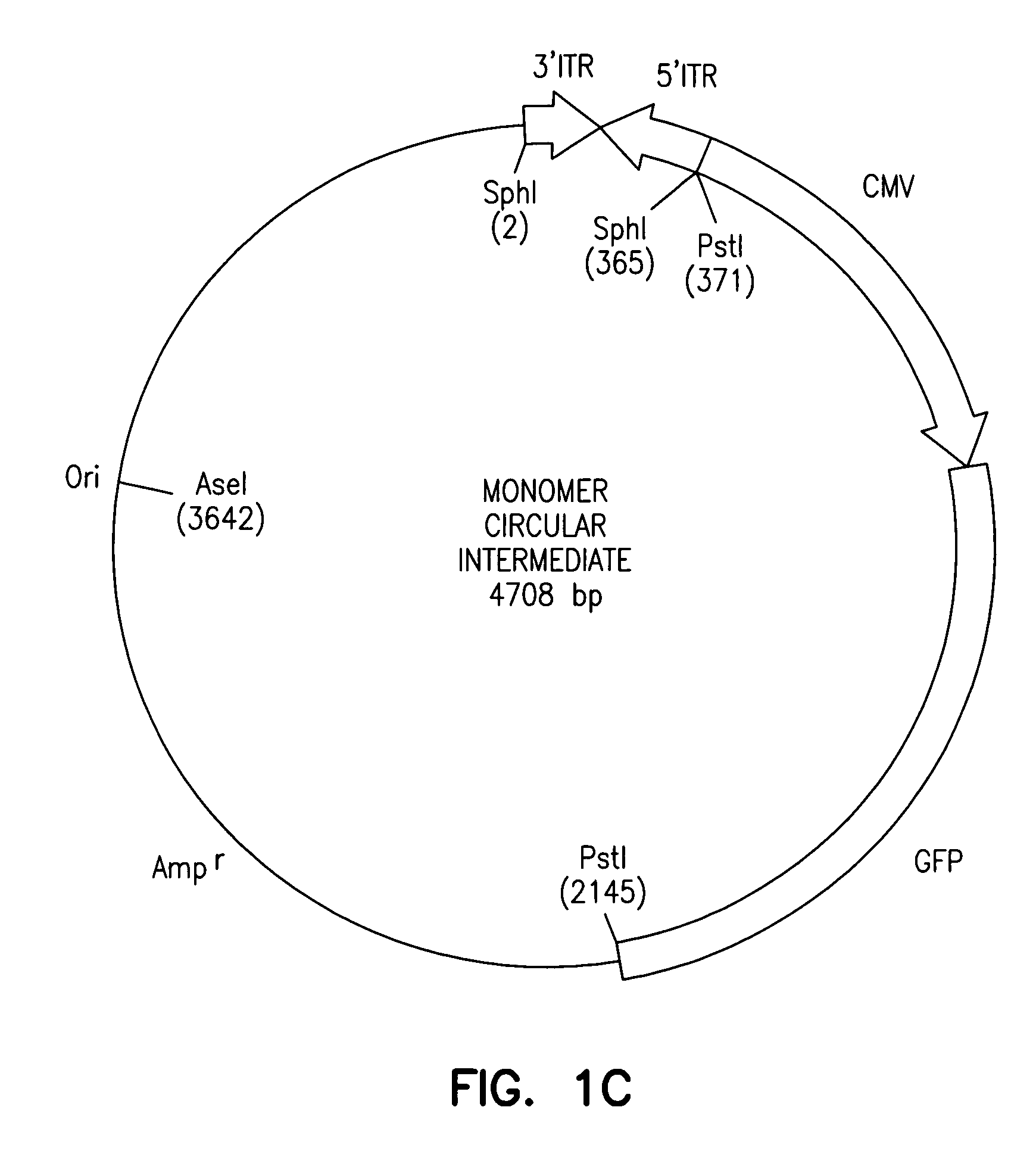

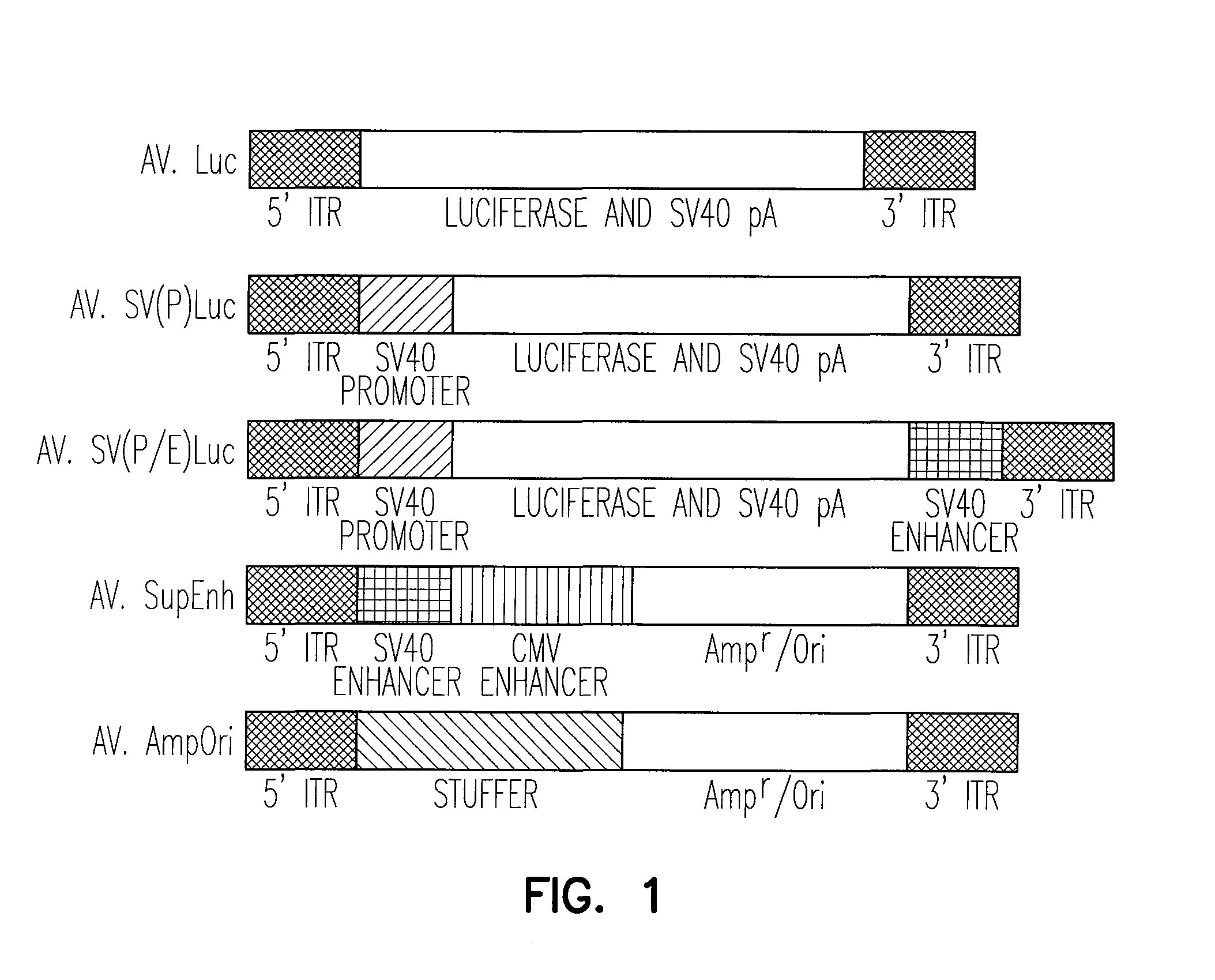

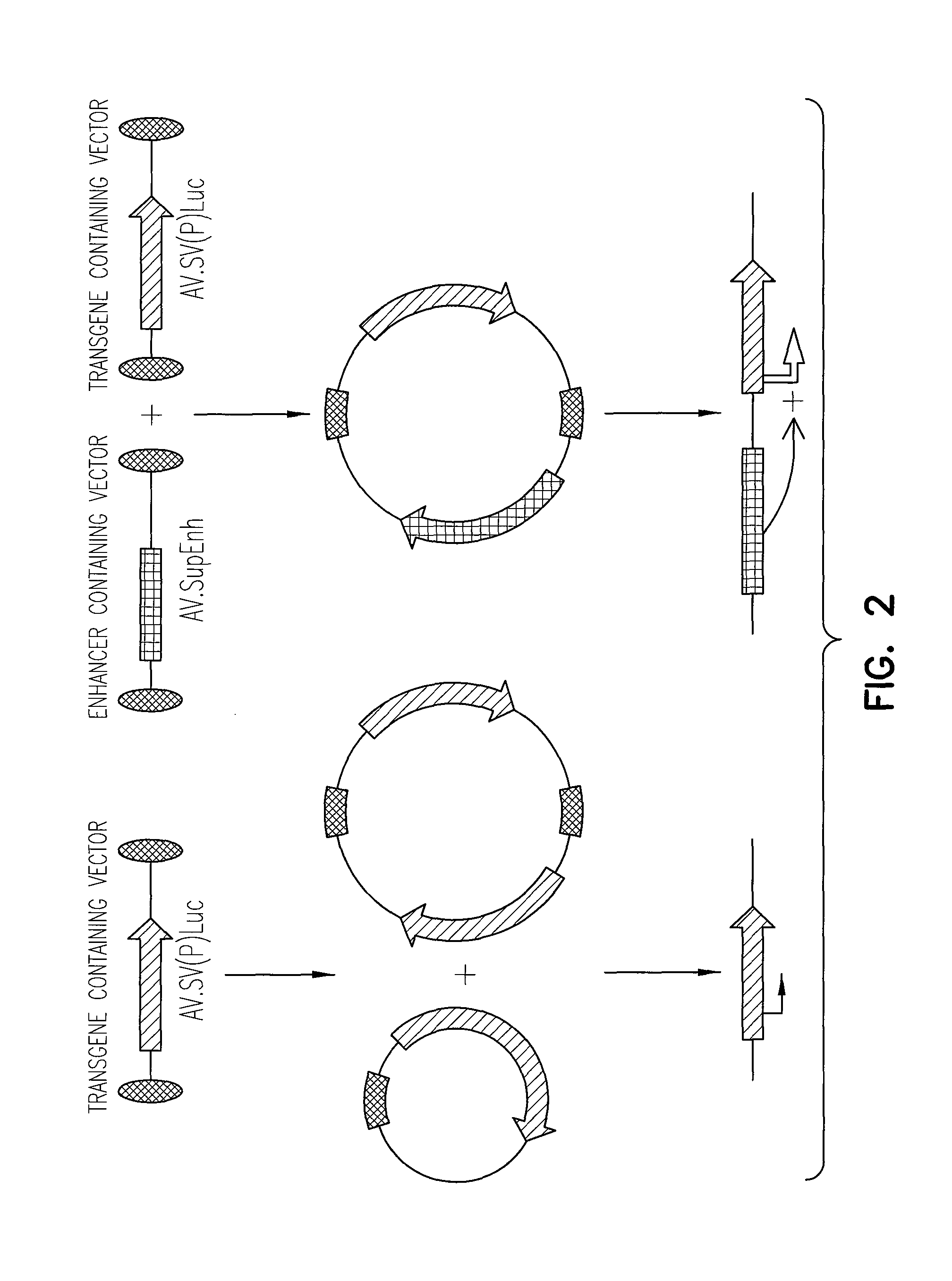

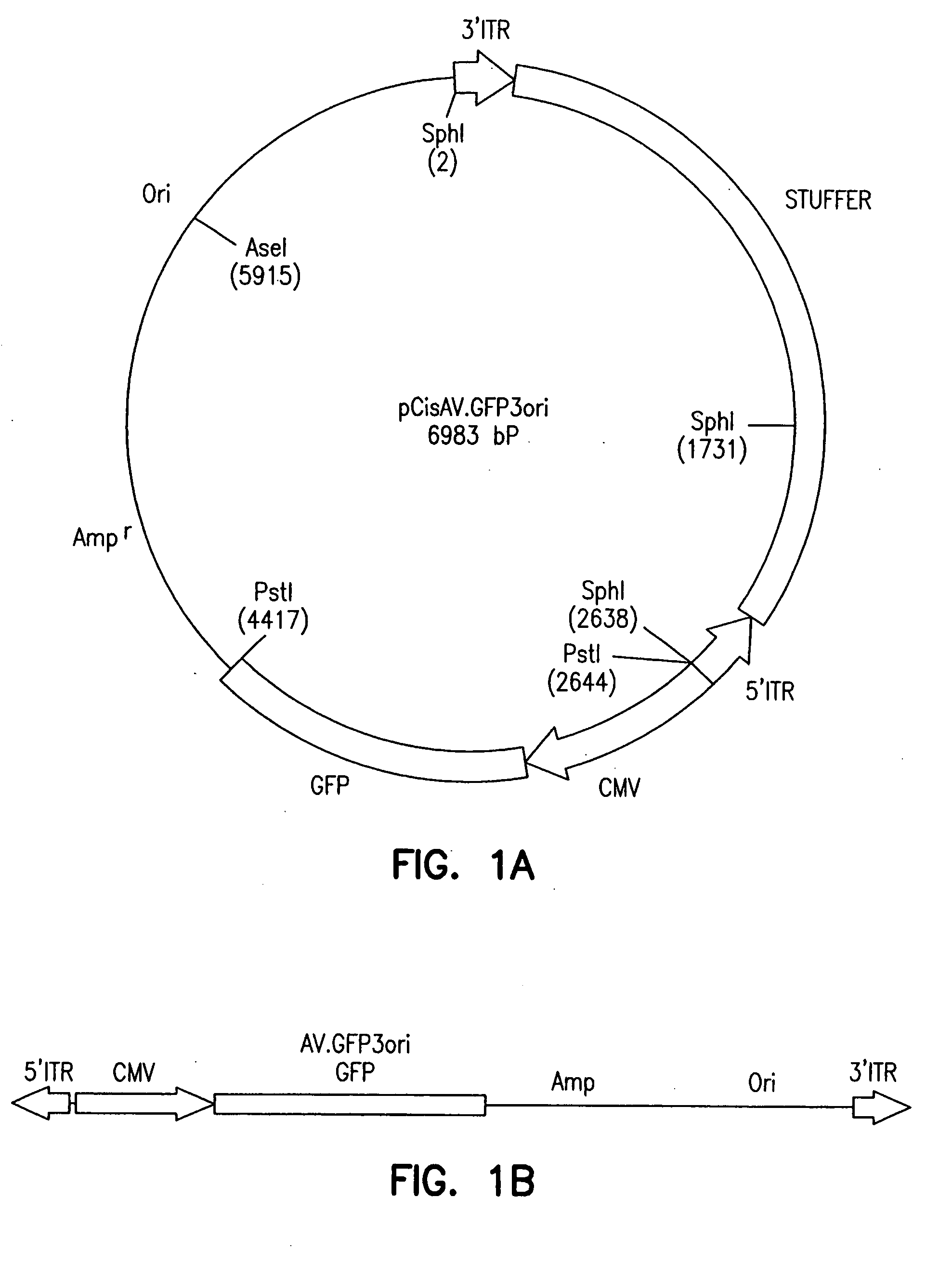

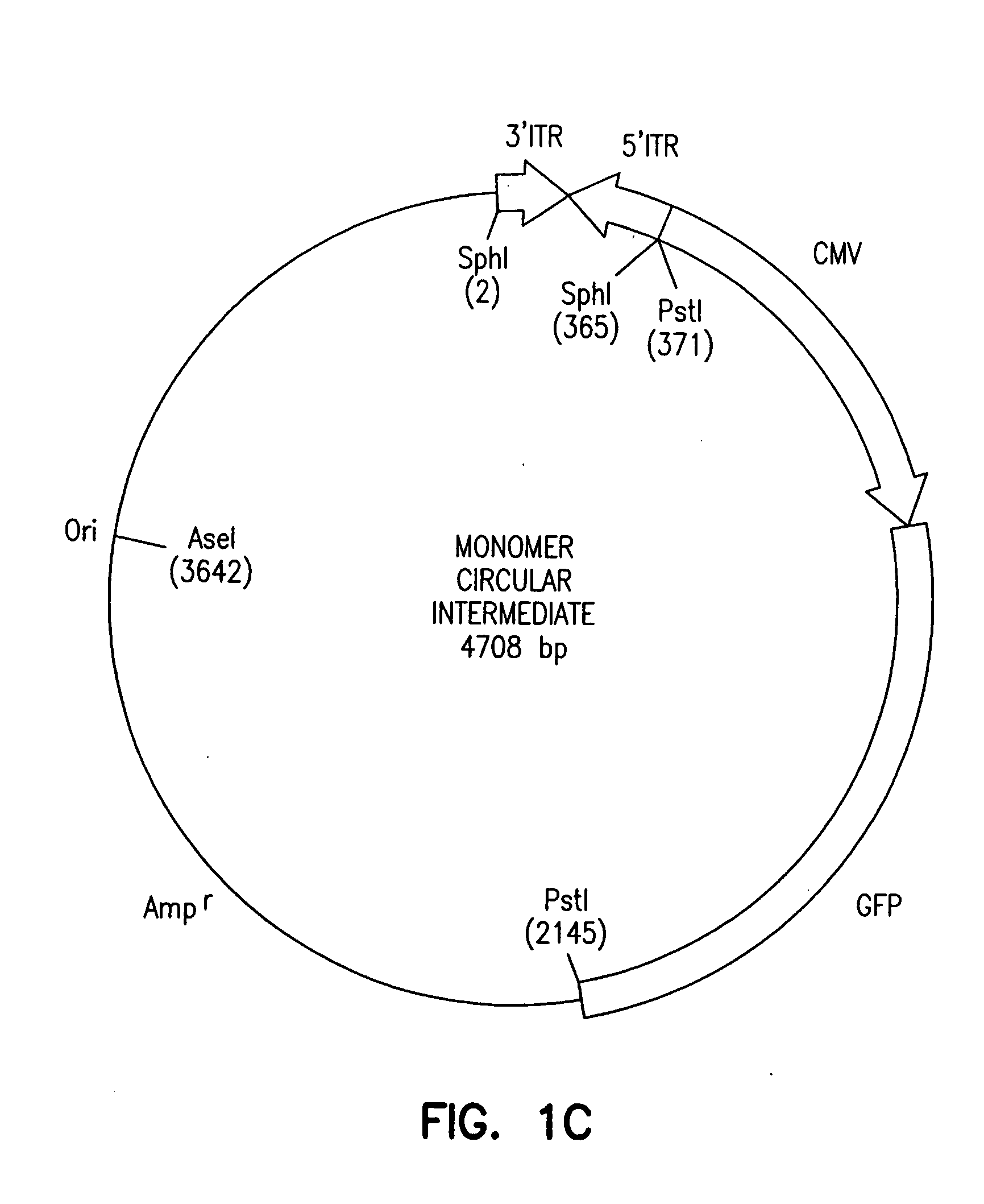

Adeno-associated virus vectors

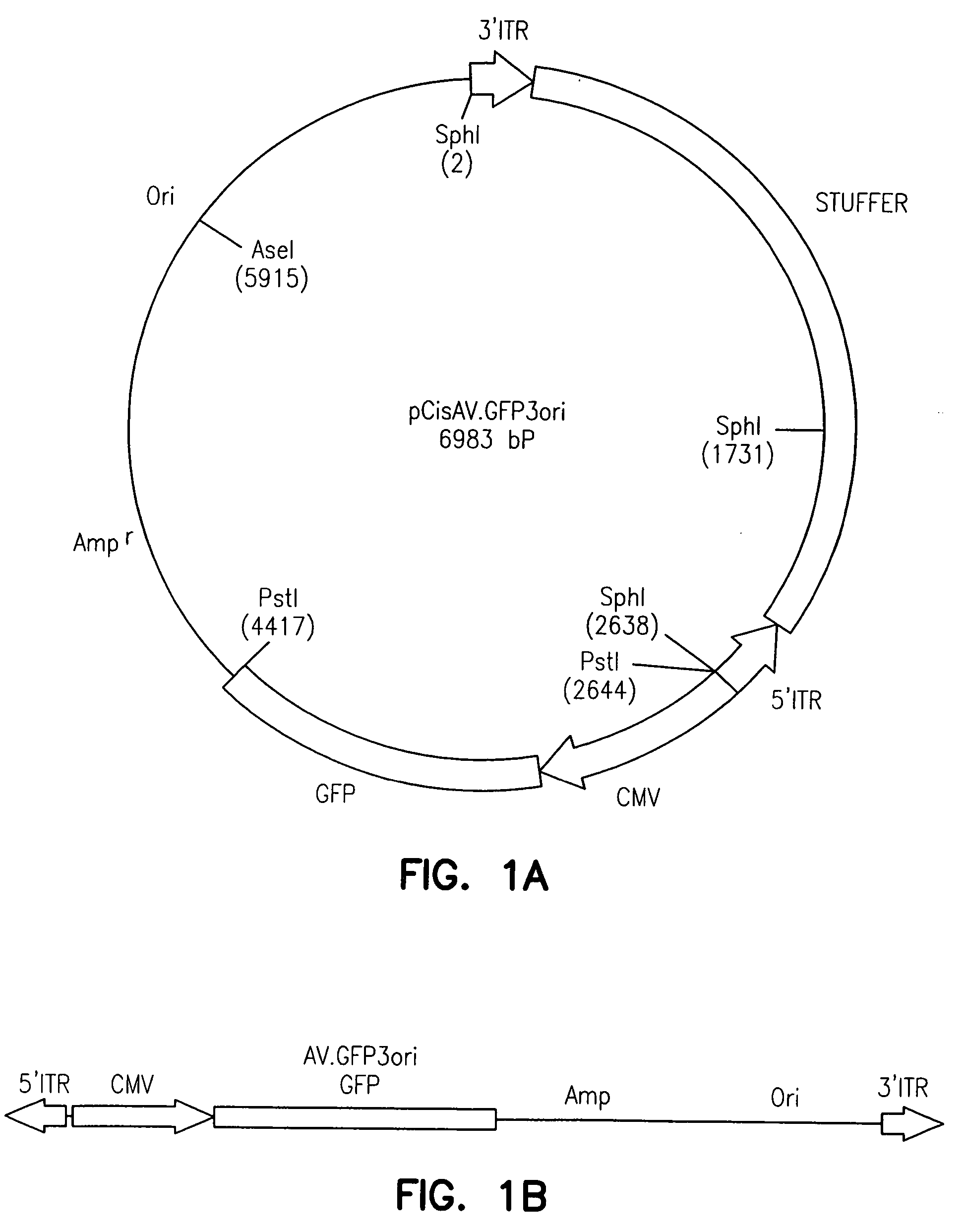

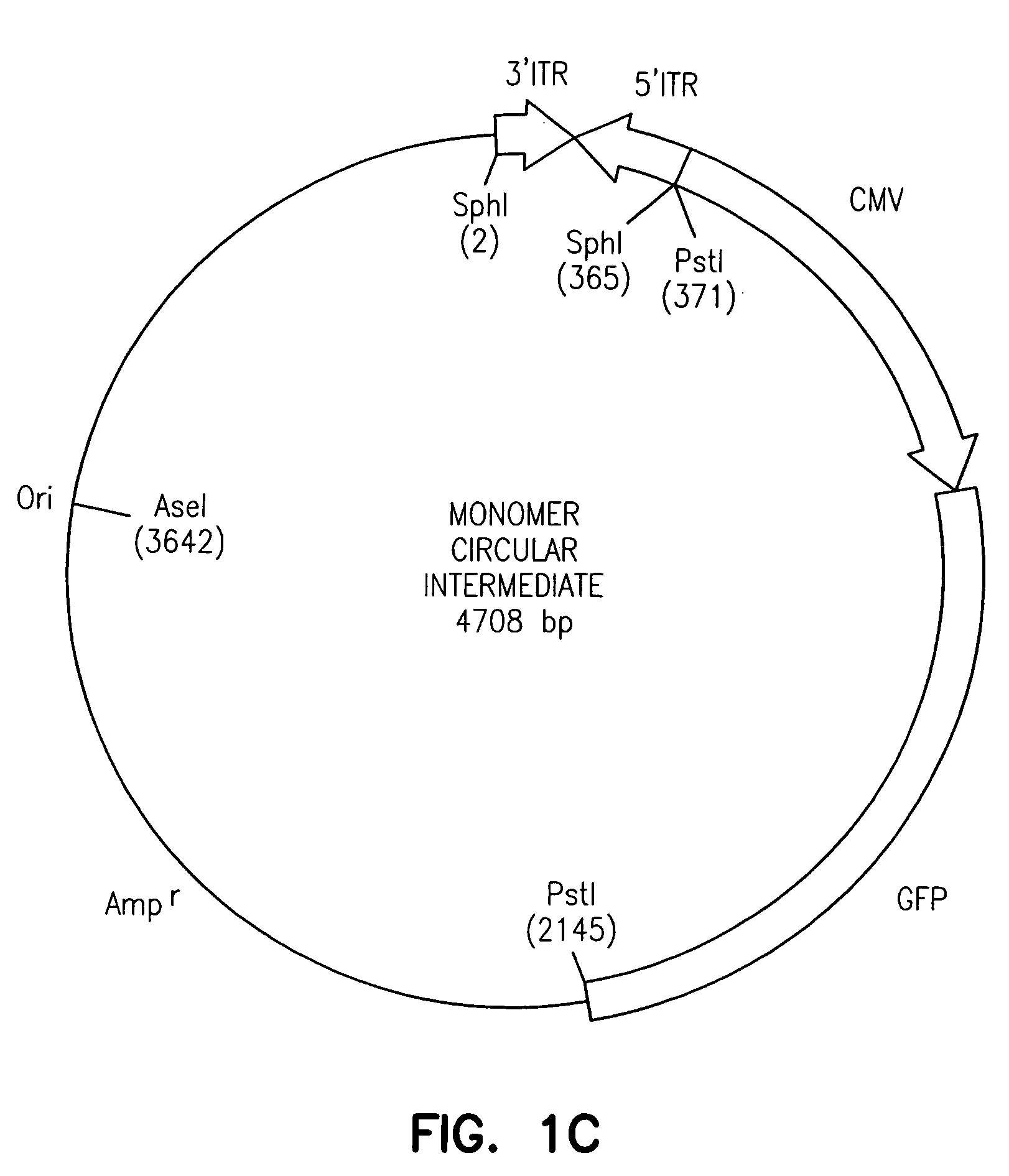

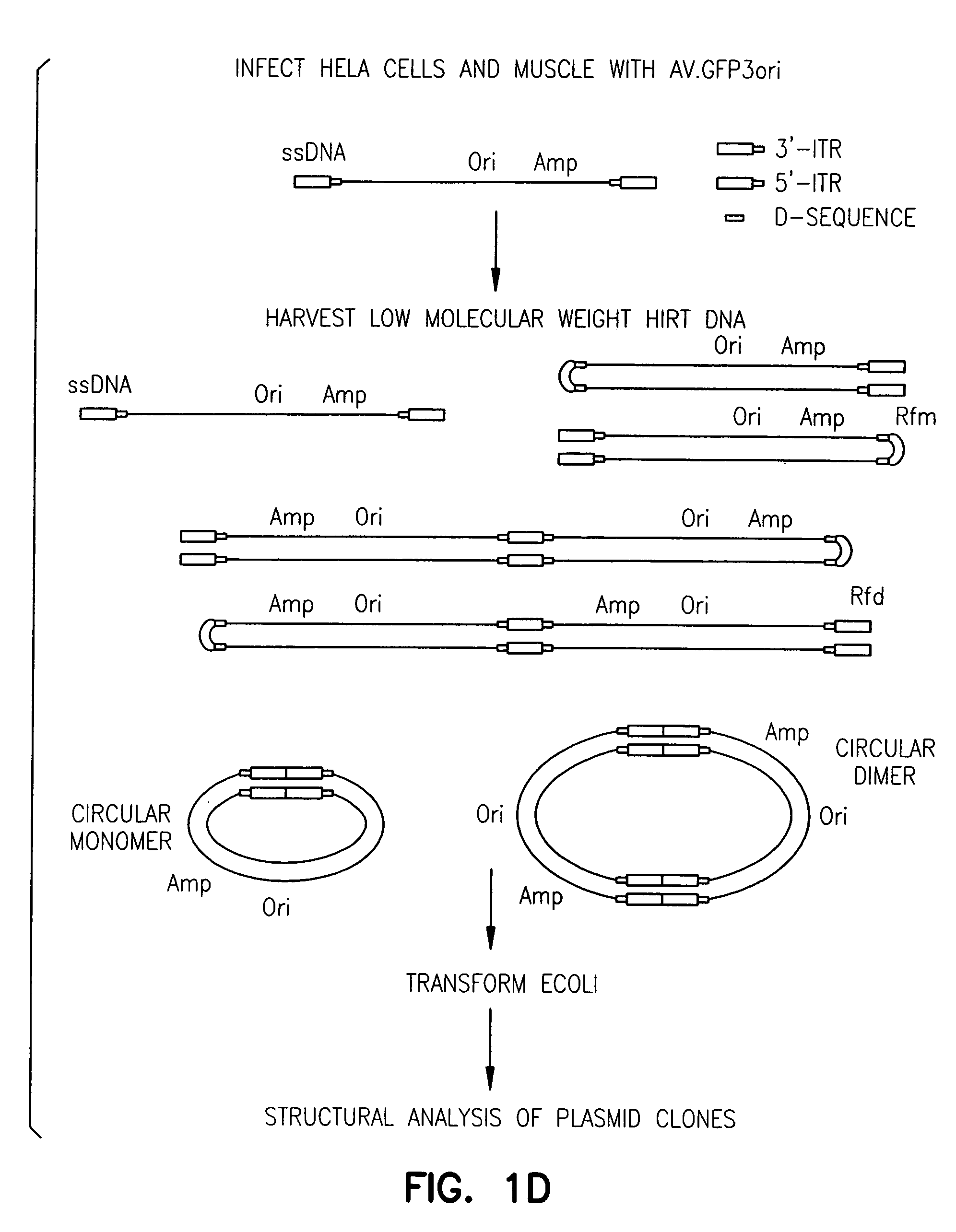

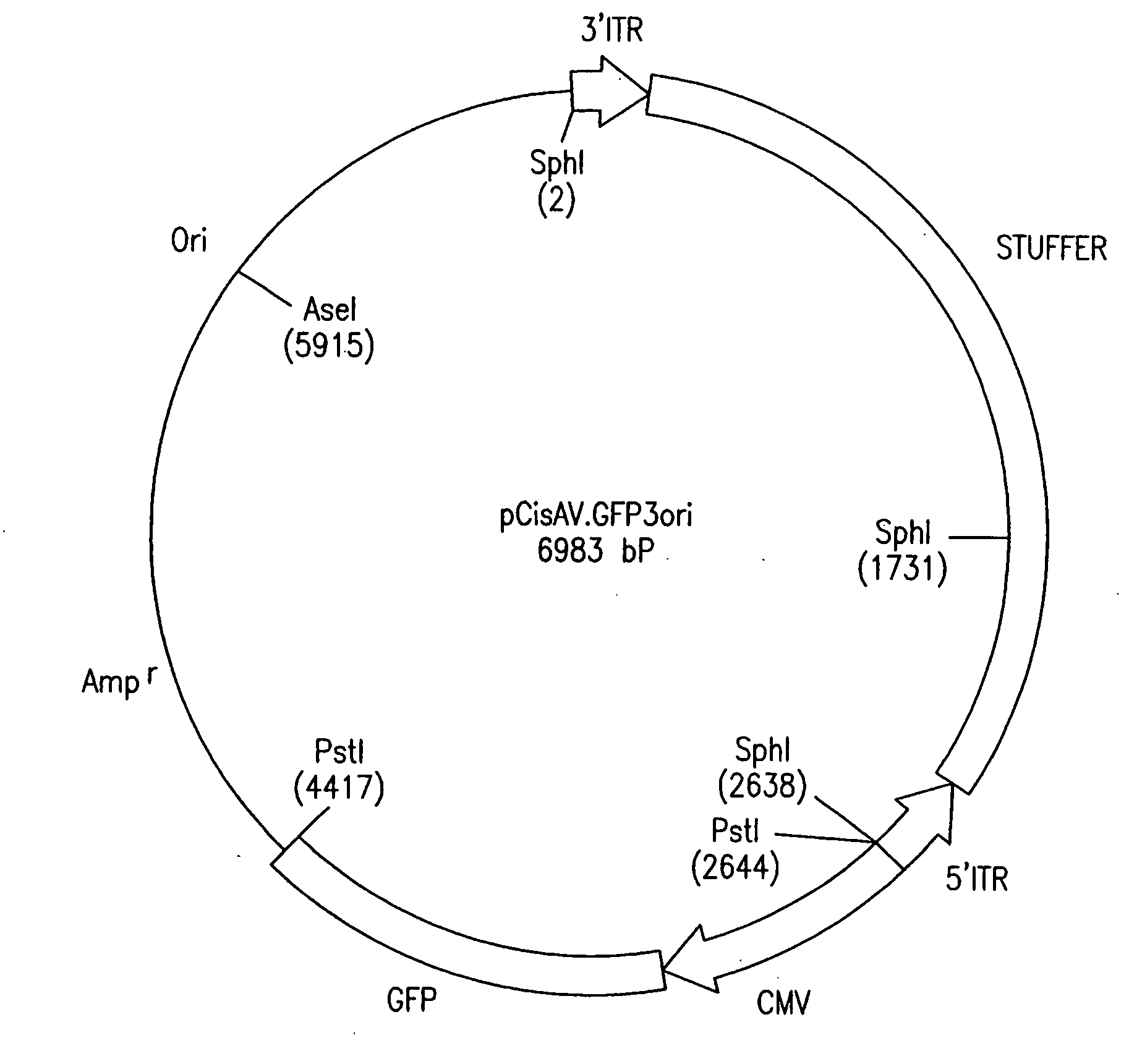

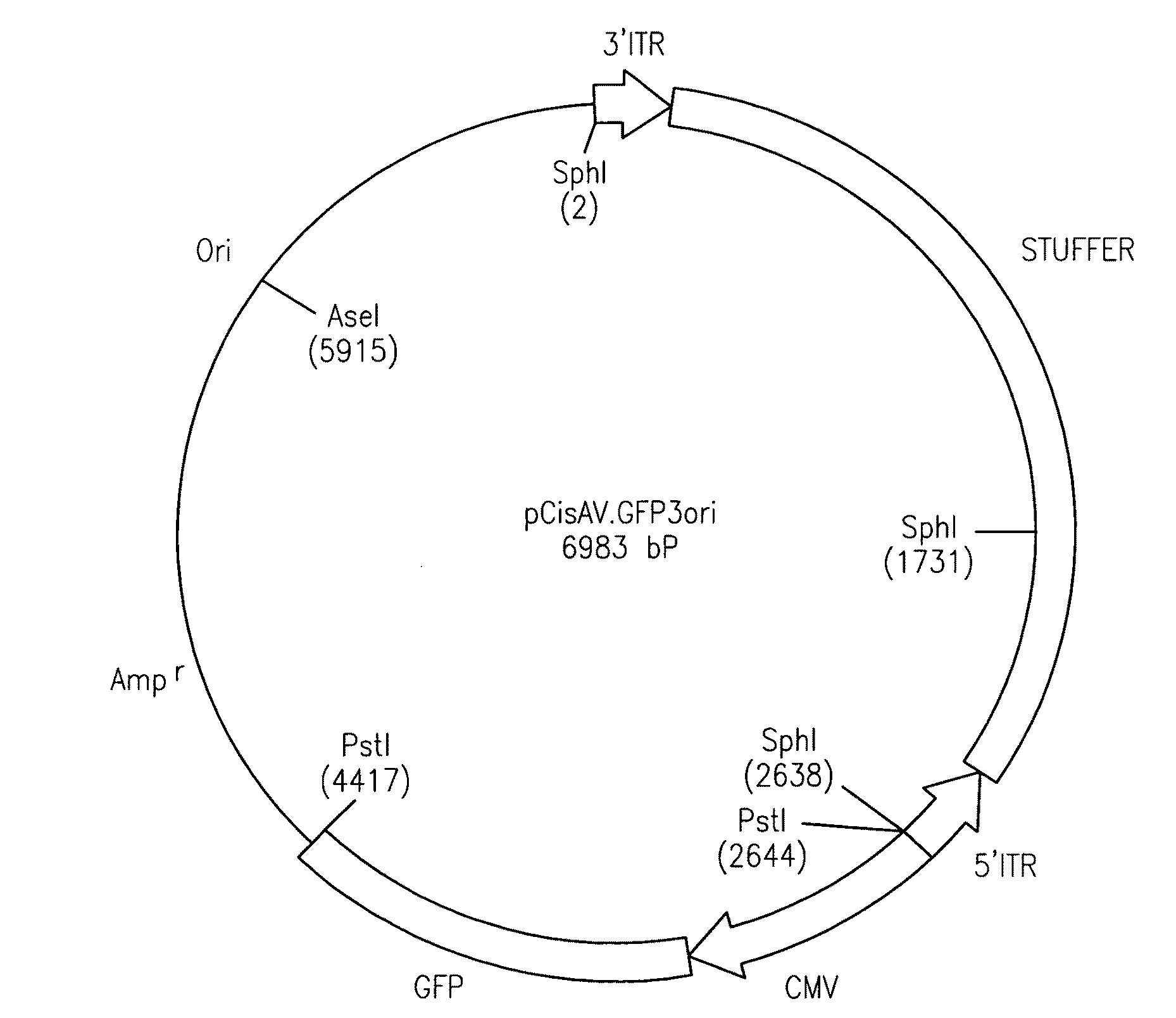

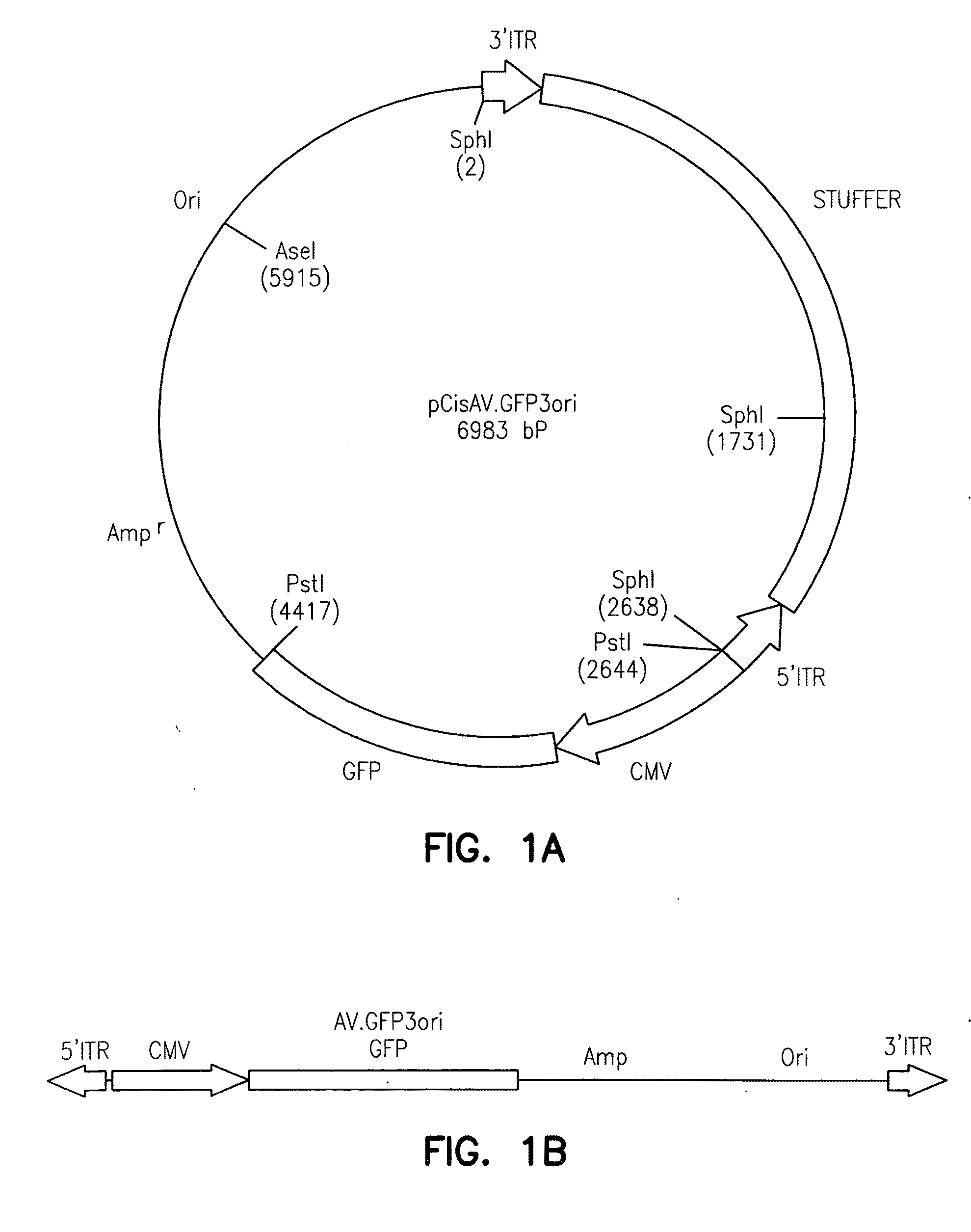

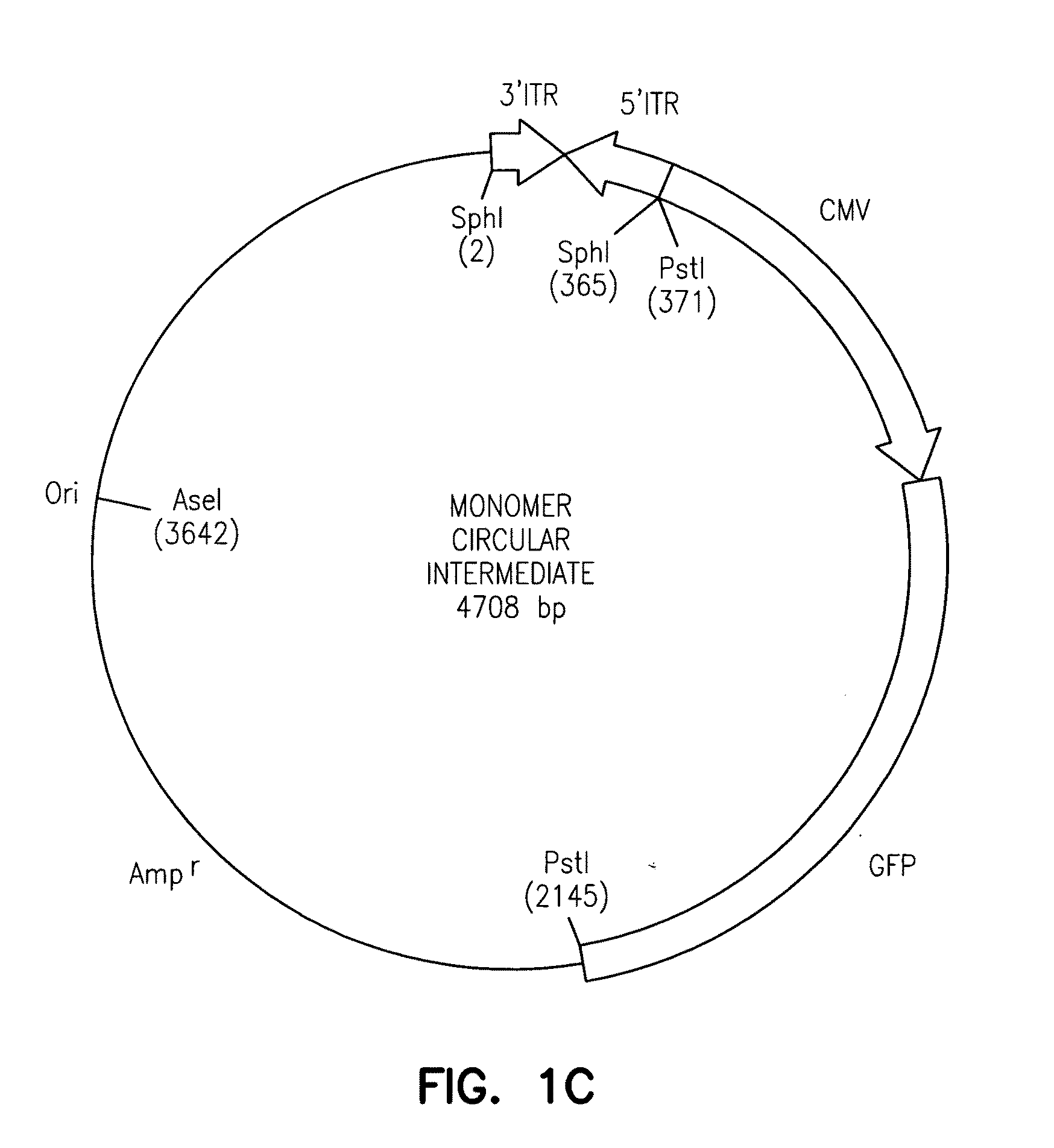

InactiveUS6897045B2Improve stabilityIncreased episomal stabilityOrganic active ingredientsBiocideVirusAdeno-associated virus

The invention provides an isolated and purified DNA molecule comprising at least one DNA segment, a biologically active subunit or variant thereof, of a circular intermediate of adeno-associated virus, which DNA segment confers increased episomal stability, persistence or abundance of the isolated DNA molecule in a host cell. The invention also provides a composition comprising at least two adeno-associated virus vectors.

Owner:UNIV OF IOWA RES FOUND

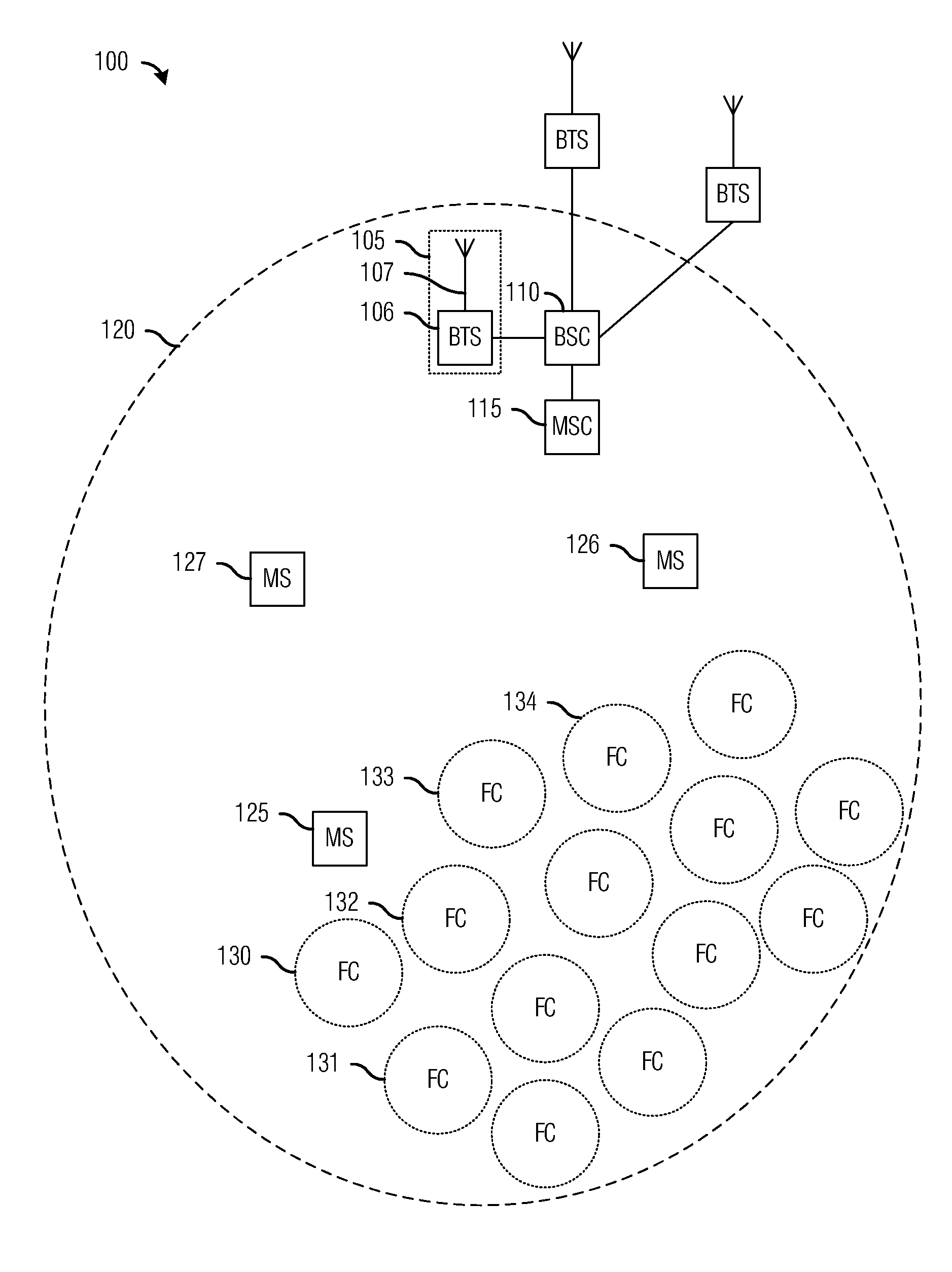

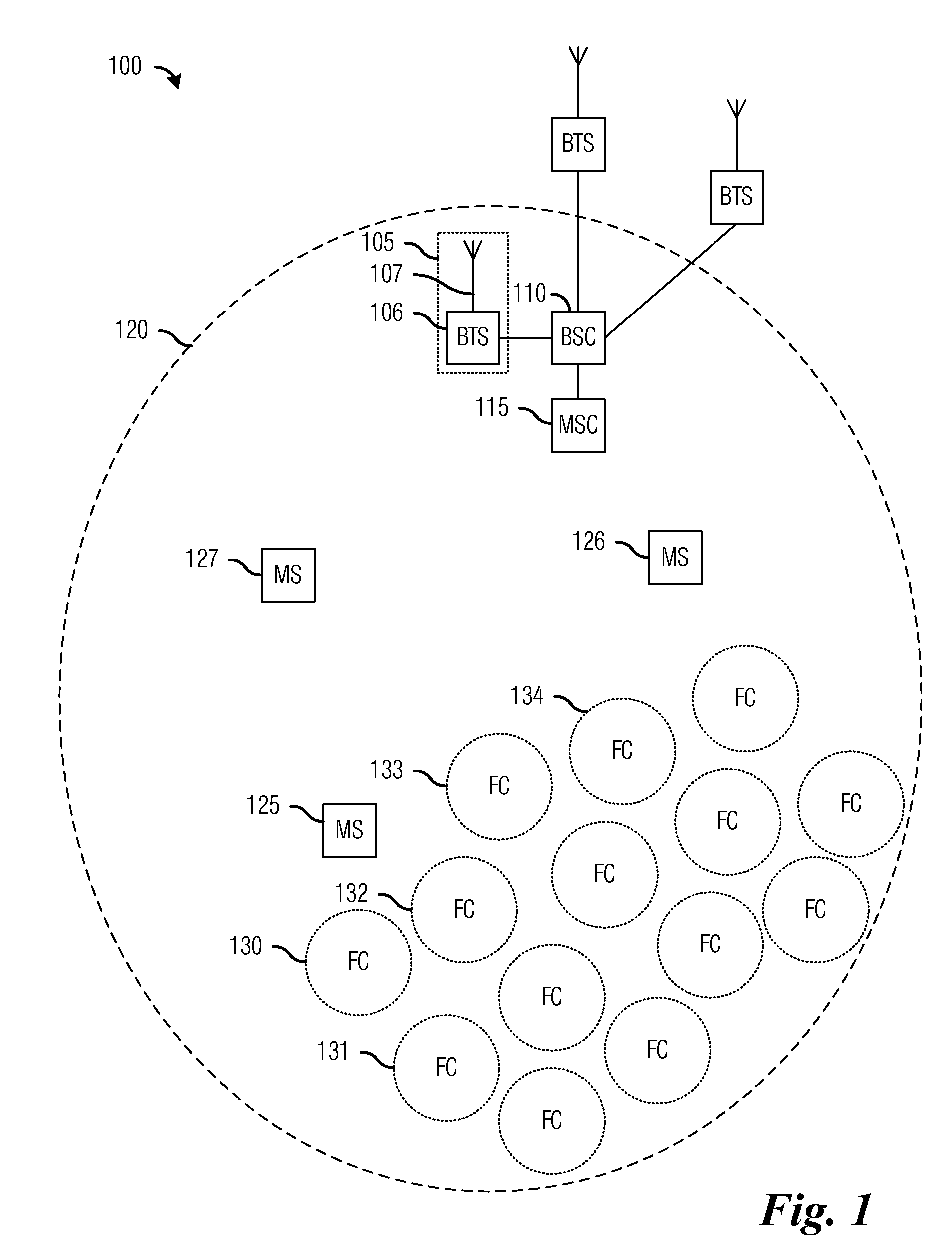

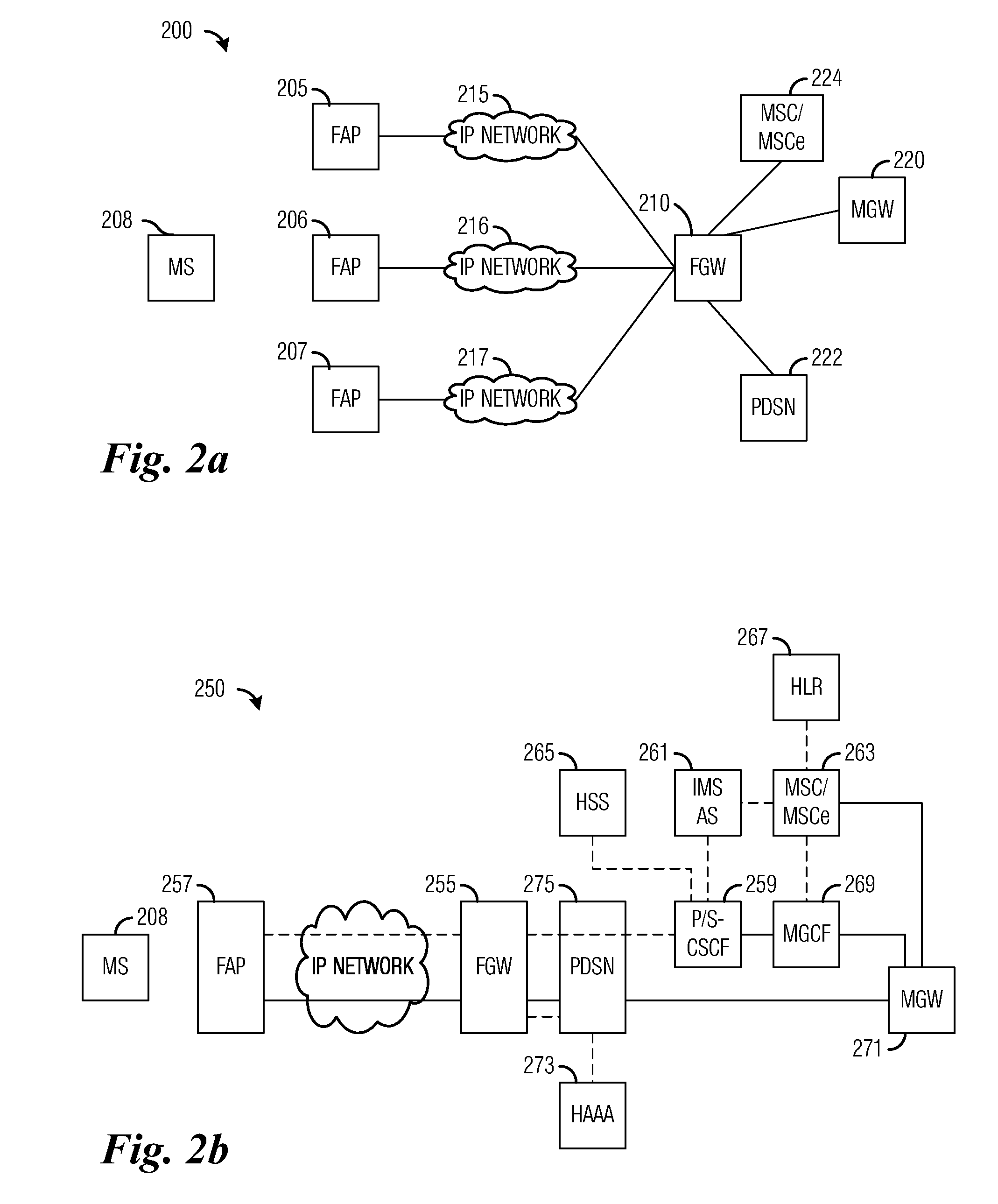

System and Method for Providing Connection Handoffs in Wireless Networks

InactiveUS20090219888A1Overcome size limitationsIncrease resourcesBroadcast service distributionWireless commuication servicesTelecommunicationsMacrocell

System and method for providing connection handoffs from macrocell to femtocell in wireless networks. A method comprises determining a group identifier from a received pseudorandom number sequence, determining a list of access points from a plurality of access points, wherein the access points in the list of access points are all identified by a group identifier, transmitting a request for detecting an identifier of the communications device to each access point in the list of access points, receiving a positive acknowledgement from a locating access point in the list of access points, and locating the communications device in a coverage area of the locating access point. The acknowledgement indicates that the locating access point successfully detected the identifier.

Owner:FUTUREWEI TECH INC

Adeno-associated virus vectors and uses thereof

InactiveUS7241447B1Improve stabilityIncreased episomal stabilityBiocideViral antigen ingredientsAdeno associate virusAdeno-associated virus

The invention provides an isolated and purified DNA molecule comprising at least one DNA segment, a biologically active subunit or variant thereof, of a circular intermediate of adeno-associated virus, which DNA segment confers increased episomal stability, persistence or abundance of the isolated DNA molecule in a host cell. The invention also provides a composition comprising at least two adeno-associated virus vectors.

