High-frequency direct-acting force motor based on mixed air gap

A direct-acting, mixed gas technology, applied in electrical components, electric components, engine components, etc., can solve the problems of different reciprocating output forces, asymmetric working air gap magnetic flux, and uneven magnetic circuit distribution, etc. Compact structure, same bidirectional output force, reasonable installation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is specifically described below by way of examples.

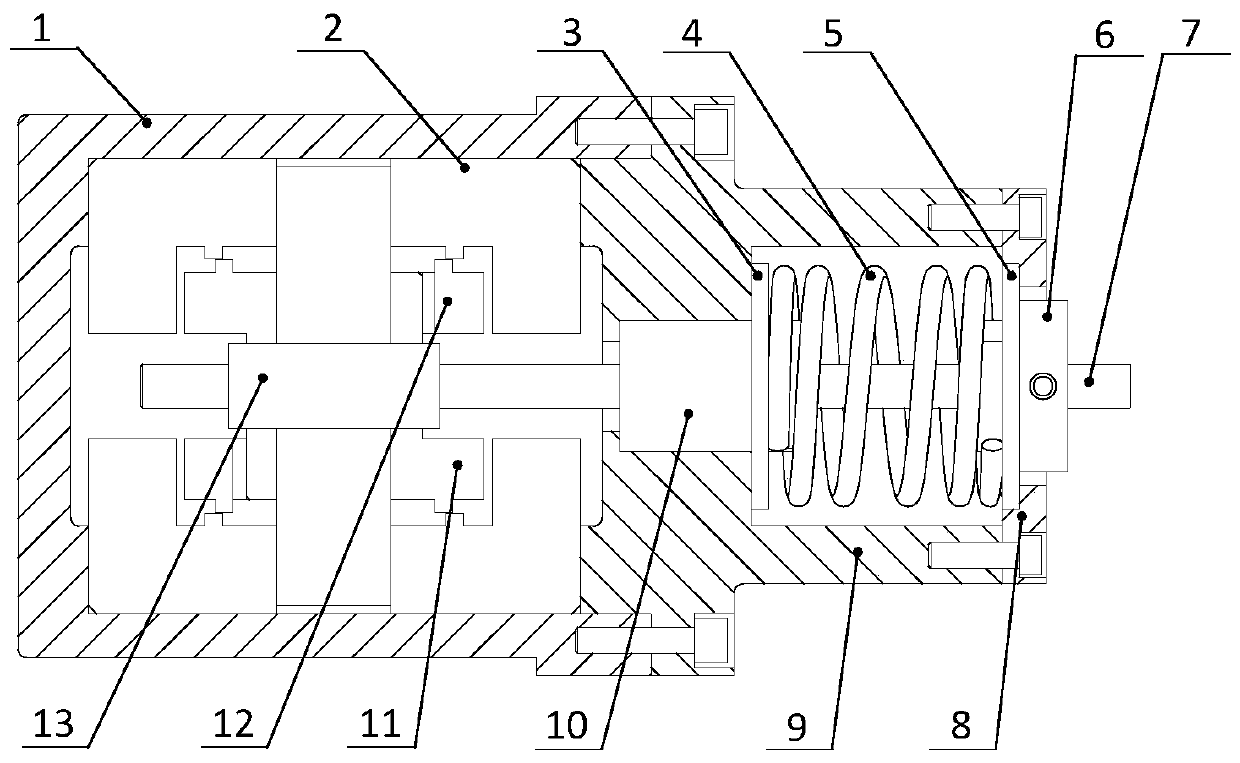

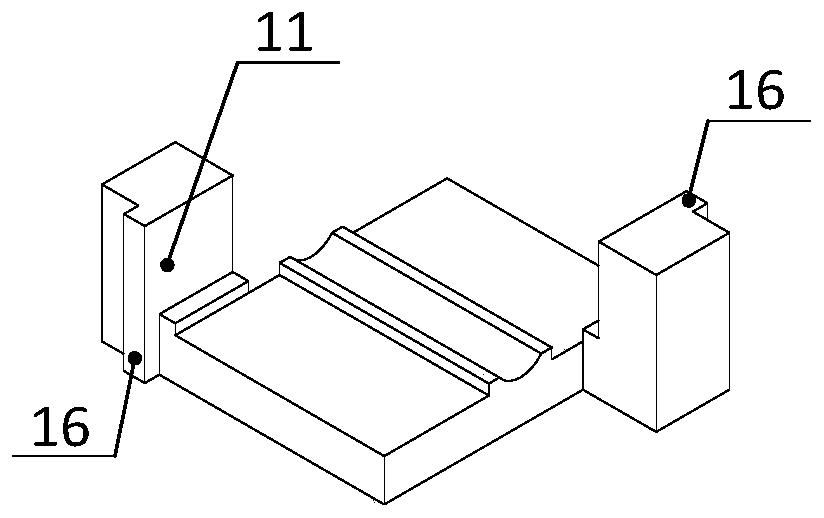

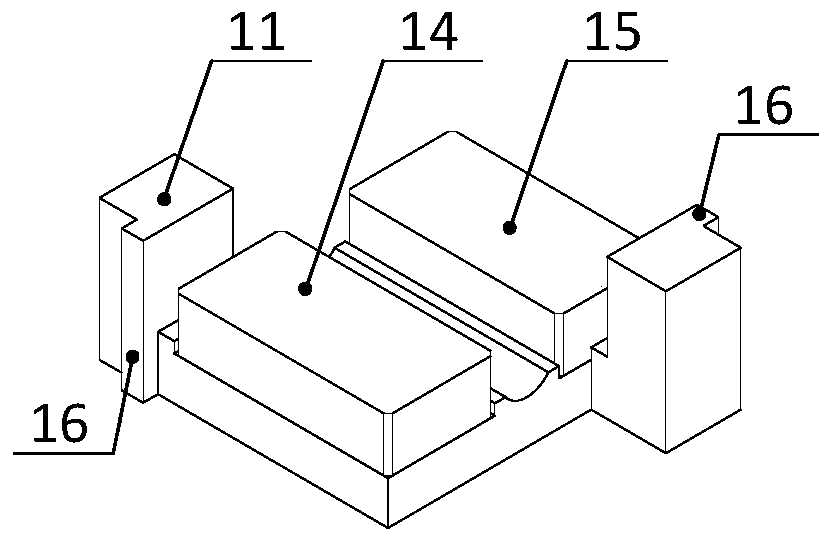

[0032] refer to Figure 1 ~ Figure 6bThe high-frequency direct-acting force motor based on the mixed air gap proposed by the present invention includes an armature part, a yoke part, a return spring part, a front end cover 8, a first housing 1 and a second housing 9, and the armature part includes the first An armature 11, a second armature 12, a push rod 7, a first permanent magnet 14 and a second permanent magnet 15, each protruding a 90° boss in opposite directions on the diagonal of the long side of the first armature 11 , a vertical first radial pole piece 16 is additionally added to the outer sides of the bosses on the first armature 11 . Both ends of the first armature 11 have a rectangular groove, the first permanent magnet 14 and the second permanent magnet 15 are radially magnetized into N-level and S poles, and the two ends of the first armature 11 are The end rectangular grooves ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com