Electric automobile frame

A technology for electric vehicles and frames, applied in the direction of electric power devices, power devices, vehicle components, etc., can solve the problems of increased weight of the vehicle body, narrow area, and limited travel of electric vehicles, and achieve rigidity and strength enhancement and easy layout , the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

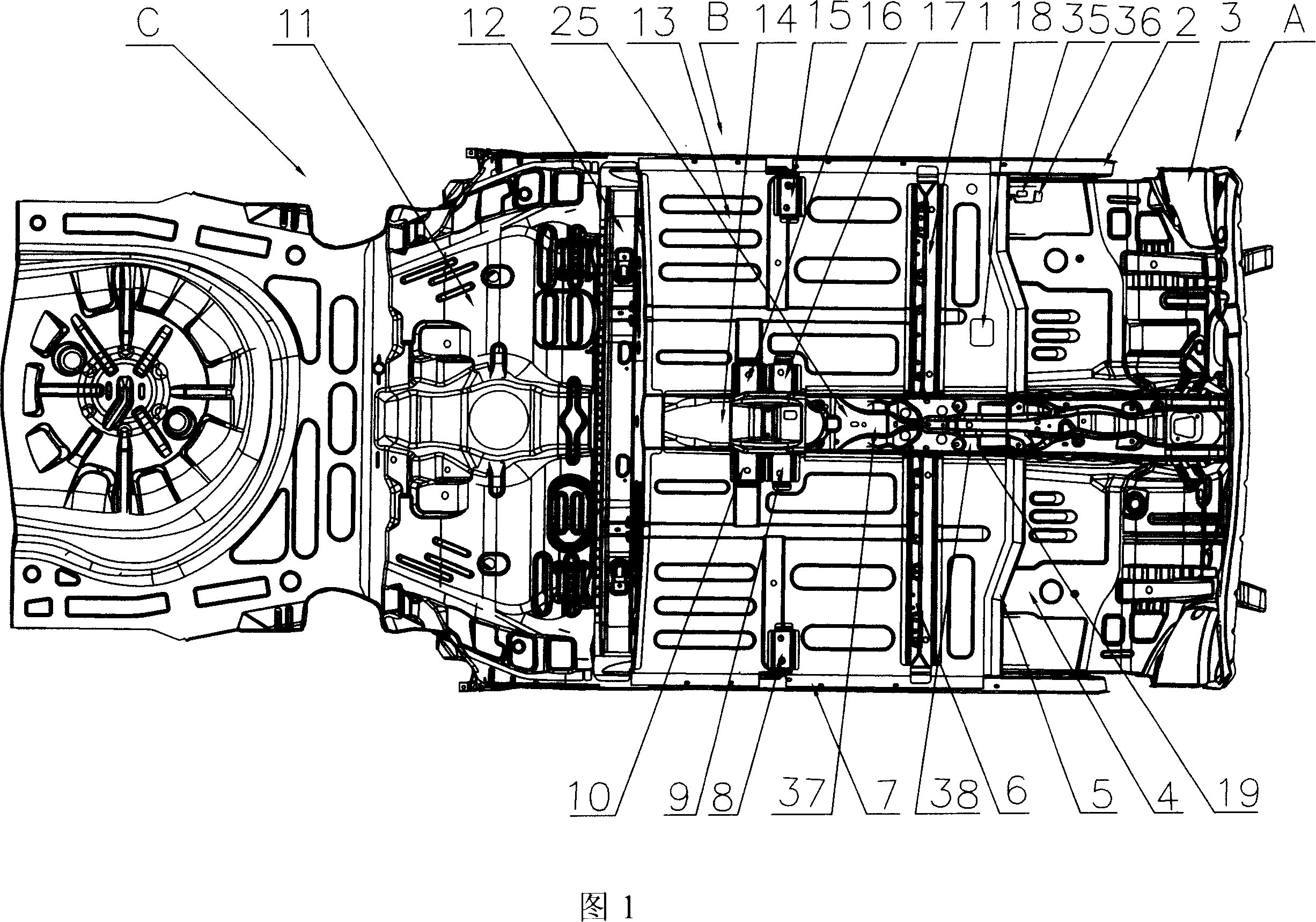

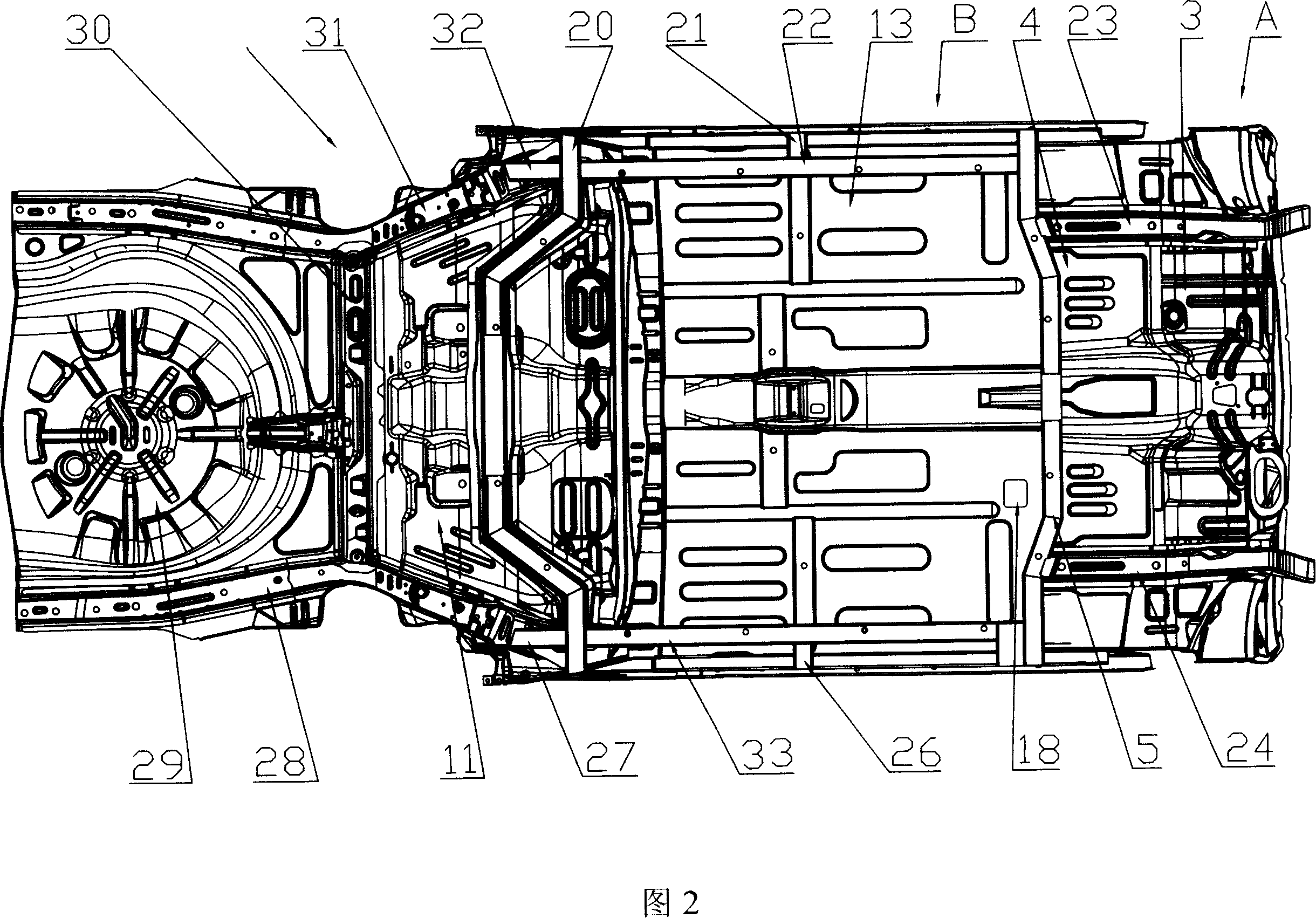

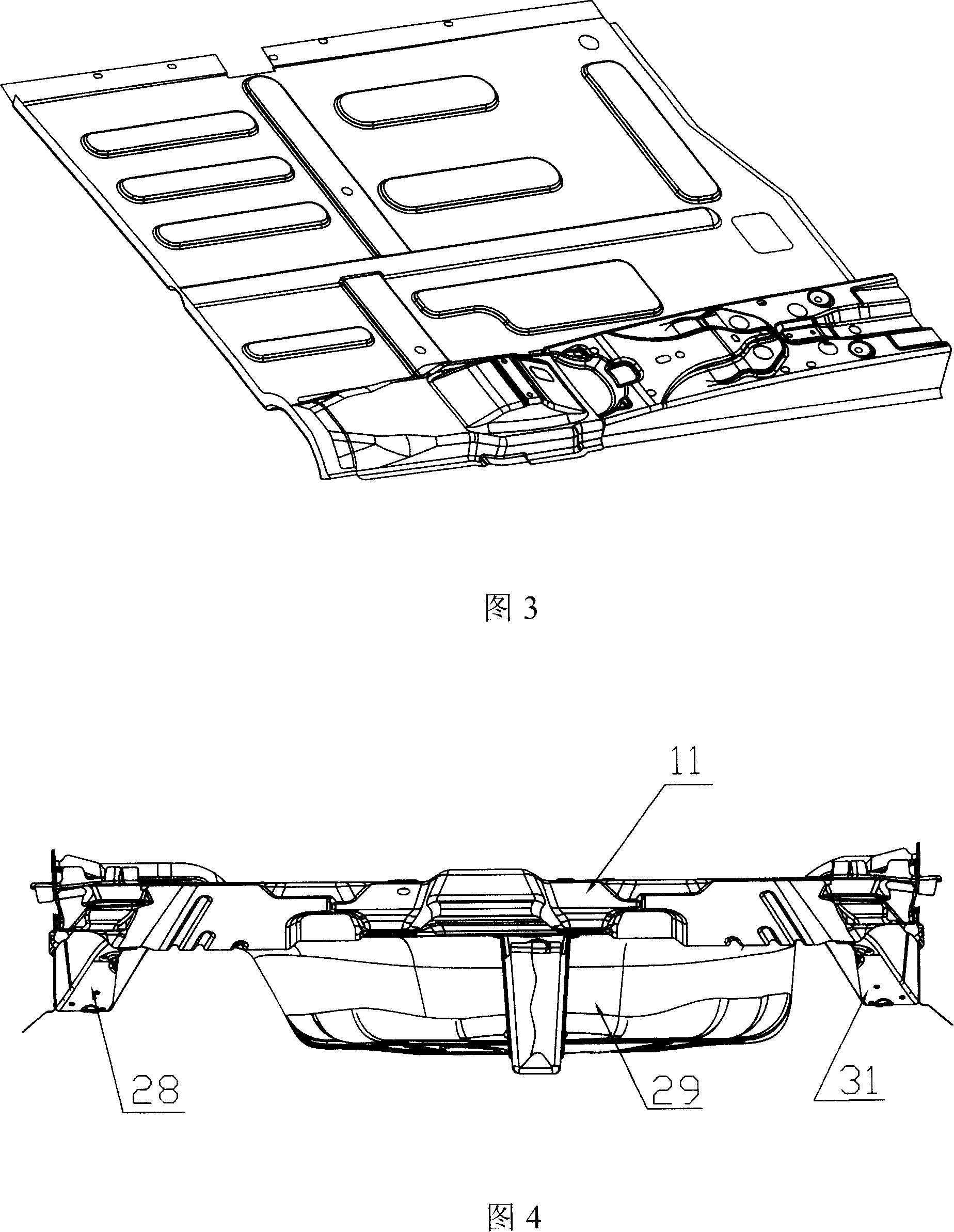

[0022] The specific meanings of the symbols in the figure are as follows: 1-left seat front mounting bracket; 2-left door sill; 3-dash panel; 4-front floor; 5-front beam; Right door sill; 8-right seat rear mounting bracket (right support point); 9-right seat rear mounting bracket (left support point); 10-right load-carrying bracket; 11-rear floor; 12-middle floor beam; 13- Middle floor; 14-middle channel; 15-left seat rear mounting bracket (left support point); 16-left bearing bracket; 17-left seat rear mounting bracket (right support point); 18-emergency power off switch; 19 -shift handle installation bracket; 20-rear cross member; 21-left longitudinal beam bracket of middle floor; 22-left longitudinal beam of middle floor; 23-left longitudinal beam of front floor; 24-right longitudinal beam of front floor; 25-front middle channel ;26-middle floor right longitudinal beam bracket; 27-middle floor right longitudinal beam reinforcement block; 28-rear floor right longitudinal bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com