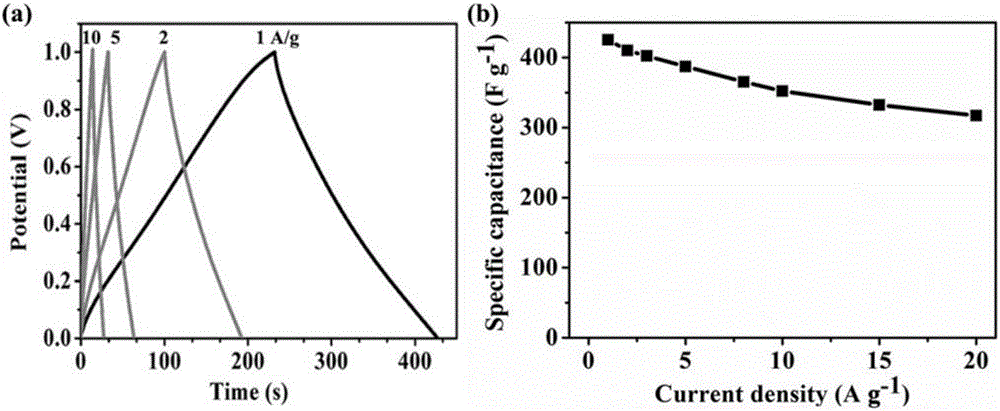

Method for increasing specific capacitance of graphene-based supercapacitor

A supercapacitor, graphene-based technology, applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problem of low capacitance retention rate of capacitance, achieve excellent specific capacitance, short reaction time, and good energy storage performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described further below in conjunction with example, but the present invention is not limited to specific embodiment.

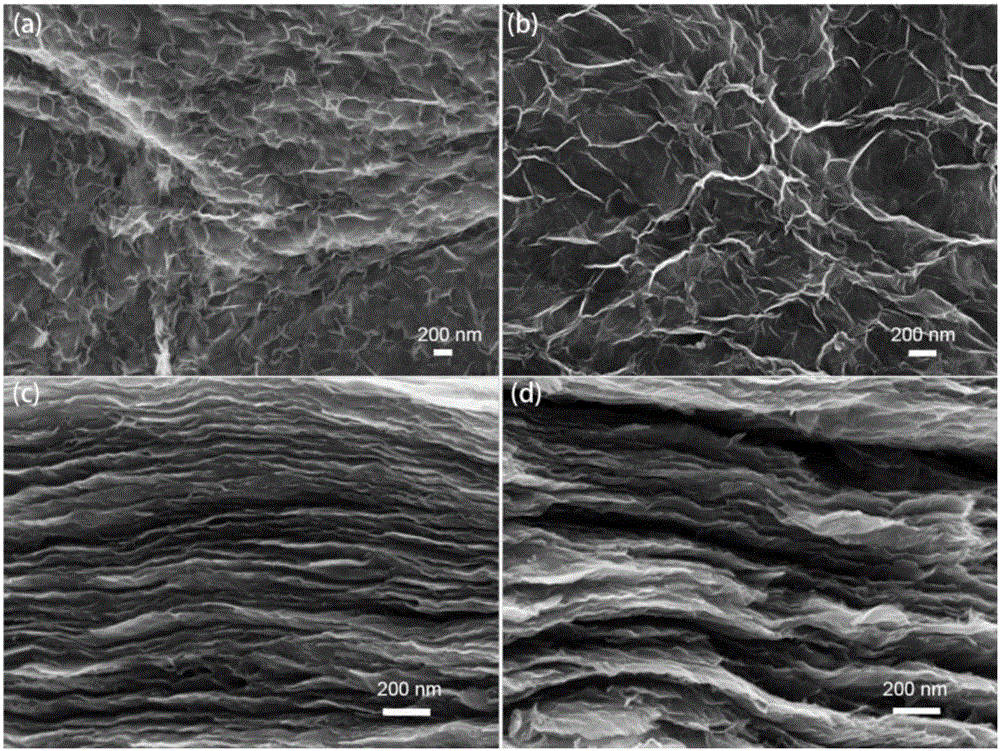

[0021] (1) Measure 5ml of 9.8mg / ml liquid crystal graphene oxide in a beaker, then add 245mg of sodium chloride and 245mg of urea, add deionized water to dilute the graphene oxide to 3mg / ml, add The rotor was subjected to magnetic stirring and ultrasonic vibration for 3 hours, and then stood still for one day to obtain a uniform liquid crystal graphene oxide / sodium chloride / urea mixed dispersion.

[0022] (2) Place the prepared liquid crystal graphene oxide / urea / sodium chloride dispersion on the glass substrate at the front edge of the scraper of the scraper coater, set the distance between the scraper and the substrate to 1mm, and advance the scraper at a specified speed of 120r / min, evenly The dispersion liquid was coated on the glass to form a liquid crystal graphene oxide / urea / sodium chloride film.

[0023] (3) Stand still...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com