Automatic stacking/reclaiming system for bulk cargo storage yard

A stacking and automatic technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of low cost, high precision, and inability to share stacking space data, and achieve low cost, high efficiency, and long-term stable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Below in conjunction with the drawings, preferred embodiments of the present invention are given and described in detail.

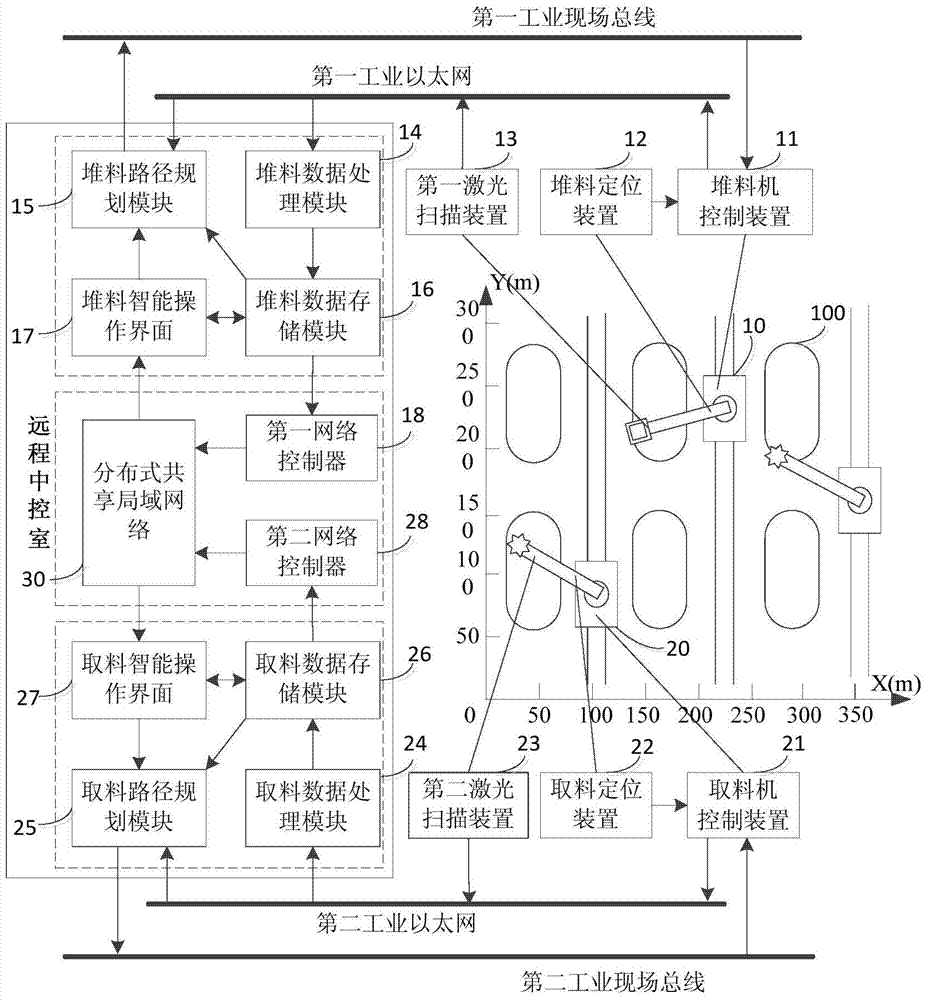

[0064] Such as figure 1 As shown, the present invention provides an automatic stacking and reclaiming system for bulk cargo yards to realize the purpose of automatically stacking bulk cargo into a stockpile 100 and taking materials from the stockpile 100, which includes The stacker 10 with the stacker cantilever and the reclaimer 20 with the reclaimer cantilever, and also includes: the first and second laser scanning devices 13, 23 installed on the stacker and reclaimer 10, 20 Stacking and reclaiming positioning devices 12, 22, stacking and reclaiming machine control devices 11, 12, remote stacking and reclaiming processing devices, and data sharing devices.

[0065] Each component is described in detail below:

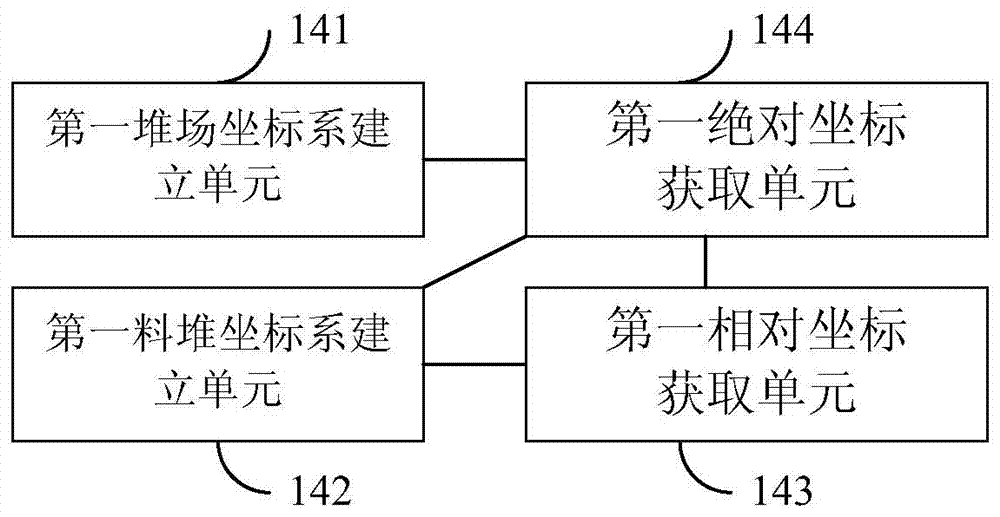

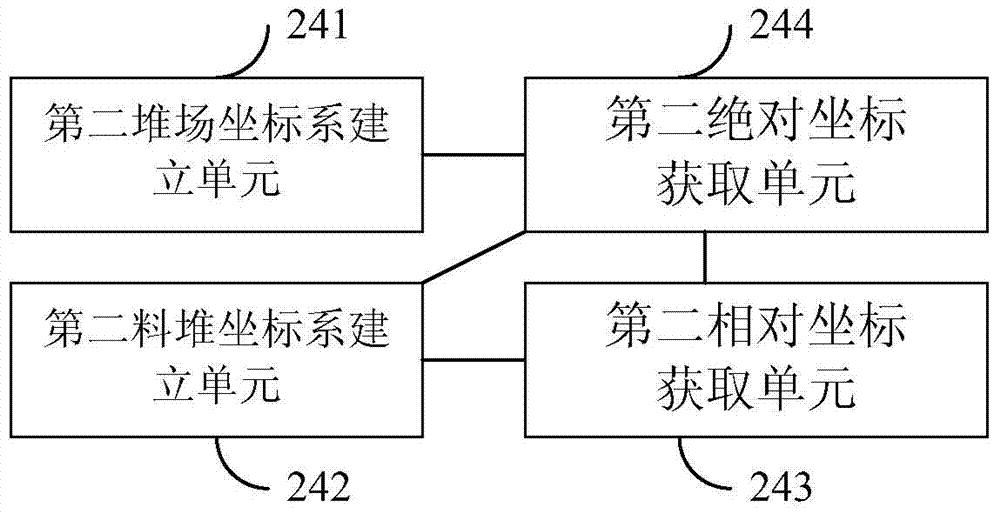

[0066] The first laser scanning device 13 is used to collect the first scan data of the stockpile. Here, the first laser scanning devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com