Material fatigue performance obtaining method for sheet sample

A technology of fatigue performance and acquisition method, which is applied in the direction of testing the strength of materials by applying repetitive force/pulsation force, and can solve problems such as lack of universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

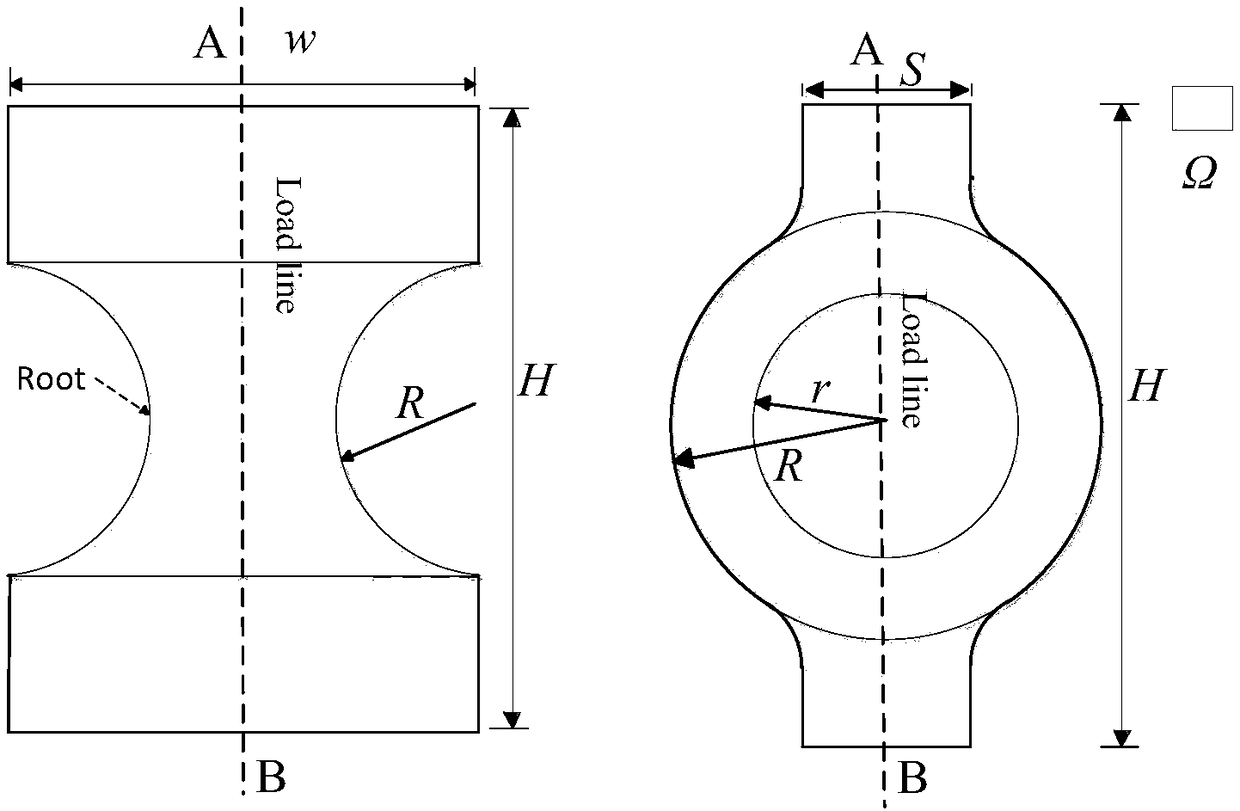

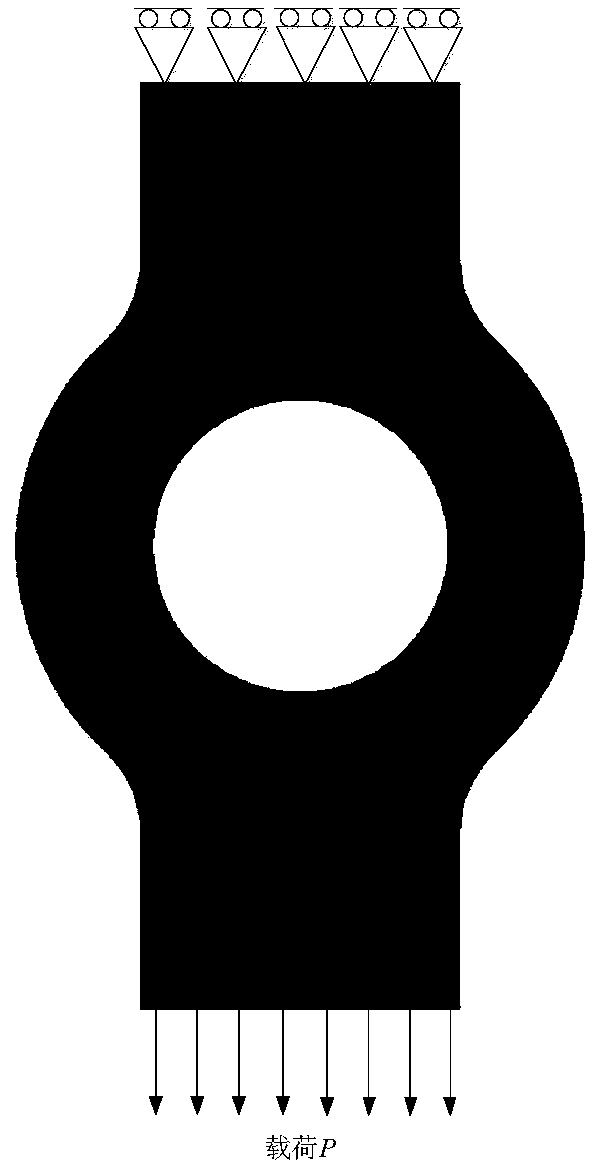

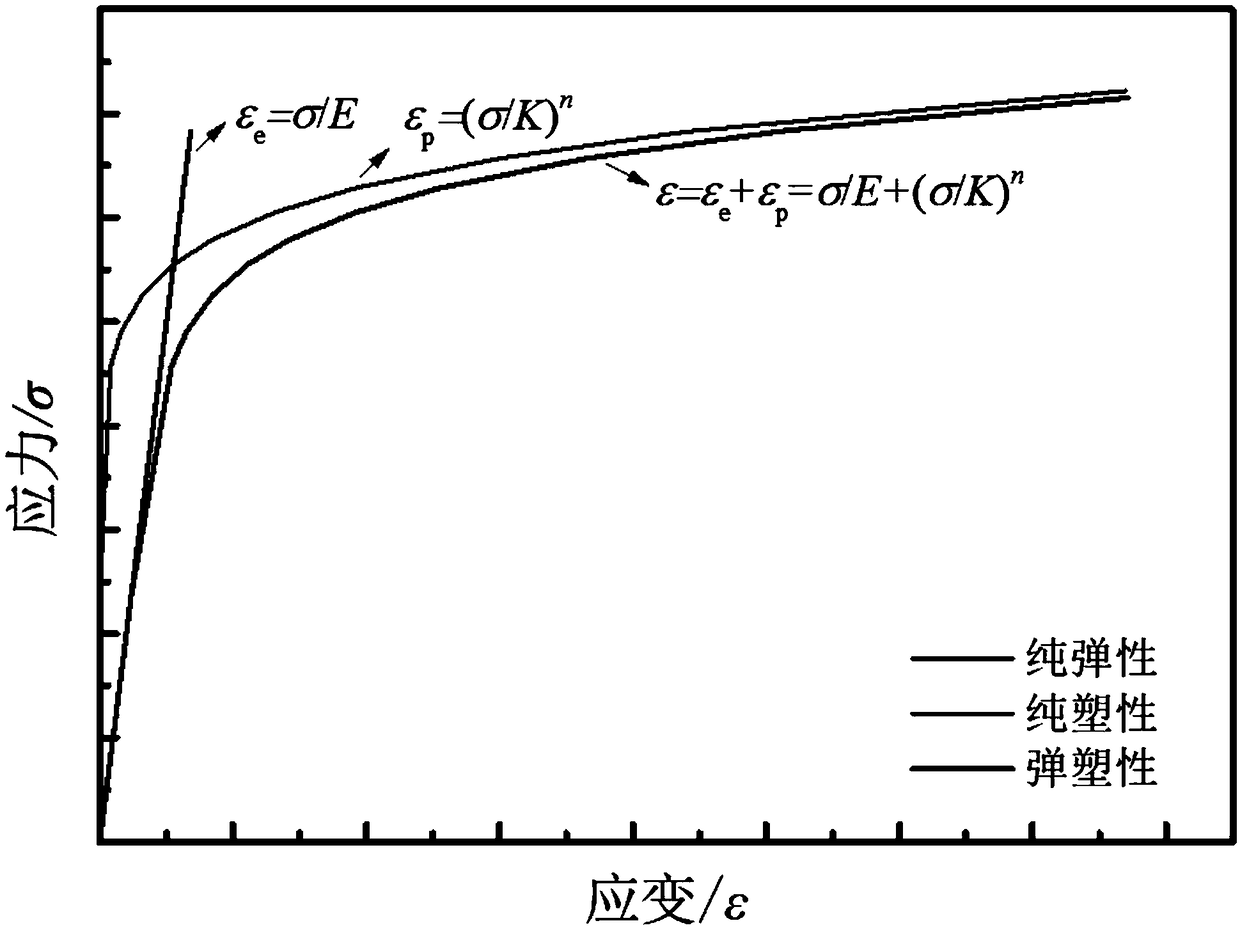

[0073] The present invention takes the fatigue performance test of the funnel slice sample and the ring slice as an example. The sample is divided into a clamping section and a working section. The working sections of the two samples are as follows: figure 1 shown. Establish the finite element simulation model, the grid model of the working section is as follows figure 2 As shown, one end adopts a fixed hinge, and the other end is unidirectionally loaded. The Ramberg-Osgood constitutive model is used as the material property for calculation, the model curve is as follows image 3 , including elastic modulus, strengthening coefficient and hardening index, changing different material parameters and geometric configuration parameters to perform finite element simulations of various working conditions, obtain corresponding load-displacement curves, and calibrate elastic and plastic coefficients.

[0074] The GH4169 material funnel sheet sample is used to complete the tension-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com