Fuel distributor

A fuel dispenser and fuel distributing technology, applied in fuel injection devices, special fuel injection devices, charging systems, etc., can solve problems such as unoptimized, strong brazed joints, loads, etc., to achieve reasonable installation and reduced leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

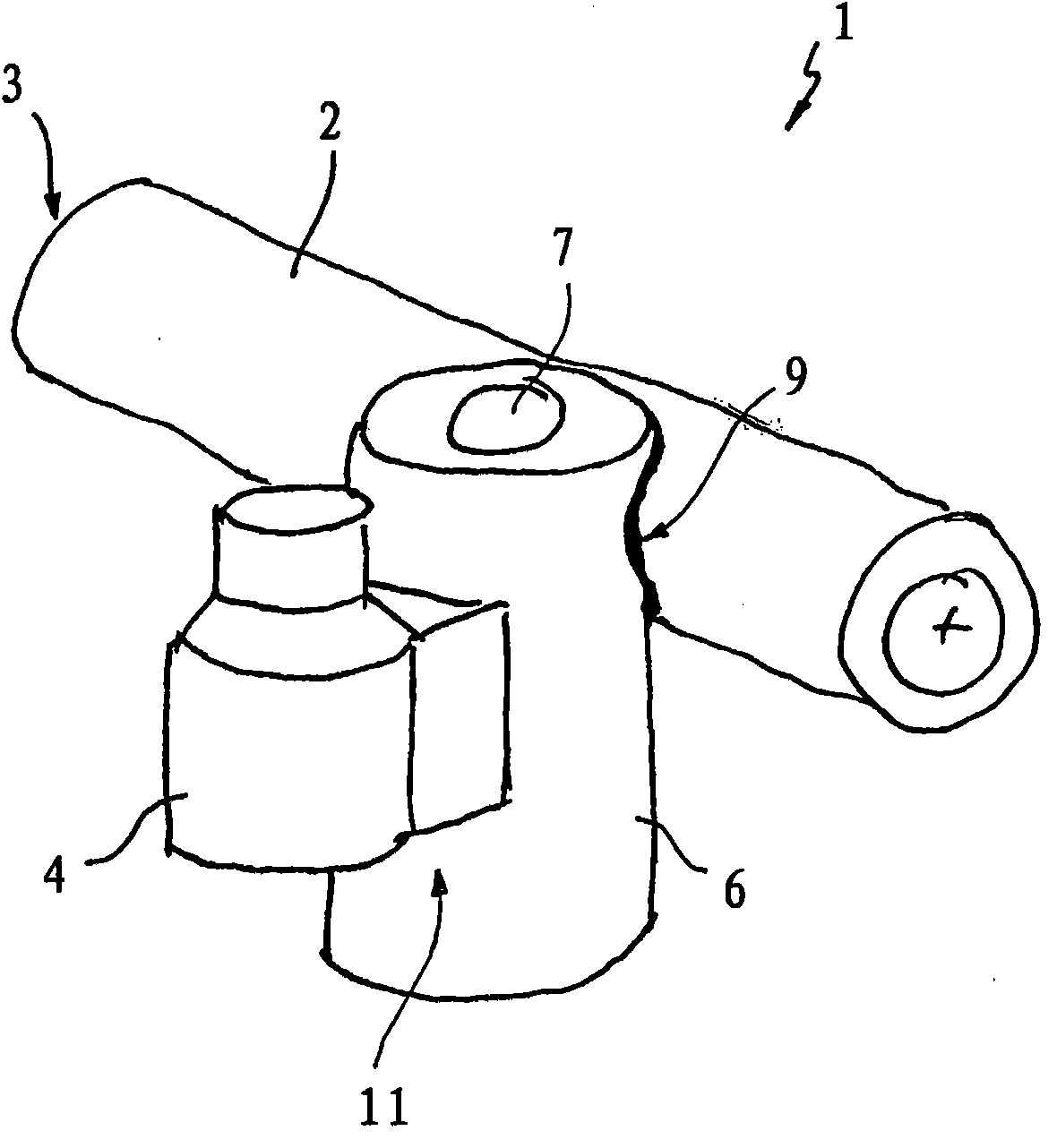

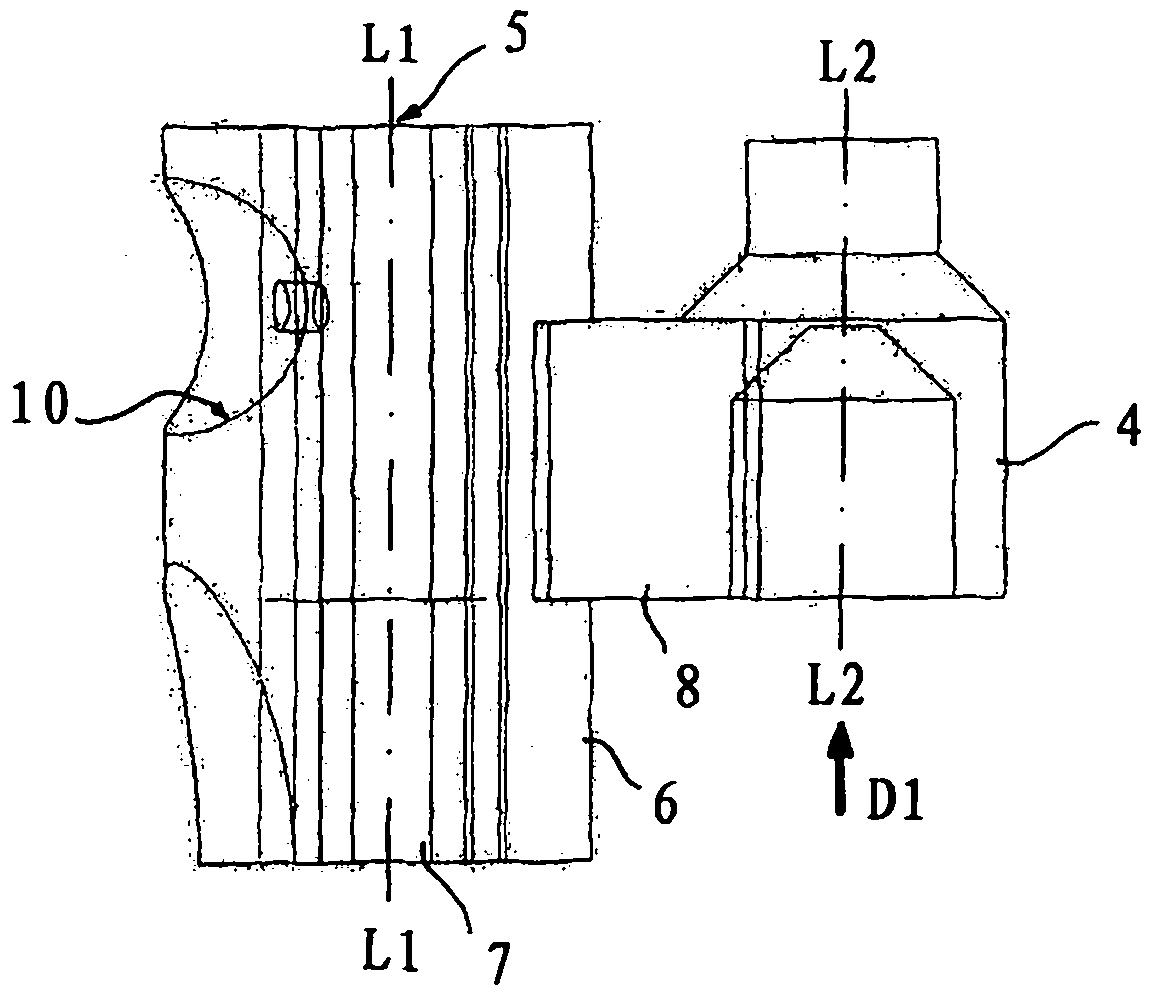

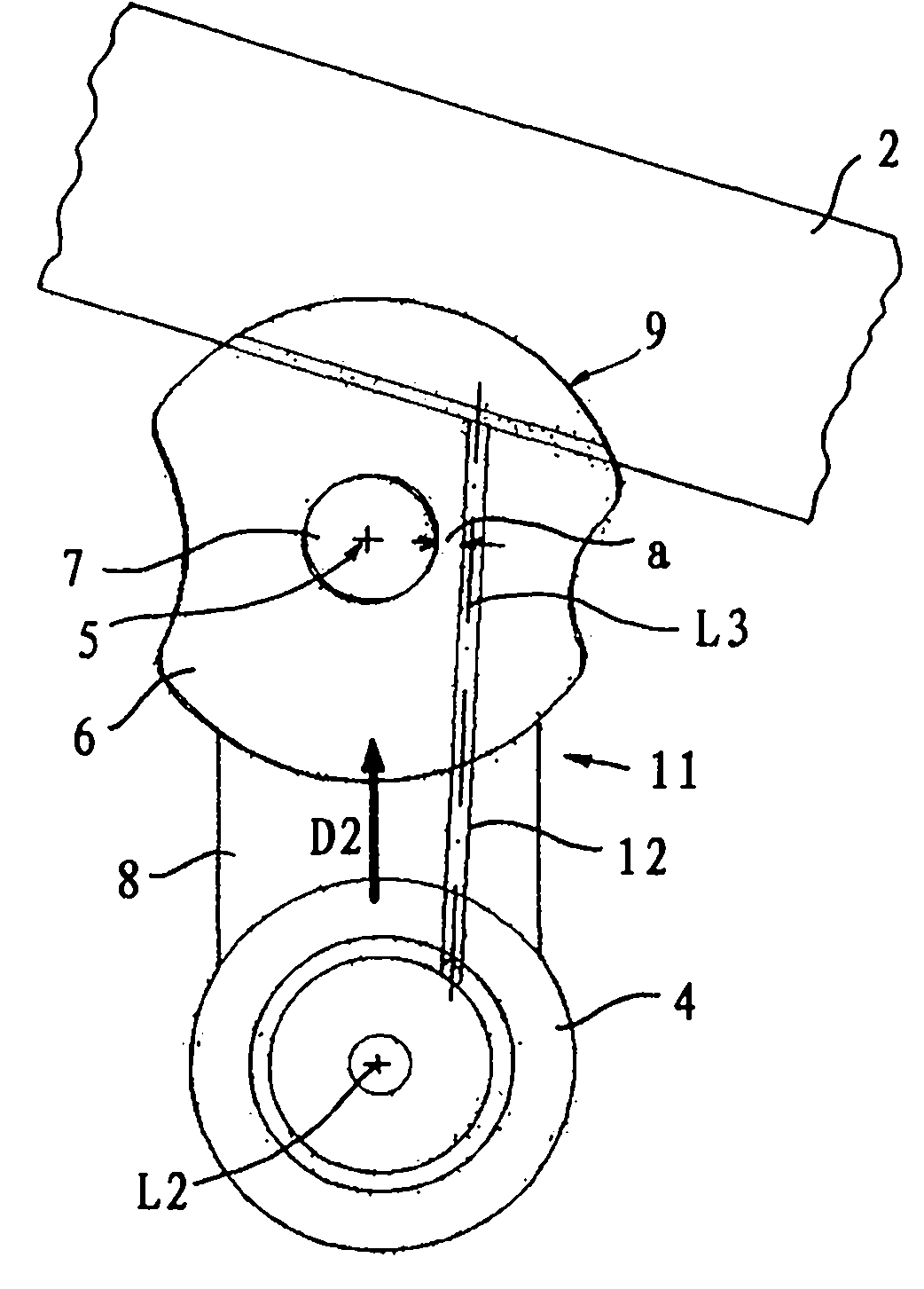

[0024] by means of Figures 1 to 3 The fuel distributor 1 according to the invention is explained. The fuel distributor 1 belongs to the storage injection system of the internal combustion engine. In such a store injection system, pressure generation and fuel injection are decoupled from each other. A separate high-pressure pump generates pressure continuously. The pressure that builds up independently of the injection sequence is provided permanently in the fuel distributor.

[0025] The fuel distributor 1 comprises a fuel inlet 3 with a pump side (in figure 1 Only schematically described in ) distribution pipe 2 and a plurality of injector receptacles 4 (only one of which is shown here). exist figure 2 Dispensing pipe 2 is not described in . The statically extruded fuel is stored in the distribution line 2 and distributed via the injector receptacle 4 to the injectors of the cylinder bank.

[0026] The distributor pipe 2 can be fastened to the internal combustion eng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com