Device and method for preparing foamed aluminum based on electromagnetic stirring under the action of composite magnetic field

A technology of electromagnetic stirring and composite magnetic field, which is applied in stirring devices, lighting and heating equipment, furnaces, etc., can solve the problems of poor electromagnetic stirring effect, etc., and achieve the effect of simple and easy-to-control foaming process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

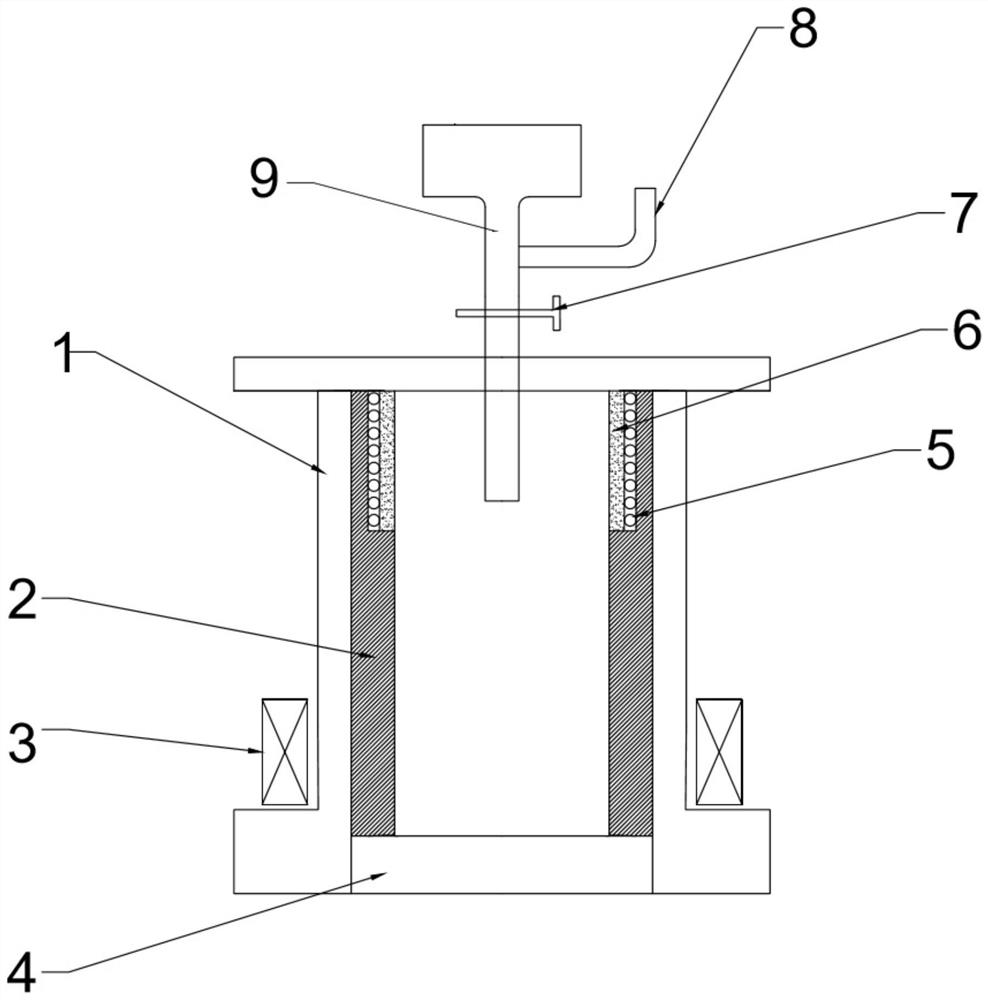

[0032] A device for preparing foamed aluminum based on electromagnetic stirring under the action of a composite magnetic field, such as figure 1 As shown, it includes: a reactor shell 1, a mold 2, an electromagnetic stirring device 3, a temperature control device 4, an induction coil 5, a filling material 6, a valve 7, a vent 8 and a feed pipe 9;

[0033] The inside of the reactor shell 1 is equipped with a detachable mold 2, the lower part of the outer wall of the reactor shell 1 is surrounded by an electromagnetic stirring device 3, and the bottom of the inner wall of the reactor shell 1 is equipped with a temperature control device 4, It is used to adjust the temperature of the inner cavity of the mold; the induction coil 5 is embedded around the upper area of the inner wall of the mold 2, and the embedded space is filled with a filling material 6, so that the induction coil 5 is fixed inside the inner wall of the mold 2; the reactor shell 1 A feed pipe 9 is provided at t...

Embodiment 2

[0048] A device for preparing foamed aluminum based on electromagnetic stirring under the action of a composite magnetic field, such as figure 1 As shown, it includes: a reactor shell 1, a mold 2, an electromagnetic stirring device 3, a temperature control device 4, an induction coil 5, a filling material 6, a valve 7, a vent 8 and a feed pipe 9;

[0049] The inside of the reactor shell 1 is equipped with a detachable mold 2, the lower part of the outer wall of the reactor shell 1 is surrounded by an electromagnetic stirring device 3, and the bottom of the inner wall of the reactor shell 1 is equipped with a temperature control device 4, It is used to adjust the temperature of the inner cavity of the mold; the induction coil 5 is embedded around the upper area of the inner wall of the mold 2, and the embedded space is filled with a filling material 6, so that the induction coil 5 is fixed inside the inner wall of the mold 2; the reactor shell 1 A feed pipe 9 is provided at t...

Embodiment 3

[0064] A device for preparing foamed aluminum based on electromagnetic stirring under the action of a composite magnetic field, such as figure 1 As shown, it includes: a reactor shell 1, a mold 2, an electromagnetic stirring device 3, a temperature control device 4, an induction coil 5, a filling material 6, a valve 7, a vent 8 and a feed pipe 9;

[0065] The inside of the reactor shell 1 is equipped with a detachable mold 2, the lower part of the outer wall of the reactor shell 1 is surrounded by an electromagnetic stirring device 3, and the bottom of the inner wall of the reactor shell 1 is equipped with a temperature control device 4, It is used to adjust the temperature of the inner cavity of the mold; the induction coil 5 is embedded around the upper area of the inner wall of the mold 2, and the embedded space is filled with a filling material 6, so that the induction coil 5 is fixed inside the inner wall of the mold 2; the reactor shell 1 A feed pipe 9 is provided at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com