Owner:RES FOUND UNIV OF IOWA

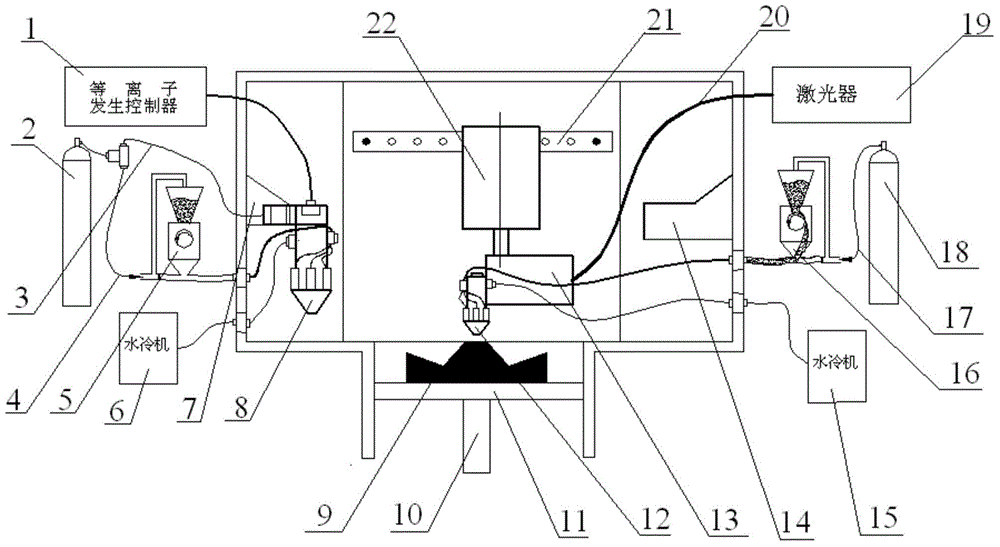

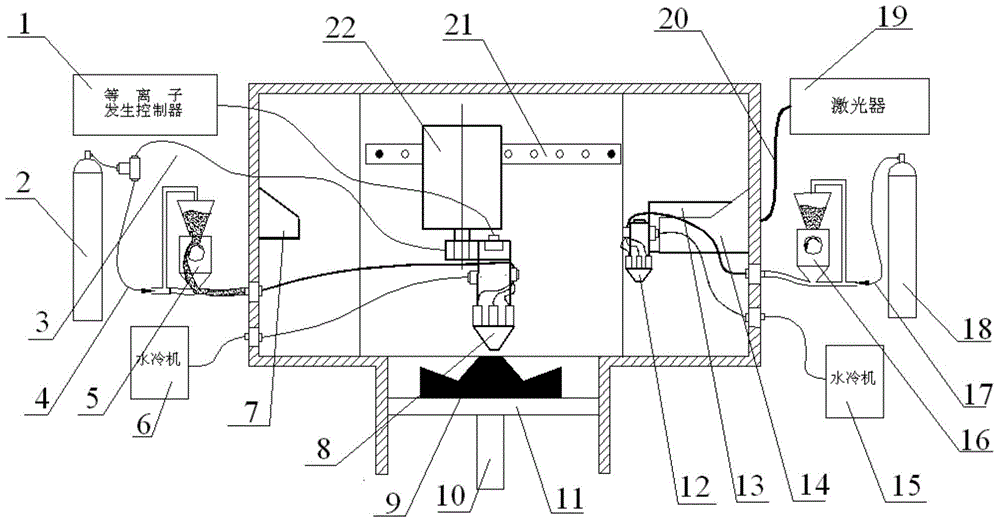

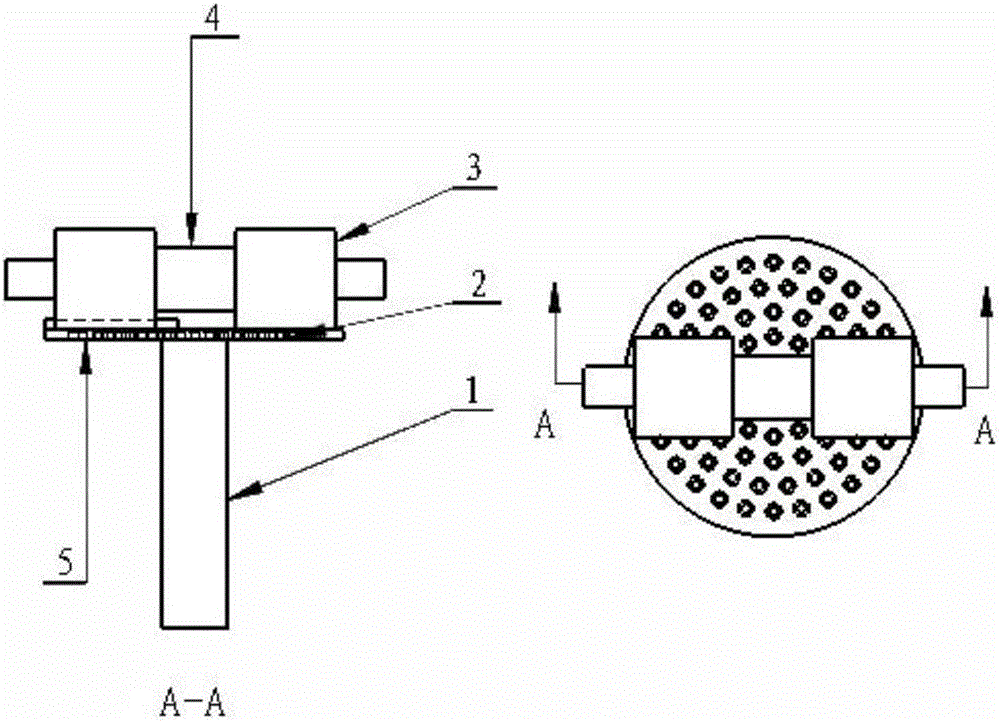

Laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method

ActiveCN104801712ASolve efficiency problemsSolve the accuracy problemAdditive manufacturing apparatusNumerical controlControl system

The invention discloses a laser and microbeam plasma composite 3D (3-dimensional) printing equipment and method. The equipment comprises a central control system, a sealing forming chamber, a laser forming device and a plasma processing device, wherein a laser forming spray head and a plasma gun are correspondingly put on a support frame arranged at the left and right side inner walls of the sealing forming chamber, and the laser forming spray head or the plasma gun is clamped through a co-work numerical control main shaft, so that the laser forming spray head or the plasma gun moves in the Z, X and Y directions in the sealing forming chamber. The central control system controls the co-work numerical control main shaft for conveying back the laser forming spray head back to the support frame, then, the co-work numerical control main shaft clamps the plasma gun for filling the inside of the profile of a formed metal part, and the work is alternately carried out in such a way until the part manufacturing is completed, so that the scanning time is reduced to a great degree. The laser fast forming is combined with the plasma, the problem of conflict between the efficiency and the precision of a metal 3D printing technology is solved, and in addition, the plasma is adopted for replacing the laser to be used as a heat source, so that the high-efficiency and low-cost industrial level metal 3D printing equipment is obtained.

Owner:SOUTH CHINA UNIV OF TECH

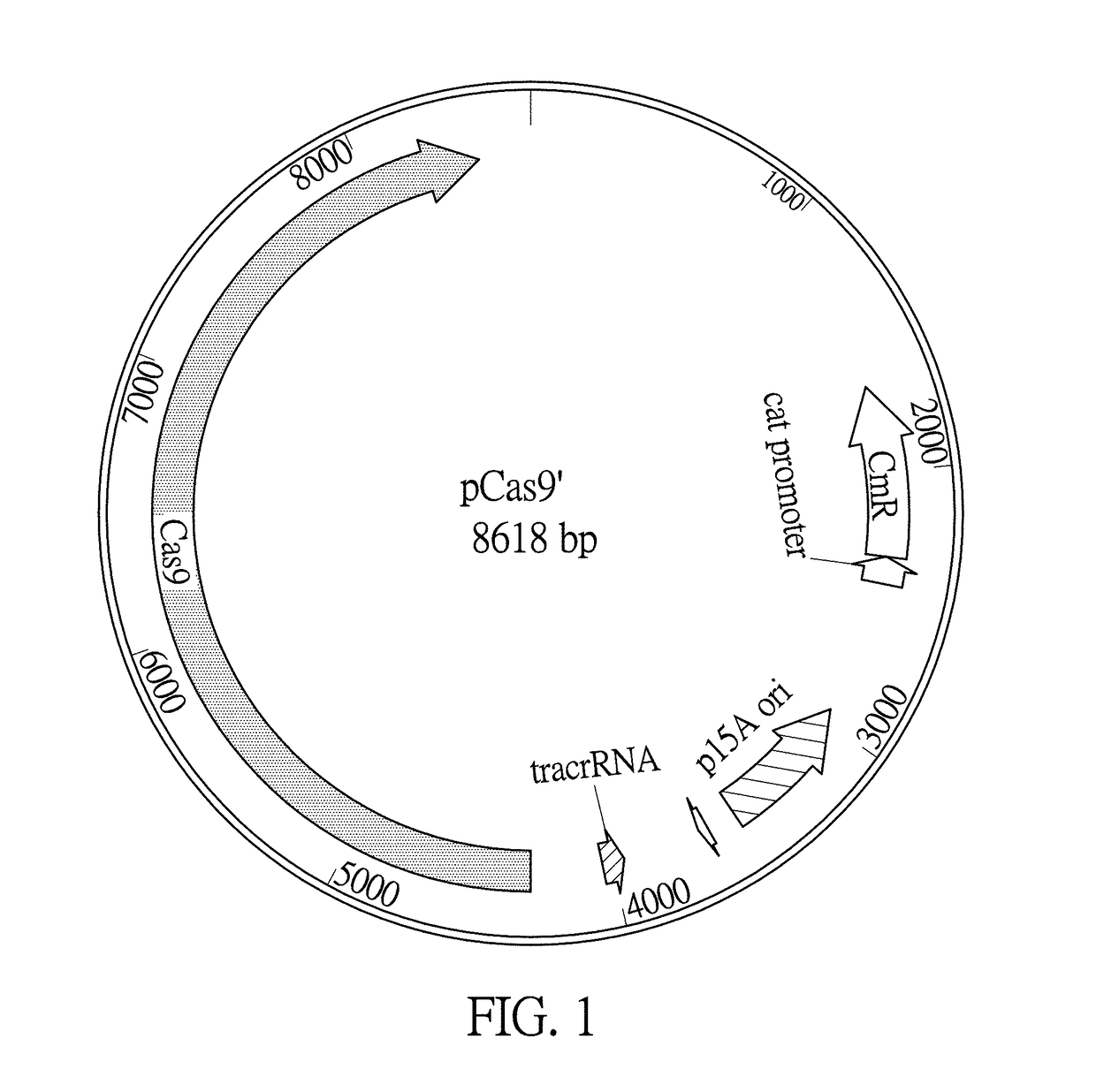

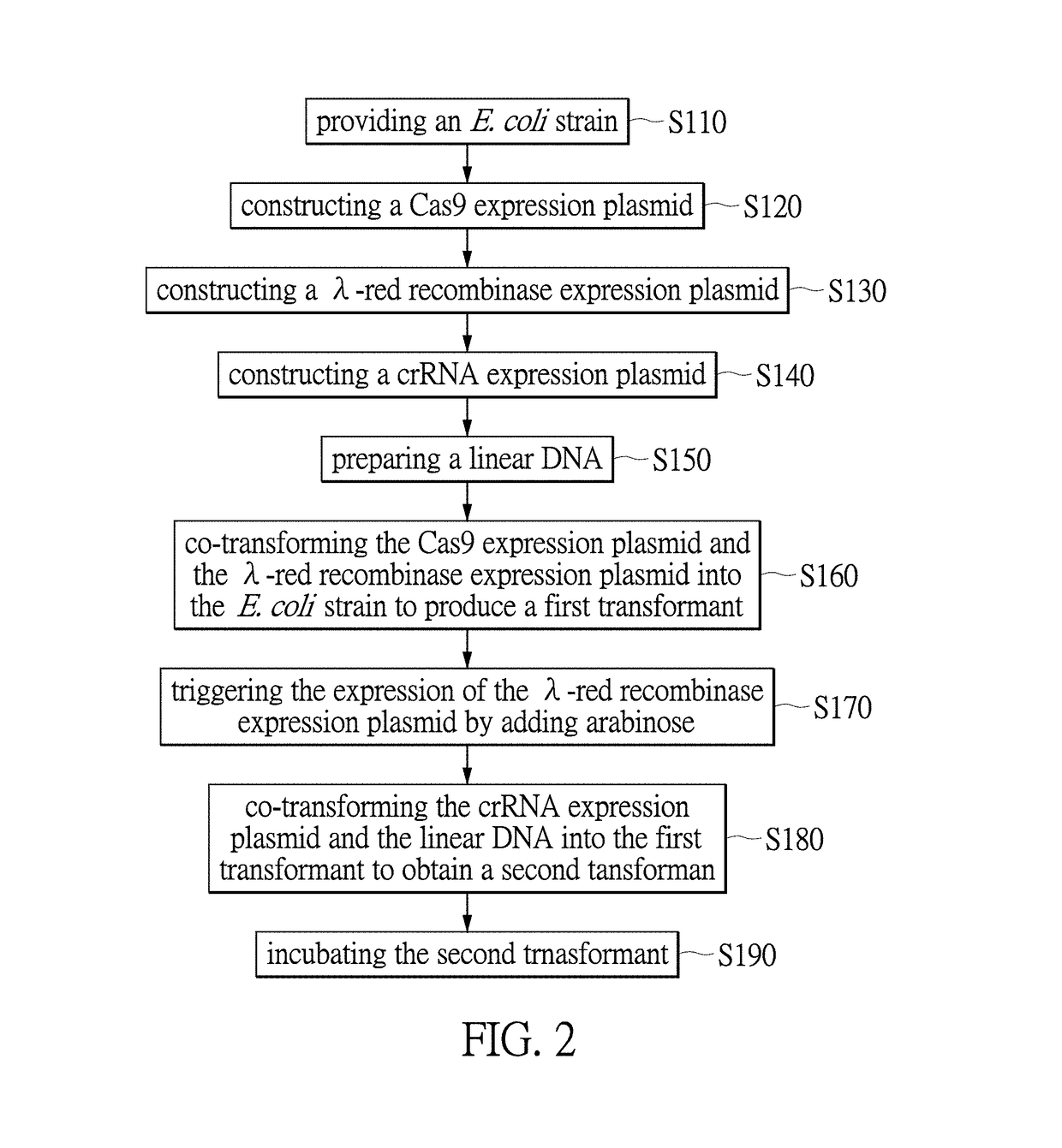

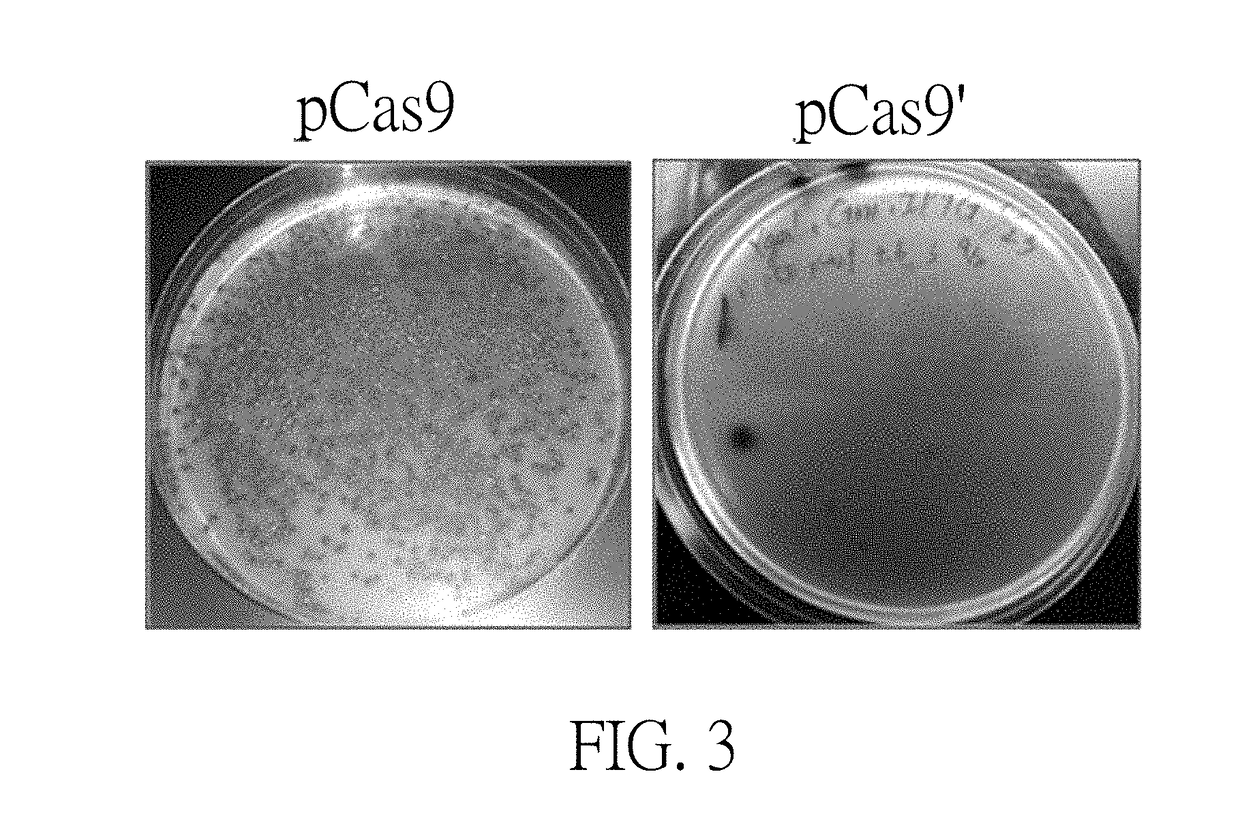

Cas9 plasmid, genome editing system and method of escherichia coli

ActiveUS20170226522A1Improve efficiencyImprove fidelityHydrolasesStable introduction of DNAEscherichia coliGenome editing

A Cas9 expression plasmid, a genome editing system and a genome editing method for Escherichia coli are provided. The Cas9 expression plasmid includes a tracrRNA sequence, a Cas9 gene and a chloramphenicol resistance gene (CmR). The Cas9 expression plasmid is applied to CRISPR / Cas-coulped λ-red recombineering system for editing genomes of E. coli with high efficiency.

Owner:NATIONAL TSING HUA UNIVERSITY

Adeno-associated virus vectors with intravector heterologous terminal palindromic sequences

InactiveUS8241622B2Increased yieldReduce capacityAntibacterial agentsBiocideAdeno-associated virusVirology

The invention provides recombinant AAV vectors, at least one of which has heterologous terminal palindromic sequences, and methods of using those vectors.

Owner:UNIV OF IOWA RES FOUND

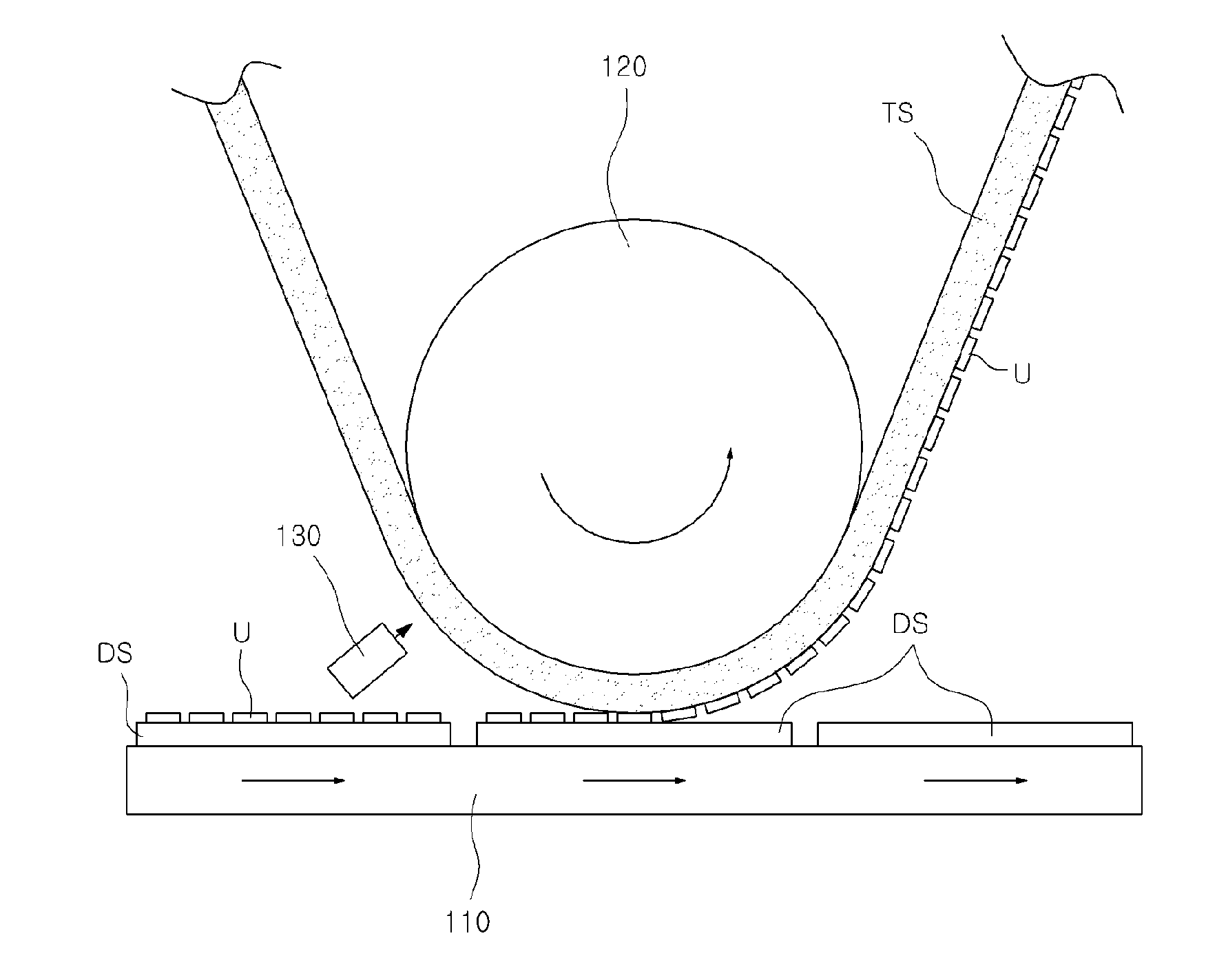

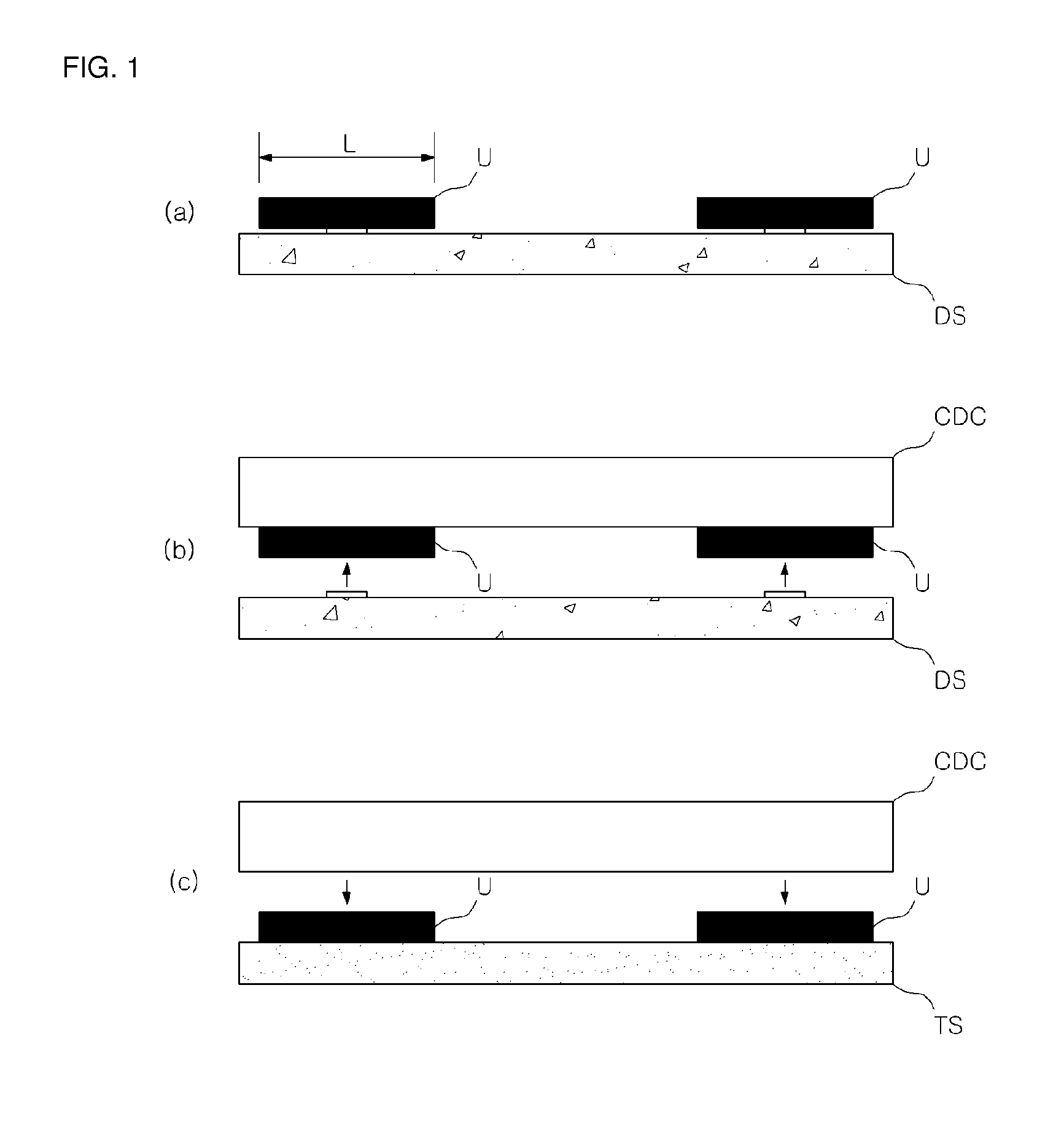

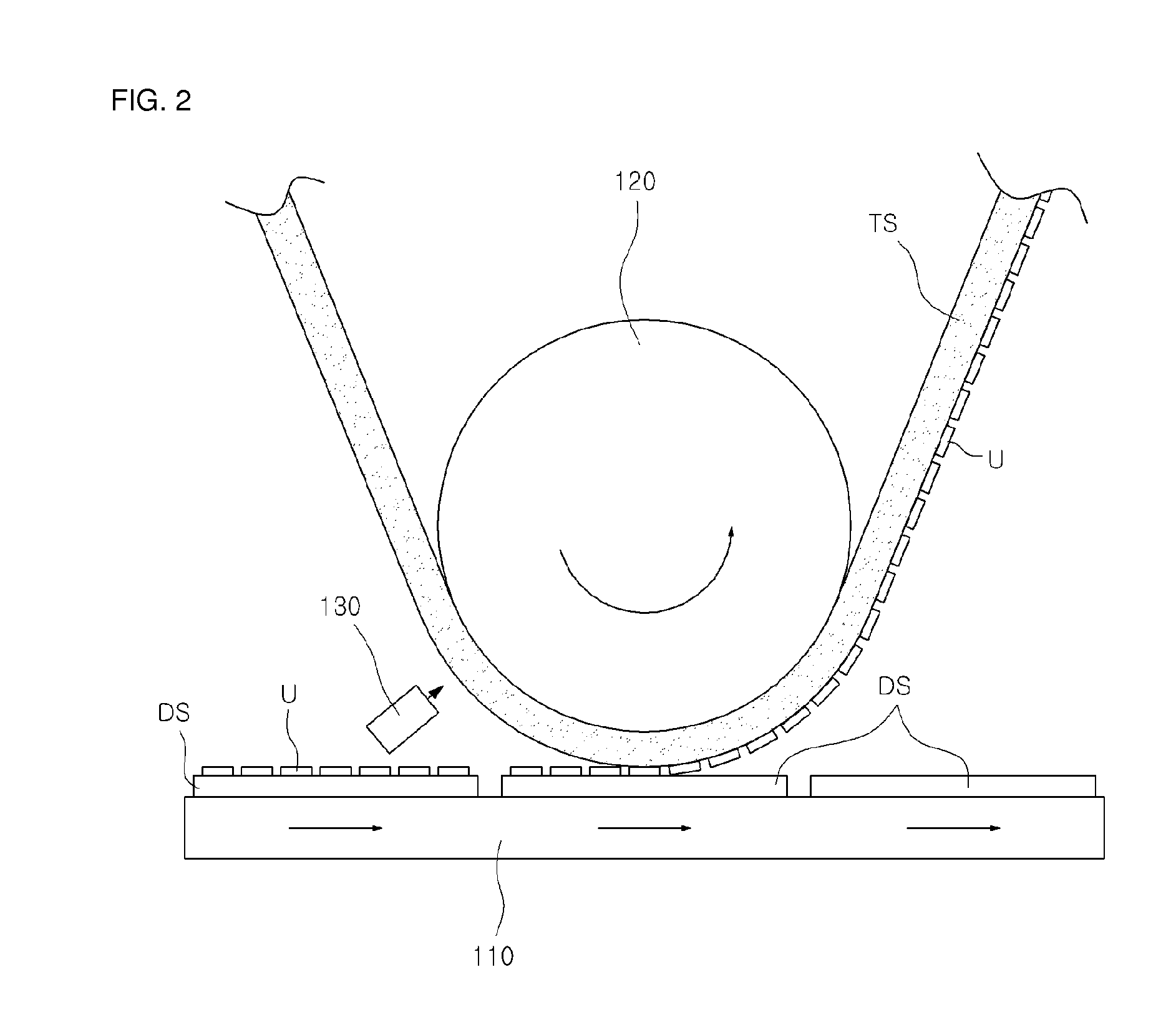

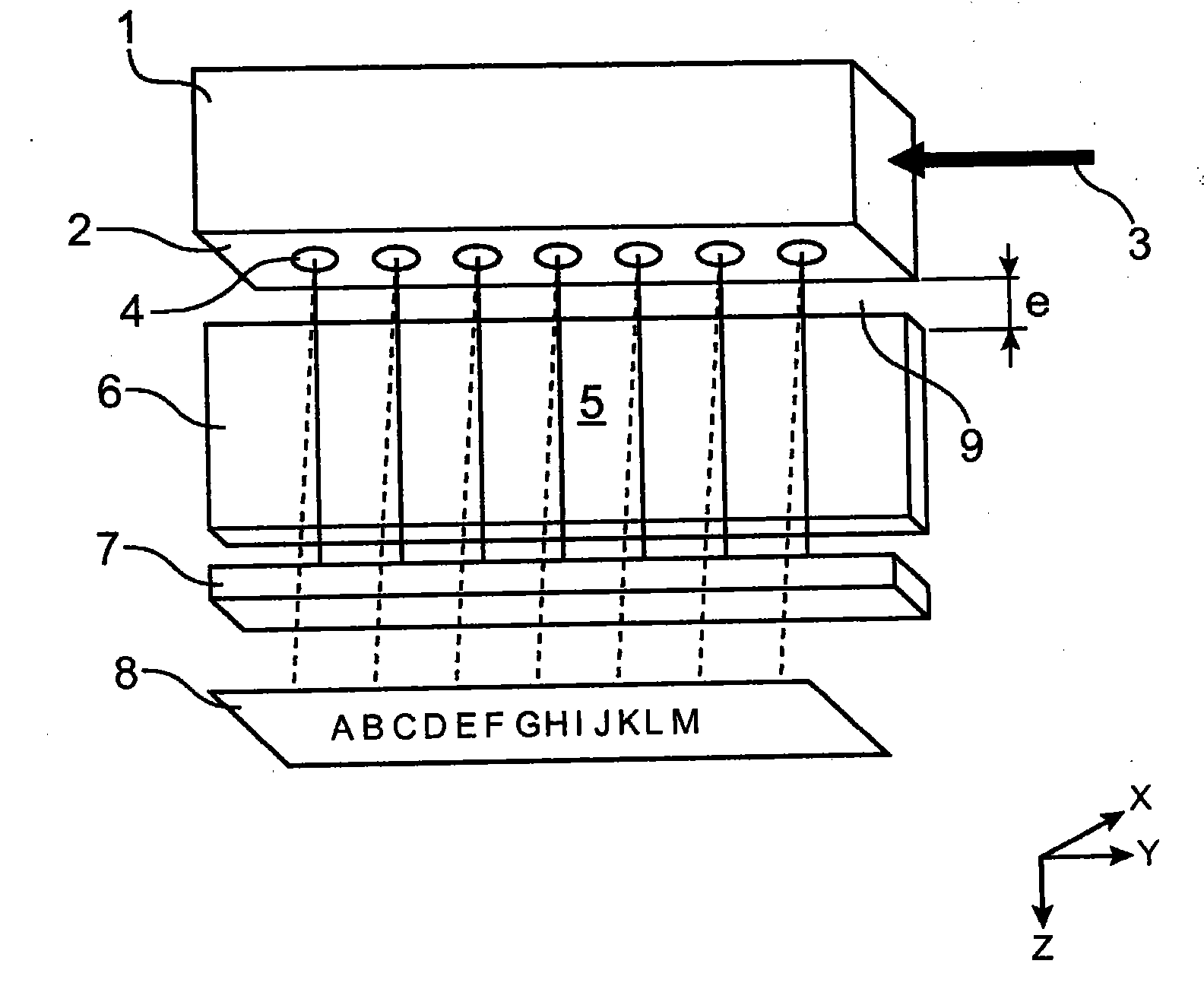

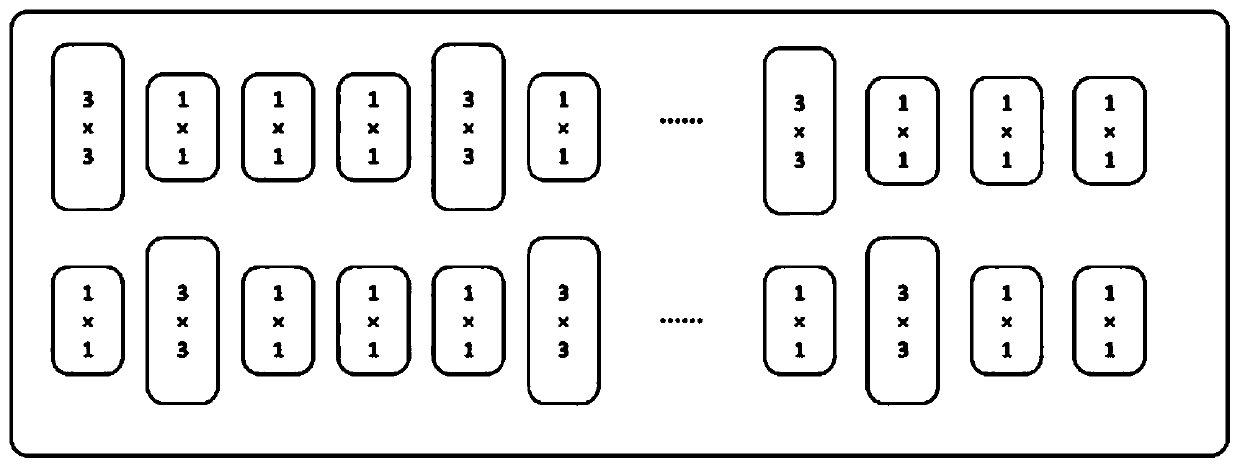

Apparatus for manufacturing a hierarchical structure

ActiveUS20120118506A1Improve performanceProcessing speed deterioratesMechanical working/deformationSolid-state devicesLayered structureElectrical and Electronics engineering

