Ink jet print head with automated cleaning at the start of printing

A print head, print head technology, applied in the field of inkjet print heads that are automatically cleaned at the beginning of printing, can solve the problems of high cost of cleaning measures, long operating time, etc., achieve excellent jet start reliability, prevent pollution, and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

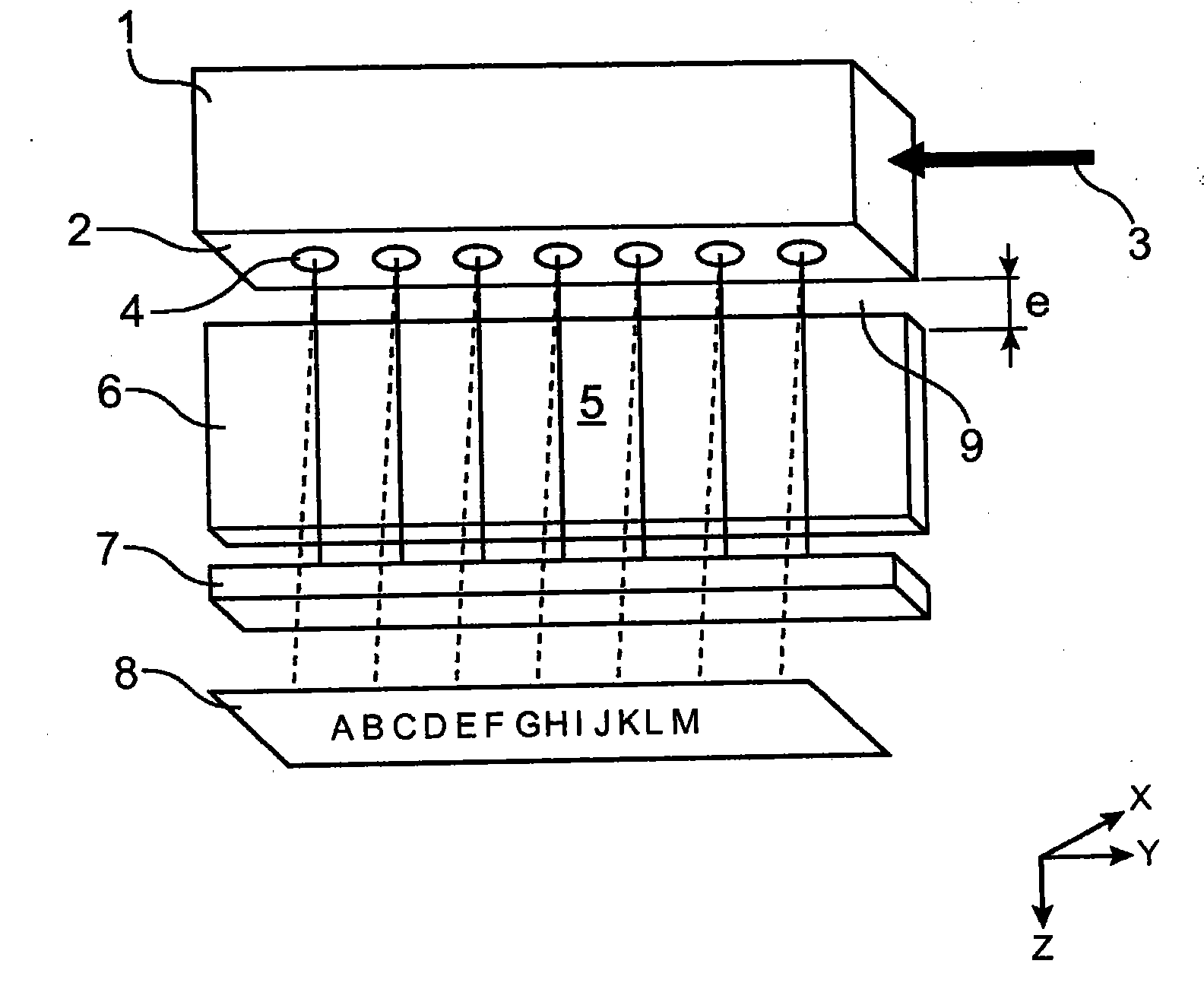

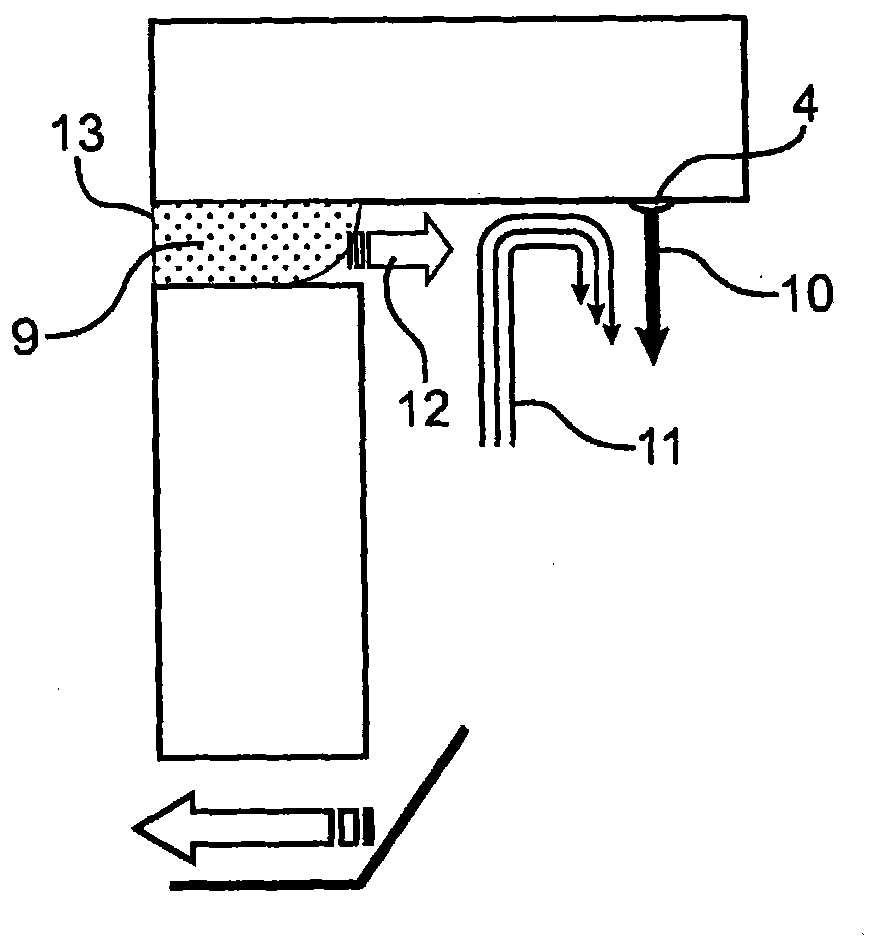

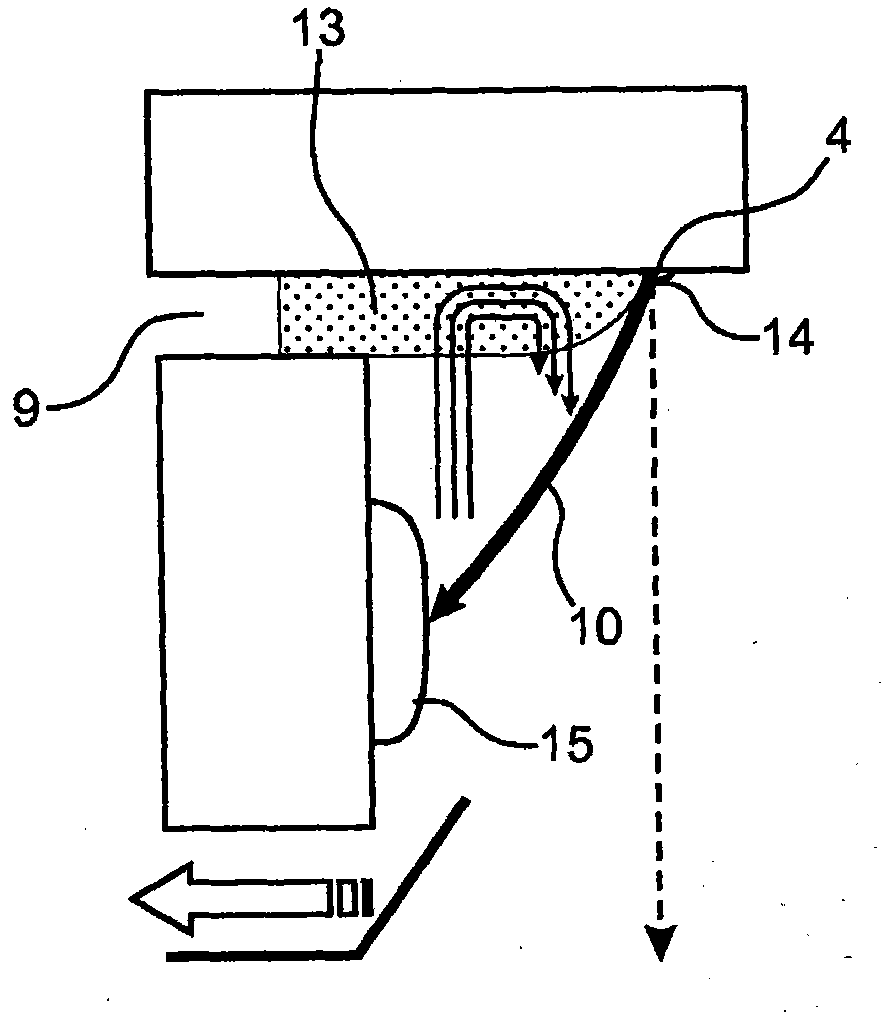

[0049] The print head T according to the invention comprises a droplet generator 1 equipped with a nozzle plate 2 . During the printing phase, the ink 3 pressurized in the generator 1 flows out through the nozzles 4 to form a jet curtain. Downstream of the nozzle plate 2 in the ink flow direction (along the Z-axis), a sorting block 5 including a functional electrode portion 6 is positioned. The role of this electrode part 6 is to be placed on the different jet trajectory parts, most of the jets are collected by the recirculation compartment 7, while the other jets are directed towards the medium to be printed 8 ( figure 1 ).

[0050] The terms "lower" and "upper" are to be understood as orienting the print head downwards (jet flow in z direction), in other words having the aforementioned generator 1 partly directly above the electrode block 5 according to the invention.

[0051] Between the nozzle plate 2 and the sorting block 5, a space 9 is constructed, the thickness of wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com