Scanning method for projected capacitive touch panels

A touch panel and projected capacitive technology, applied in the direction of electrical digital data processing, input/output process of data processing, instruments, etc., can solve the problem of reduced positioning accuracy, achieve improved positioning accuracy, increased scanning frequency, and obvious advantages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

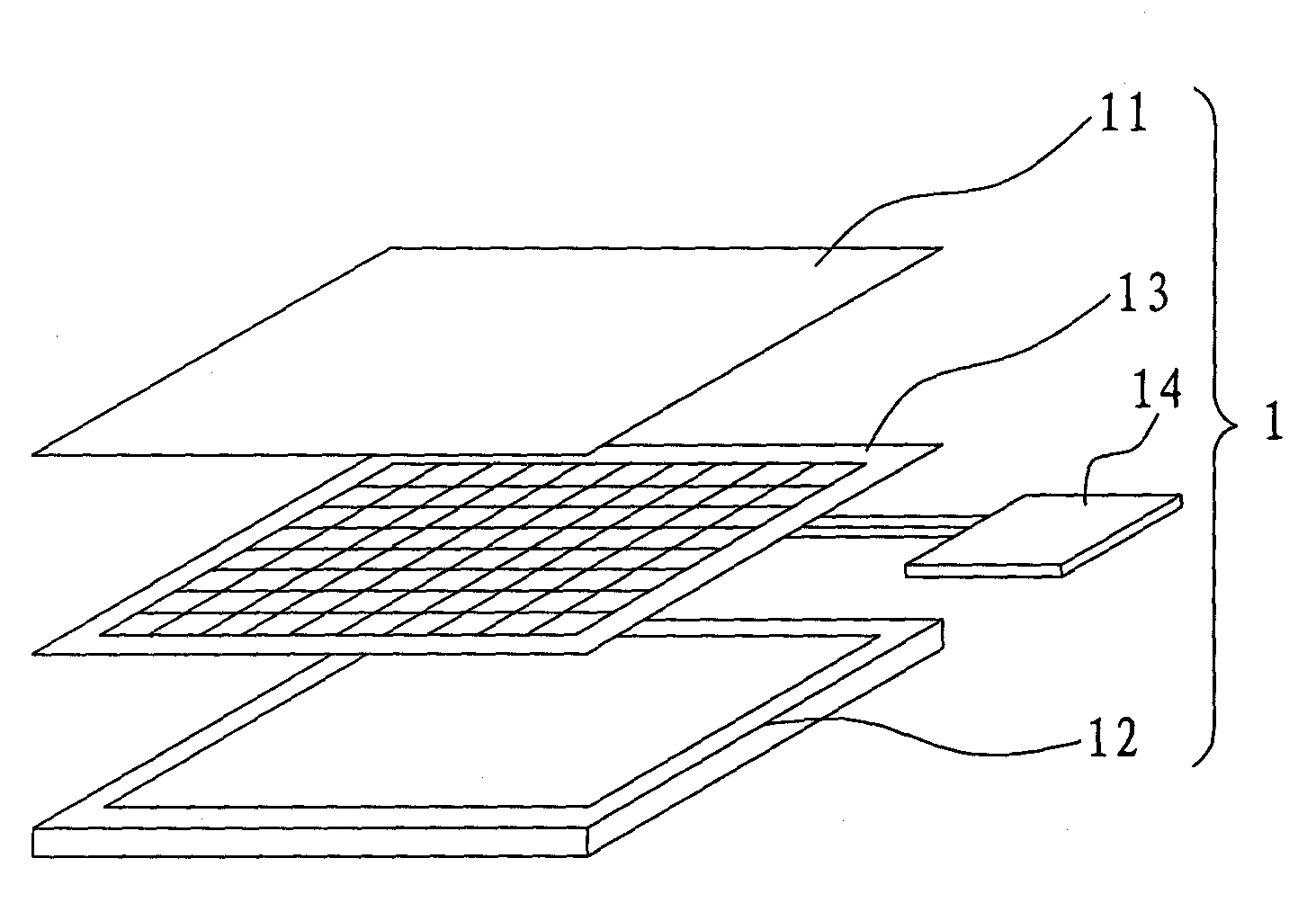

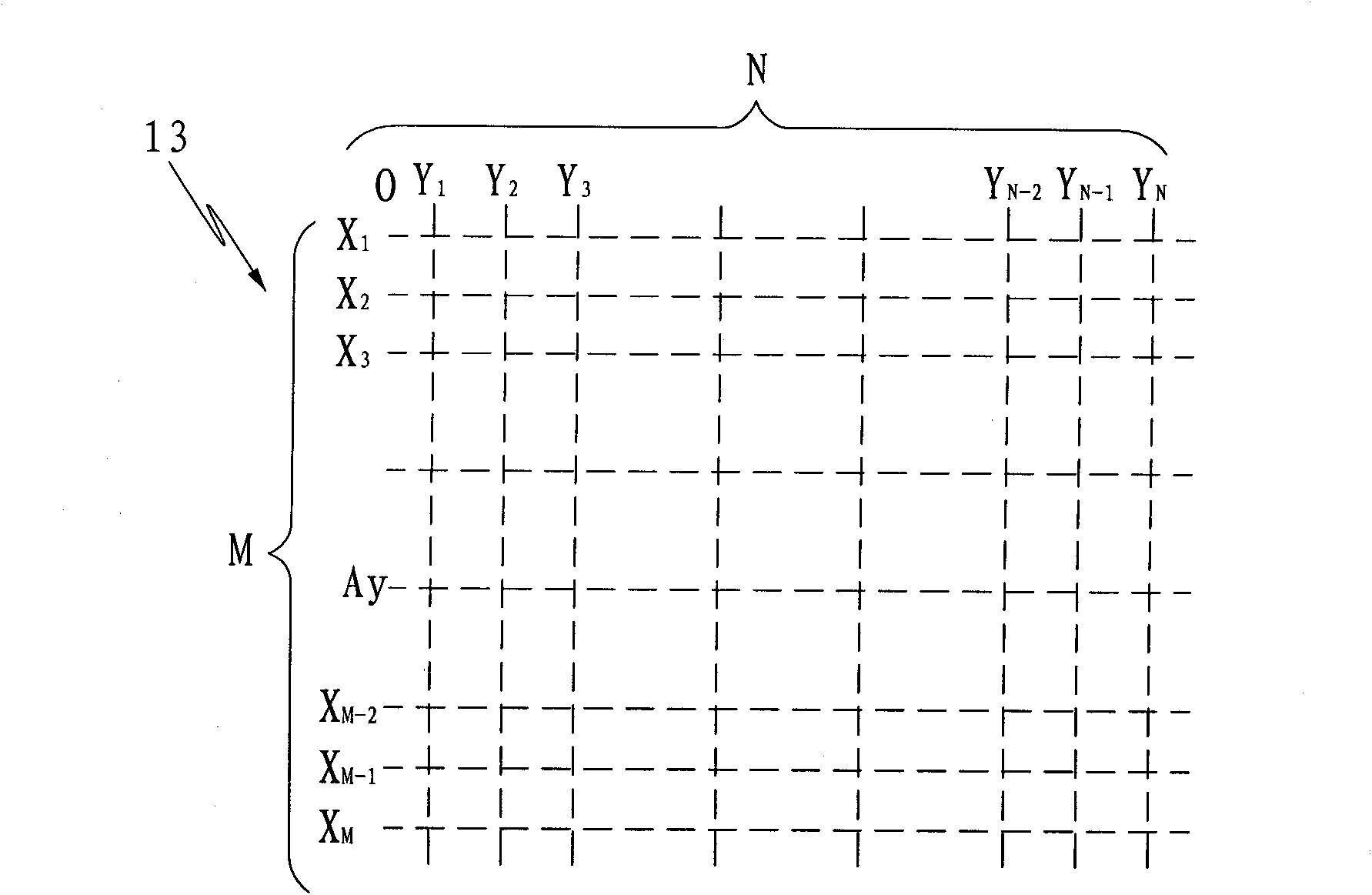