Owner:KOREA INST OF MASCH & MATERIALS

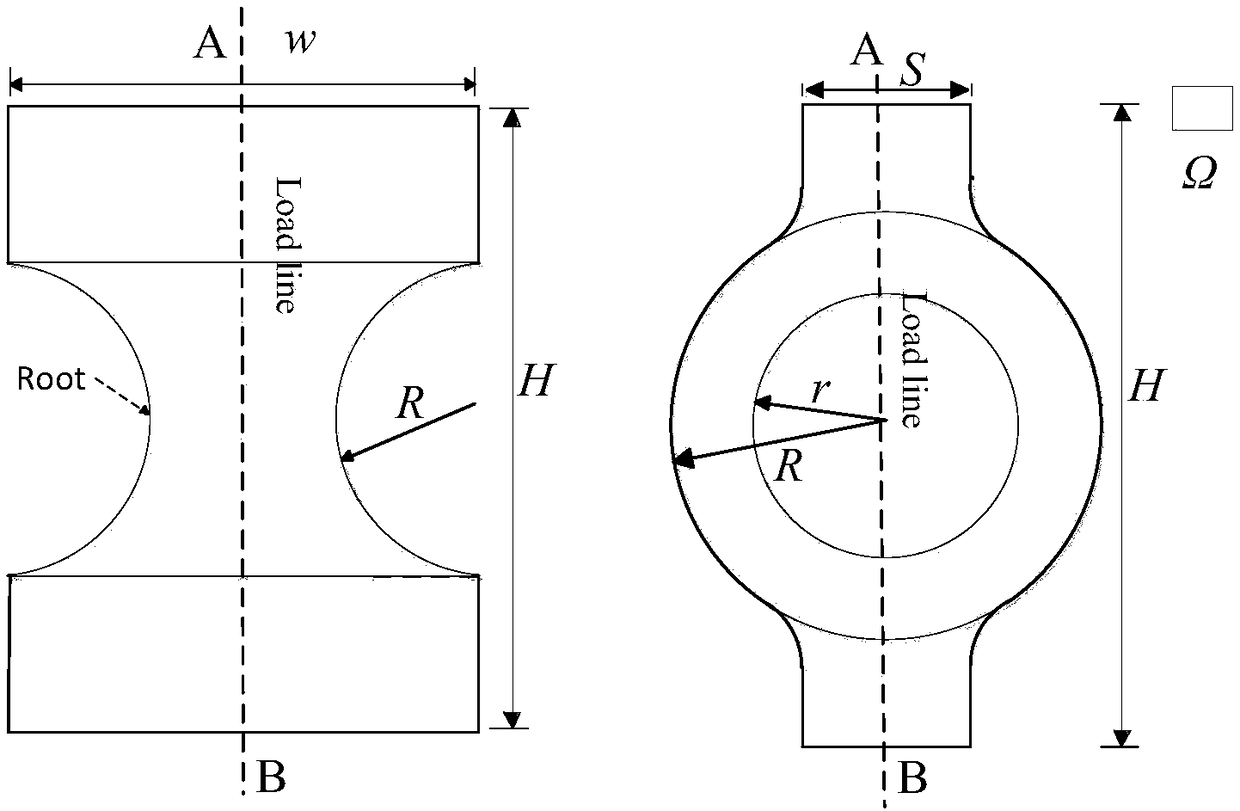

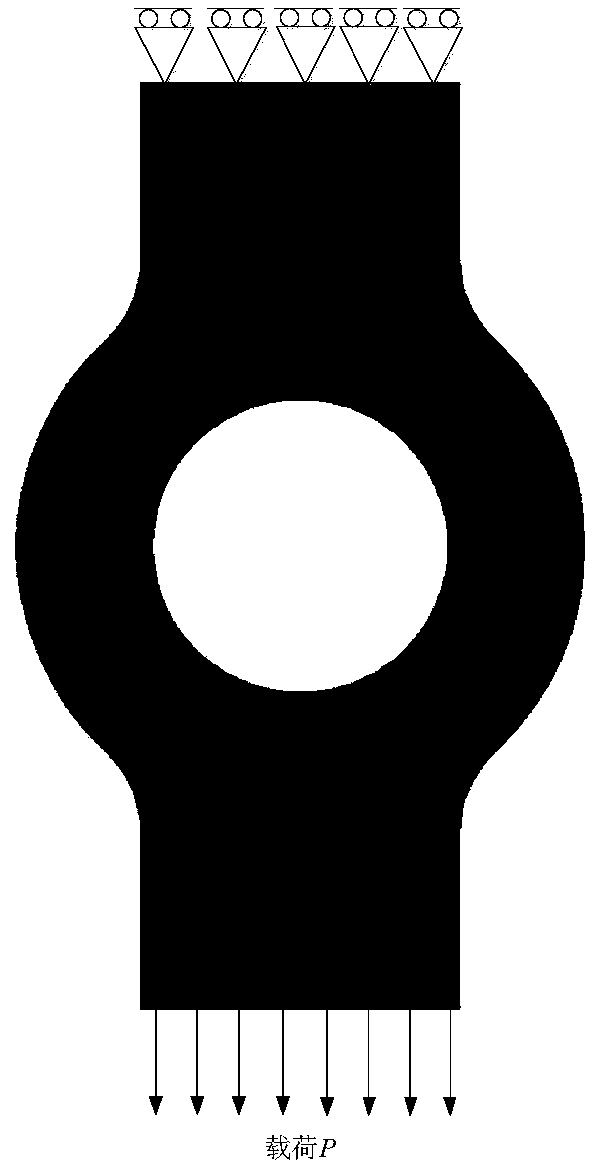

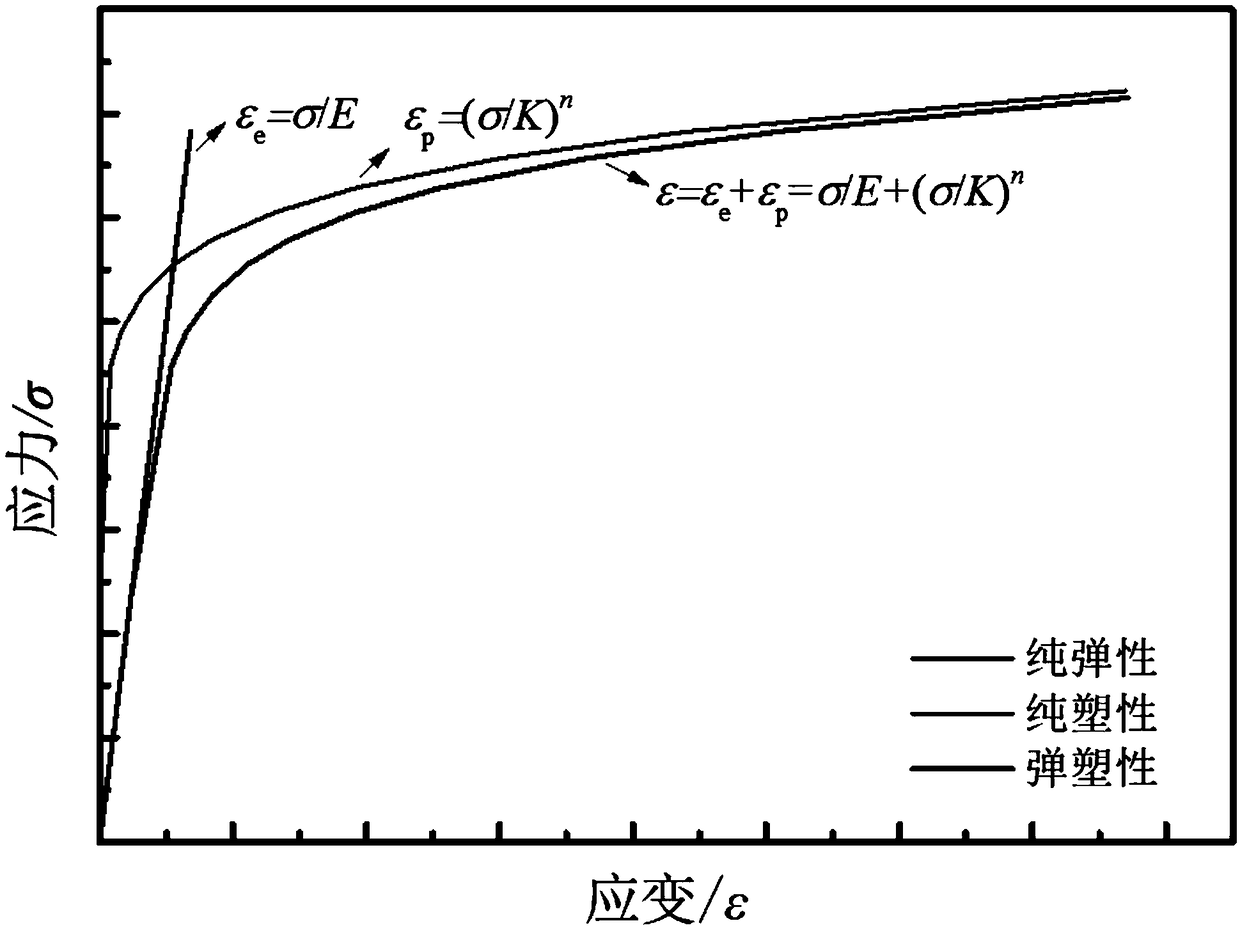

Material fatigue performance obtaining method for sheet sample

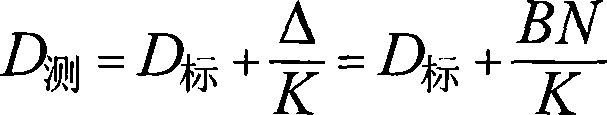

ActiveCN108693055AOvercome size limitationsMaterial strength using repeated/pulsating forcesHysteresisRamberg osgood

The invention discloses a material fatigue performance obtaining method for a sheet sample, which comprises the following steps: step 1: completing a tension-pressure symmetric cyclic loading test ofa multi-stage strain amplitude for the sheet sample under strain control to obtain a cyclic stable load-displacement curve; step 2: connecting load-displacement curve hysteresis loop tips as the cyclic load-displacement curve, and predicting a cyclic stress-strain relationship in accordance with a Ramberg-Osgood constitutive model with a cyclic load-displacement relationship; step 3: establishinga relationship between a true strain amplitude epsilon r, a stress amplitude sigma r and a measured and controlled strain amplitude epsilon eq of a fatigue source RVE by using the cyclic stress-strainrelationship as a material parameter; step 4: establishing a fatigue life estimation model according to epsilon r and sigma r to obtain the fatigue property of the material. According to the materialfatigue performance obtaining method, the material dimension limitations of the traditional fatigue performance test method are overcome, and the method does not rely on empirical formulas, and is applied to different materials and sample configurations.

Owner:SOUTHWEST JIAOTONG UNIV

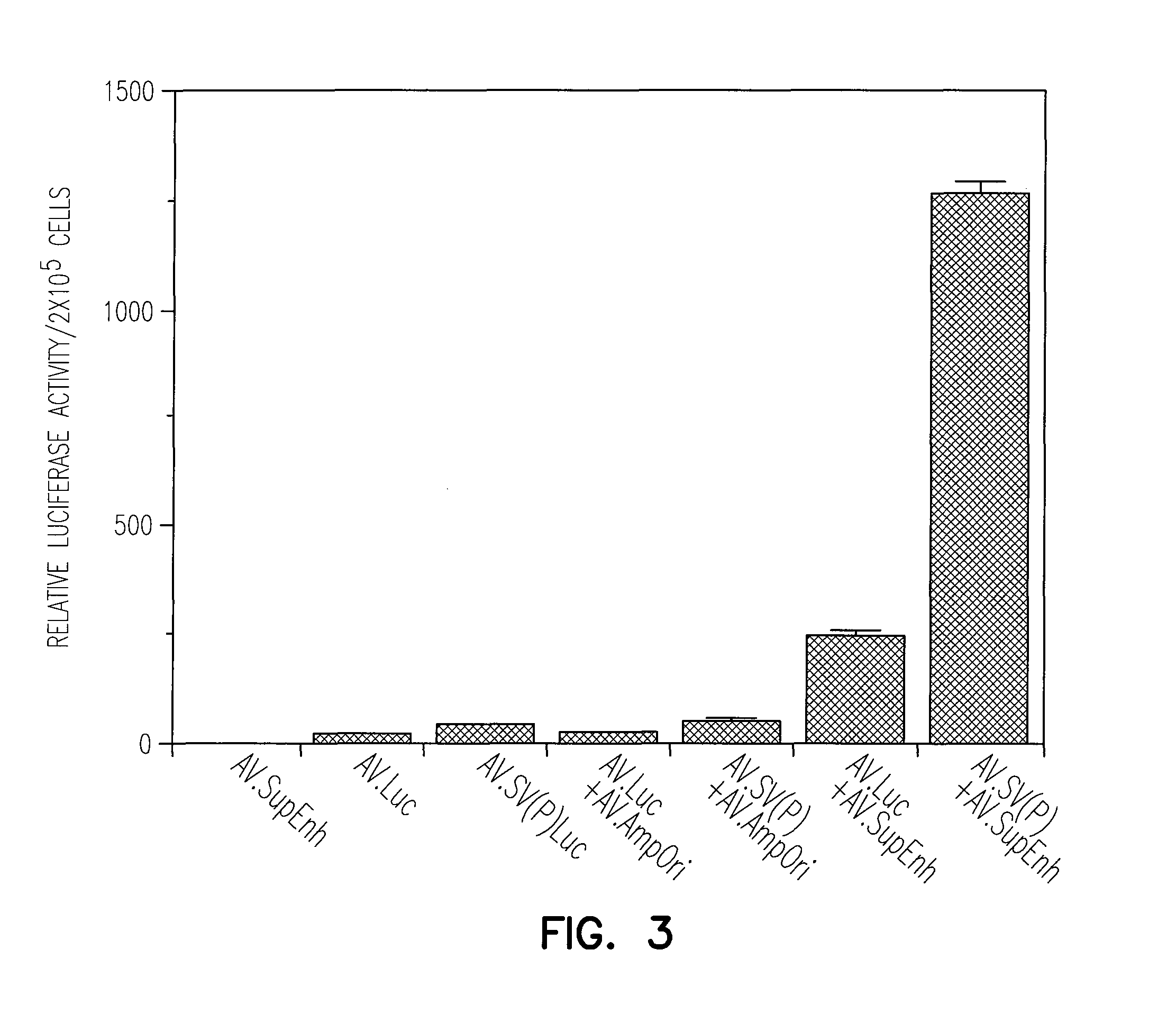

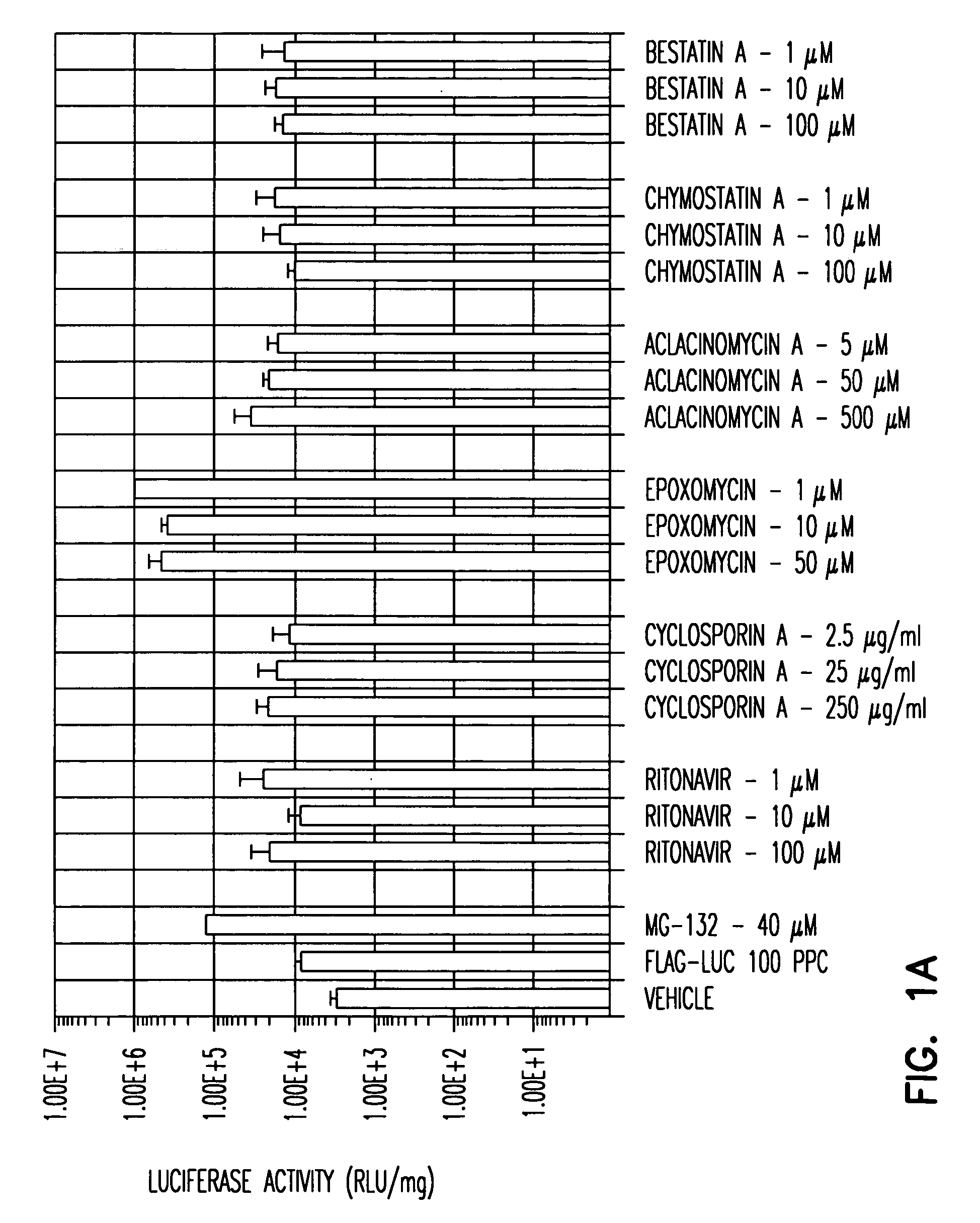

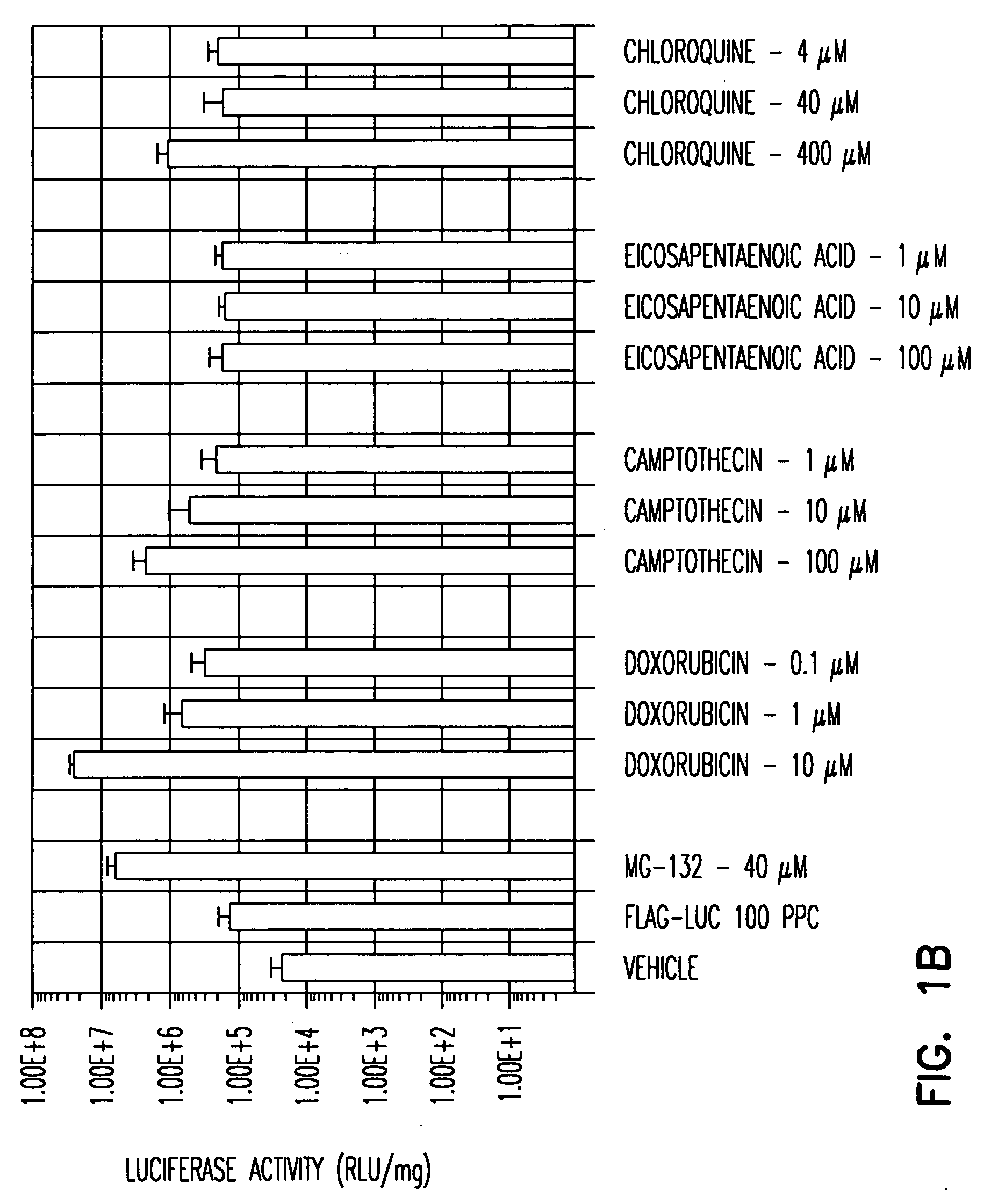

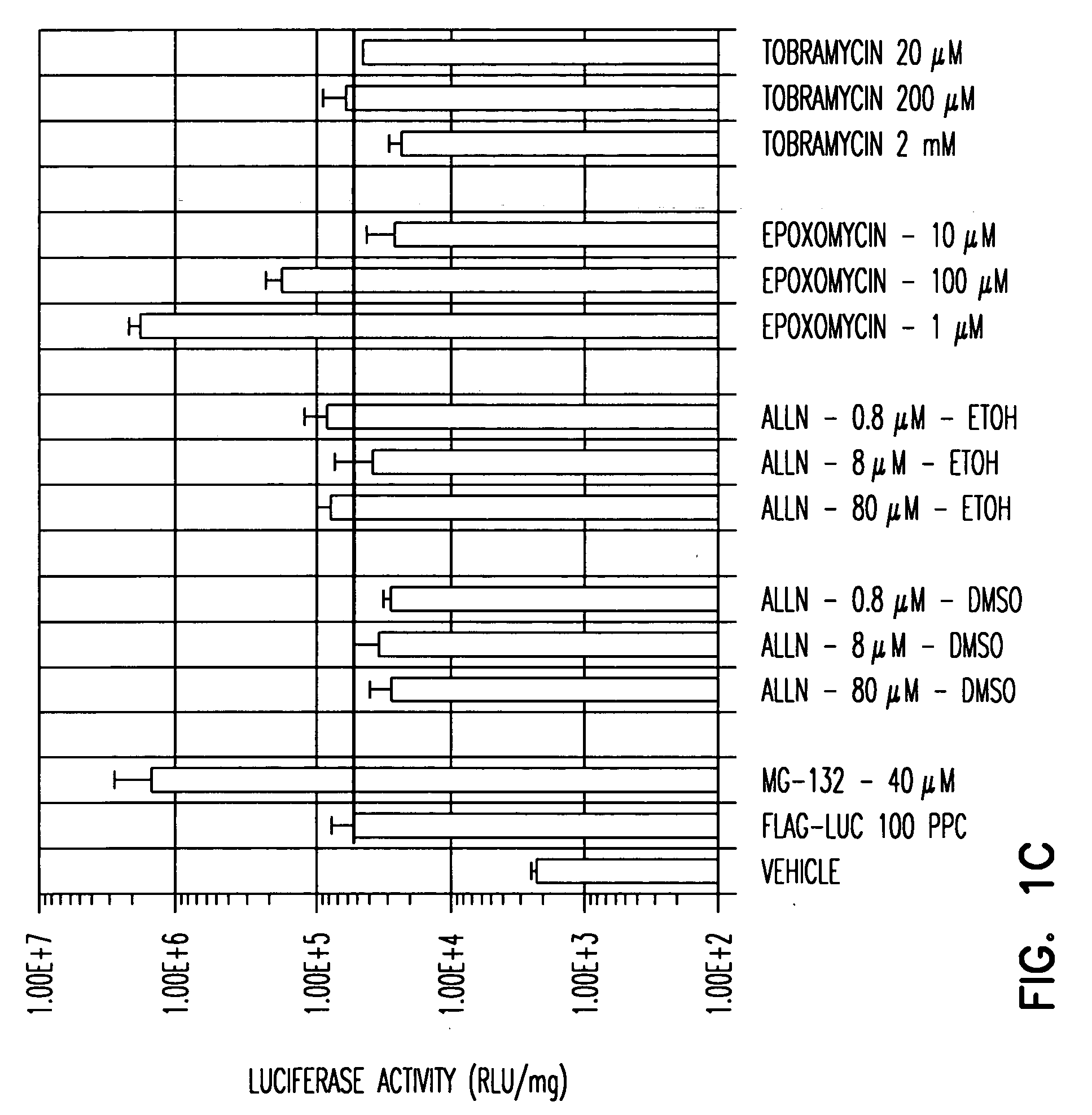

Compounds and methods to enhance rAAV transduction

ActiveUS20050037497A1Increasing steady state abundanceEnhanced transduction frequencyAntibacterial agentsNervous disorderBiophysicsBiochemistry

Owner:UNIV OF IOWA RES FOUND +1

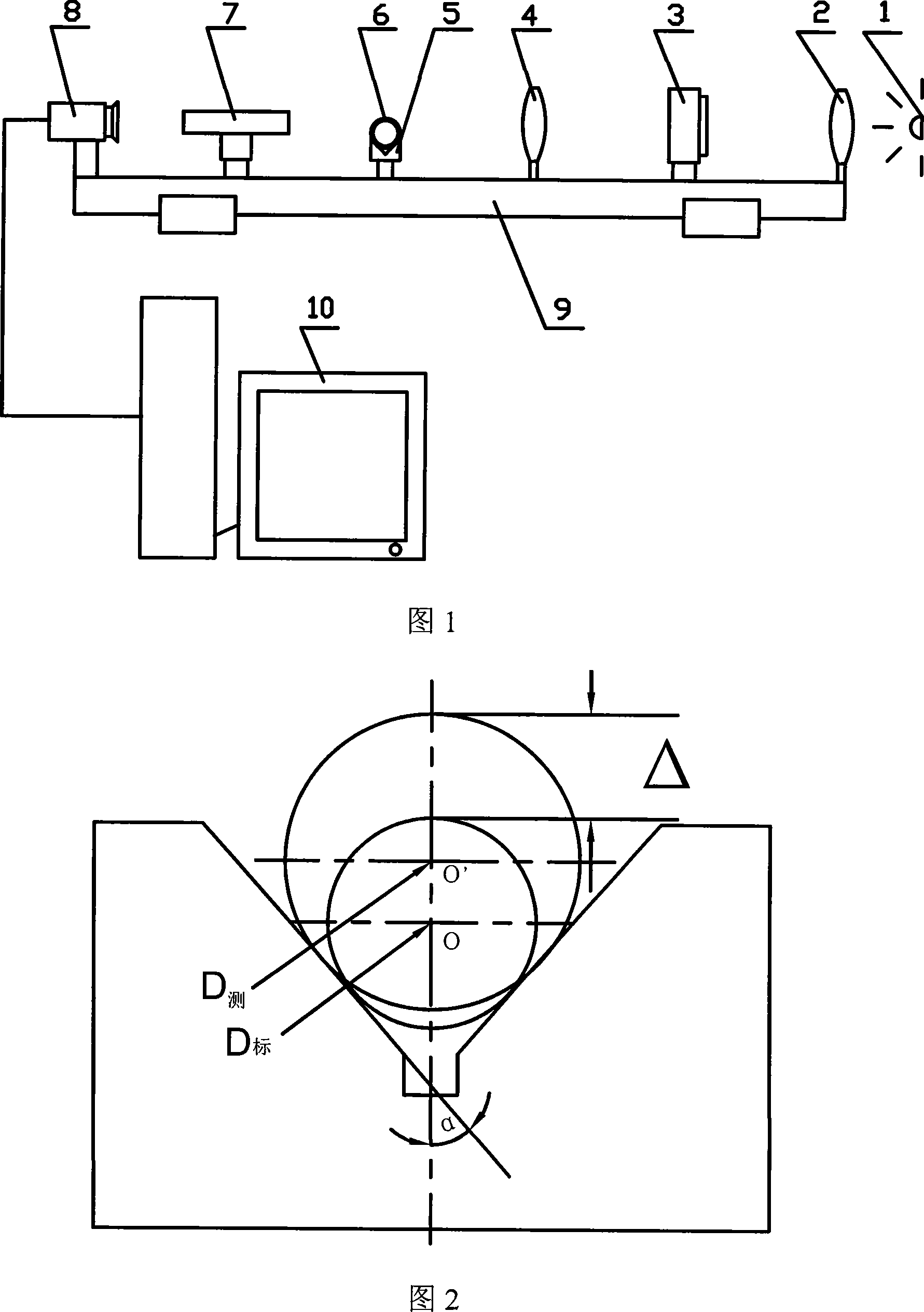

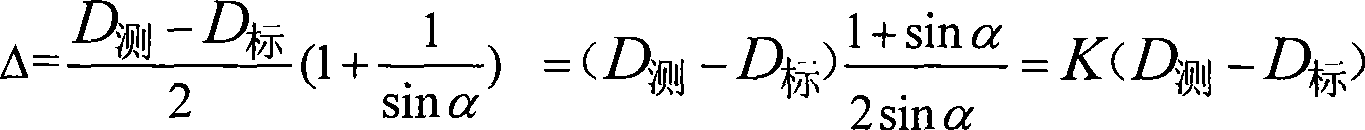

Non-contact type on-line detector for piston pin external diameter

InactiveCN101216293AEasy to operateImprove detection efficiencyUsing optical meansImaging processingOptical axis

The invention discloses a non-contact device for online measurement of the outer diameter of a piston pin. A light source, a first lens, apertures, a second lens, a V-shaped groove, an objective lens and a planar CCD are sequentially disposed on a guide track and positioned on the same optical axis, a measured piston pin is disposed inside the V-shaped groove, and the planar CCD is connected with a computer via a data acquisition card. The measured piston pin is provided with uniform parallel lights by a Kohler illumination system to allow the upside contour of the measured piston pin to be imaged on the planar CCD sensor, and the outer diameter of the piston pin can be determined by image processing and calibrating the imaging part of the piston pin, so as to overcome the limitation of the CCD area to the size of the measured piston pin. Meanwhile, the invention uses sub-pixel image processing method, so as to overcome the influence of the CCD resolution to measurement accuracy. The invention has the advantages of rapid operation, remarkably improved measurement efficiency, and remarkably improved measurement accuracy arising from the sub-pixel image processing method.

