Diaphragm unwinding device

A technology of unwinding device and diaphragm, which is applied in the direction of winding strips, transportation and packaging, thin material processing, etc. Precise tension control, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific drawings.

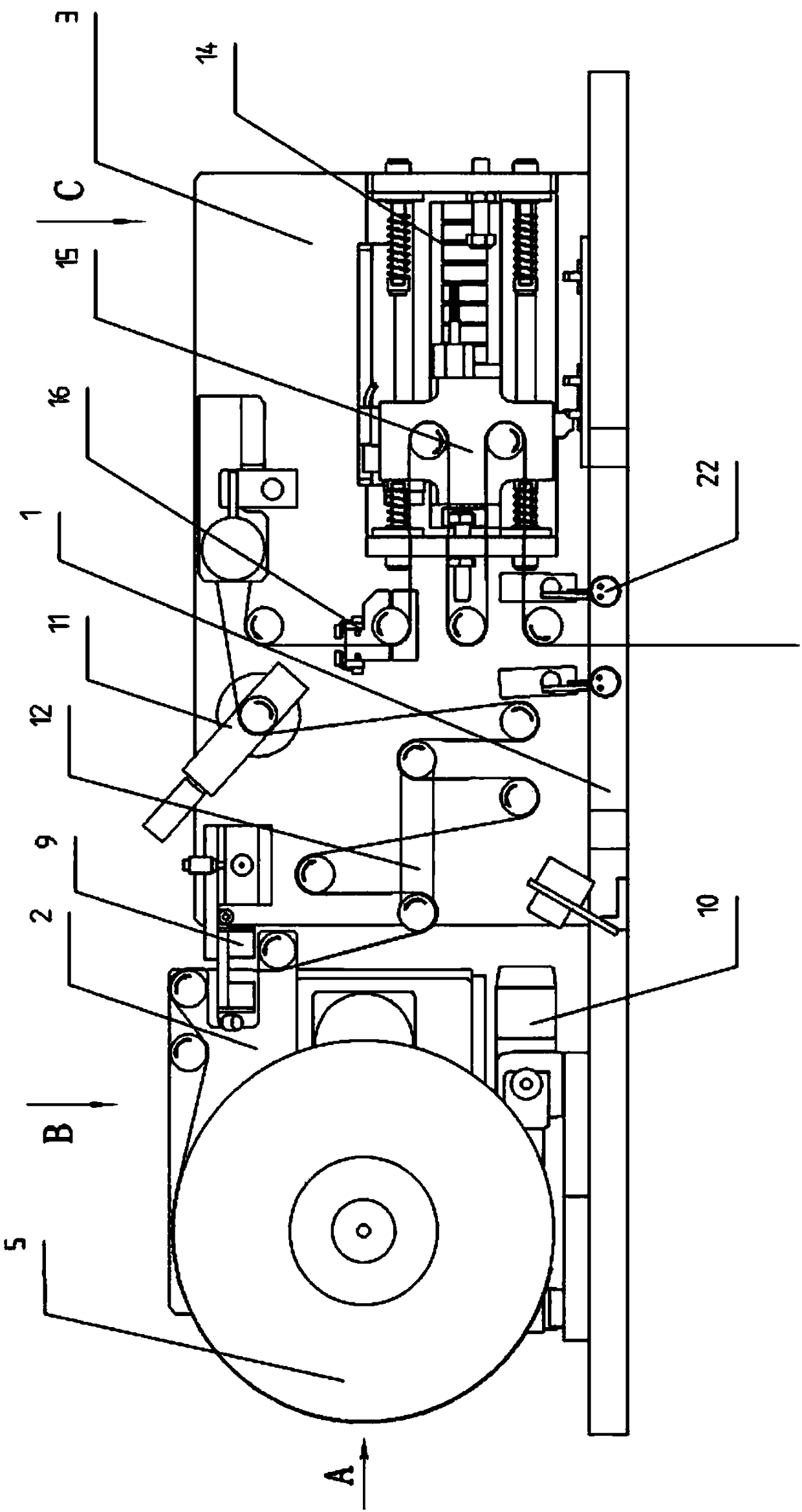

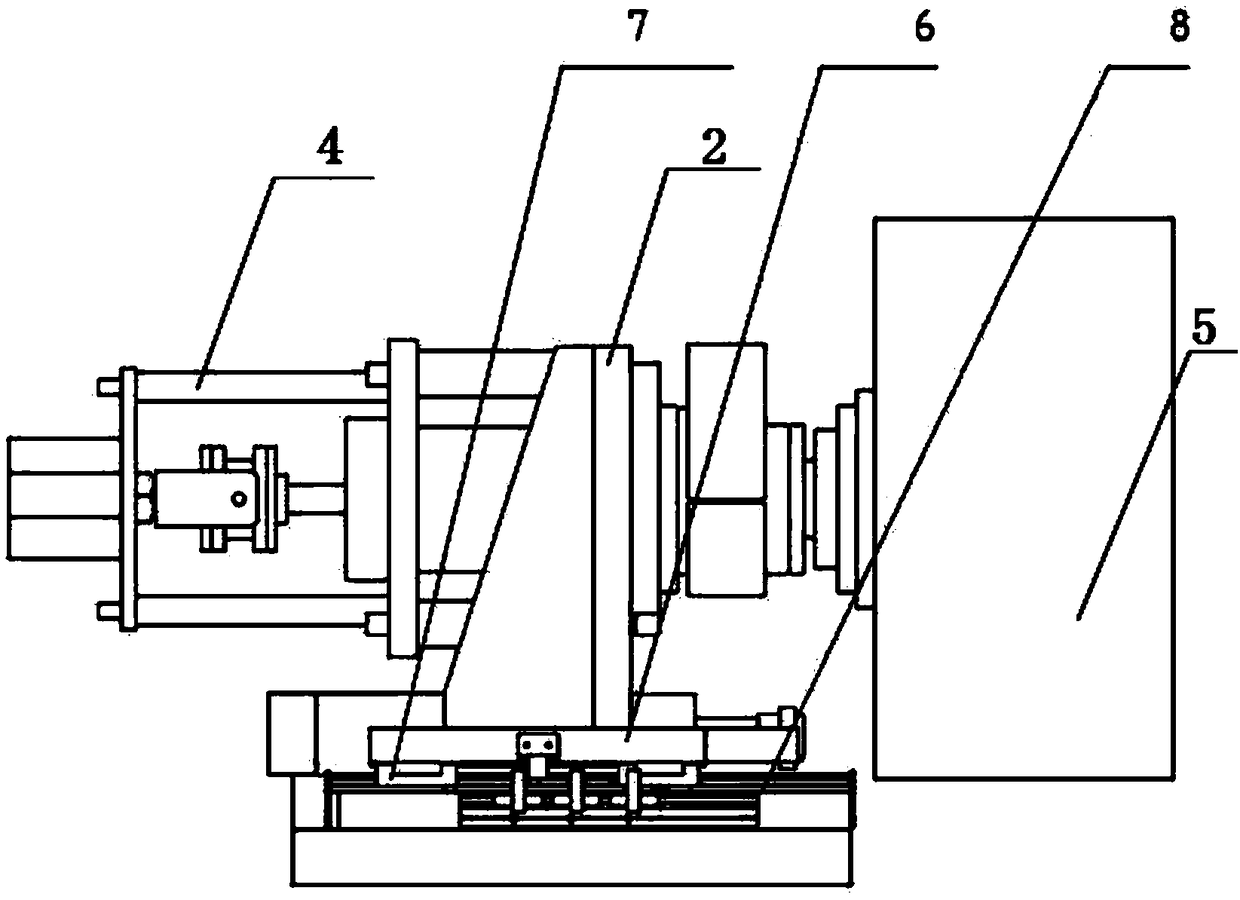

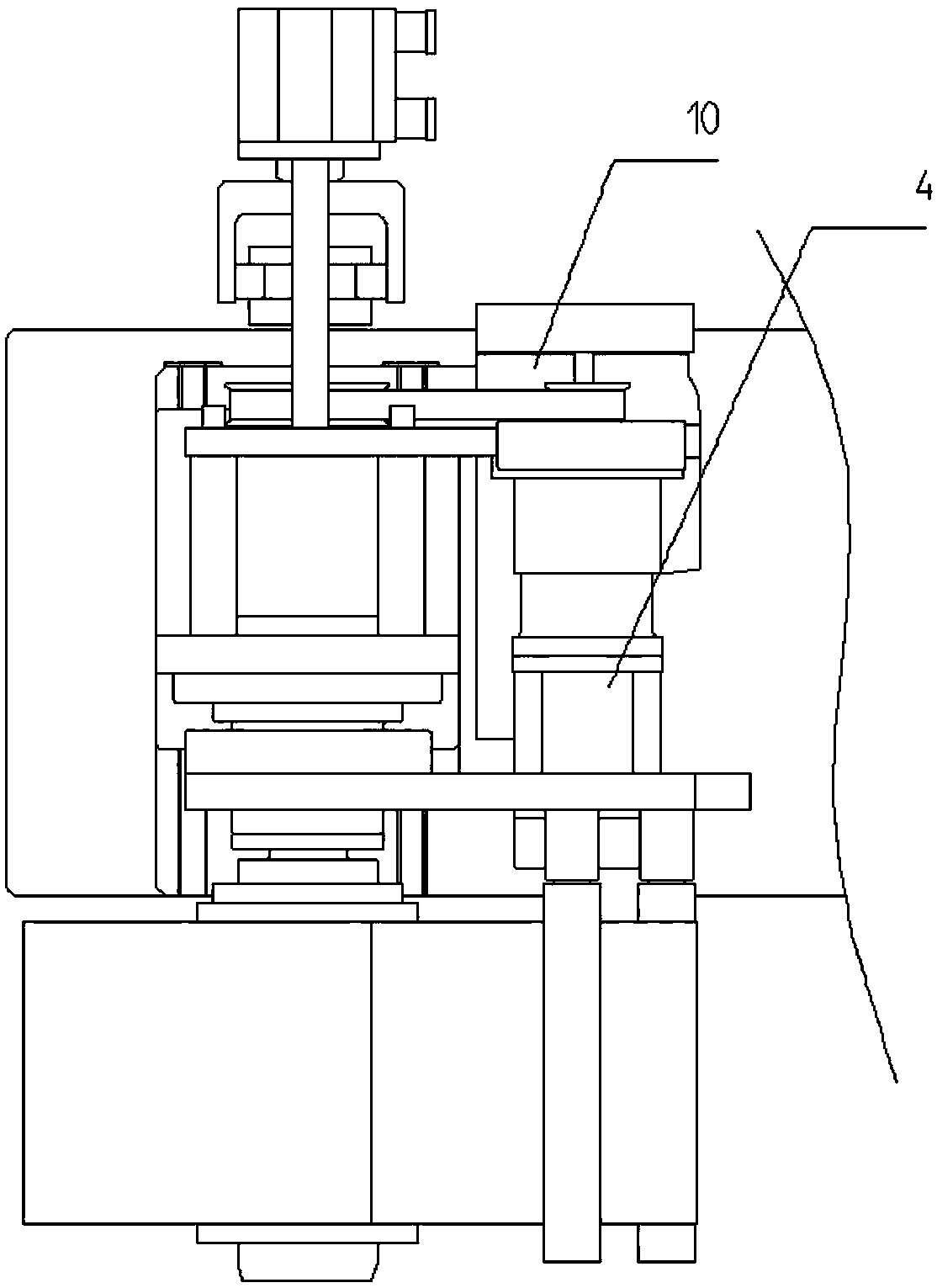

[0025] like Figure 1 to Figure 5 As shown: the diaphragm unwinding device includes a frame base 1, a first partition 2, a second partition 3, a servo motor 4, a roll roller 5, a partition base 6, a slide rail slider 7, and a slide rail track 8. Deviation correction sensor 9, electric cylinder 10, tension sensor 11, swing roller 12, swing roller cylinder 13, linear motor 14, linear motor slider 15, length sensor 16, rubber wrapping roller 17, sliding connecting plate 18, adjustment platform 19. Lead screw 20, lead screw nut 21, static electricity removal device 22, stop screw 23, magnetic strip ruler 24, reading head 25.

[0026] like figure 1 As shown, the diaphragm unwinding device of the present invention includes a frame, a frame base 1 and several rollers, the frame is vertically installed on the frame base 1, and the frame includes a first partition 2 and a second part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com