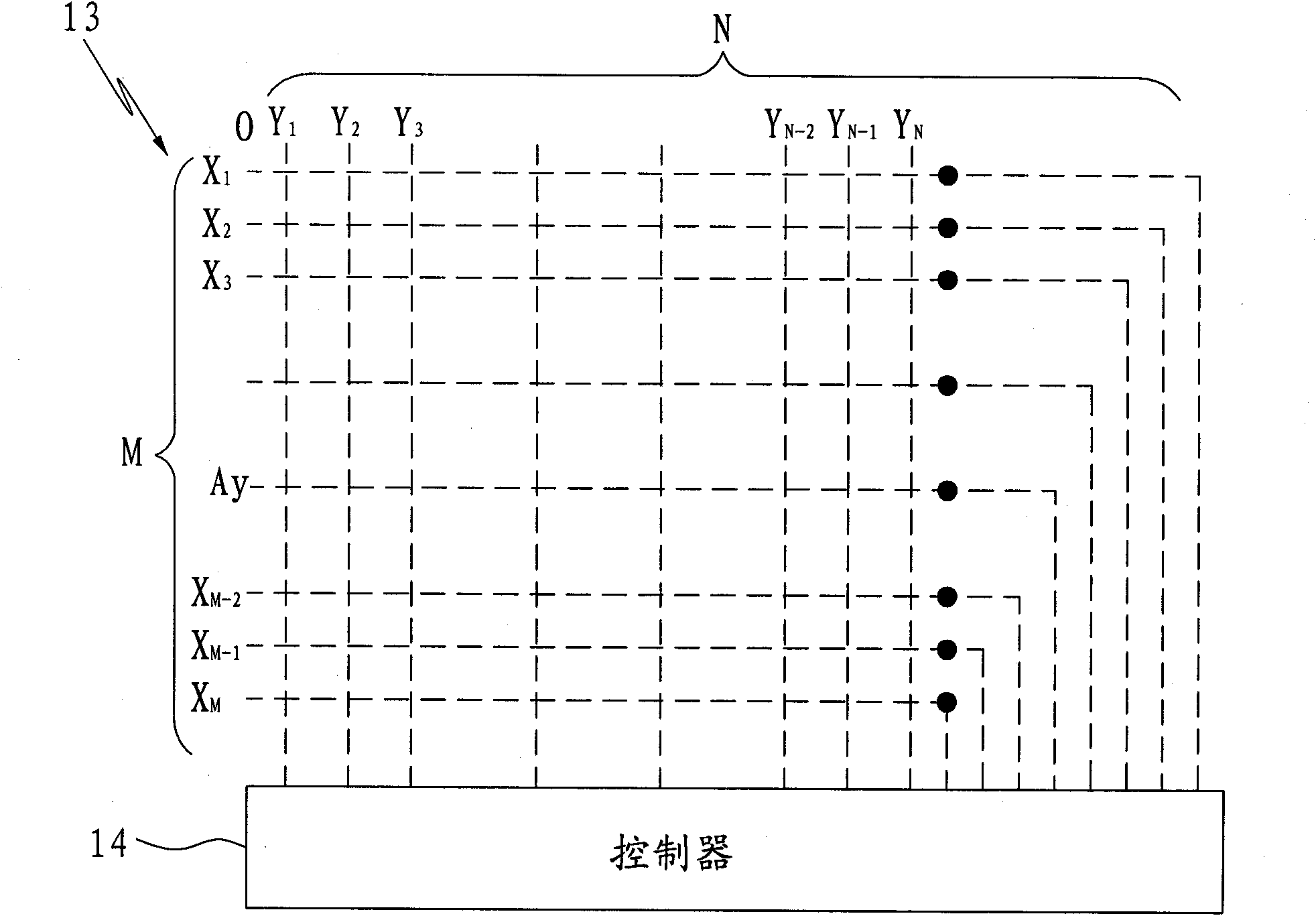

[0050] The scanning method of the present invention is mainly completed by the projected capacitive touch panel 13 and the controller 14, such as image 3 Shown: the electrical connection between the projected capacitive touch panel 13 and the controller 14, the projected capacitive touch panel 13 includes conductive electrodes insulated from each other, that is, arranged along the first direction (X-axis direction) M (M ≥ 1) first electrodes (horizontal axis electrodes) substantially parallel to each other and N (N ≥ 1) arranged along the second direction (Y-axis direction) that are also substantially parallel to each other and perpendicular to the horizontal axis electrodes ) strips of the second electrode (vertical axis electrode), the first electrode and the second electrode are formed in an electrode matrix between each other, and the first electrode or the second electrode is respectively connected to a third-party potential (human finger, M and N self-capacitances are f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com