Air exhaust integration workstation device

A workbench and integrated technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problems of high production base requirements, long production cycle, large floor area, etc., to improve production efficiency, easy maintenance and easy operation , the effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with specific drawings and embodiments.

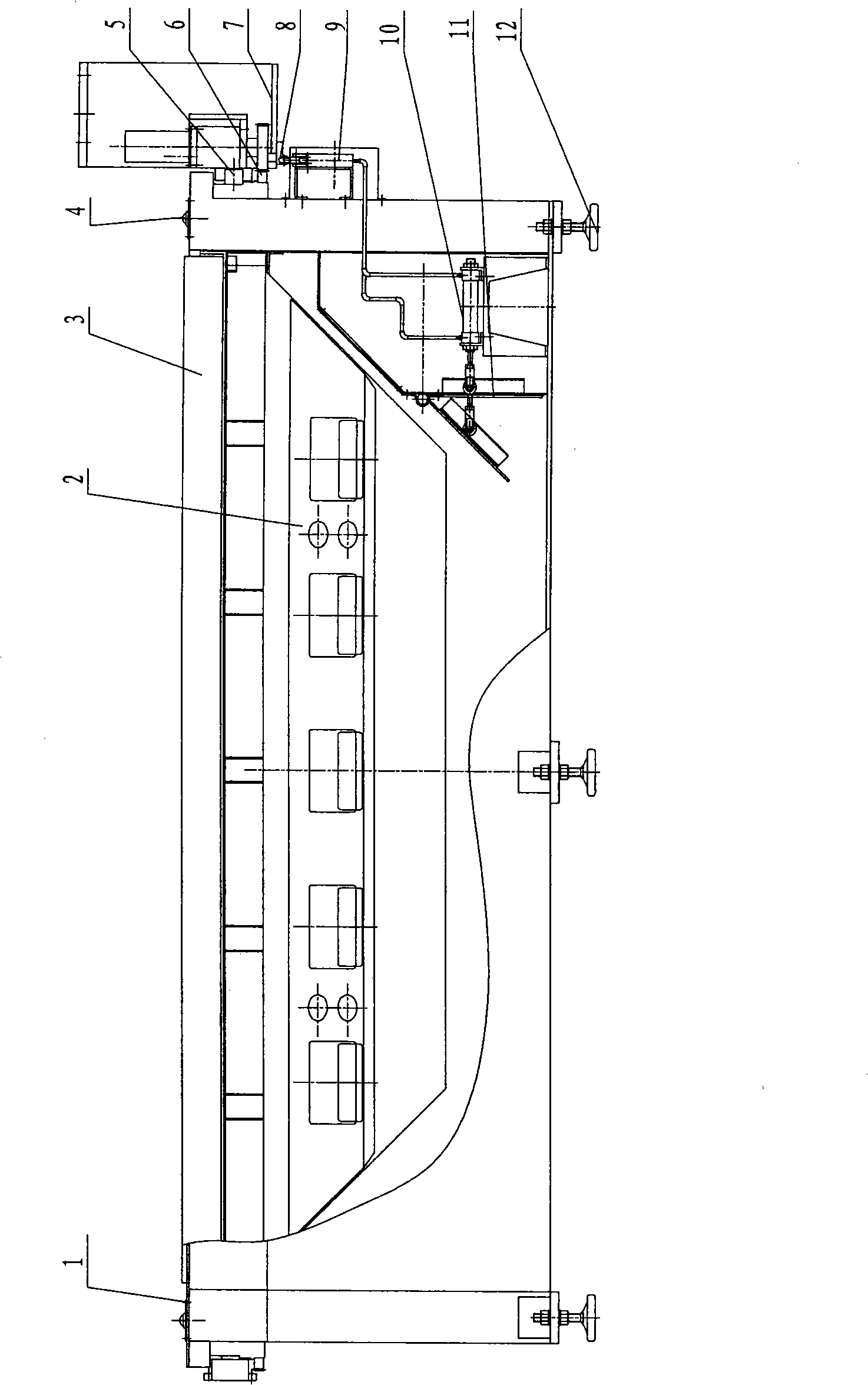

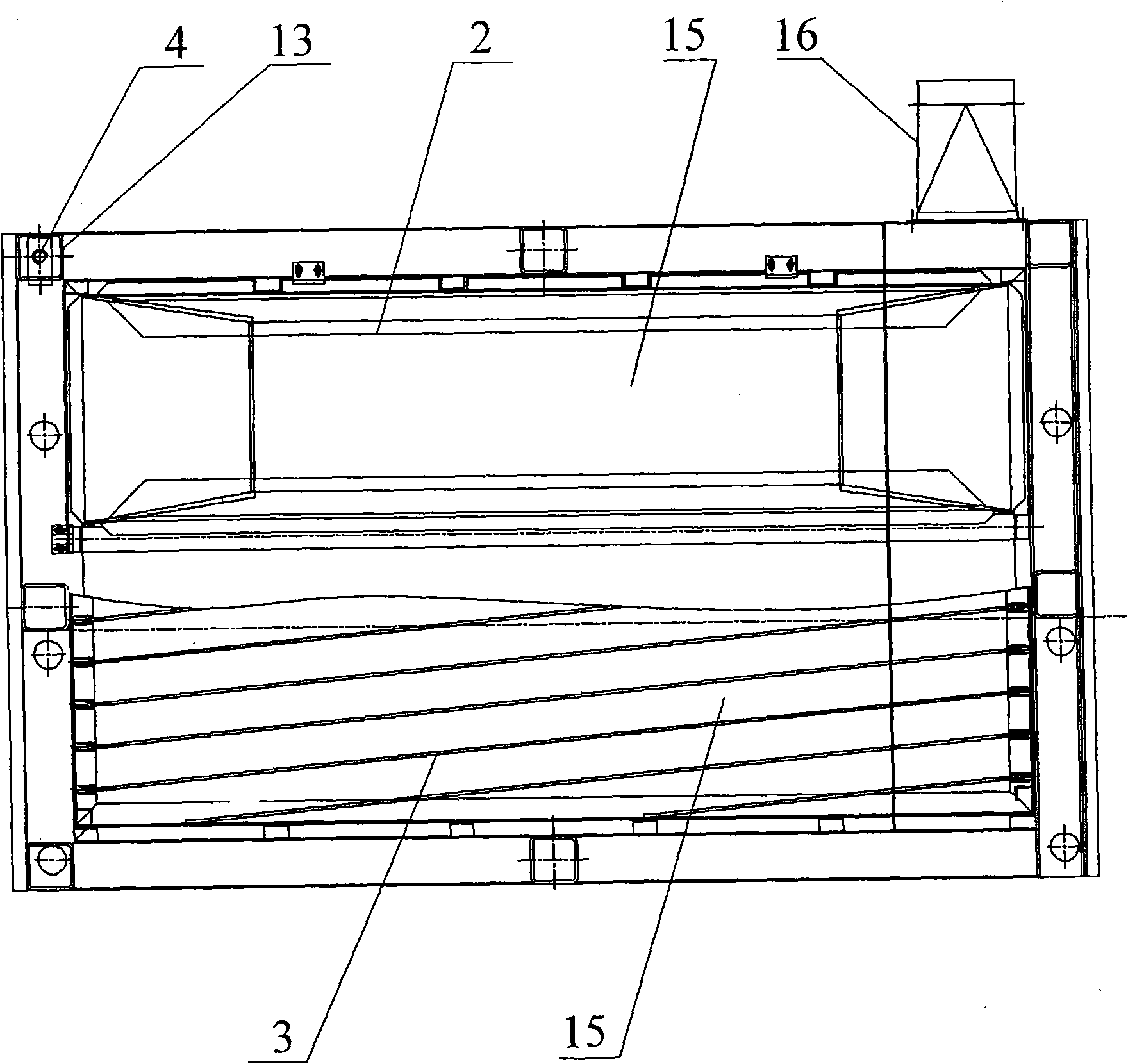

[0010] Such as figure 1 , figure 2 As shown, it includes: ventilation table 1, hopper 2, material rack 3, supporting ball 4, linear guide 5, rack 6, driving gantry 7, impact block 8, mechanical control valve 9, cylinder 10, opening and closing door body 11. Adjusting bolt 12, frame 13, output gear 14, exhaust chamber 15 and main suction pipe 16, etc.

[0011] The ventilation integrated workbench device of the present invention comprises that a ventilation workbench 1 is arranged on a frame 13, and the ventilation workbench 1 is divided into a plurality of ventilation chambers 15 which are equal in geometric size and arranged longitudinally, and each ventilation chamber 15 is Connect with the main air suction pipe 16, support balls 4 are provided on both sides of the top surface of the exhaust workbench 1, a material rack 3 is provided on the frame 13 between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com