Electromagnetic braking tensioning winch

A technology of electromagnetic brake and electromagnetic brake, applied in the direction of hoisting device, spring mechanism, etc., can solve the problems of many control links, complicated installation, inability to achieve tension balance and release, etc., to achieve fast response ability and precise tension control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

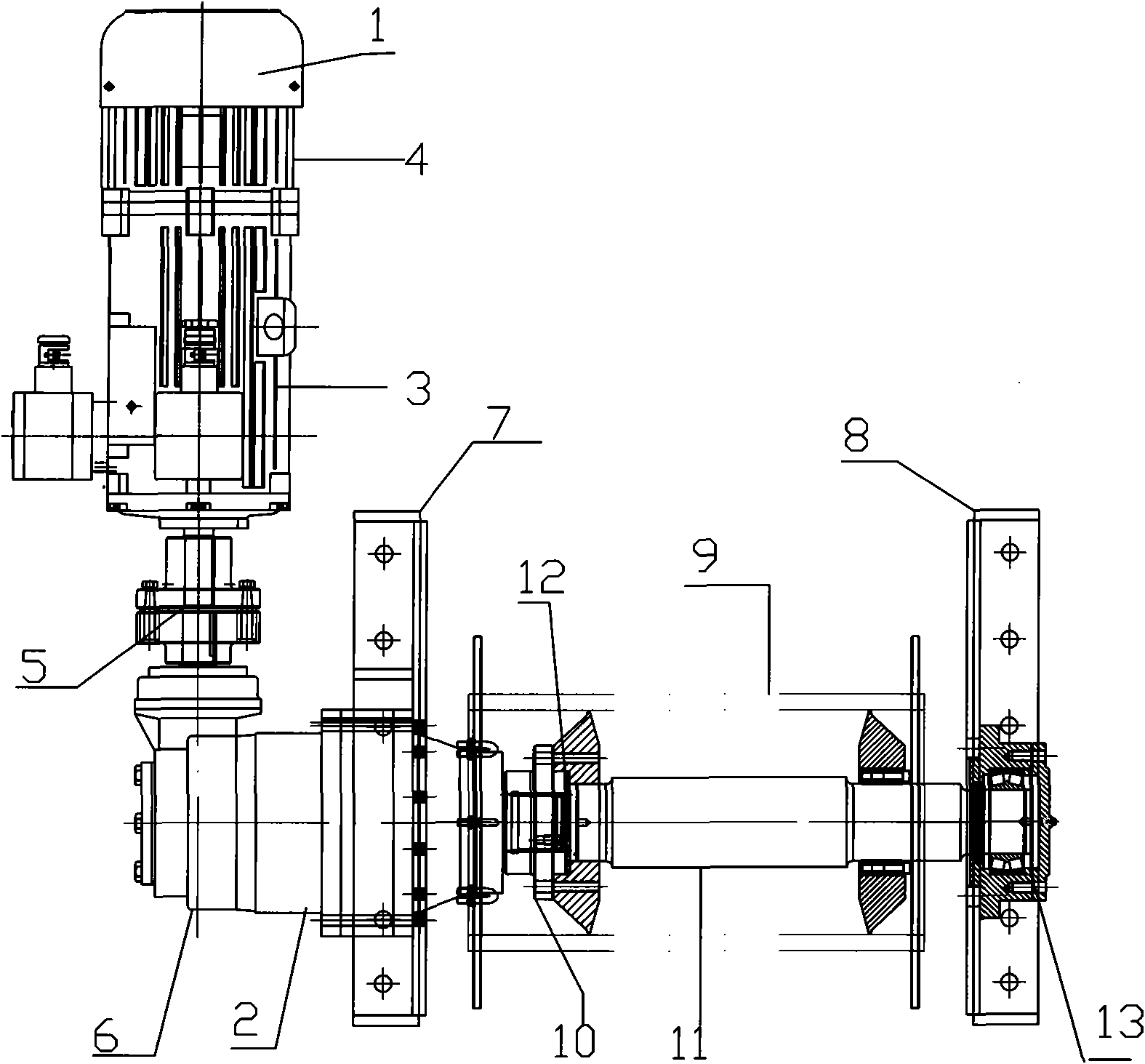

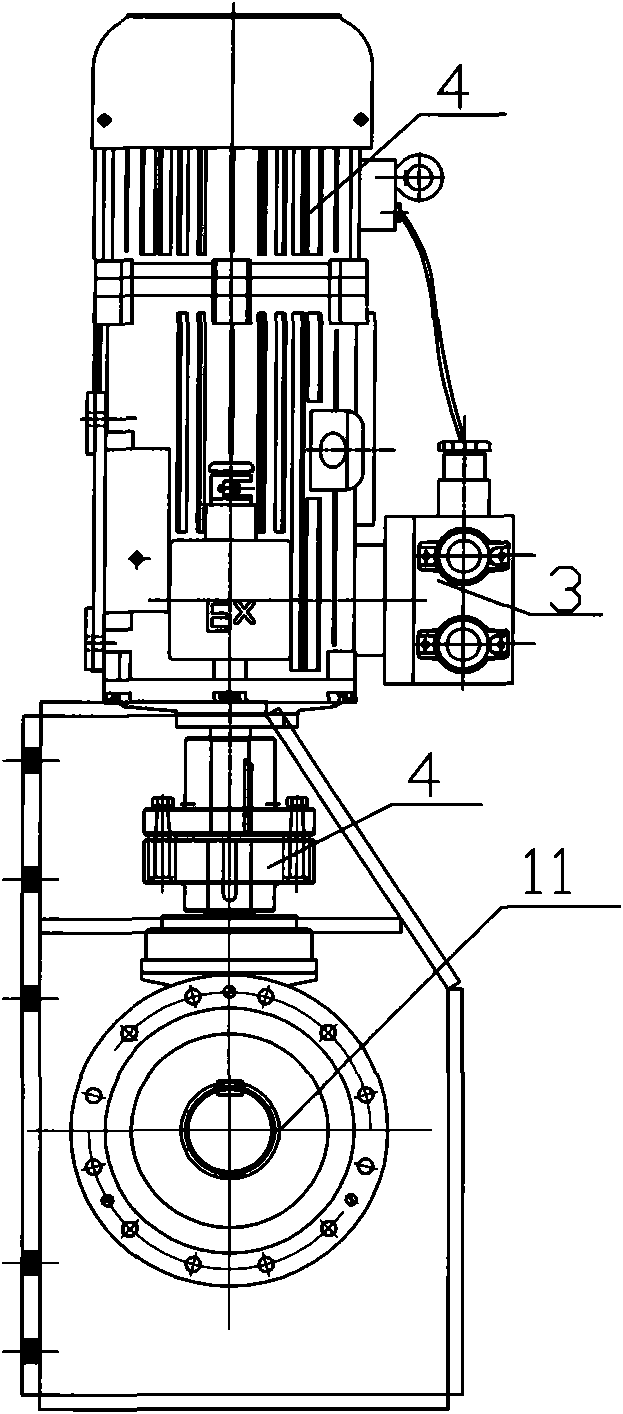

[0025]The electromagnetic brake tensioning winch includes an electromagnetic brake motor 1 and a winch 2, the electromagnetic brake motor 1 includes a motor 3 and an electromagnetic brake 4, and the electromagnetic brake 4 is coaxially installed at the tail of the motor 3; The motor shafts are connected; the winch 2 includes a reducer 6, a support base 7, a drum support 8, a rope drum 9, a transition connection plate 10, a drum shaft 11 and a bearing seat 12 assembly, wherein the reducer 6 is installed on the support base 7 Above, the speed reducer 6 is connected with the rope drum 9, and the drum support 8 is installed on the other end of the rope drum 9. The drum shaft 11 is installed and fixed on the rope drum 9 through an adapter sleeve, the extended end of the drum shaft 11 is directly supported on the drum support 8 through the bearing seat assembly 13, and the output shaft of the reducer 6 is input to the rope drum 9. end connection installation. The drum shaft 11 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com