Tensioning equipment for high-speed railway track slab pre-tensioning assembly line production line

A technology for high-speed railways and track slabs, applied in the field of tensioning equipment in the production line of high-speed railway track slab pre-tensioning assembly line, it can solve the problems of poor tensioning precision, complicated positioning of tensioning molds, and low degree of automation, etc. Accurate precision control, simple tensioning process and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] The invention is a set of key equipment in the production line of the ballastless track slab assembly line of the high-speed railway. The idea of the invention is to realize the fully automatic operation of the tensioning equipment with hydraulic drive and control as the core.

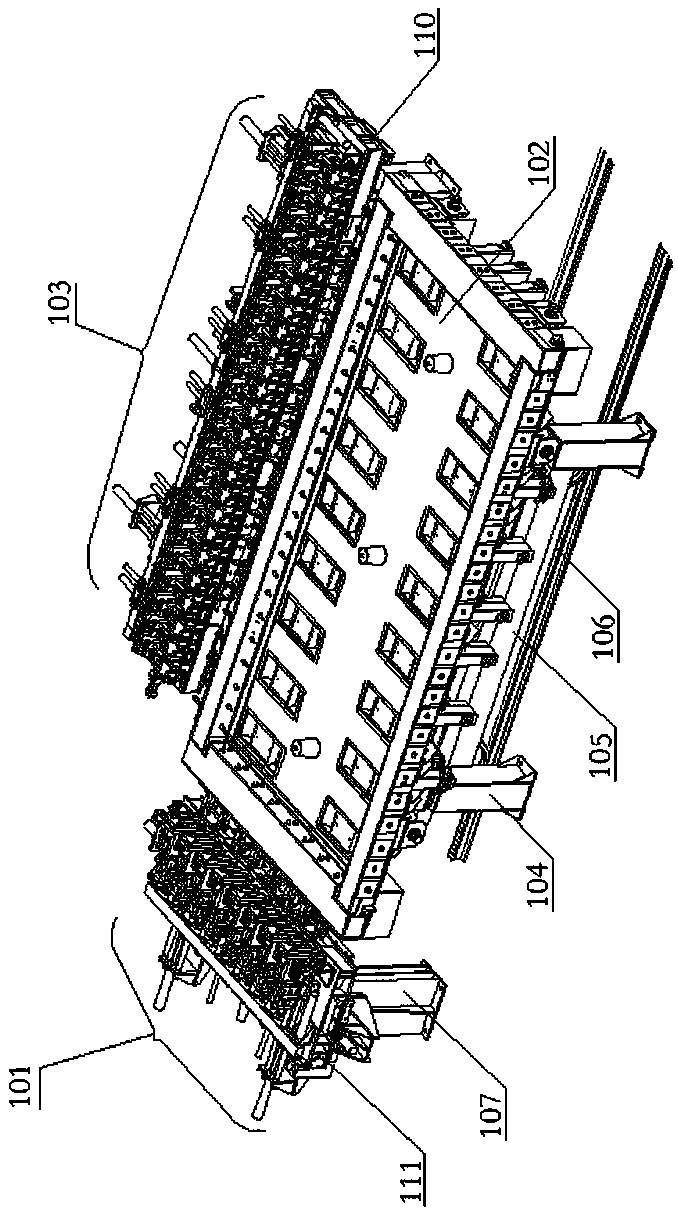

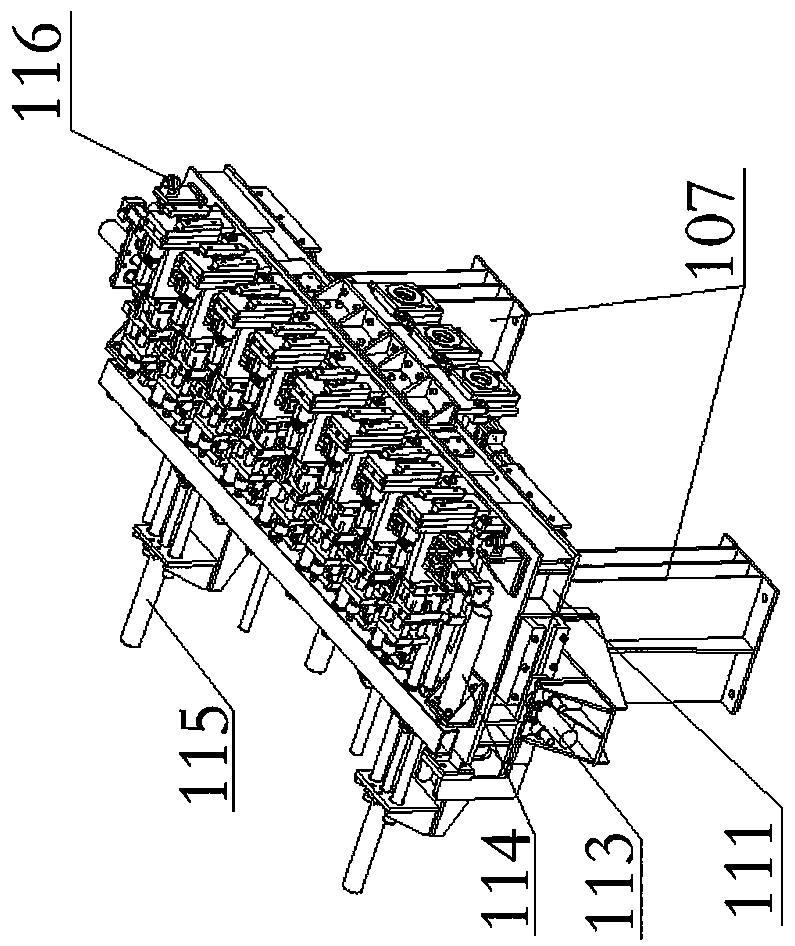

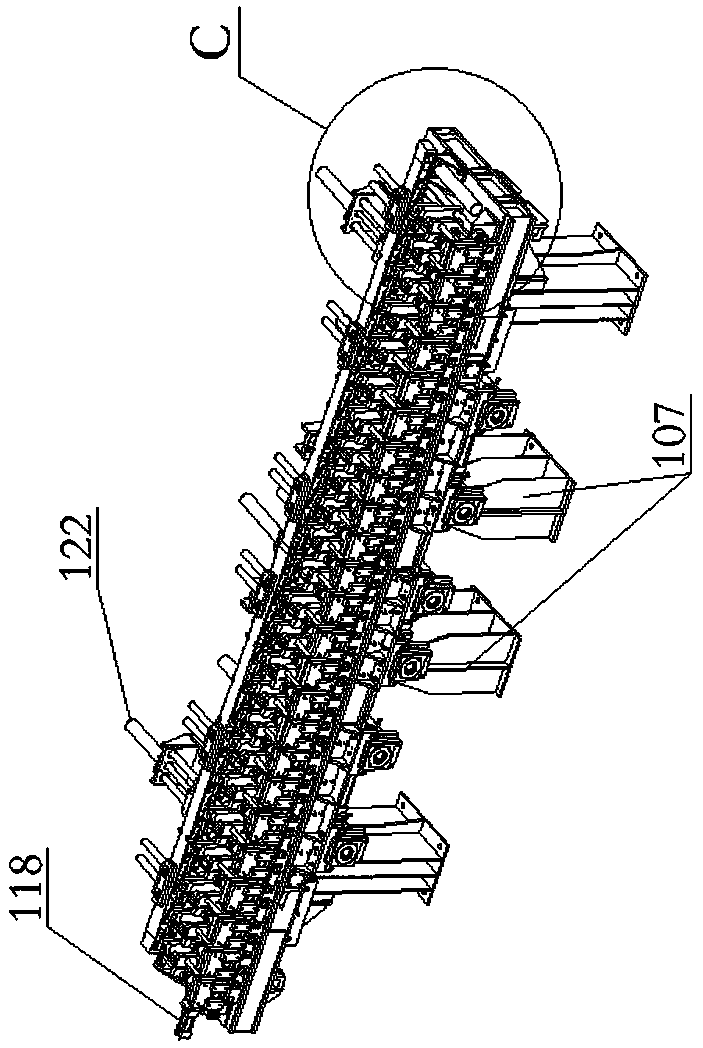

[0026] Figure 1-4 As shown, according to the high-speed railway type III track slab design standard, longitudinal and transverse prestressed steel bars need to be placed in the track slab, and stretched to generate stress and fix it before forming. According to this, the tensioning equipment is arranged in two directions. In the figure, the longitudinal tensioning device 101 and the lateral tensioning device 103 are respectively arranged at the tensioning positions on the vertical and horizontal sides of the track plate mold 102 . The mold is transported to the stretching station a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com