Owner:CHINA JILIANG UNIV

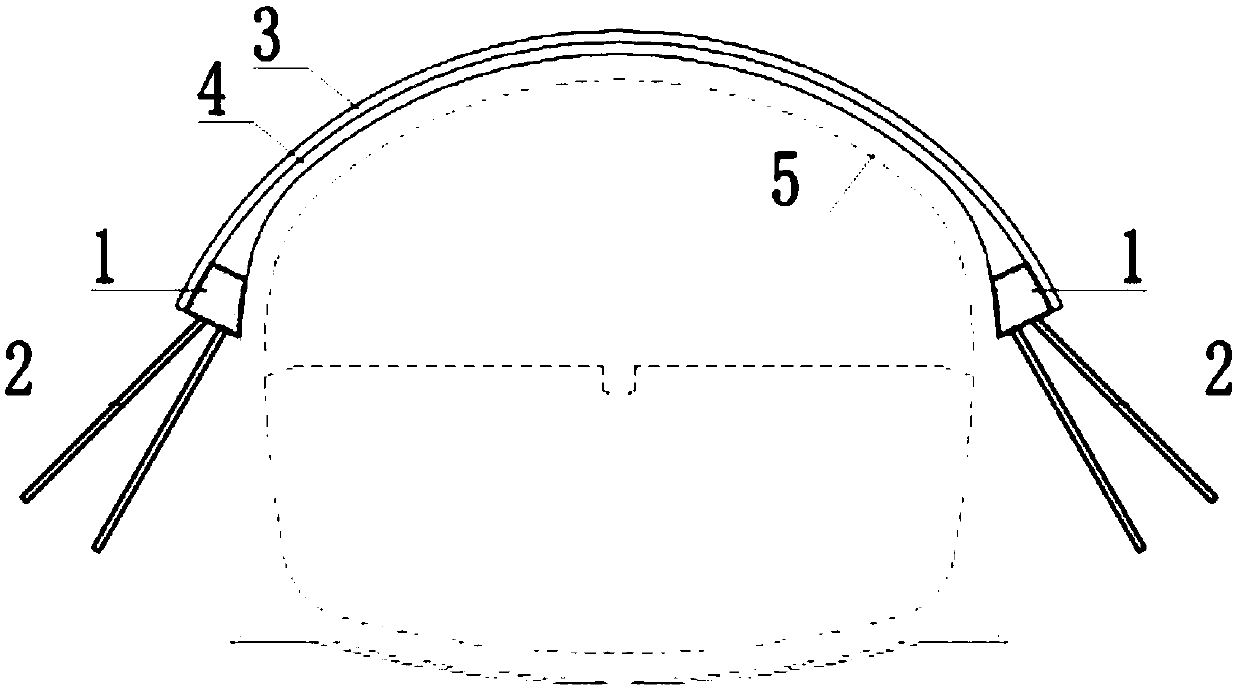

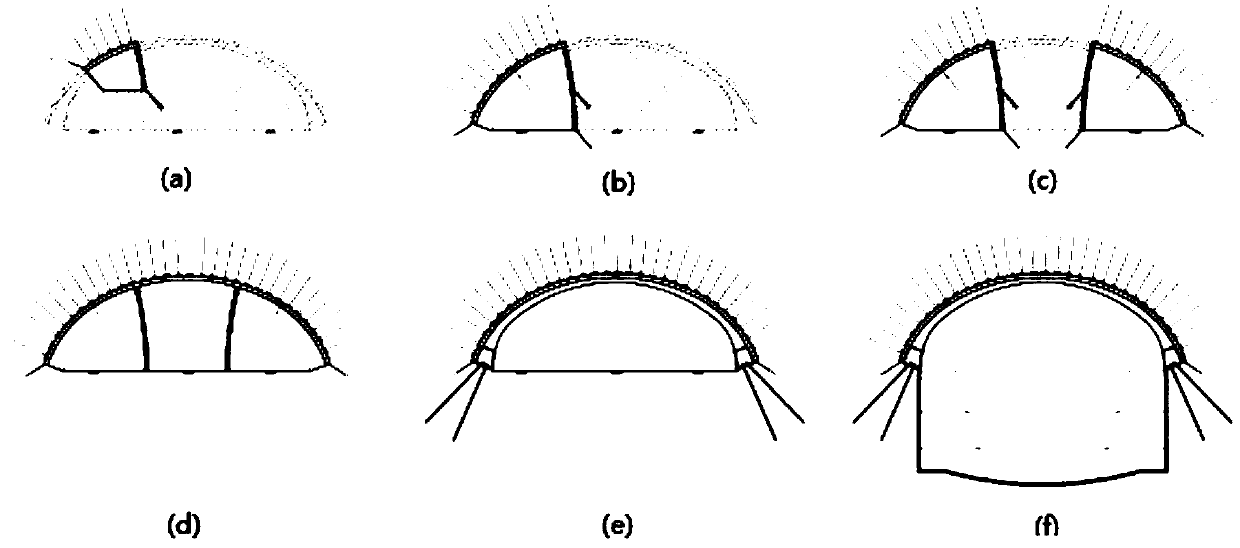

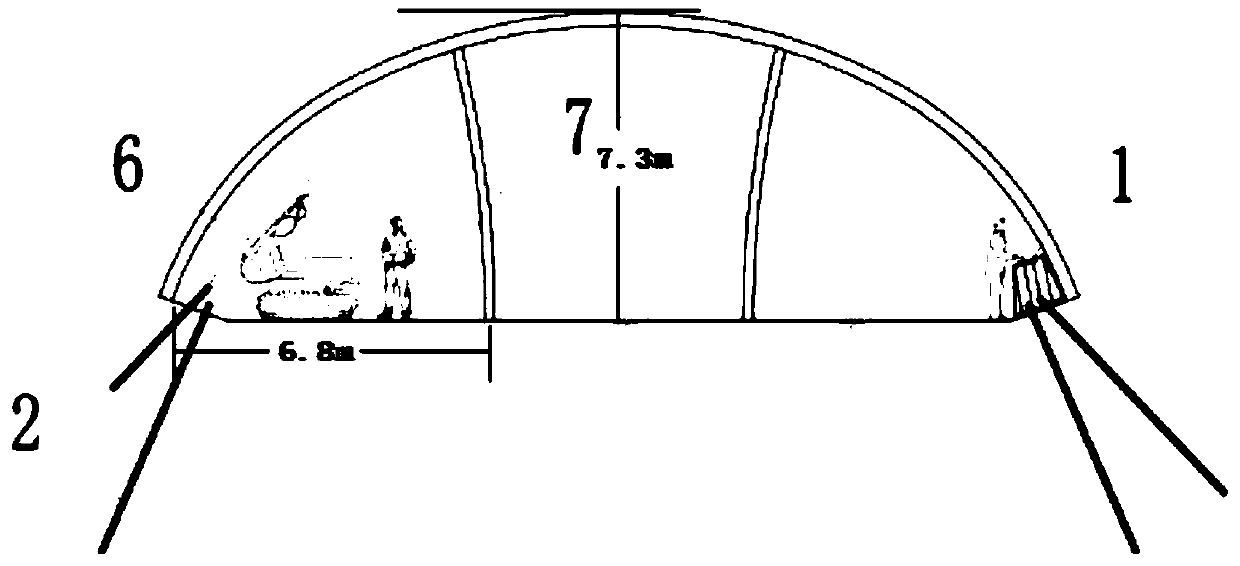

Reinforcement structure for arch-covering-method underground excavation subway station arch feet and construction method

PendingCN109538246AEasy to controlIncrease stiffnessUnderground chambersTunnel liningSubway stationStructural integrity

The invention discloses a reinforcement structure for arch-covering-method underground excavation subway station arch feet and a construction method. The reinforcement structure for the arch feet comprises two layers of arch cover supports, arch foot piles distributed at the arch feet of the left and right sides of subway station arch cover bodies and arch foot longitudinal beams, the arch foot longitudinal beams and the arch foot piles are integrally connected, and pile bodies of the arch foot piles are distributed along the tangent line of the arch feet; each arch foot pile is composed of asection steel framework and fine aggregate concrete which is poured into the section steel framework and pile holes. The reinforcement structure is a reinforcement system combining the arch foot pileswith the longitudinal beams, the longitudinal beams are connected with the arch foot piles and the first and second layers of arch cover supports, the structural integrity is good, the capacity of resisting local stress and deformation is high, and deep and thick smashed surrounding rock at the arch feet can be effectively reinforced and protected; in addition, according to the construction method of the reinforcement structure for the arch feet, the reinforcement range and implementation objects are flexibly selected, rock layers of the arch feet for supporting arch covers are smashed, the integrity influence cannot be caused, and the advantages of an arch-cover method in the aspects such as project cost, construction working period, implementation efficiency and mechanical operation cannot be influenced.

Owner:中铁科学研究院有限公司

Adeno-associated virus vectors

InactiveUS20050255087A1Improve stabilityIncrease in abundance and stabilityOrganic active ingredientsBiocideAdeno associate virusDNA

Owner:UNIV OF IOWA RES FOUND

Adeno-associated viruses and uses thereof

InactiveUS20080166758A1Improve stabilityIncrease in abundance and stabilityMicroorganismsGenetic material ingredientsAdeno associate virusDrug biological activity

The invention provides an isolated and purified DNA molecule comprising at least one DNA segment, a biologically active subunit or variant thereof, of a circular intermediate of adeno-associated virus, which DNA segment confers increased episomal stability, persistence or abundance of the isolated DNA molecule in a host cell. The invention also provides a composition comprising at least two adeno-associated virus vectors.

Owner:UNIV OF IOWA RES FOUND

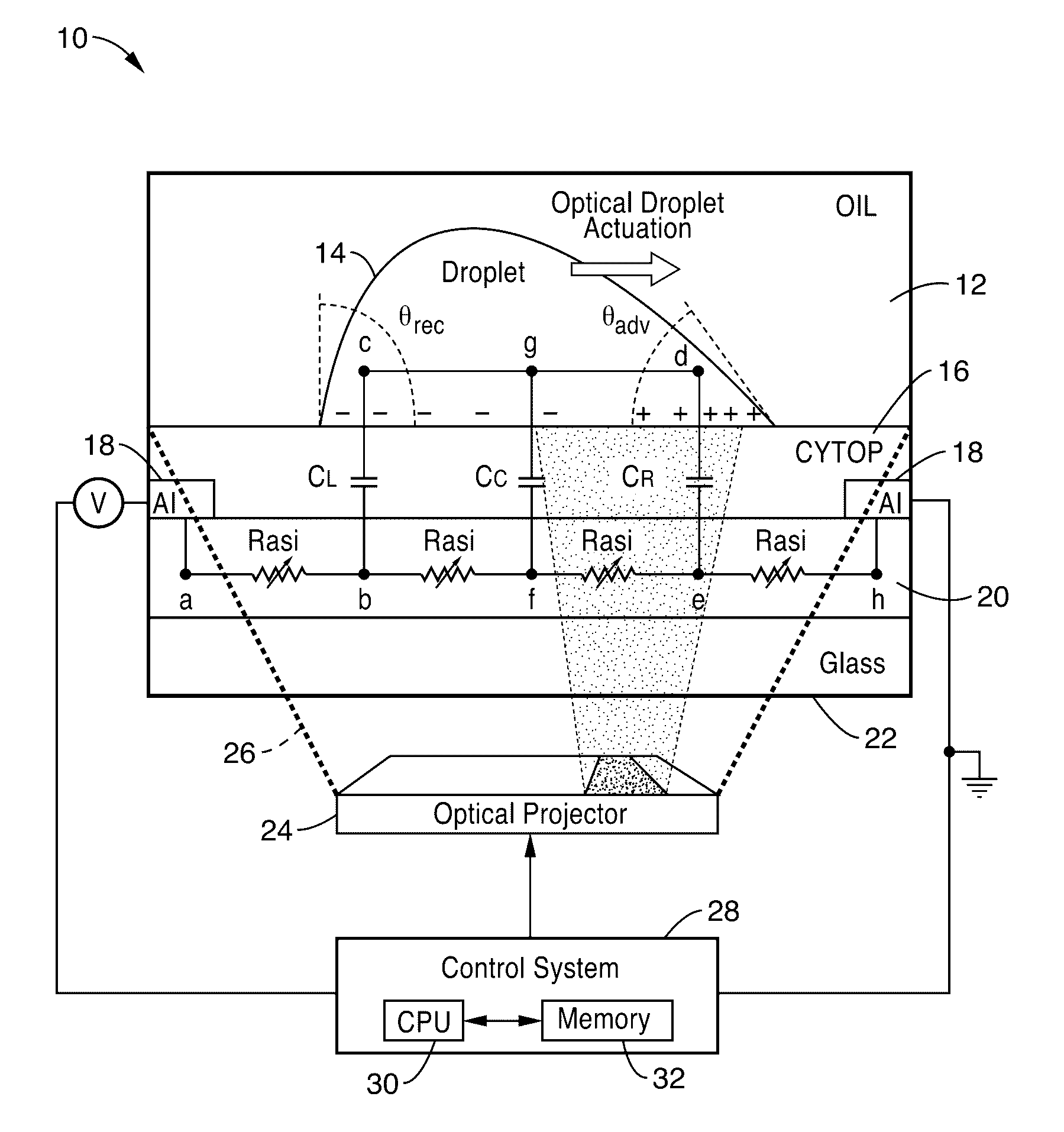

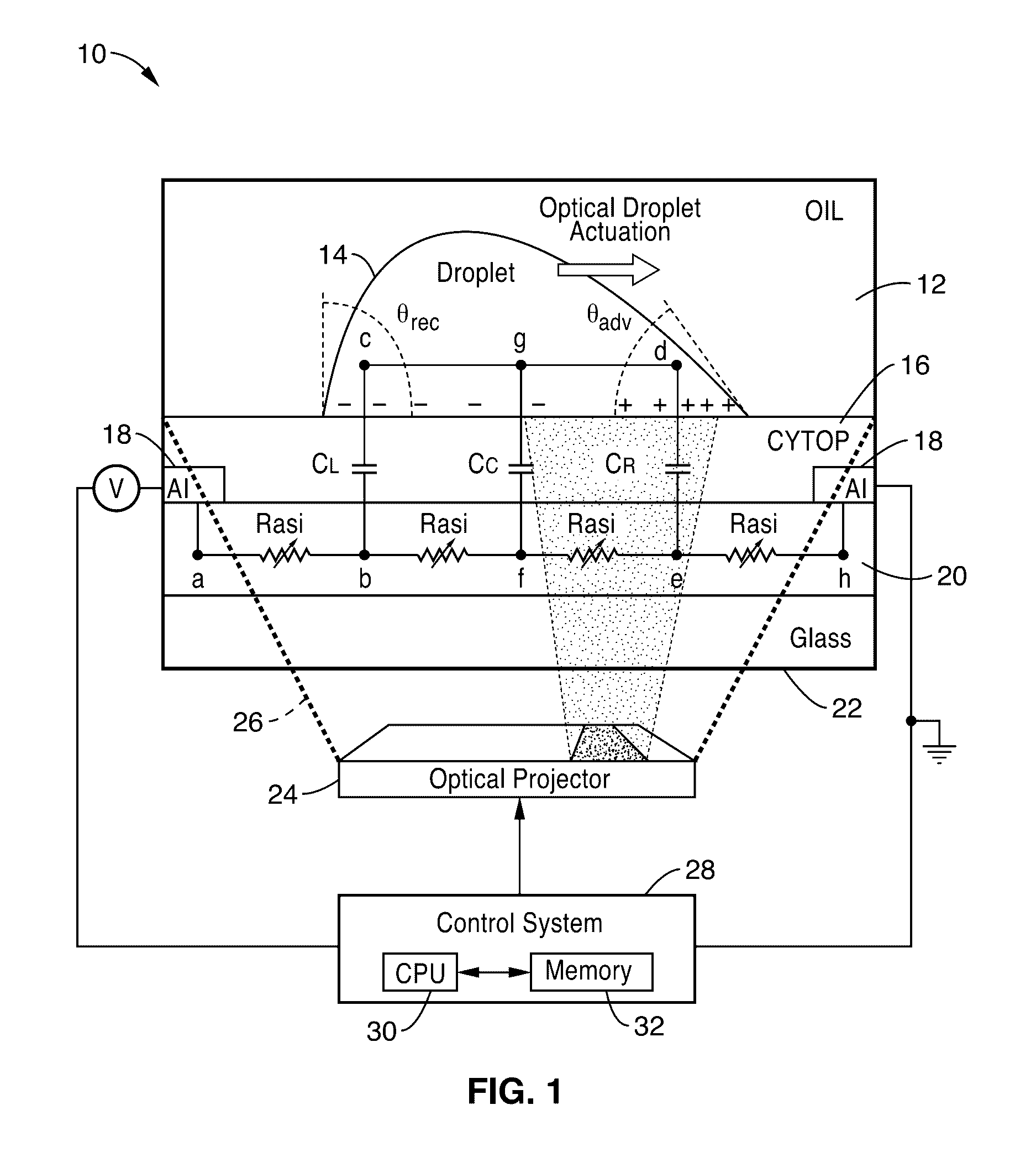

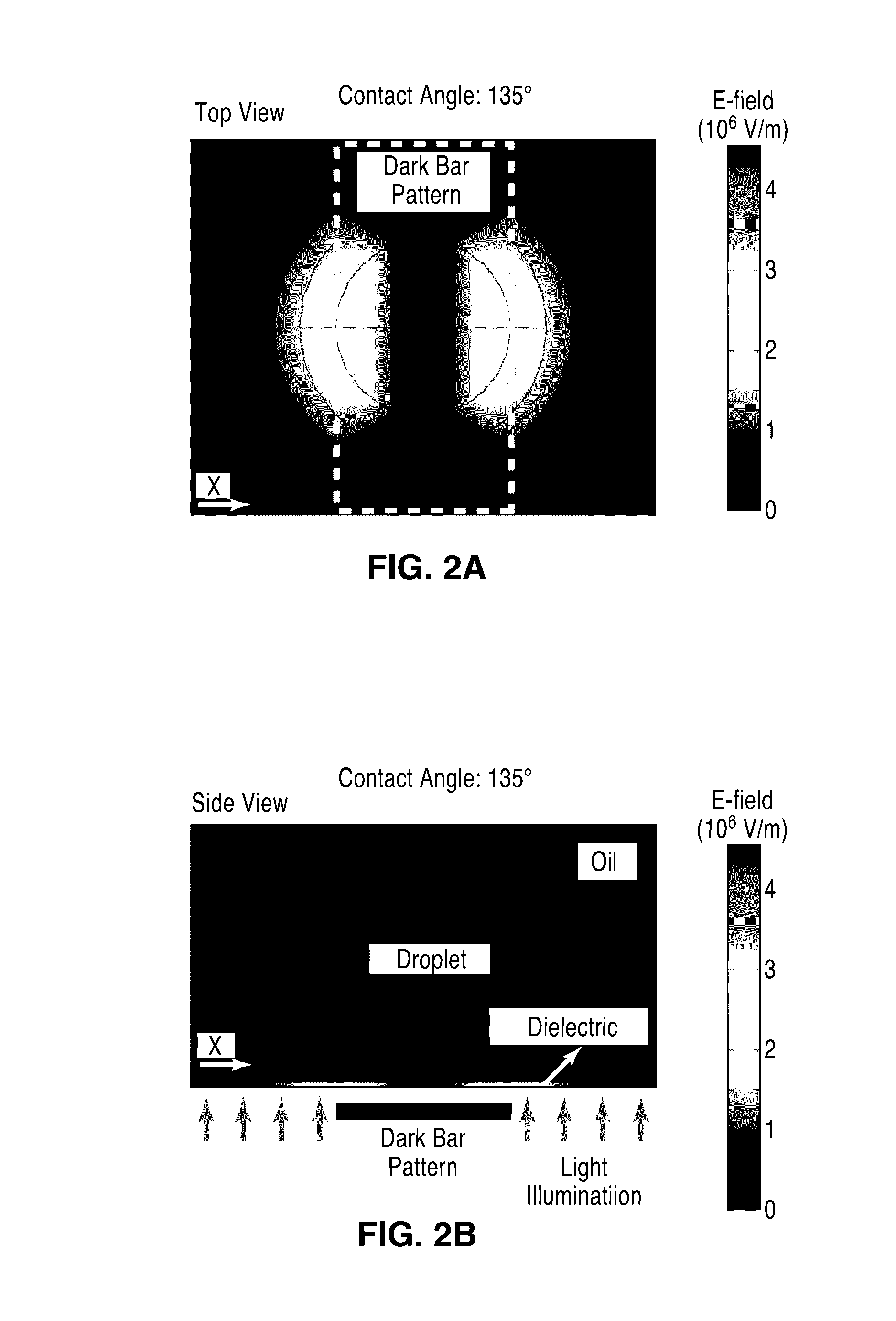

Single sided continuous optoelectrowetting (SCEOW) device for droplet manipulation with light patterns

ActiveUS9533306B2Low light intensity actuationContinuous transportCellsSludge treatmentElectric fieldElectricity

A single-sided continuous optoelectrowetting (SCOEW) device for manipulating droplets retained in a fluid over the SCOEW device with dynamic patterns of low intensity light, such as from a display screen, is described. A single pair of lateral electrodes are utilized for providing a lateral electric field bias, with transport motion controlled in response to projecting light through a photoconductive layer and dielectric layer adjacent to which droplets are retained. The device is configured for optically manipulating droplets having volumes spanning over five orders of magnitude, and can be configured to perform droplet dispensing, transport, splitting, merging, mixing and other droplet manipulation functions involving any of the above on a single sided surface.

Owner:RGT UNIV OF CALIFORNIA

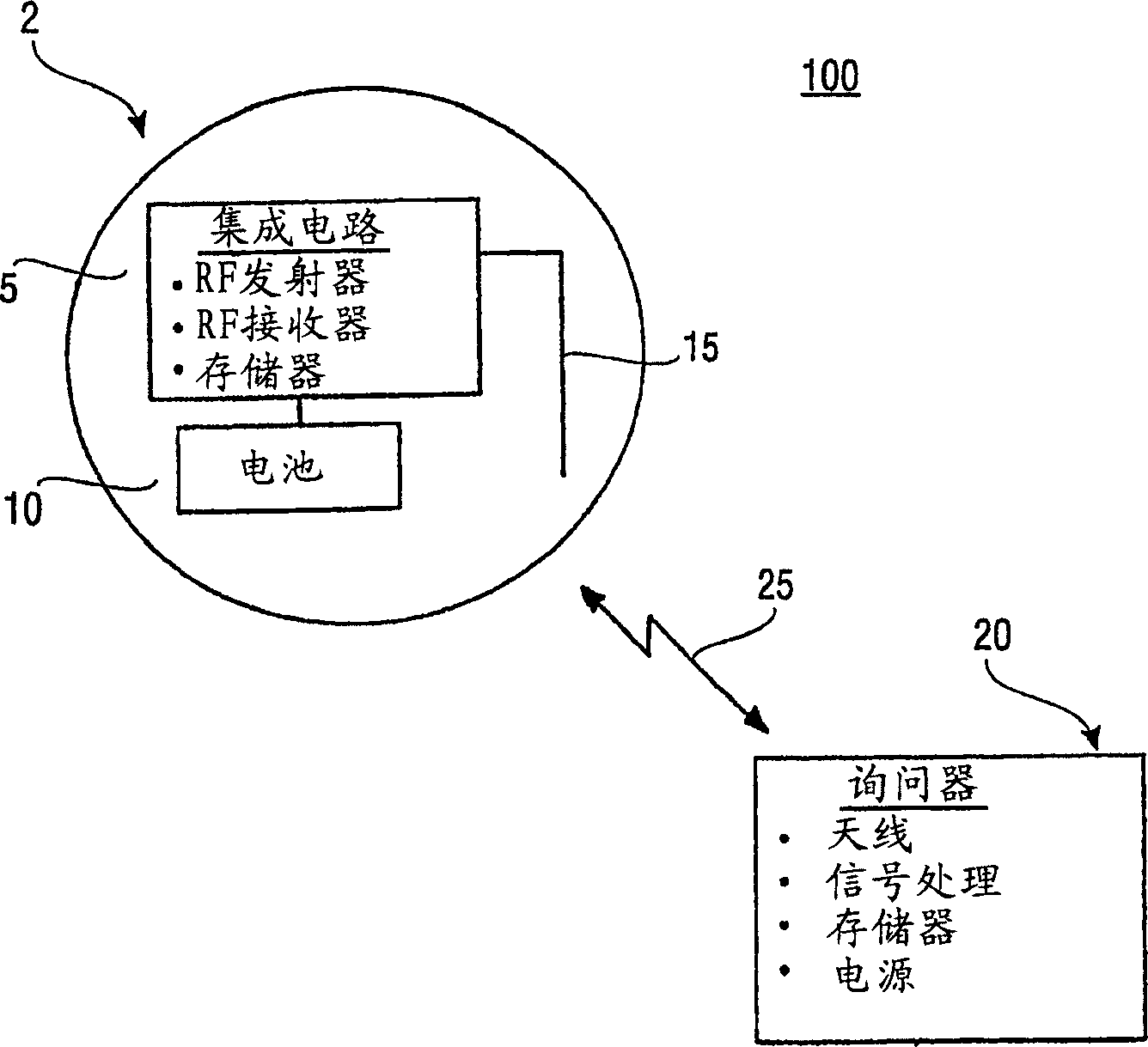

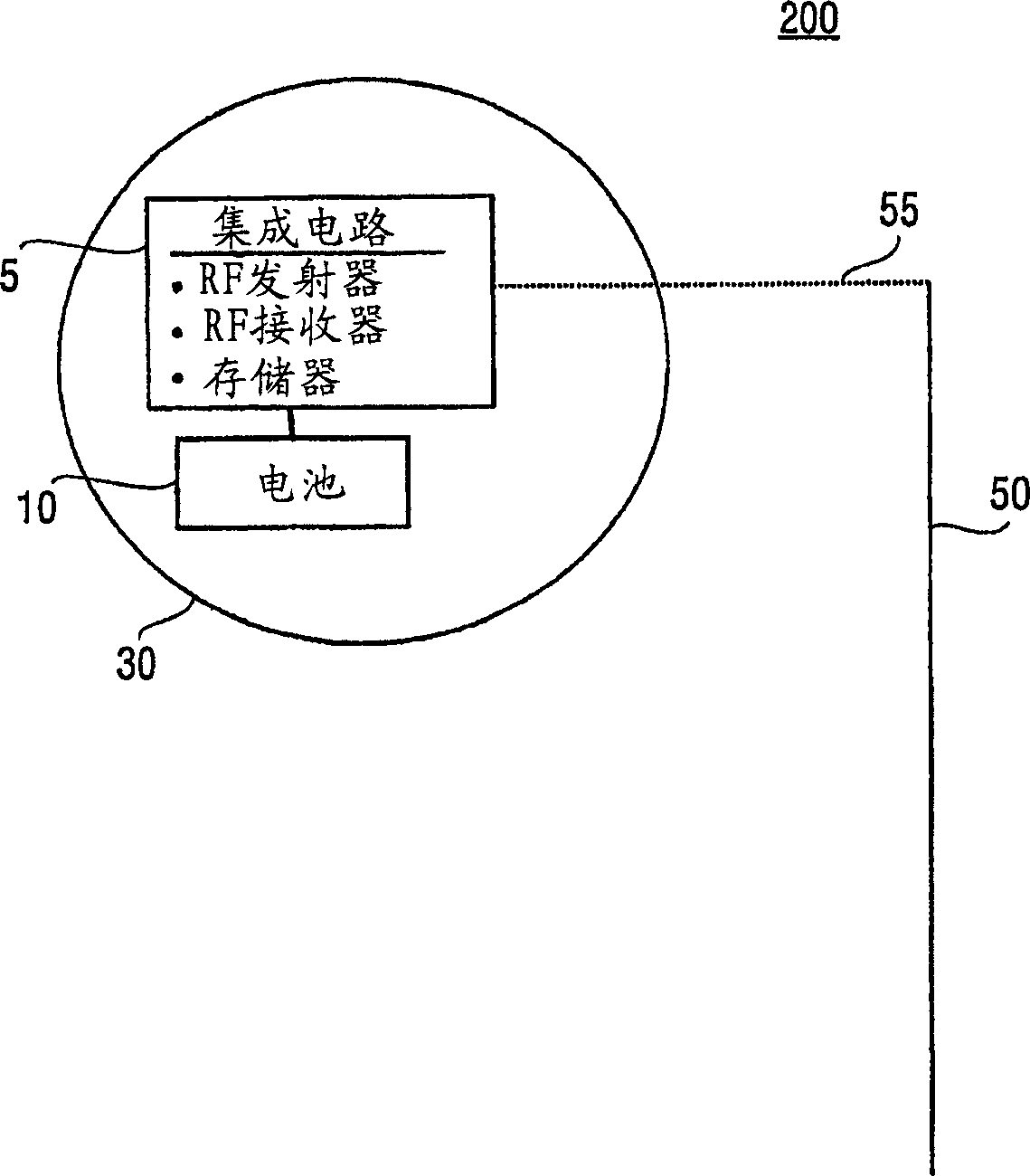

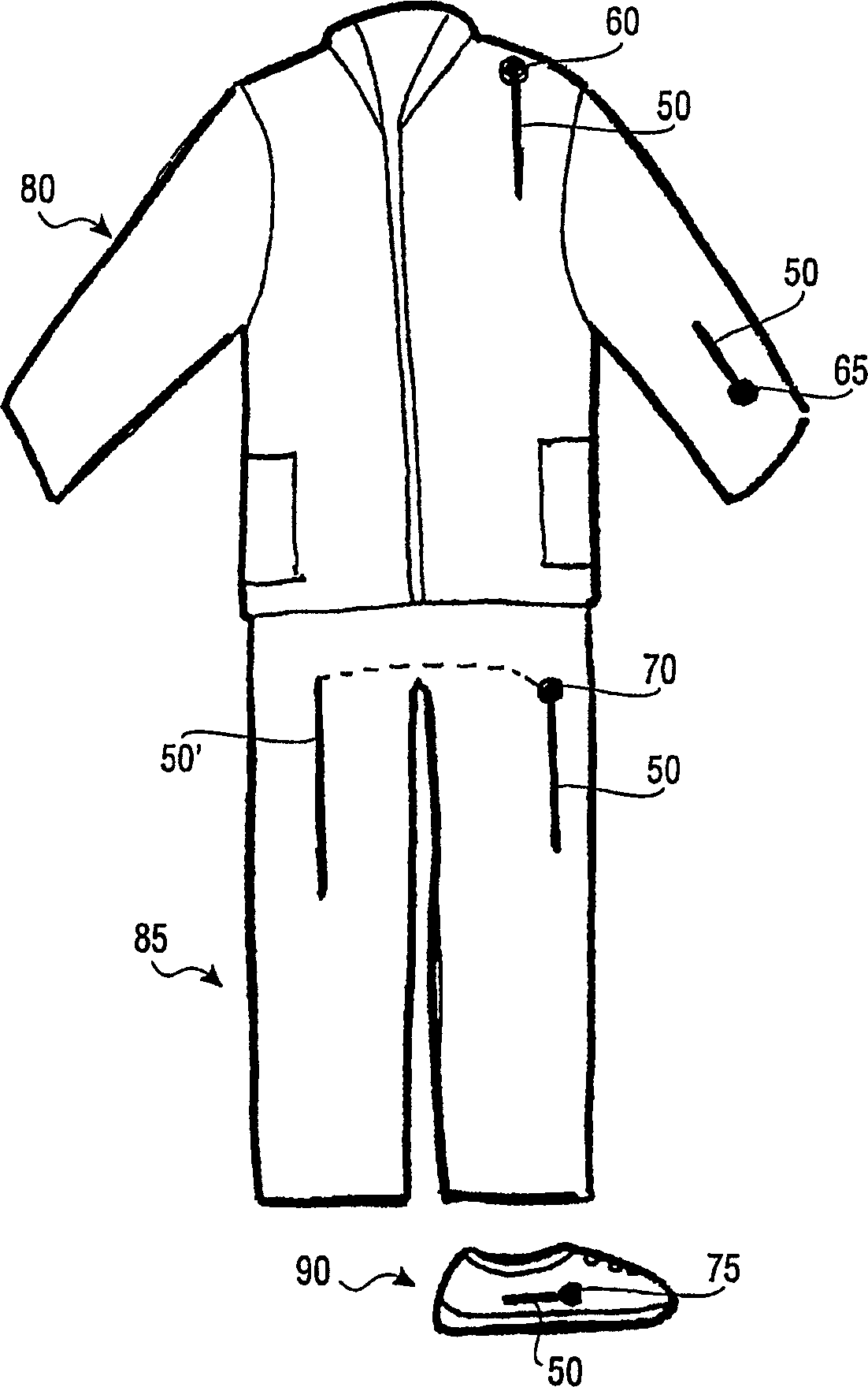

Fabric antenna for tags

InactiveCN1639732AOvercome size limitationsEasy to detectGarmentsAntenna adaptation in movable bodiesTransponderRf circuit

