Particle extruding and forming mechanism provided with concave-convex pattern roller pairs

A technology of extrusion mechanism and pattern roller, which is applied in the extrusion and granulation of molds, material forming presses, presses, etc., can solve the problems of low safety, easy to get stuck, easy to damage, etc. Enhanced die hole strength and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

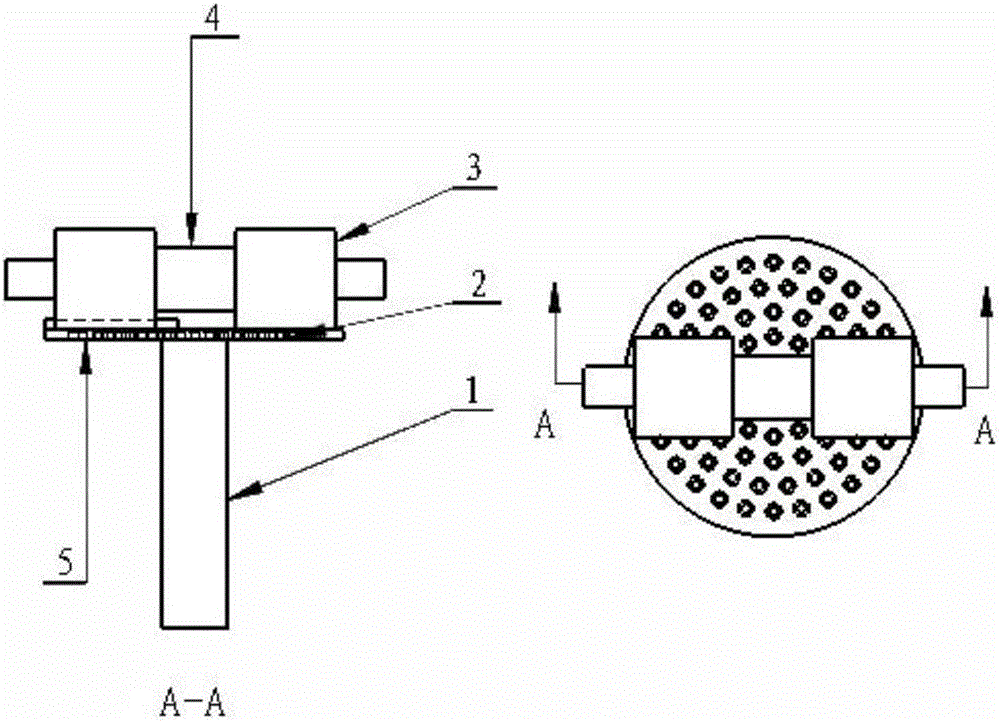

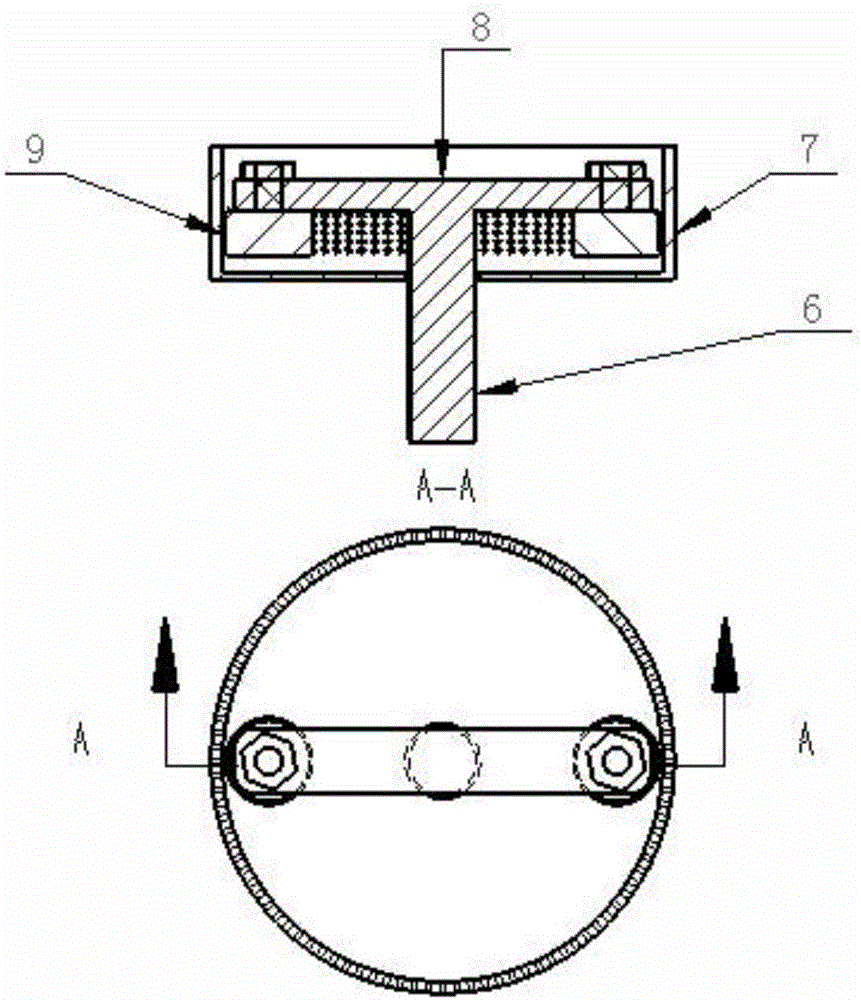

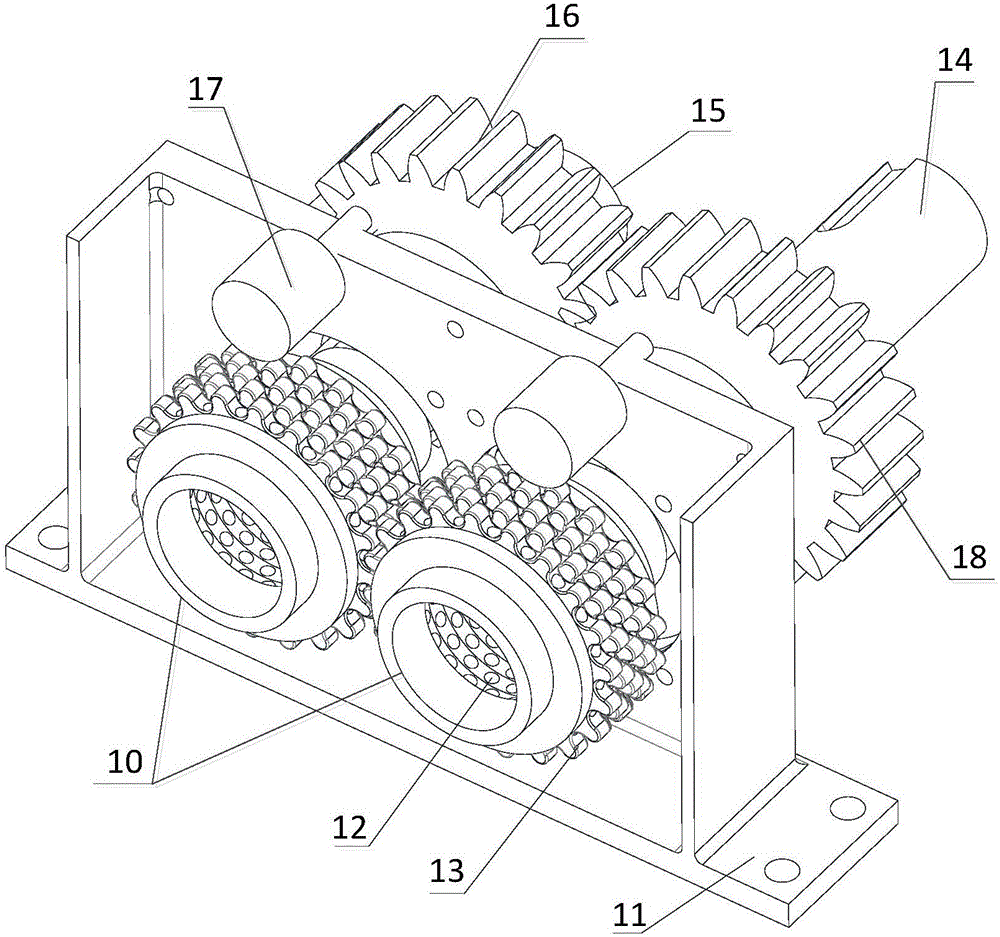

[0047] Such as Figure 3-7As shown, the concave-convex pattern roller-to-extrusion compression molding particle mechanism includes a headstock 11 and a transmission extrusion mechanism arranged on the headstock. Transmission shaft 14, the driving gear 18 that is located on the main transmission shaft, the driven gear 16 that meshes with the driving gear, the driven gear is provided with the driven shaft 15. The machine head base includes a base and a stand, the base is provided with screw holes, and the two sides of the stand are provided with partitions.

[0048] The transmission extrusion mechanism also includes a pair of extrusion rollers 10 that are fixedly connected to one end of the main transmission shaft 14 and the driven shaft 15 respectively and are used to extrude the compressed material. The rollers of the extrusion rollers are hollow rollers, and the rollers A plurality of die holes 12 are arranged on the cylinder, and the die holes run through the inner and oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com