Method for controlling bottom dead center of slider of oil press

A technology of hydraulic press and slider, which is applied in the field of hydraulic press control, can solve the problems of complex control structure, high maintenance cost and unsatisfactory effect of hydraulic press, and achieve the effects of easy maintenance, low equipment cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

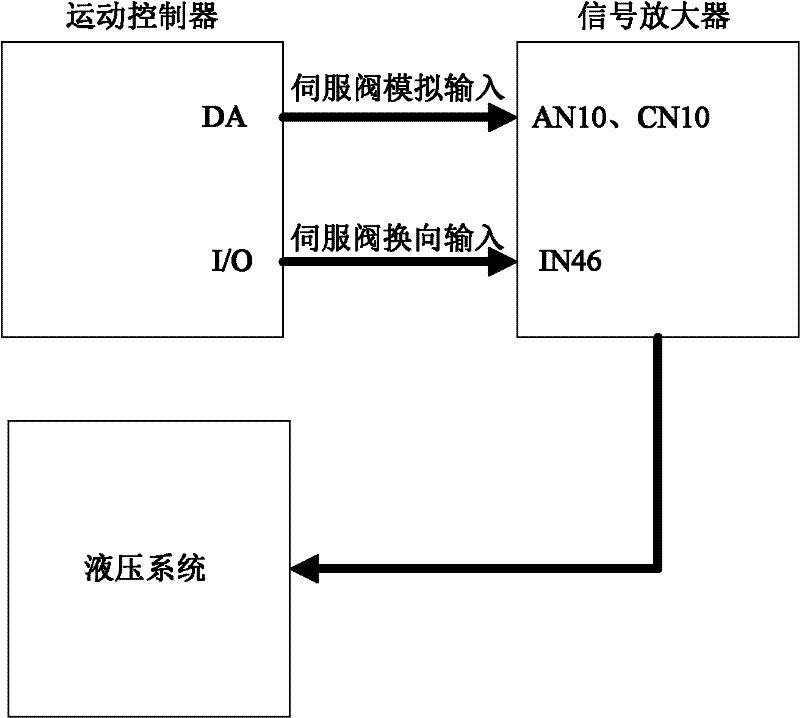

Method used

Image

Examples

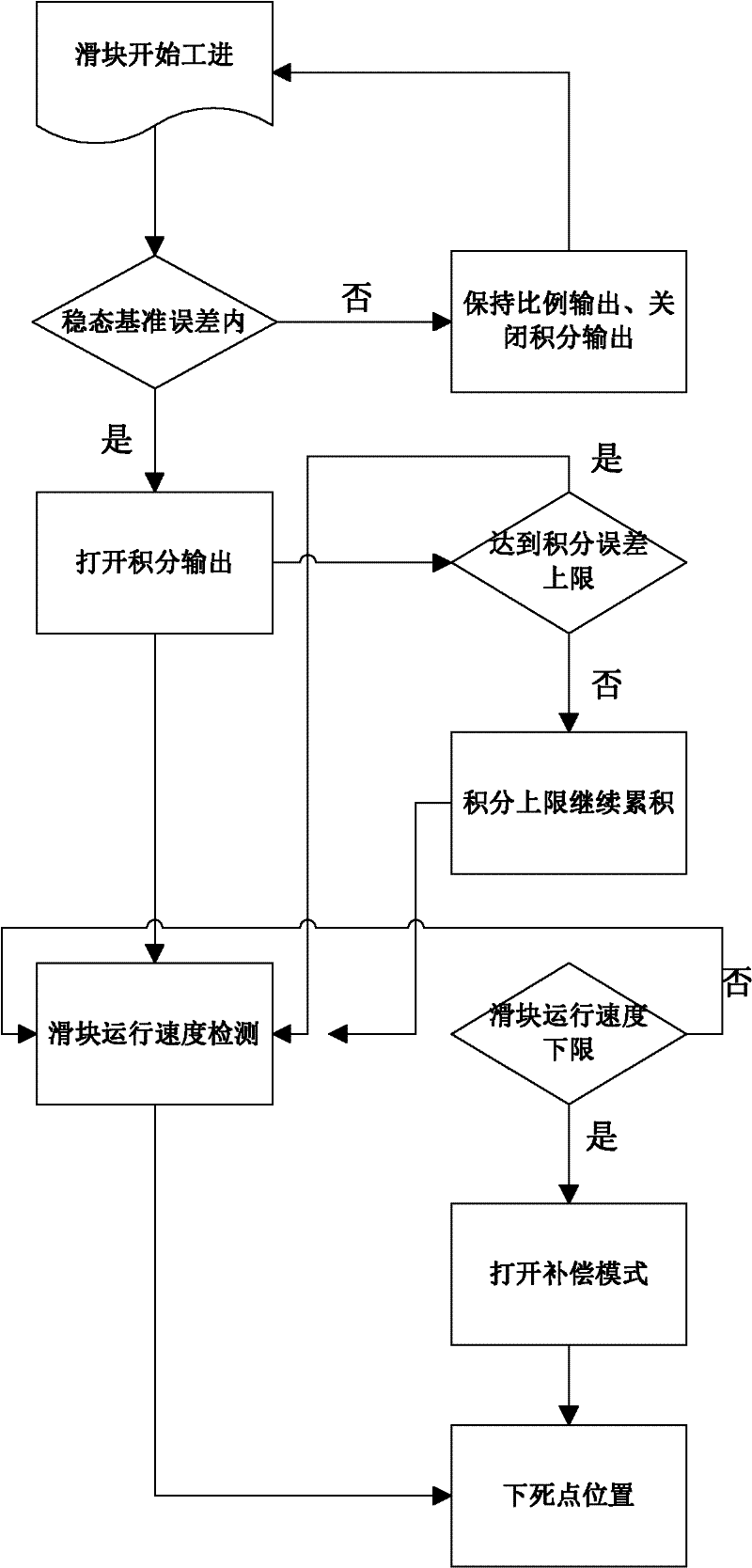

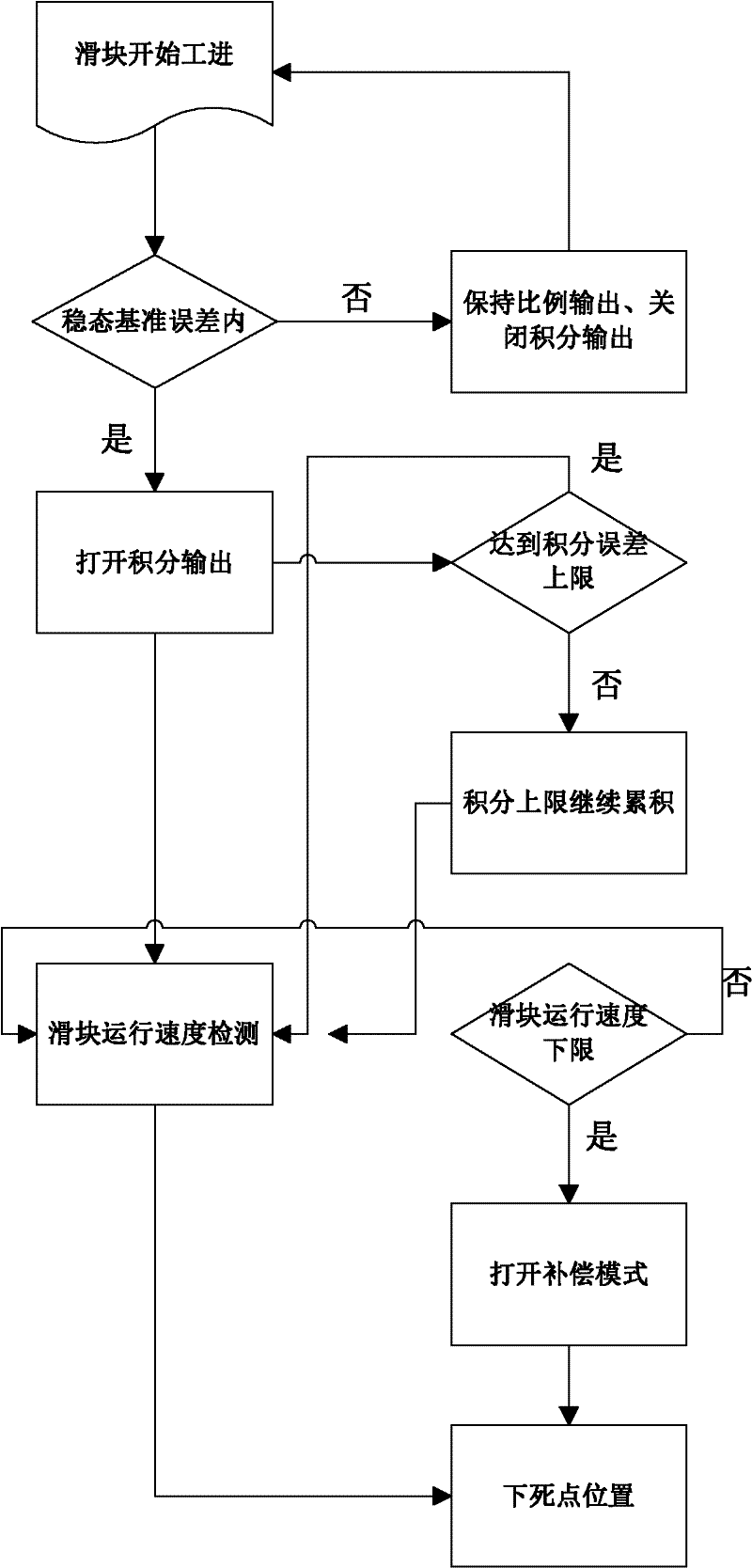

specific Embodiment approach

[0030] 1) First set the reference deviation of the bottom dead center steady state position to 60pls, set the upper limit of the integral error to 2000, and the gain of the integral error to 1.5, both of which are used to control the output of the saturated integral; set the compensation interval time to 300ms, and set the position change of the slider The lower limit of the amount is 2pls, and this value matches the output compensation of the slider movement speed;

[0031] 2) Set the running track of the slider, including setting the distance, maximum speed, and holding time of fast down, work, unloading, return, etc.; details are shown in Table 1 and Table 2:

[0032] Table 1

[0033] slider upper limit

slider shift point

Slider lower limit

compress time

Unloading distance

10mm

320mm

360mm

1s

0.5mm

[0034] Table 2

[0035] get off

work into

unload

return journey

time

5s

3s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com