A method and system for providing an RFID transponder (200) with a fabric antenna (50). The system includes a radio frequency (RF) transponder having a housing (30) in which RF circuitry (5) is encapsulated and a fabric antenna coupled to the RF circuitry. A method of manufacturing a radio frequency (RF) transponder includes the steps of enclosing an RF circuit in a housing, forming a fabric antenna, and coupling the fabric antenna to the RF circuit.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

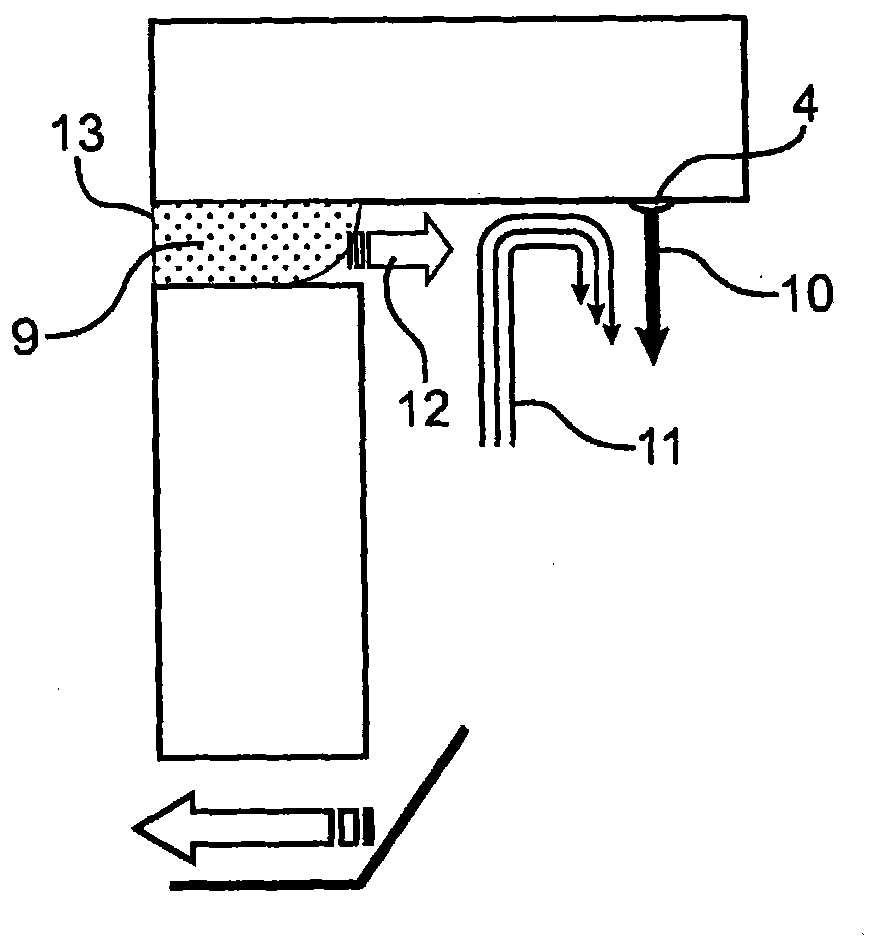

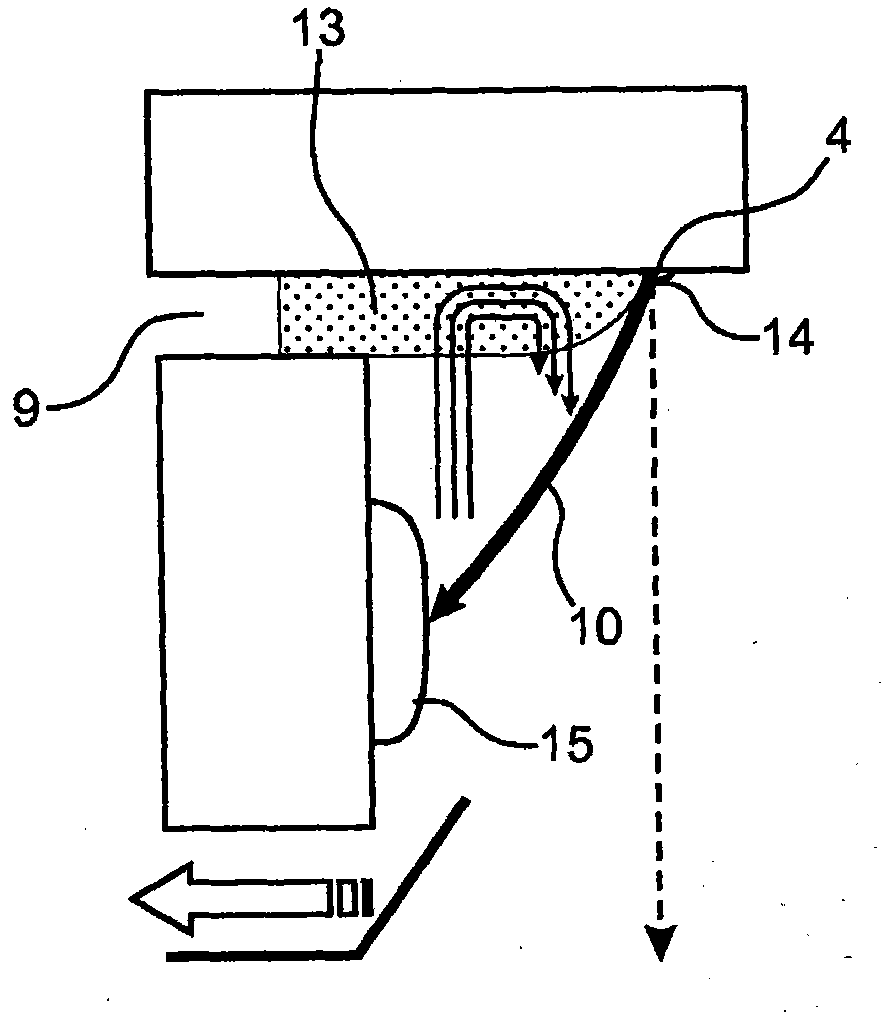

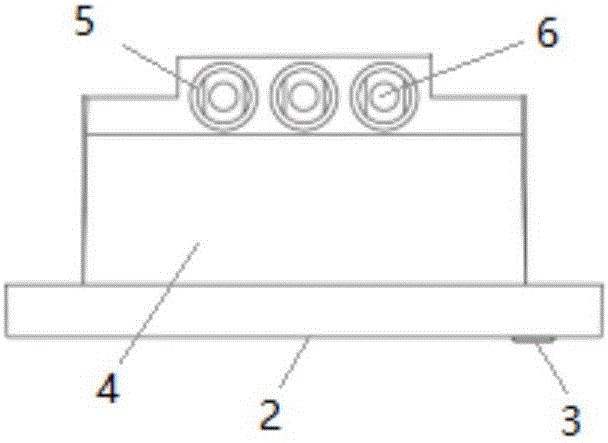

Ink jet print head with automated cleaning at the start of printing

Liquid jet print head (3) comprising: a generator (1) of drops of liquid, the lower part of which comprises a plate (2) equipped with at least one nozzle (4) for ejecting the liquid, a sorting block (5) laid out below the nozzle plate (2) and offset in relation to the axis (Z) of the nozzle; wherein the block and the generator are fixed in relation to each other by delimiting a first space (9) and by forming an angle alpha in a vertical plane (YZ), means (50, 51) to suck up any stagnant liquid (13) in the first space and / or in the angle before the ejection of liquid via the nozzle at the start up of printing.

Owner:MARKEM IMAJE HLDG

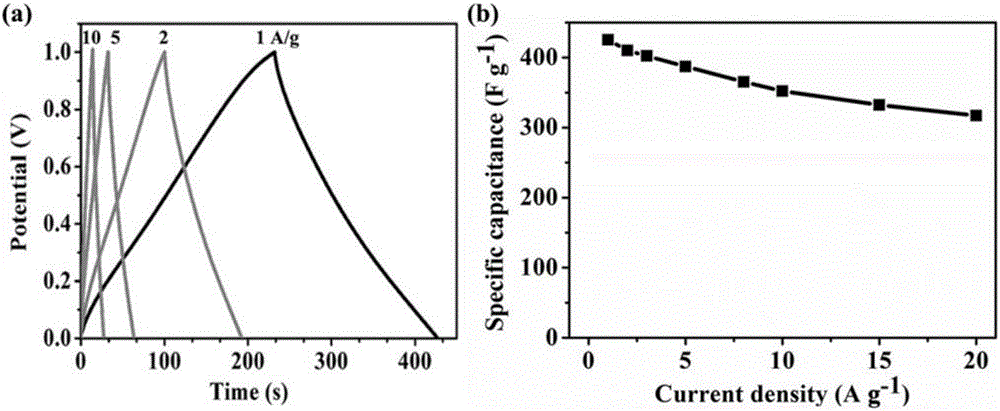

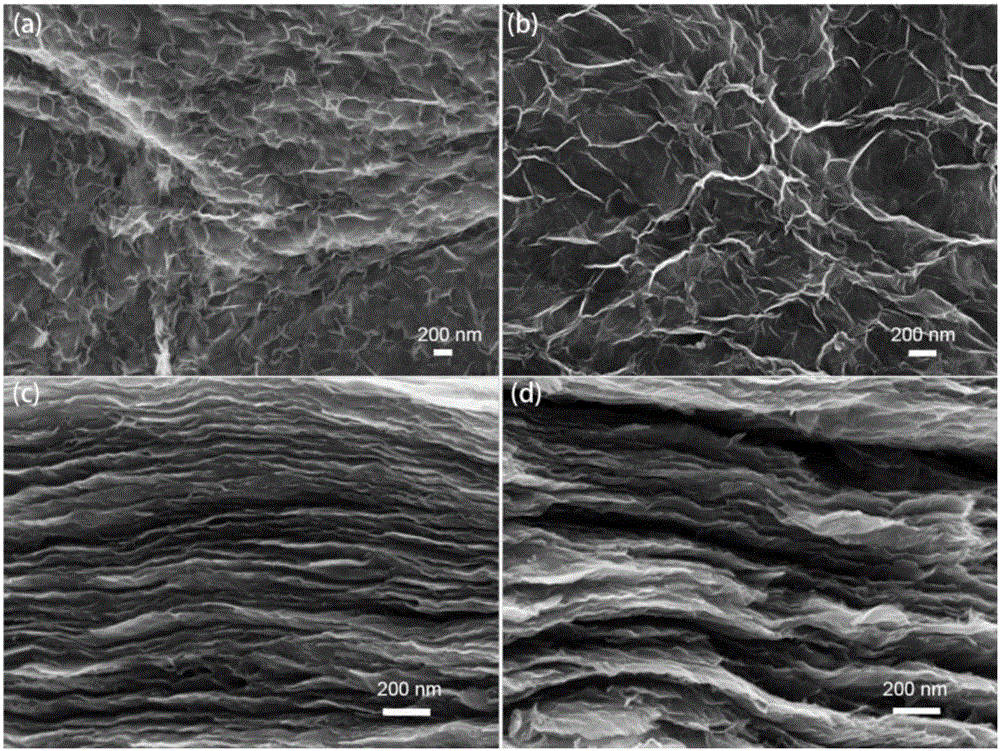

Method for increasing specific capacitance of graphene-based supercapacitor

InactiveCN106449180AEasy accessOvercome size limitationsHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceOperability

The invention relates to a method for increasing the specific capacitance of a graphene-based supercapacitor. An electrode of a supercapacitor is prepared from graphene, and the theoretical capacitance can be up to 550F / g. However, because of factors such as material properties and preparation techniques, generally the contained specific capacitance is within 150-300F / g. According to the method, sodium chloride and urea are doped into a graphene oxide solution of a liquid crystal state for the first time, a film is prepared from the solution by using a scraper in a coating manner, and thus a film obtained after hydrothermal reduction is adopted as the electrode of the supercapacitor. Due to added substances, graphitization stacking of graphene layers can be prevented and nitrogen doping can be achieved in the hydrothermal reduction process of the graphene film, so that the specific capacitance can be greater than 400F / g when aqueous electrolyte is used, and is at a relatively high level. The electrode of the graphene-based supercapacitor prepared by using the method is uniform in thickness, good in operability and simple to operate, in addition, the used raw materials are cheap, and the method is green. The process of the scraper coating method for preparing the film can be further improved, and can be applied to industrial production.

Owner:BEIHANG UNIV

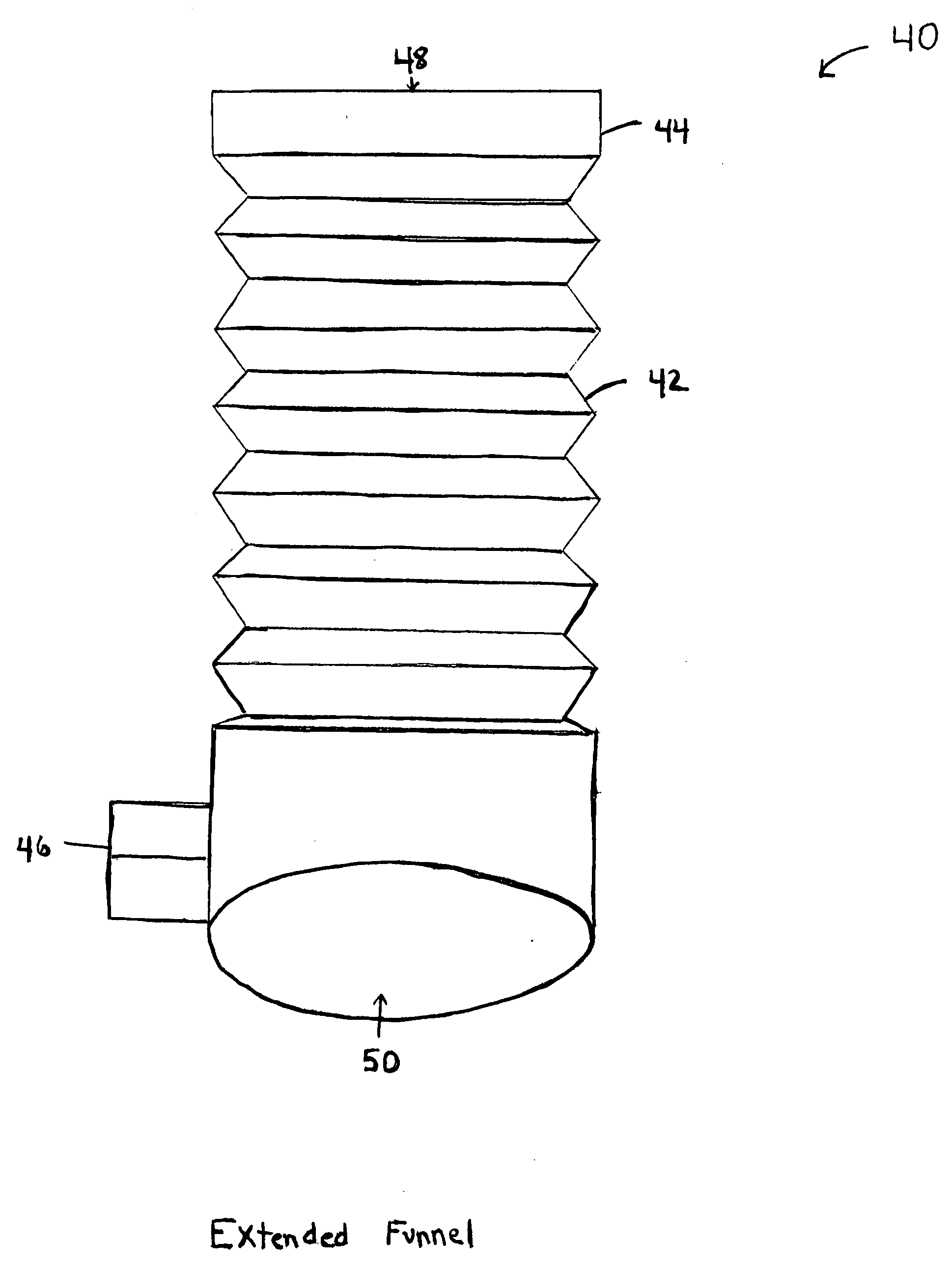

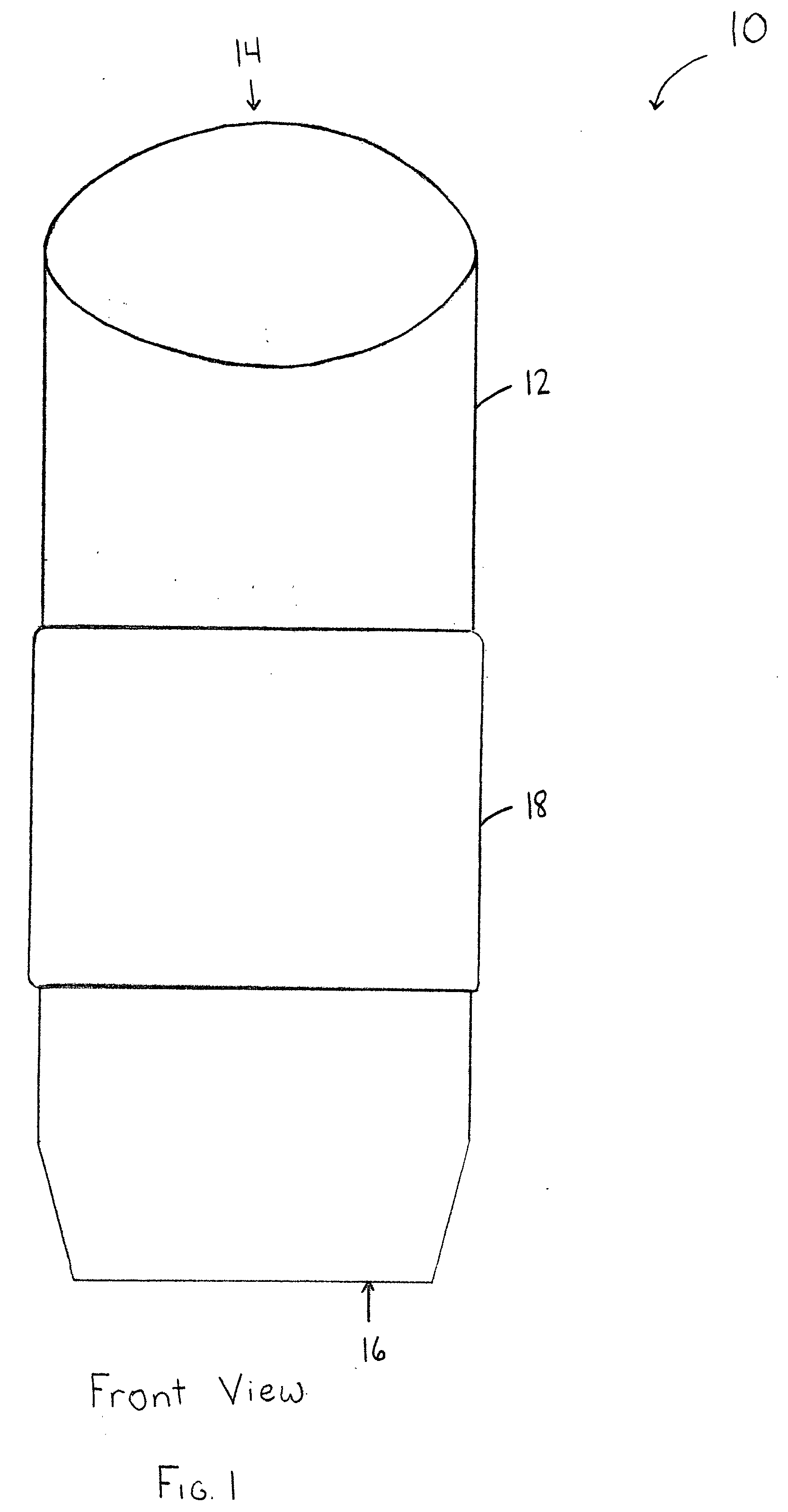

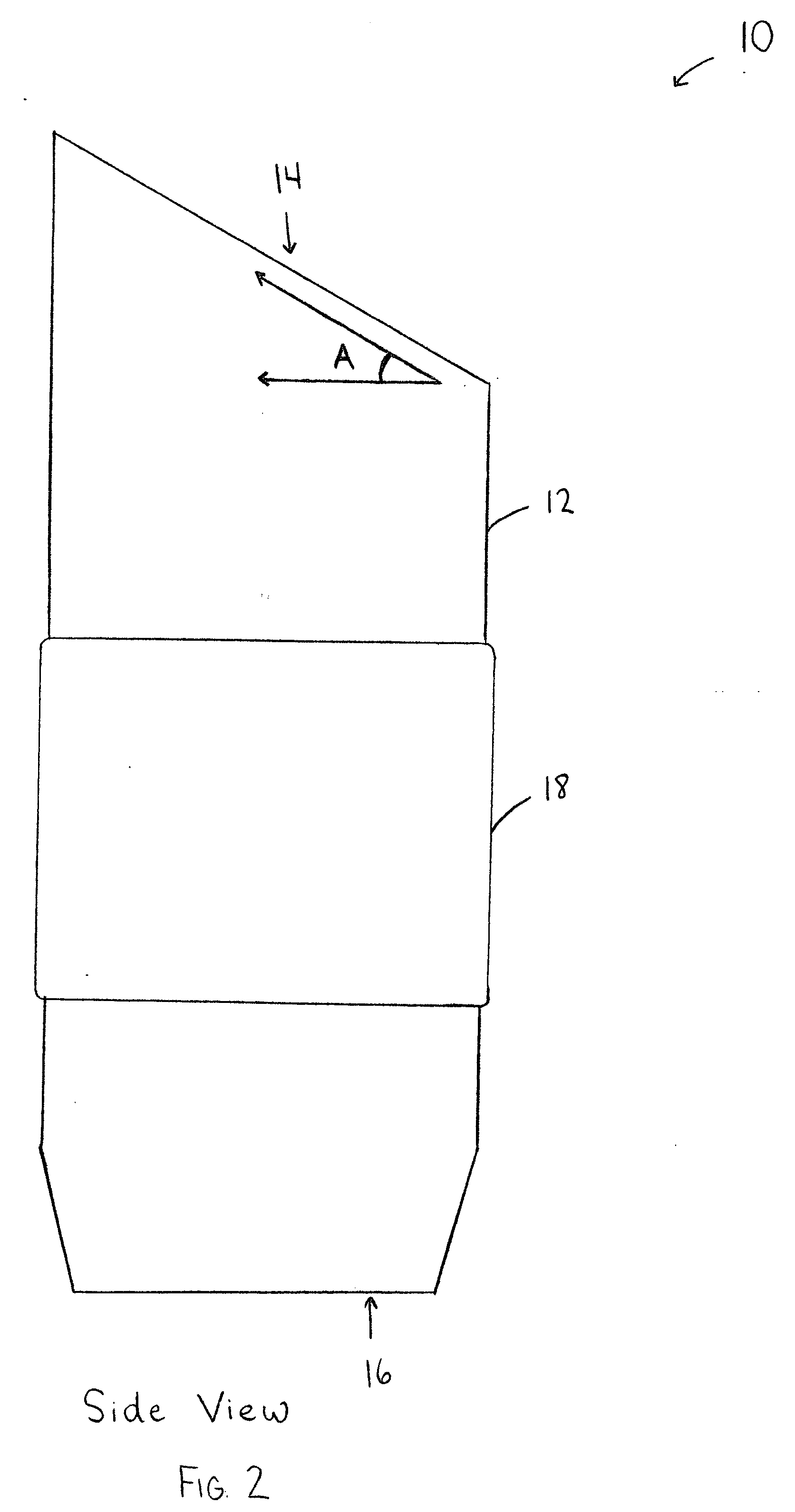

Funnel in combination with a commercial appliance

InactiveUS20080047631A1Easy to seeOvercome size limitationsLarge containersFunnelsEngineeringMechanical engineering

A funnel in combination with a commercial appliance, such as a refrigerator or icemaker, that will allow a product, such as water or ice, to be redirected and dispensed into a container that would otherwise be too large to fit into a recessed dispensing cavity typically allotted for smaller containers. To accomplish this, a sleeve member is operably coupled to the appliance in either a friction-fit arrangement or a mounting arrangement at or around an optimal deflection angle of 30°, thus allowing the water or ice to overcome a lip on the dispensing cavity and be redirected into a larger container.

Owner:BAKER SCOTT

Adeno-associated virus vectors

InactiveUS20090265796A1Improve stabilityIncreased persistenceOrganic active ingredientsMicroencapsulation basedVirusAdeno-associated virus

The invention provides an isolated and purified DNA molecule comprising at least one DNA segment, a biologically active subunit or variant thereof, of a circular intermediate of adeno-associated virus, which DNA segment confers increased episomal stability, persistence or abundance of the isolated DNA molecule in a host cell. The invention also provides a composition comprising at least two adeno-associated virus vectors.

