Submicron electric car driven by electric machine with hub

A hub motor and electric car technology, applied in electric vehicles, electric traction, vehicle energy storage, etc., can solve problems such as immature installation and connection methods, low energy efficiency ratio, and poor practicability, and achieve excellent power performance and low price advantages , improve energy efficiency ratio, good overall effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

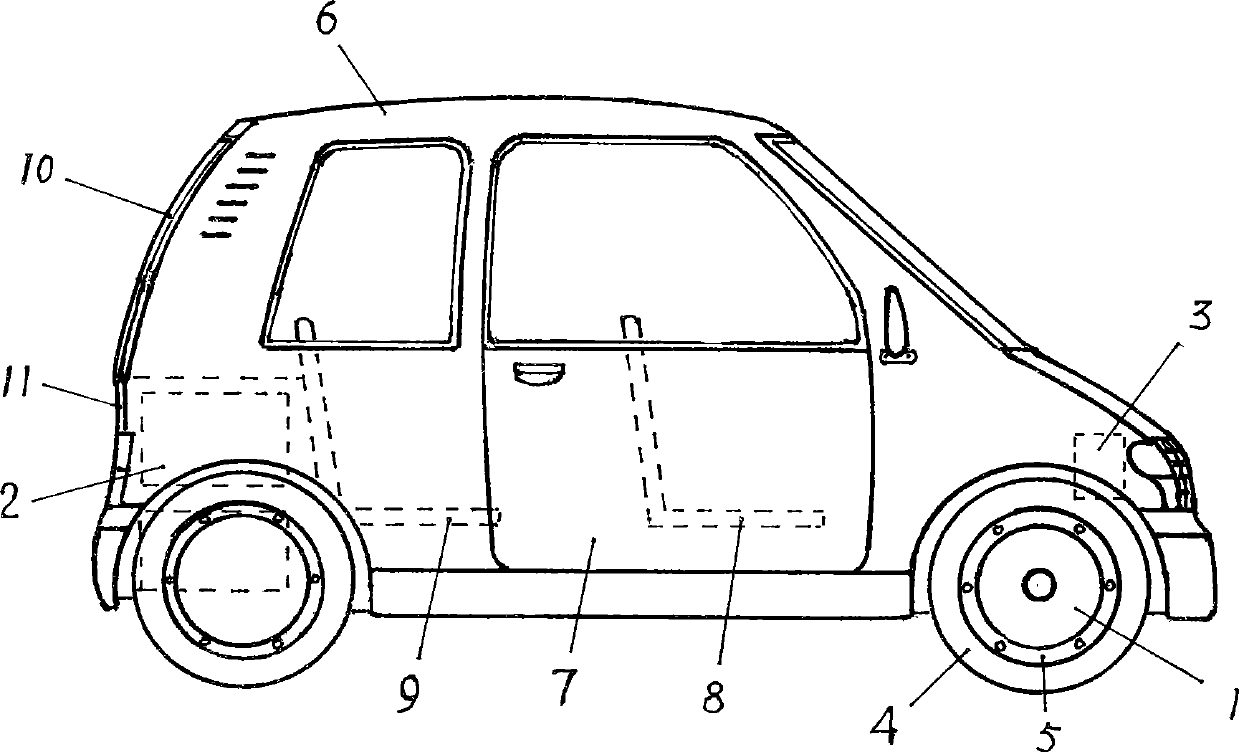

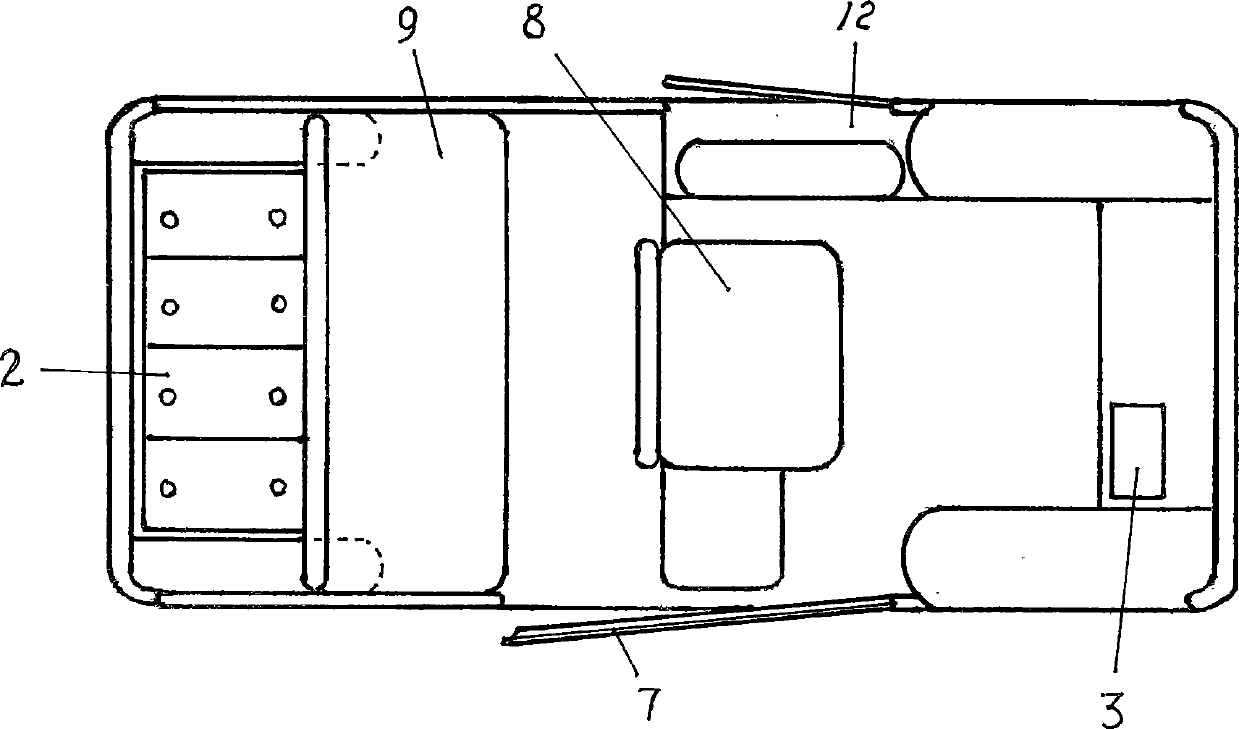

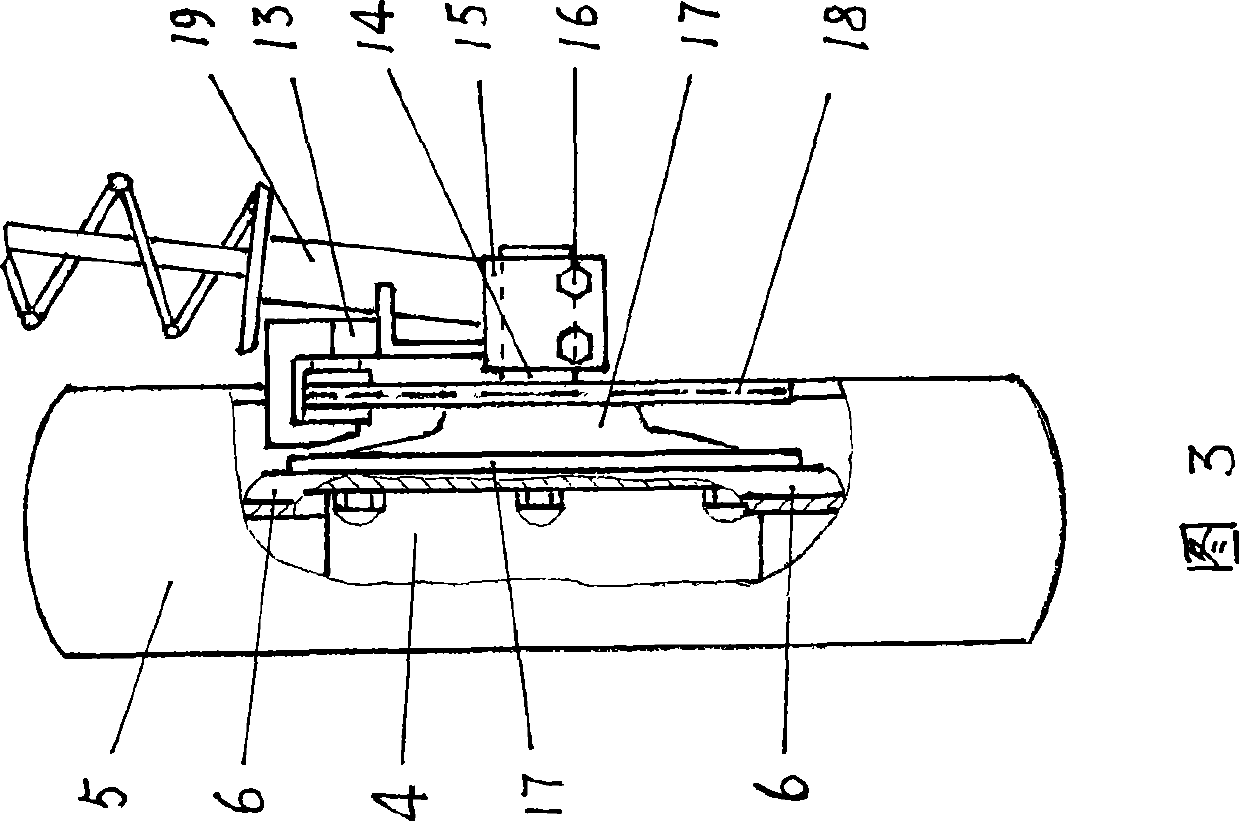

[0023] figure 1 , 2 Among them, the front wheel 4 of the electric car is equipped with a specially designed and matched hub motor 1 as the driving power, the battery 2 is the total power supply of the electric car, and is installed in the battery box at the rear of the electric car, and the frequency converter 3 is installed at the front of the electric car. The front box is also used to install other equipment such as brake pumps, air conditioners, and steering gears. The electric car box body 6 is only provided with a single door 7 on one side, and the other side is provided with a spare tire box 12 with a door. The spare tire box 12 is wider than the spare tire, leaving a larger space, which is convenient for lowering the car window. Glass, the window glass must be fully raised before taking and putting the spare tire. The upper part of the tail end of the box body 6 is provided with an emergency door 10, and the emergency door 10 can be opened upwards and can be opened f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com