Non-contact type on-line detector for piston pin external diameter

A non-contact, piston pin technology, applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of low price, low-end competition, low detection efficiency, etc., to improve detection accuracy, improve efficiency, and operate quickly Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

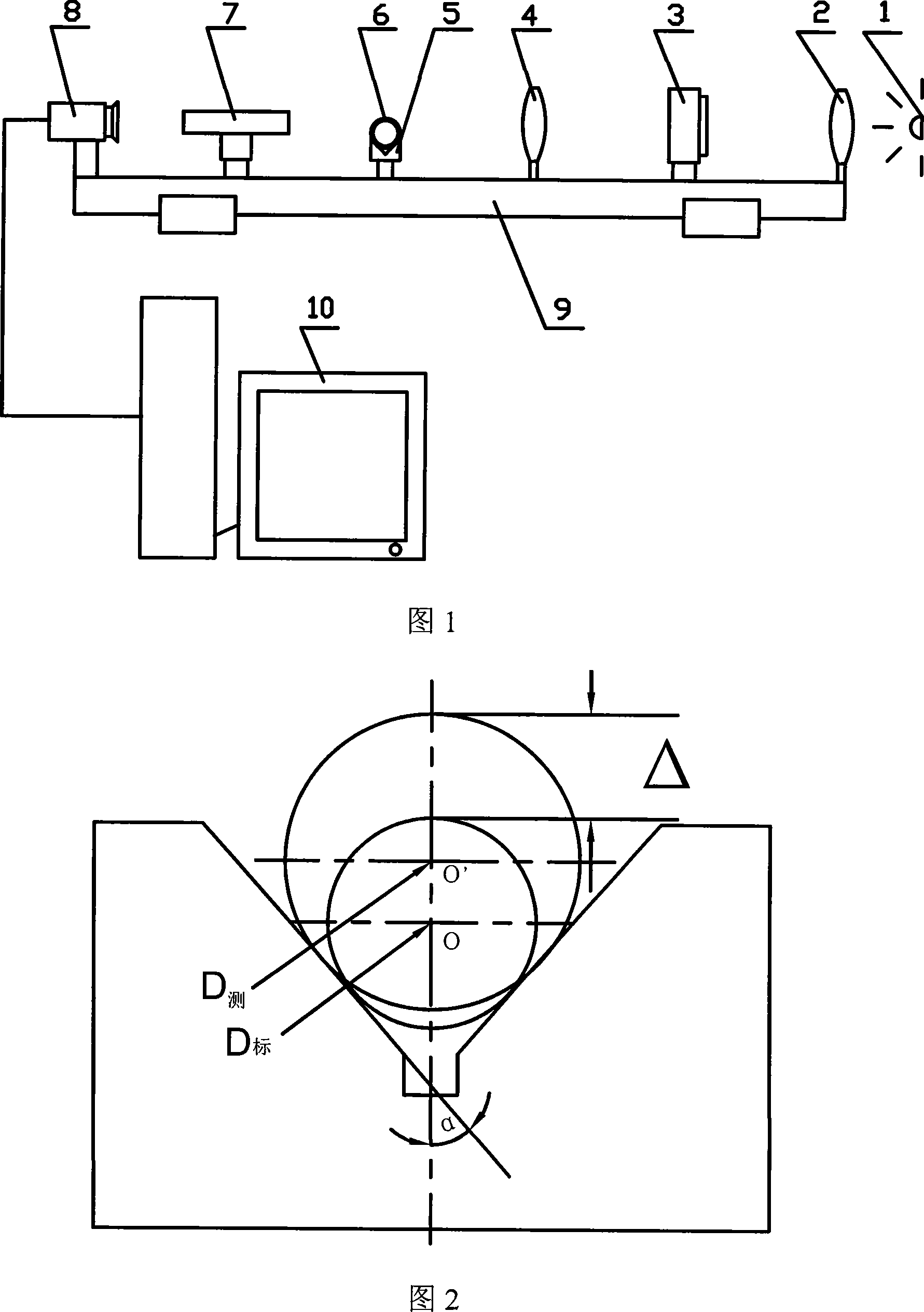

[0014] The device for non-contact on-line detection of the outer diameter of the piston pin of the present invention utilizes modern optical technology, digital technology, image processing technology, etc. to measure the outer diameter of the piston pin on-line. , CCD collects image data and inputs it to the computer, and performs sub-pixel processing on the image through software programming, and finally obtains the outer diameter of the workpiece to be measured, and realizes the measurement of the outer diameter of the piston pin.

[0015] As shown in Fig. 1, light source 1, lens 2, diaphragm 3, lens 4, V-shaped groove 5, objective lens 7 and area array CCD8 are installed on the guide rail 9 in sequence, and are located on the same optical axis, and the V-shaped groove 5 is located in the same optical axis. The measured piston pin 6 is installed, and the area array CCD8 is connected with the computer 10 through the data acquisition card.

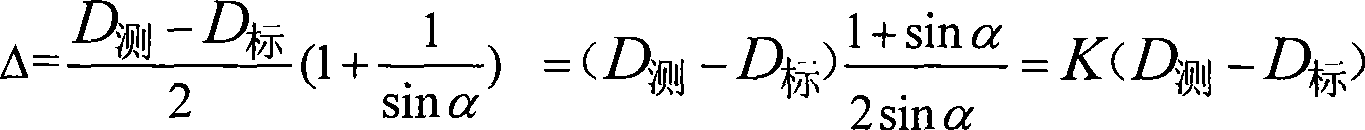

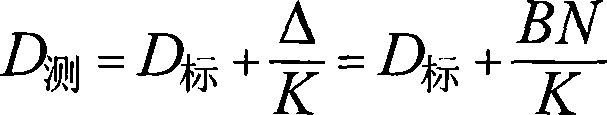

[0016] The measured piston pin 6 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com