Owner:UNIV OF IOWA RES FOUND

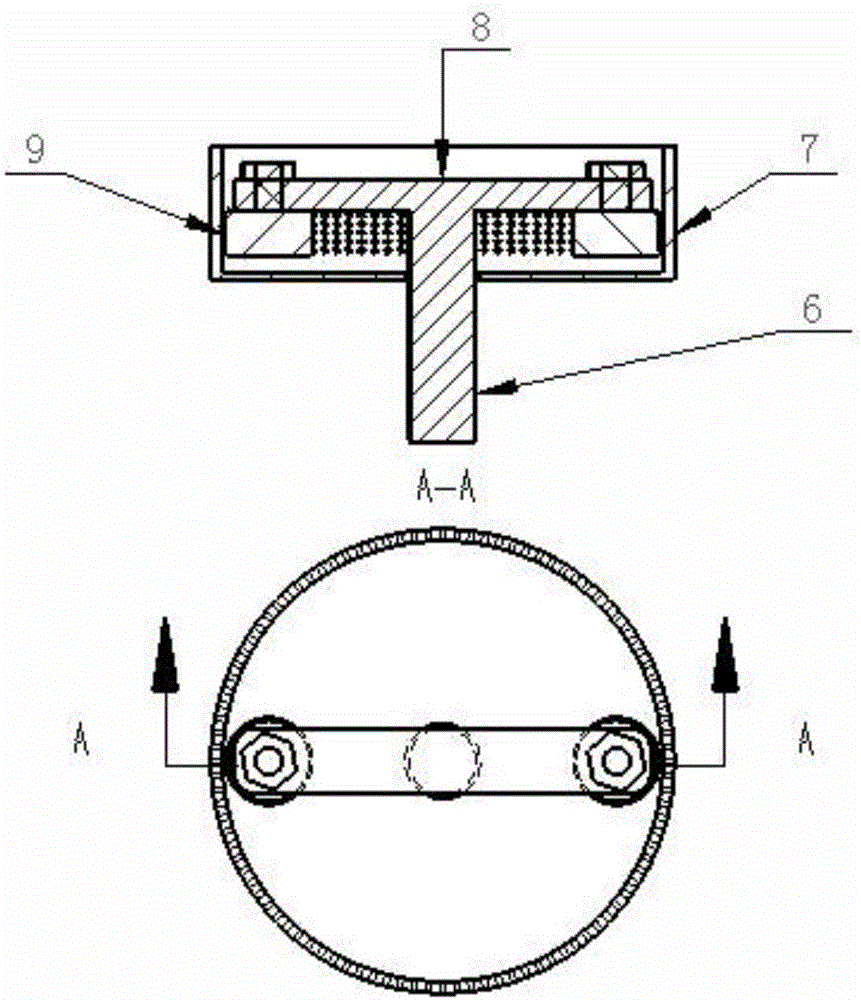

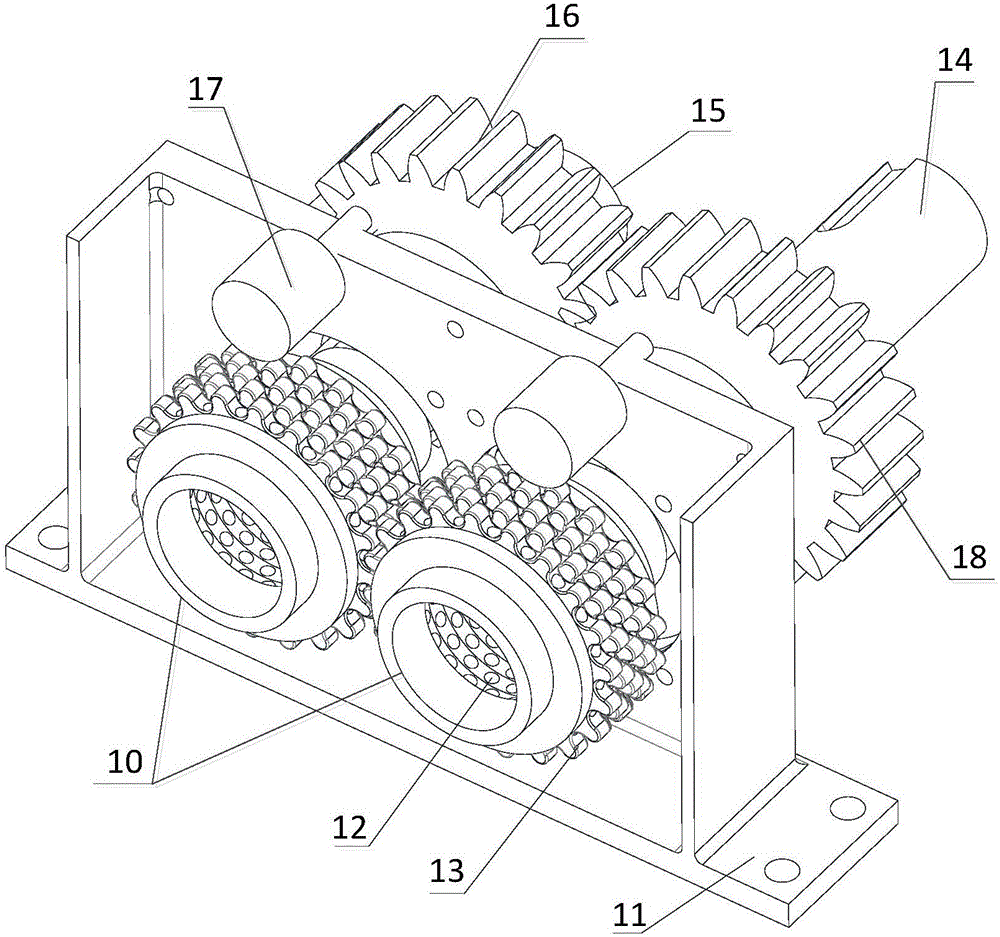

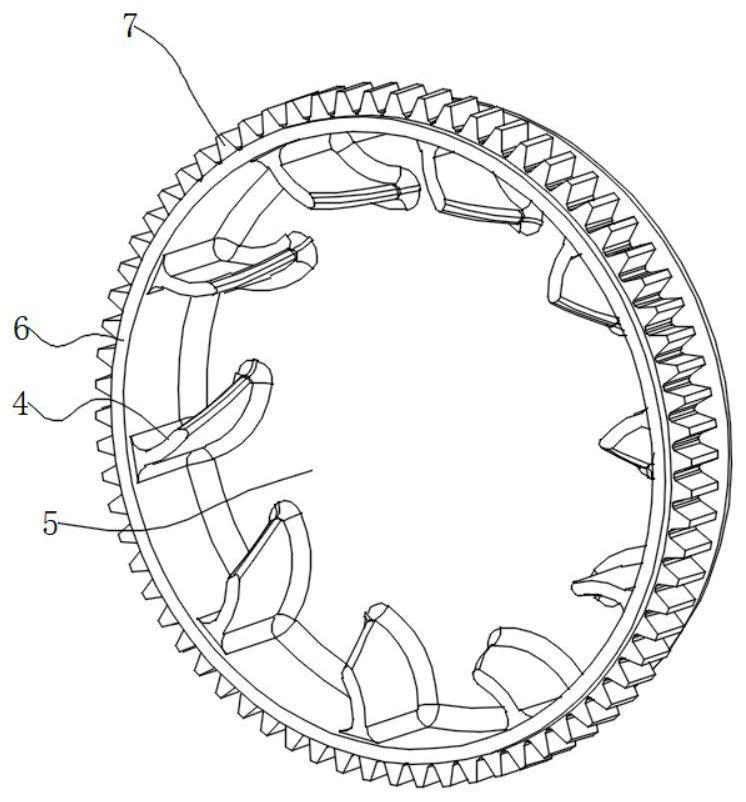

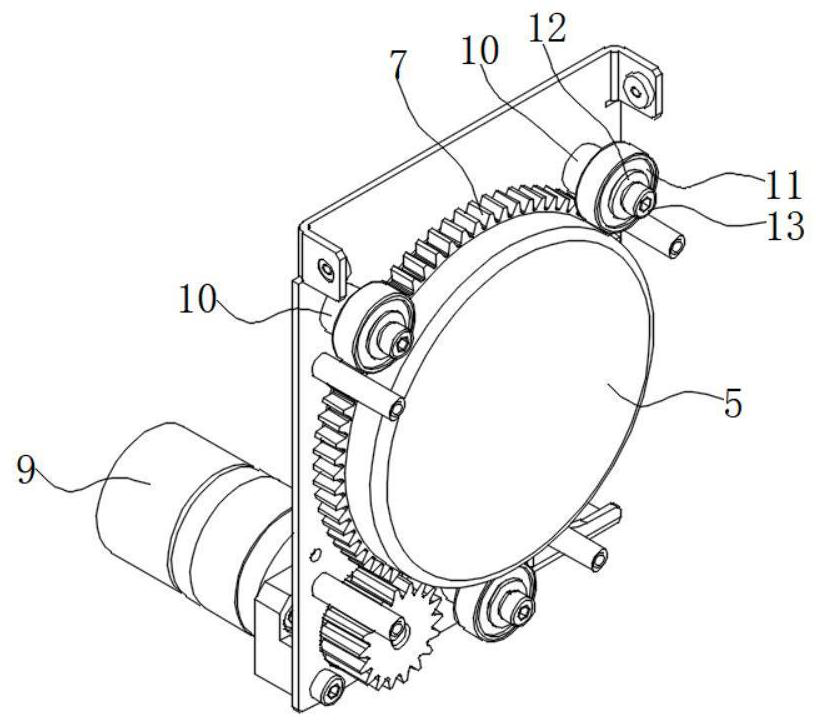

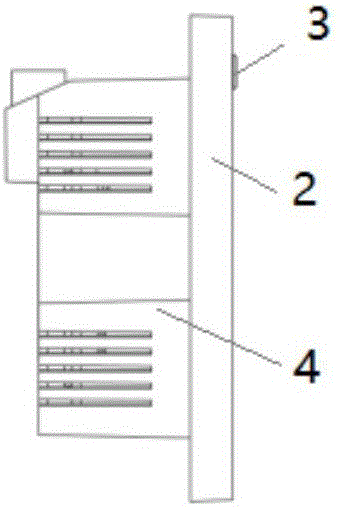

Particle extruding and forming mechanism provided with concave-convex pattern roller pairs

InactiveCN105056834AReduce power consumptionPrevent slippingGranulation by pressingShaping pressCompression moldingStress concentration

The invention discloses a particle extruding and forming mechanism provided with concave-convex pattern roller pairs. The particle extruding and forming mechanism comprises a handpiece base, a transmission mechanism and an extruding mechanism, wherein the transmission mechanism and the extruding mechanism are arranged on the handpiece base. The extruding mechanism comprises a pair of extruding rollers used for extruding raw materials. The transmission mechanism is connected with the extruding rollers and drives the extruding rollers to move in the opposite directions. Drums of the extruding rollers are hollow drums. A plurality of rows of protruding structures extending in the longitudinal directions of the drums are uniformly arranged outside the ends, connected with the transmission mechanism, of the two drums. The protruding structures in every two adjacent rows make mutual contact. Each protruding structure in each row comprises a plurality of protruding tops equally spaced. The protruding tops form the outer surfaces of the extruding rollers together. A die hole is formed in a depression between every two protruding tops. According to the particle extruding and forming mechanism, power consumption is small, the defect that the size of particles is limited is overcome, the strength of space gaps formed by the protruding tops is sufficient, the technological problem of hole wall cracking caused by stress concentration in the heat treatment process is solved, the service life of the extruding rollers is prolonged, and cost is saved.

Owner:罗成跃

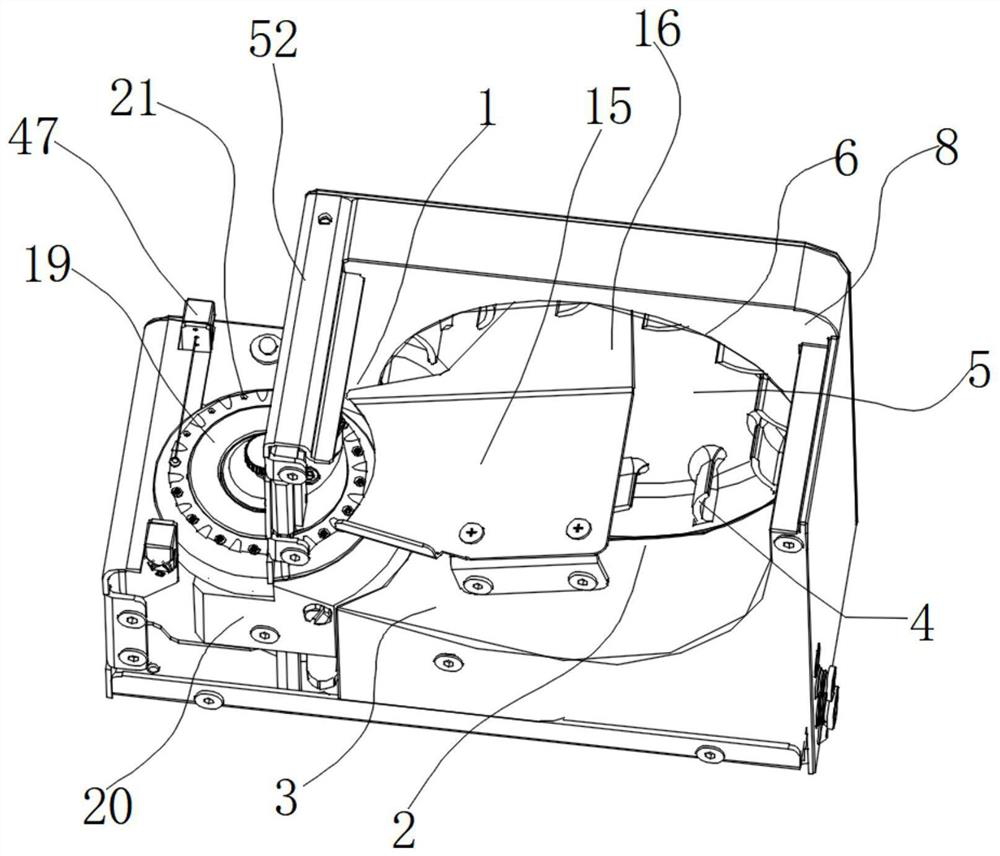

An automatic feeding system for bar material with lifting head

ActiveCN111099318BIncrease cycle rateIncreased probability of successful attractionConveyor partsModular designEngineering

The invention discloses a hanging head provided rod feeding system achieving active feeding. The system comprises a base, a hopper portion, a conveying portion and a controller. The hopper portion andthe conveying portion are arranged on the base. The hopper portion comprises a bin, a collection rotating wheel and a first drive mechanism. The bin comprises a falling area, a collection area and abevel. The falling area is higher than the collection area, and the bevel is connected with the falling area and the collection area. The collection rotating wheel is perpendicularly or obliquely connected with the bin by a set angle and is connected with the first drive mechanism. The lower edge of the circumferential wall of the collection rotating wheel is arranged on the collection area and isconnected with the lowest edge of the bevel. Multiple blades are arranged on the inner circumferential wall of the collection rotating wheel. The conveying portion comprises a rotating disc, a mounting seat and a second drive mechanism. The rotating disc is arranged on the falling area and is horizontally and obliquely arranged on the mounting seat by a set angle. The system has the beneficial effects that modular design is achieved, the structure is compact and coordinated, running is stable, work efficiency is high, and the diversified requirements of clients for the feeding system are met.

Owner:无锡丹尼克尔自动化科技有限公司

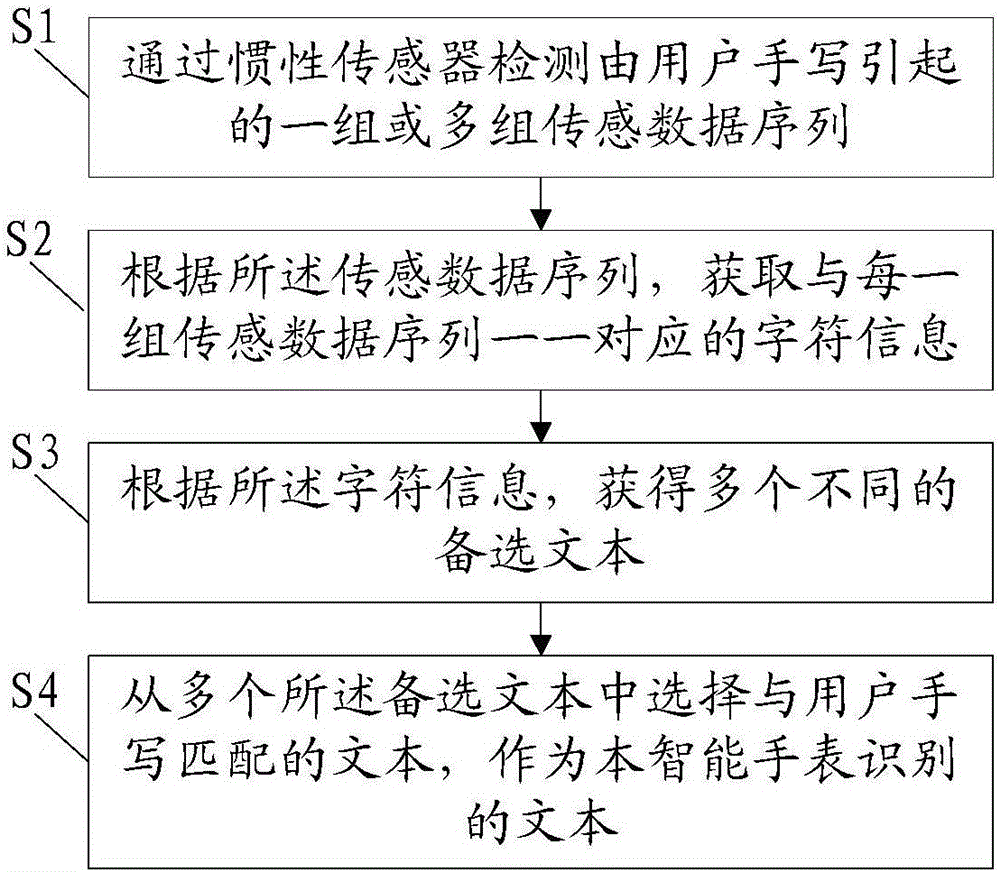

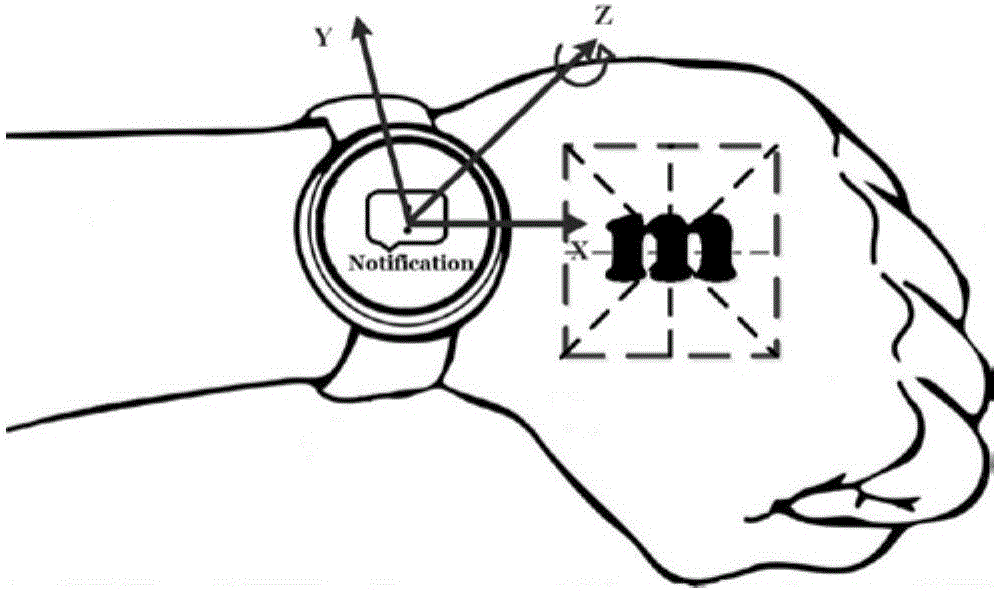

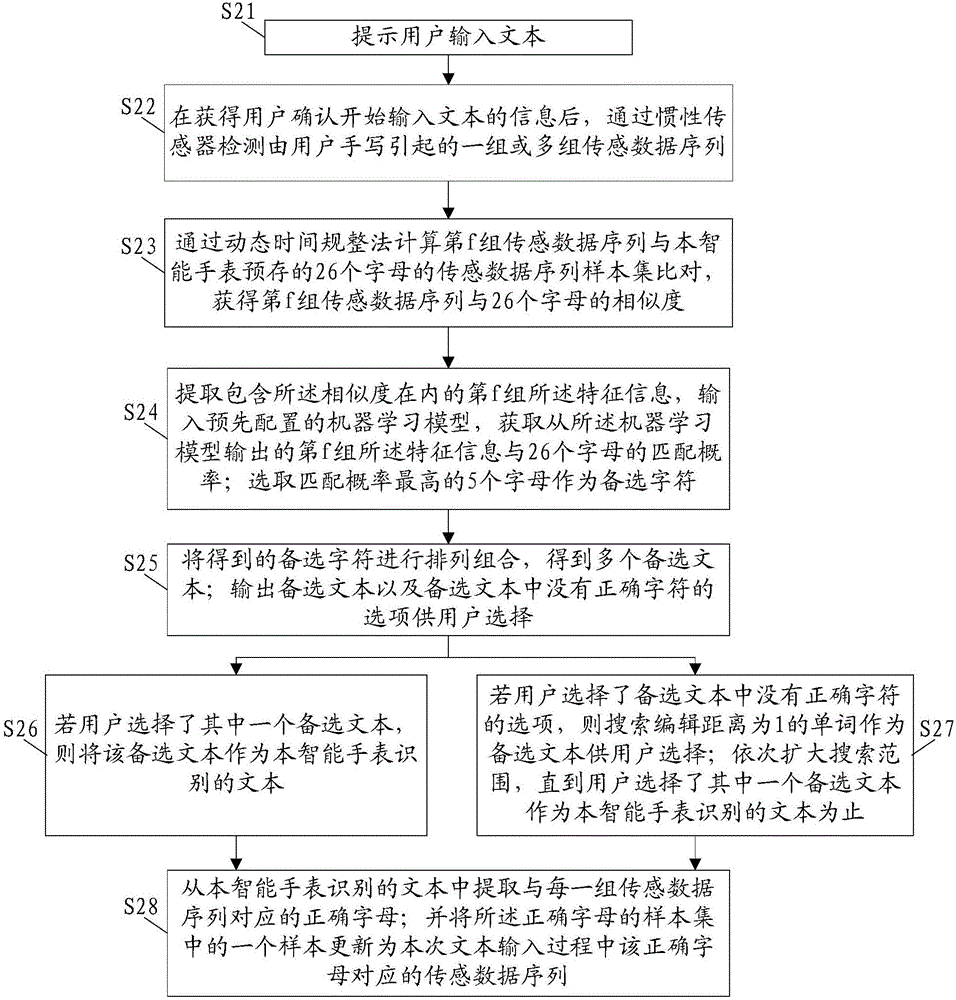

Text input method and device for smart watch

ActiveCN106339104AOvercome size limitationsOvercoming the demands of the surrounding environmentInput/output processes for data processingText entryComputer vision

The invention discloses a text input method for a smart watch. The text input method comprises the following steps: detecting one or more groups of sensor data sequences caused by user handwriting through an inertial sensor; acquiring character information corresponding to each group of sensor data sequences one by one according to the sensor data sequences, wherein each group of the character information comprises M candidate characters; acquiring a plurality of different candidate texts according to the character information; and selecting a text matched with the user handwriting from the plurality of candidate texts as the text recognized by the smart watch. Accordingly, the invention also discloses a text input device for the smart watch. The text input method and the text input device provided by the invention do not need to set a keyboard on a touch screen, overcomes the limitation on the size of the touch screen, also saves the space for displaying the keyboard, can have larger space for displaying other contents, and overcomes requirements of voice input on surroundings, so that the text input is not restricted by occasions.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

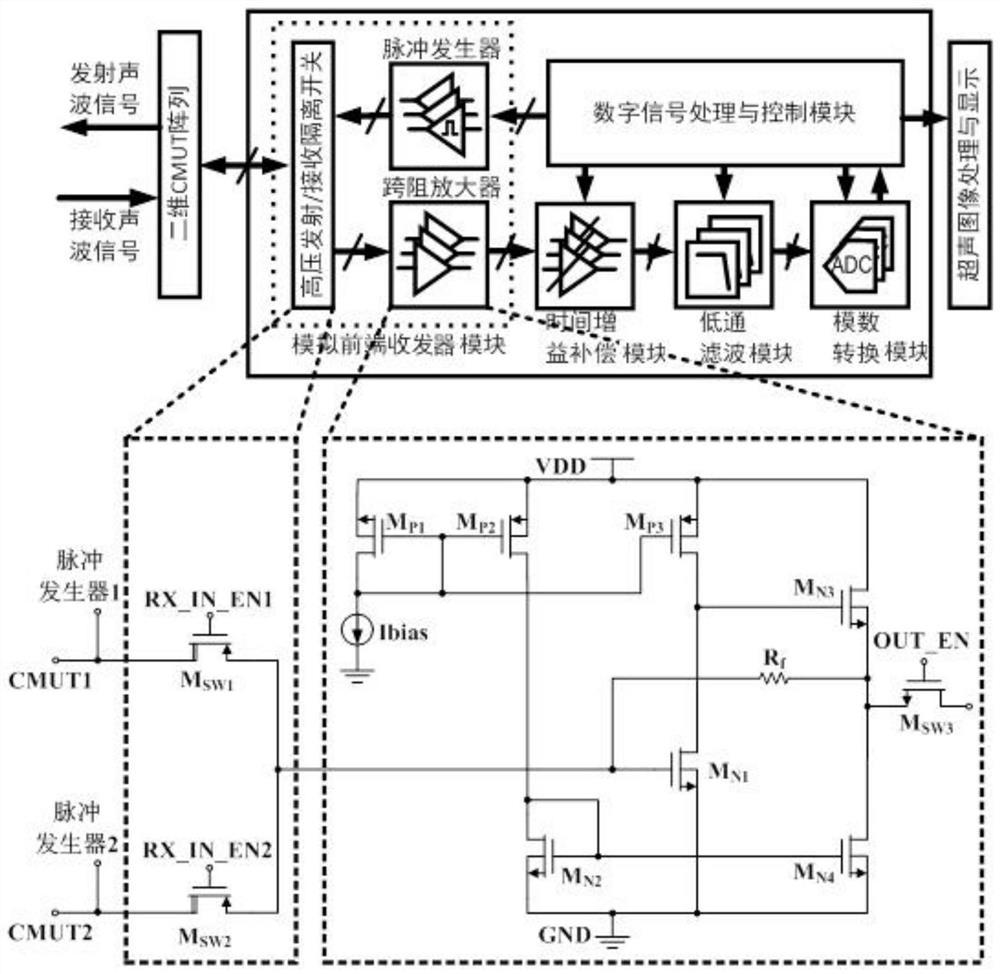

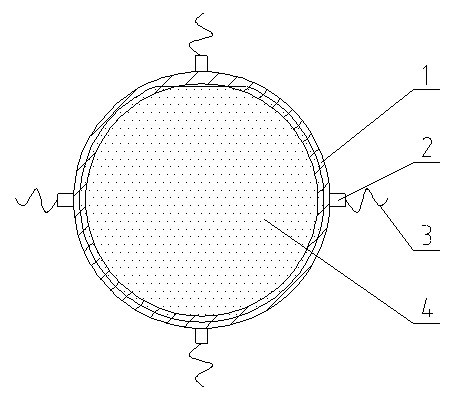

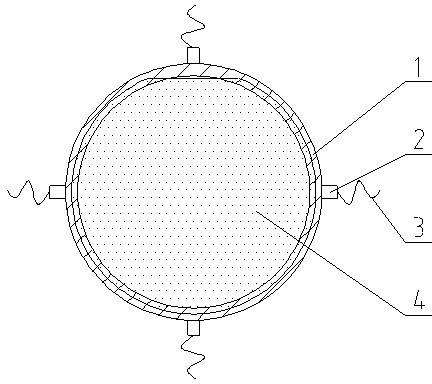

A three-dimensional ultrasound imaging system

ActiveCN110057921BImprove transconductanceImprove spatial resolutionMaterial analysis using sonic/ultrasonic/infrasonic wavesMeasurement apparatus componentsDigital signal processingTransceiver

The invention provides a three-dimensional ultrasonic imaging system, including: a two-dimensional CMUT array, an analog front-end transceiver module, a time gain compensation module, a low-pass filter module, an ADC conversion module, a digital signal processing and control module, and the analog front-end transceiver module The device includes: a high-voltage transmitting / receiving isolation switch, a transimpedance amplifier, and a pulse generator; the two-dimensional CMUT array and the array of analog front-end transceiver modules are correspondingly connected through vertical silicon vias; the transimpedance amplifier includes: a single-ended amplifier and a feedback resistor R f ; The single-ended amplifier is composed of a common-source amplifier MN1 cascaded with an N-type source follower MN3. The three-dimensional ultrasonic imaging system provided by the present invention has the characteristics of low input resistance, high transconductance and feedback resistance of the high-frequency transimpedance amplifier in the analog receiver, so that the system has a wider frequency bandwidth and enables the system to work at higher frequencies , the spatial resolution of 3D imaging is higher.

Owner:成都华芯微医疗科技有限公司

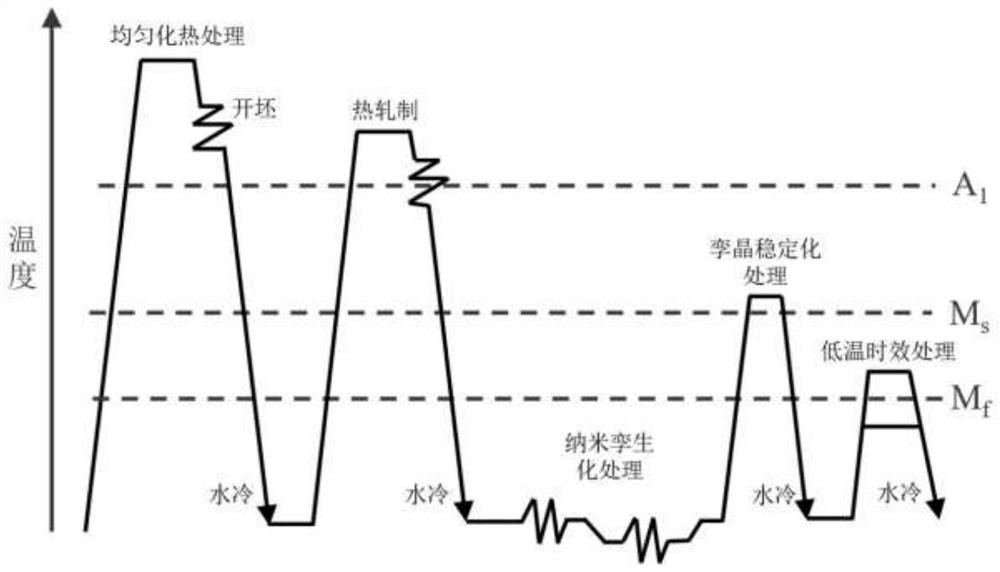

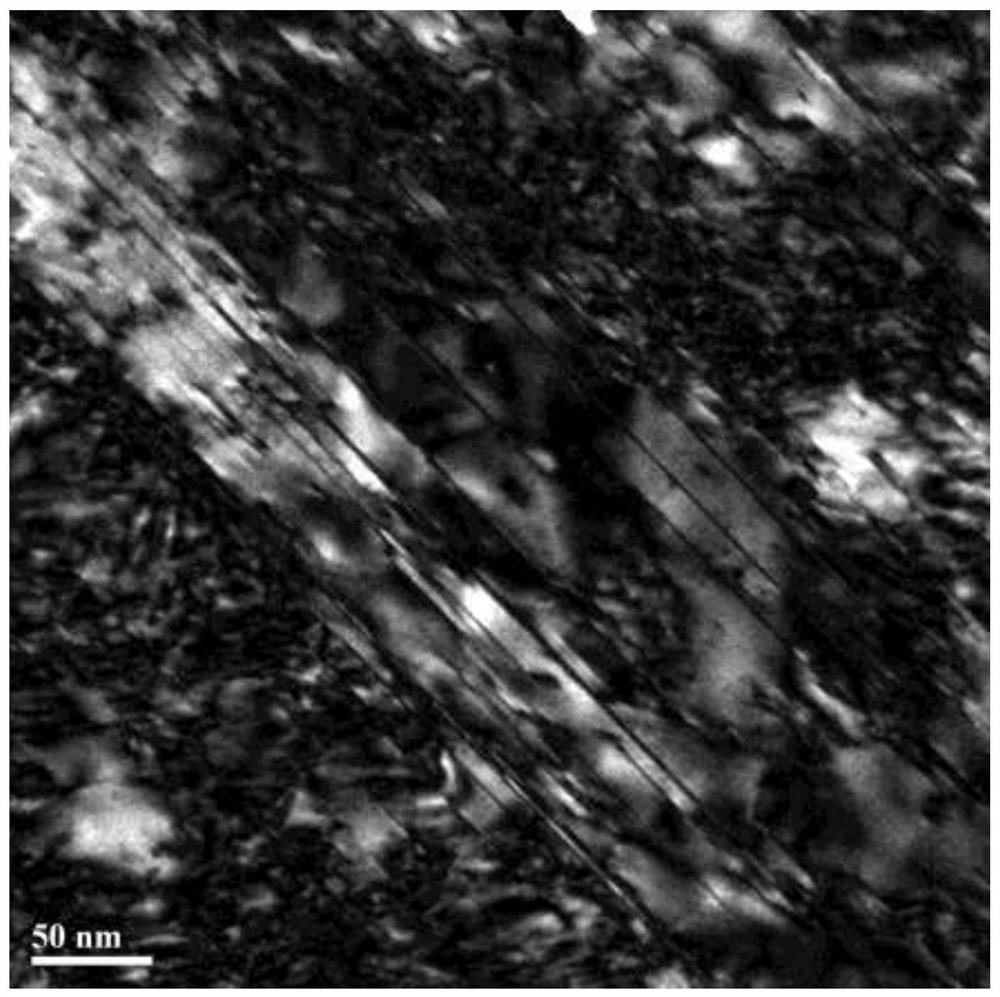

High-strength and high-toughness wear-resistant steel and preparation method for nano twin crystal reinforcement and toughening of high-strength and high-toughness wear-resistant steel

ActiveCN113388787AGood value for moneyImprove mechanical propertiesRoll force/gap control deviceTemperature control devicePressure castingIndustrial equipment

The invention relates to high-strength and high-toughness wear-resistant steel and a preparation method for nano twin crystal reinforcement and toughening of high-strength and high-toughness wear-resistant steel. The steel comprises the components in percent by mass: 0.35%-0.85% of C, 15.2%-24.8% of Mn, 0.1%-0.5% of Si, smaller than or equal to 1.0% of Al, smaller than or equal to 0.005% of S, smaller than or equal to 0.01% of P, 0.5%-1.5% of Nb, 0.2%-0.8% of Ti, 0.2%-0.75% of V, 0.005%-0.05% of N, 0.02%-0.1% of rare earth RE and the balance Fe and inevitable impurities. The stacking fault energy of an alloy is 24-30 kJ / m <2>, and the mass percent of the addition amount of Ti, Nb and V is 2: 1: 1. The preparation process comprises the steps of alloy smelting and negative pressure casting, homogenization heat treatment and cogging, hot rolling, nanometer twinning treatment, nanometer twinning stabilization and low-temperature aging treatment. According to the invention, fine structure regulation and control are carried out based on means of deformation and heat treatment by means of low fault energy and microalloying component optimization matching design, so that good structure matching is realized, and the alloy has high strength, high toughness and high wear resistance. The wear-resistant steel is excellent in comprehensive mechanical property, low in alloy cost, simple in preparation process, low in production and manufacturing cost and easy to put into industrial production and large-scale industrial equipment.

Owner:上交(徐州)新材料研究院有限公司

Chip back side drape tin eutectic technology and loading method thereof

InactiveCN102593010AOvercome size limitationsAvoid torsional driftSemiconductor/solid-state device manufacturingTinningAlloy

The invention relates to a chip back side drape tin eutectic technology and a loading method thereof. The method comprises the following steps: step (1), carrying out backside silver or backside gold processing on a chip back side; step (2), carrying out tinning or tin alloy work on a backside silver surface or a backside gold surface of a chip which is subjected to the backside silver or backside gold processing in the step (1); step (3), cutting the chip whose backside silver surface or backside gold surface is subjected to the tinning or tin alloy work in the step (2); step (4), employing eutectic technology to install the chip which is cut in the step (3) to a basic island to complete loading. According to the chip back side drape tin eutectic technology and the loading method, there is no requirement to chip dimension, after the chip back side is coated with a layer of tin or tin alloy, since the thickness of the tin or tin alloy can be controlled, the thickness of the tin or tin alloy can effectively absorb different stresses between the chip and the basic island, and lamination and rupture problems of a traditional eutectic chip are solved.

Owner:CHANGJIANG ELECTRONICS TECH CHUZHOU

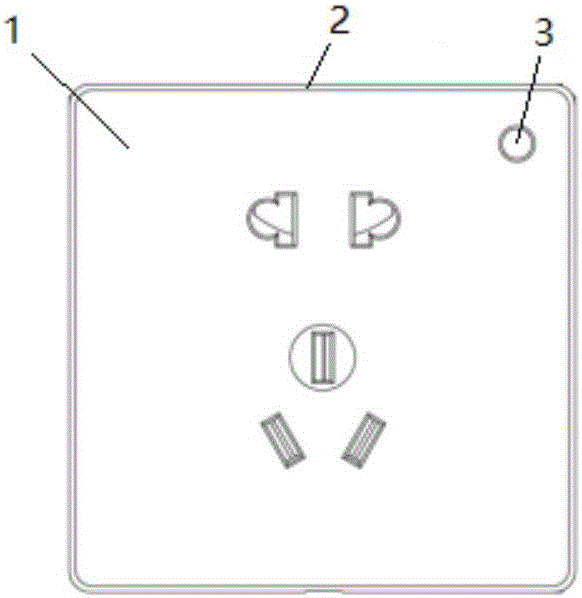

Wall-embedded smart five-hole socket

InactiveCN106654682AImprove practicalityHigh popularityCoupling device detailsNational standardMobile phone

The invention relates to a wall-embedded smart five-hole socket, and belongs to the technical field of sockets. The wall-embedded five-hole smart socket comprises a terminal fixing plate arranged in a bottom box, two relays, a five-hole socket inner core, a switching power supply module, a power detection PCB and a CPU main control board. In order to meet the requirements of a green energy-saving smart community advocated by the state at present, internal structure layout and functions of multiple existing external five-hole sockets and embedded five-hole sockets are combined, so that individual controlling and measurement and quantitative statistics of a remote smart terminal (mobile phone) on a two-hole jack and a three-hole jack of the smart five-hole socket are achieved, the utilization rate of the internal space of the bottom box is also improved, various control components are reasonably and compactly arranged in the bottom box, the size limitation of a national standard 86 box is overcome and the practicality and the universality of the embedded smart five-hole socket are improved.

Owner:SHANGHAI CITONG INFORMATION TECH CO LTD

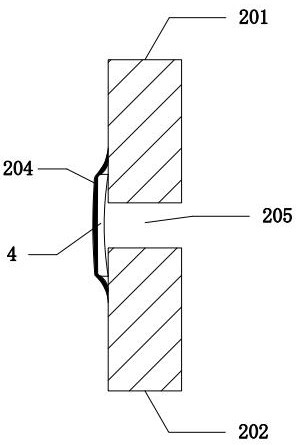

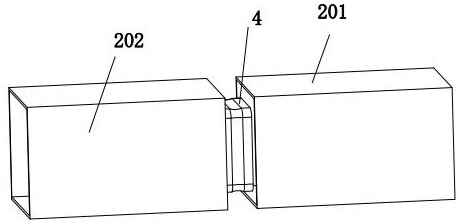

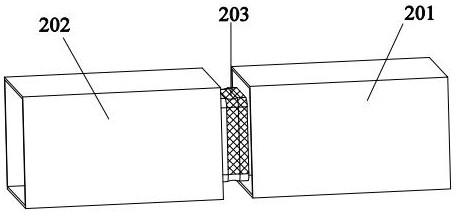

Butt welding auxiliary device for single-side welding and double-side forming of small-size rectangular pipe and construction method

ActiveCN112589370AOvercome size limitationsPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesWeld seamStructural engineering

The invention discloses a butt welding auxiliary device for single-side welding and double-side forming of a small-size rectangular pipe and a construction method. The auxiliary device comprises a body framework, a ceramic liner, a ceramic liner guide module and a limiting device. The limiting device comprises four tabulate limiting plates arranged on the upper, lower, left and right sides of a supporting framework, each limiting plate is connected with the supporting framework through multiple elastic connecting pieces, the ceramic liner guide module is a tapered square shell, the small end of the ceramic liner guide module is away from the ceramic liner, and the other end of the ceramic liner guide module is fixedly connected with the ceramic liner. According to the construction method,the ceramic liner is fixed to the inner side of a weld joint of a first rectangular pipe and a second rectangular pipe through the auxiliary device. The auxiliary device is high in assembling degree,and components of the auxiliary device are directly installed and used on a welding site after being prefabricated, machined and assembled in a factory. The assembling degree is high, and the weldingconstruction efficiency is improved.

Owner:SHANDONG JIAOTONG UNIV +1

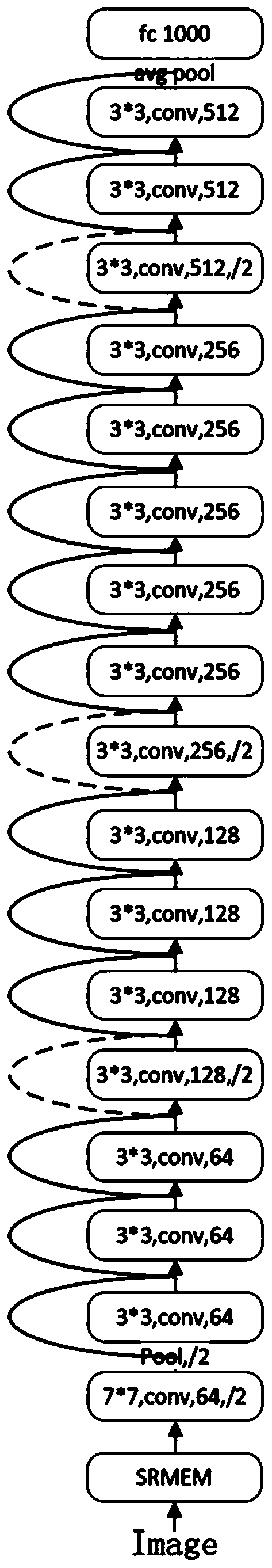

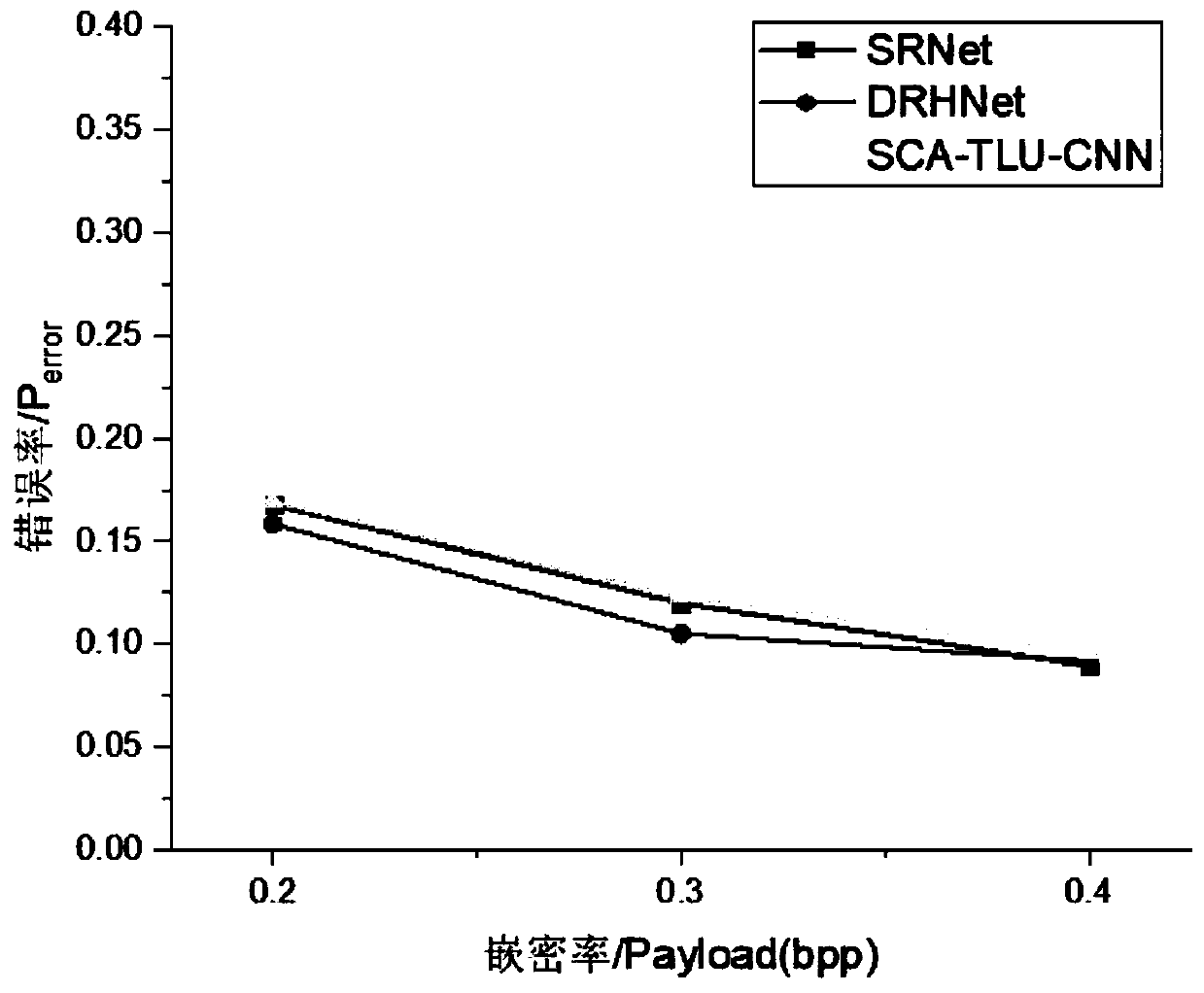

Deep residual steganalysis method based on heterogeneous kernel

ActiveCN110533575AReduce interferenceOvercoming the limitation of steganographic image sizeImage data processing detailsNeural architecturesNetwork modelConvolution

Owner:GUIZHOU NORMAL UNIVERSITY

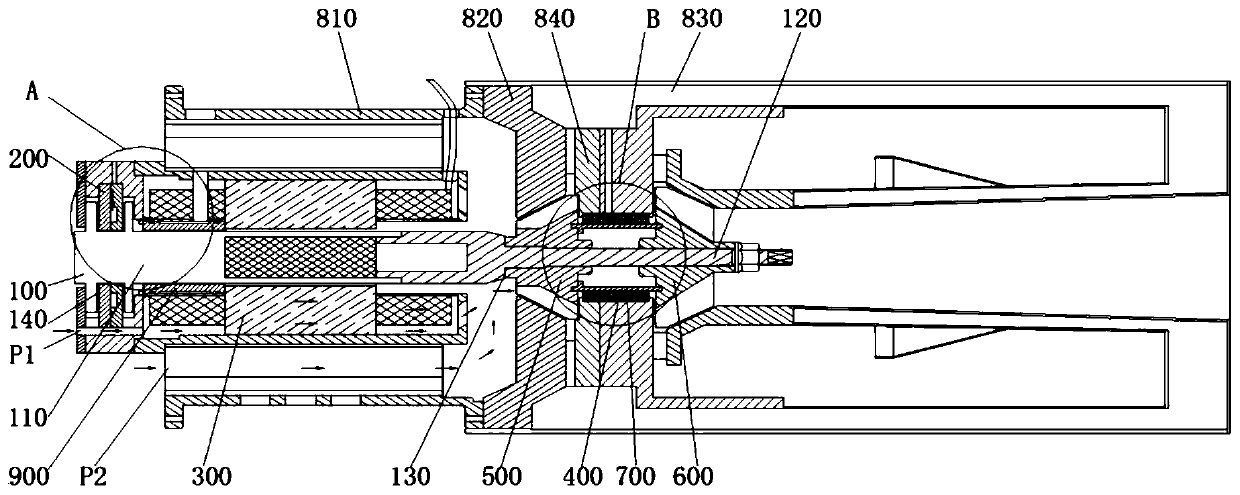

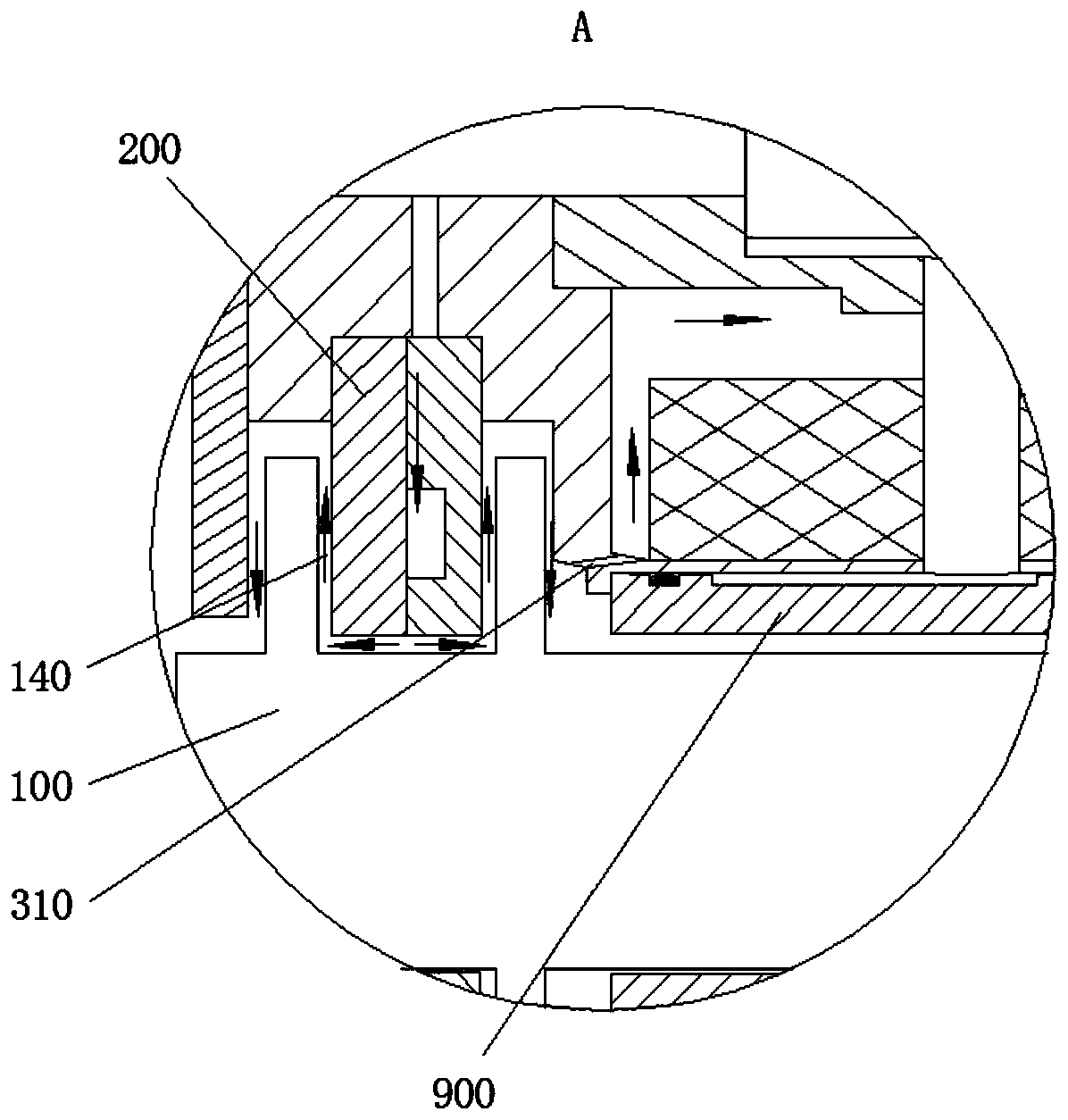

Long-span rotor system and gas turbine generator set

PendingCN110863910AImprove running stabilitySolve runnabilityGas turbine plantsJet propulsion plantsElectric machineGas compressor

The invention provides a long-span rotor system and a gas turbine generator set. The rotor system comprises a rotating shaft which is of an integrally formed structure. A thrust bearing, a first radial bearing, a motor, a gas compressor, a second radial bearing and a turbine are successively arranged on the rotating shaft. In the rotor system, two supporting points (the first radial bearing and the second radial bearing) are placed at two ends of the rotating shaft, separately, so that the rotating shaft is better in equilibrium and the rotor system is good in operating stability. The long-span rotor system can solve the problems of dimensional limit of the tail of the rotating shaft and unstable operation and severe vibration of the rotor system.

Owner:TECH XANADU OF RESONATORY SOLAR SYSTD CO LTD +1

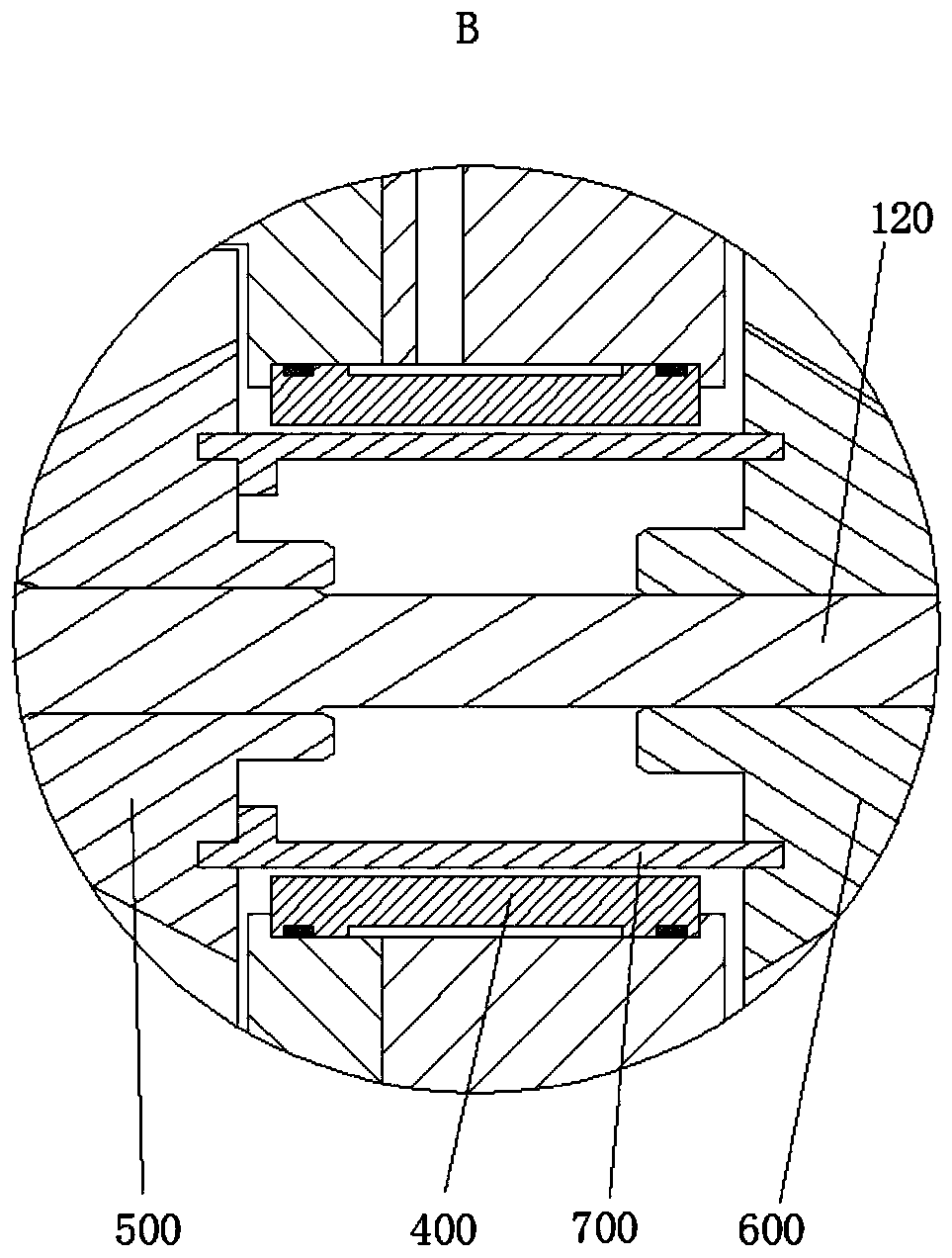

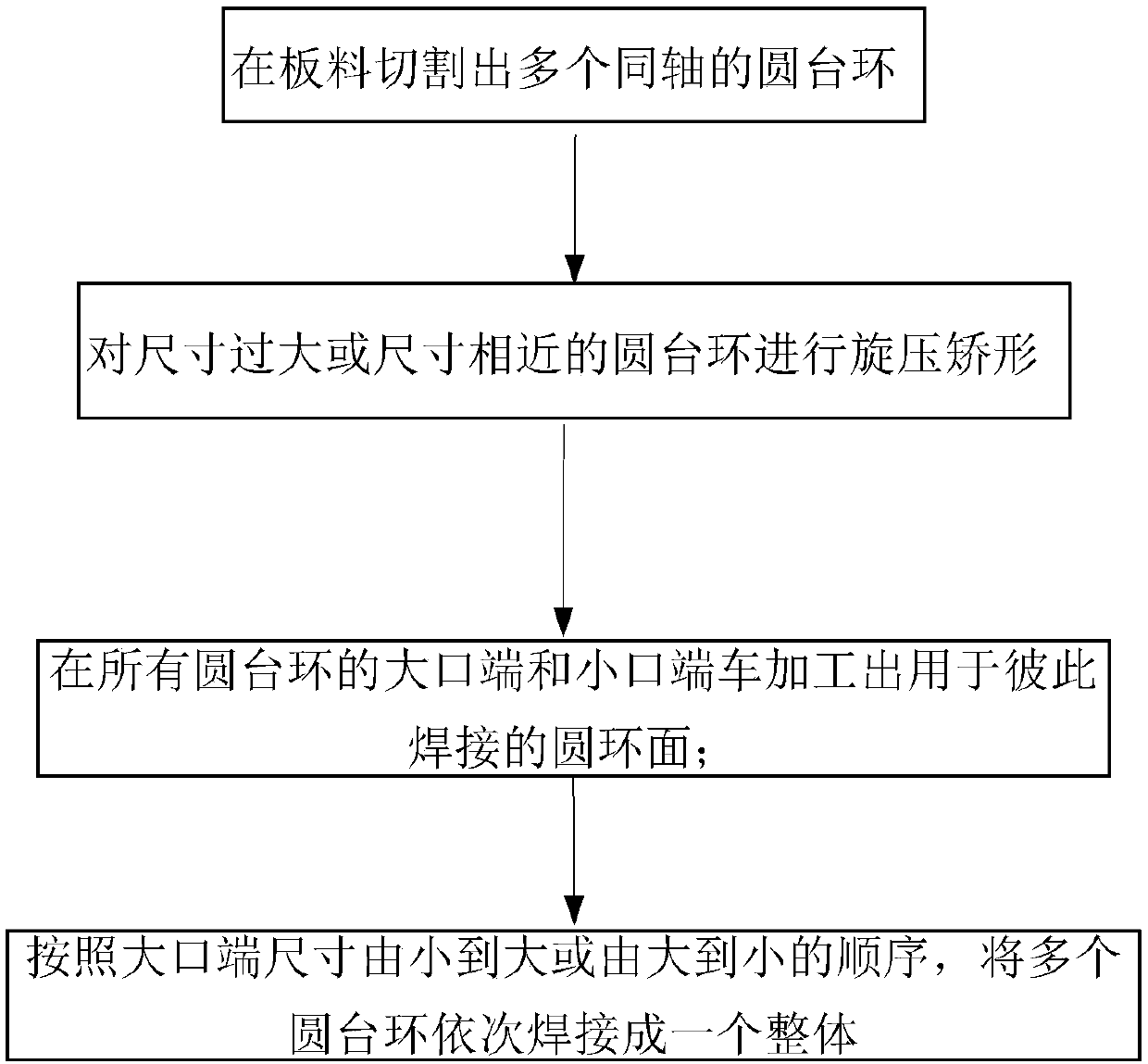

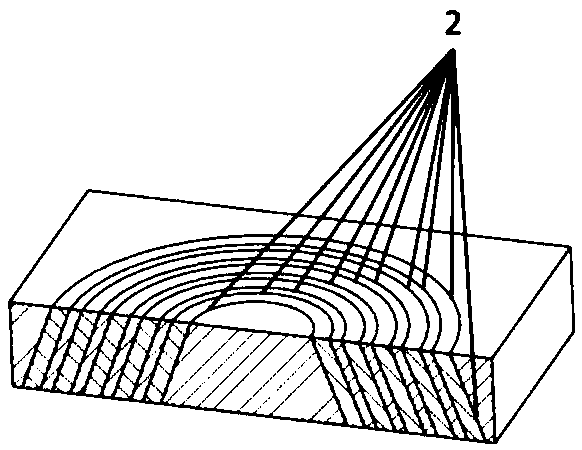

Forming method for airspace engine spray tube part

ActiveCN109676326ASimple processThe process is detectable and measurableJet propulsion plantsDiameter ratioEngineering

The invention provides a forming method for an airspace engine spray tube part. The method comprises the following steps: step I, cutting out a plurality of coaxial circular table rings on a plate; step II, performing spinning and shape-correcting on the circular table rings with too great dimensions or similar dimensions; step III, turning out circular ring surfaces which are welded with one another at large hole ends and small hole ends of all circular table rings; and step IV, sequentially welding the circular table rings into an integer according to the dimensions of the large hole ends from small to big or from big to small. The forming method for the airspace engine spray tube part provided by the invention has the advantages of being simple in process, not limited by an axle diameter ratio and a dimension, being capable of detecting and measuring the process, capable of being integrally formed, being high in production quality stability, being suitable for large-batch automaticproduction, and the like.

Owner:BEIJING LANDSPACETECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com